Sampling device for vacuum coating sample and sampling method thereof

A sampling device and vacuum coating technology, which is applied in the direction of sampling device, vacuum evaporation coating, sputtering coating, etc., can solve the problem of unstable storage of vacuum coating samples, and achieve the effect of fastening samples and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

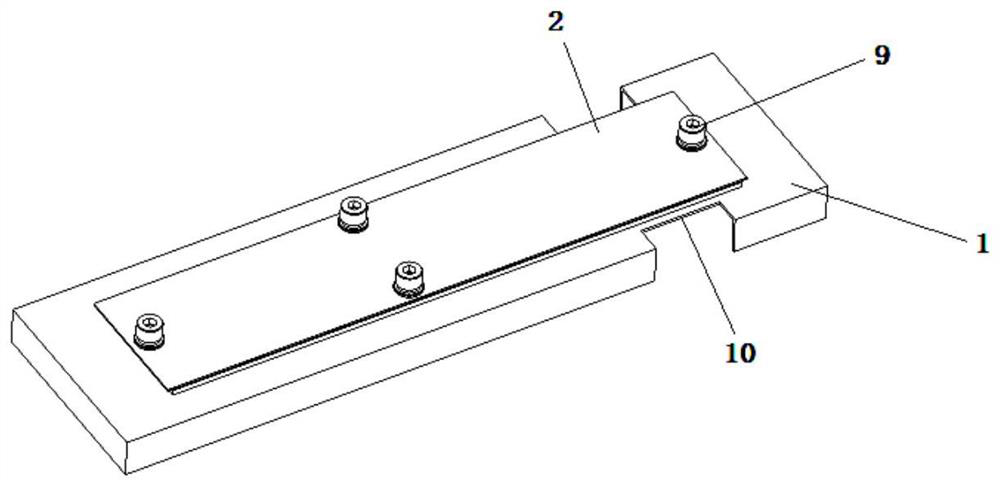

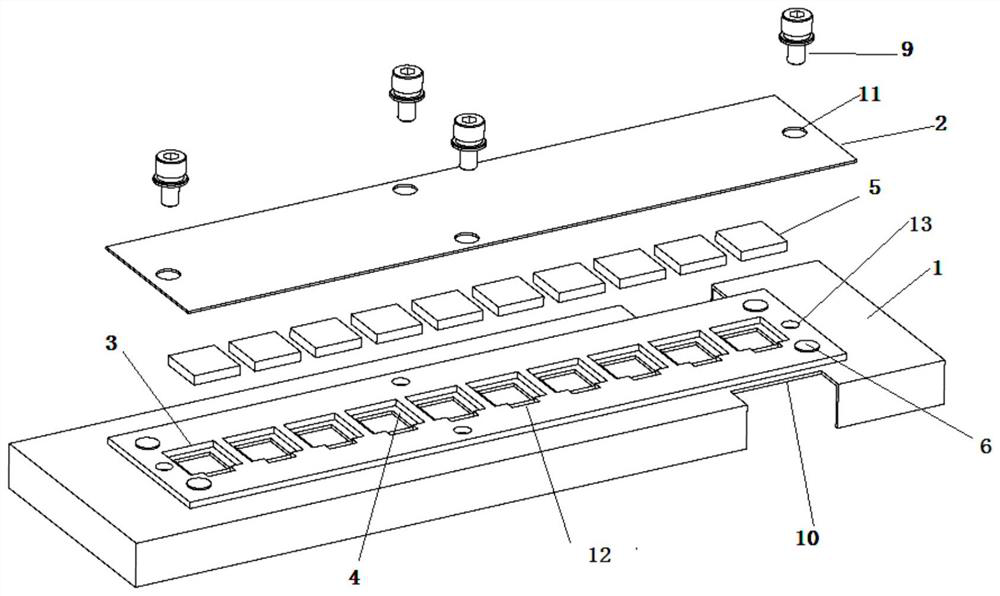

[0039] A sampling device for vacuum coating samples, comprising a sampling device base 1 and a sampling device cover plate 2, the sampling device base 1 is provided with one or more sampling chip mounting grooves 3, and the sampling chip mounting grooves 3 are up and down. An open groove, a boss 4 is provided in the sample chip installation groove 3 to receive the sample chip 5, and the sample device cover plate 2 is detachably assembled on the sample device base 1 to cover all the sample chip installation grooves 3.

[0040] Preferably, there are a plurality of the sampling piece installation slots 3 , which are evenly distributed on the base 1 of the sampling device in a matrix.

[0041] The sampling method of the sampling device comprises the following steps:

[0042] In step 1, firstly, the vacuum coating samples 5 are loaded into the sample installation groove 3 in sequence, and then the sampling device cover plate 2 is installed on the top of the sampling device base 1 ...

Embodiment 2

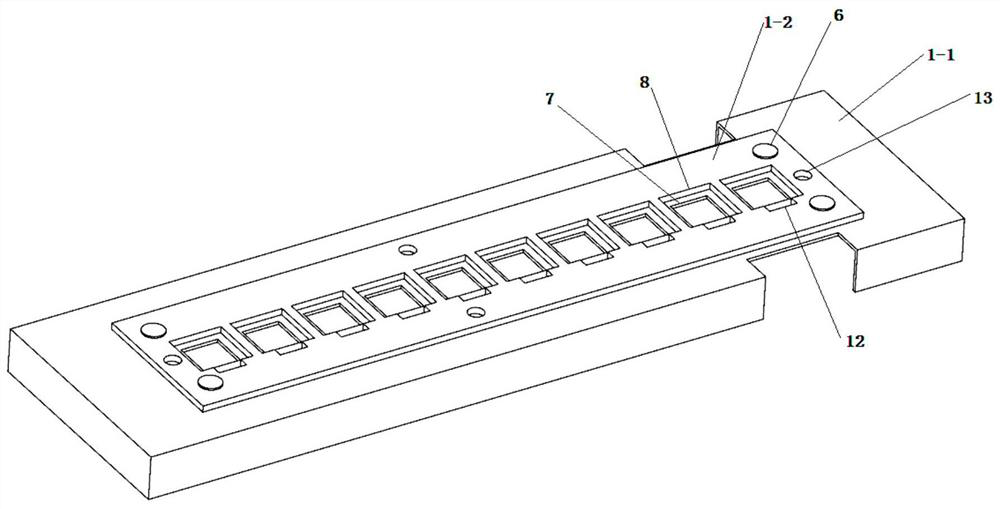

[0047] The base 1 of the sampling device can either adopt an integrally formed structure, or can adopt the following split structure:

[0048] Preferably, the sampling device base 1 is formed by fixedly connecting a lower base plate 1-1 and an upper base plate 1-2, and the lower base plate 1-1 is provided with a plurality of lower through holes 7. The upper base plate 1-2 is provided with one or more upper through holes 8, the lower through holes 7 and the upper through holes 8 are correspondingly arranged one by one, and the size of the lower through holes 7 is smaller than that of the upper through holes 8. The size of the hole 8 , each corresponding upper through hole 8 and lower through hole 7 correspondingly forms one of the sample chip mounting grooves 3 . The base of the sampling device is formed by CNC machining and riveting.

[0049] Further, the lower base plate 1-1 includes an upper plane plate and a side support plate fixed on the edge of the upper plane plate, wh...

Embodiment 3

[0053] The detachable connection method of the sampling device base 1 and the sampling device cover plate 2 can be in any manner, such as snap connection, adsorption connection, etc., preferably the following connection is fastened by bolts.

[0054] Preferably, the sampling device base 1 is provided with threaded holes, the sampling device cover plate 2 is provided with through holes 11 , the through holes and the threaded holes are arranged in a one-to-one correspondence, and the screw fasteners 9 pass through The sampling device cover plate 2 is fastened on the sampling device base 1 through the through holes 11 and the threaded holes 13, and the disassembly is realized by the cooperation of the screws and the threaded holes, and the disassembly is convenient and quick.

[0055] Preferably, the sampling device base 1 is provided with two symmetrically arranged gaps 10, and the gaps are gaps 10 for the manipulator to grasp, which is convenient for the manipulator to grasp the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com