Secondary seed-feeding mechanism of drum-type hole sowing device

A technology for secondary seeding and hole seeding, which is applied in the field of agricultural machinery, can solve the problems of inconsistent number of grains in holes, unequal plant spacing, and inability to accurately fall into the duck's bill, achieve consistent plant spacing, solve unequal plant spacing, and extend the casting effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

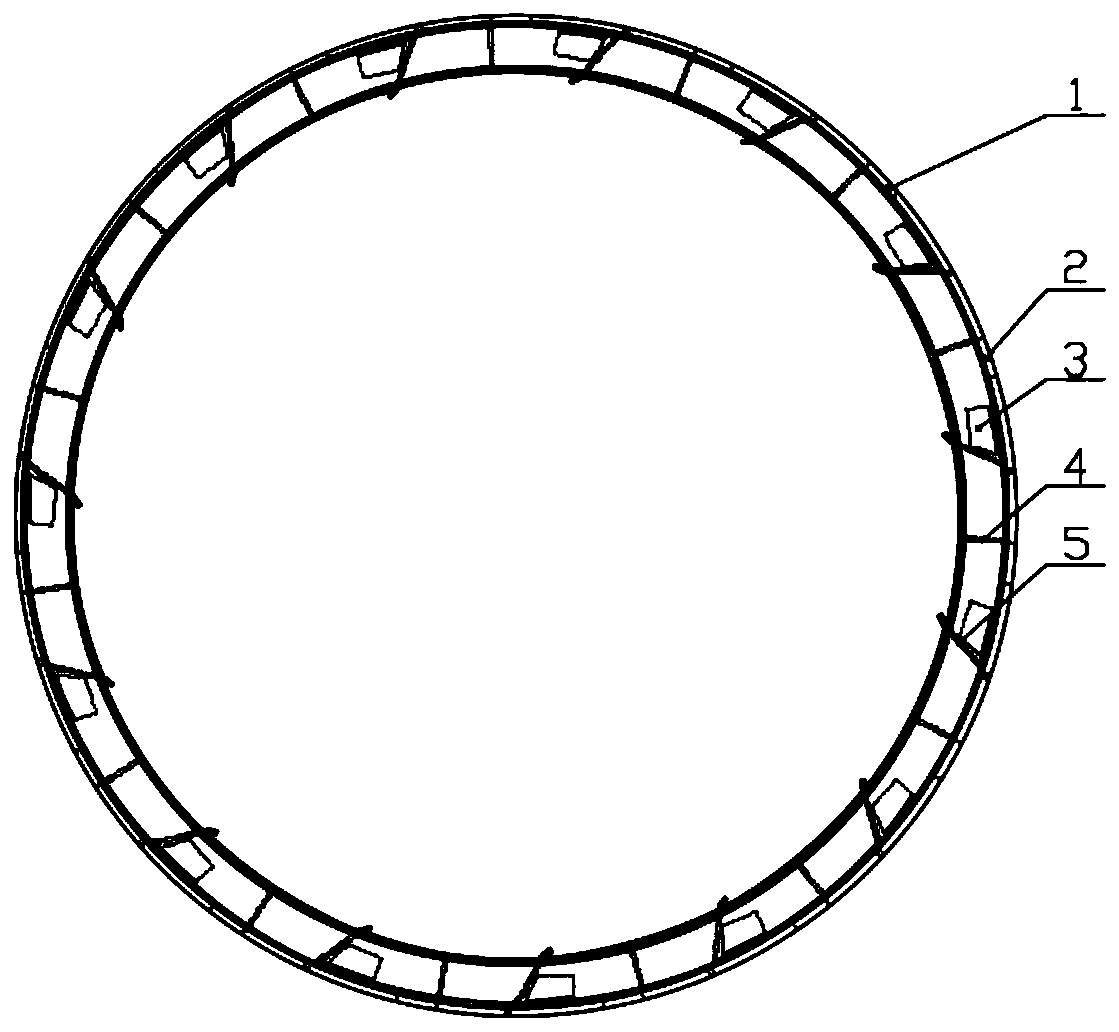

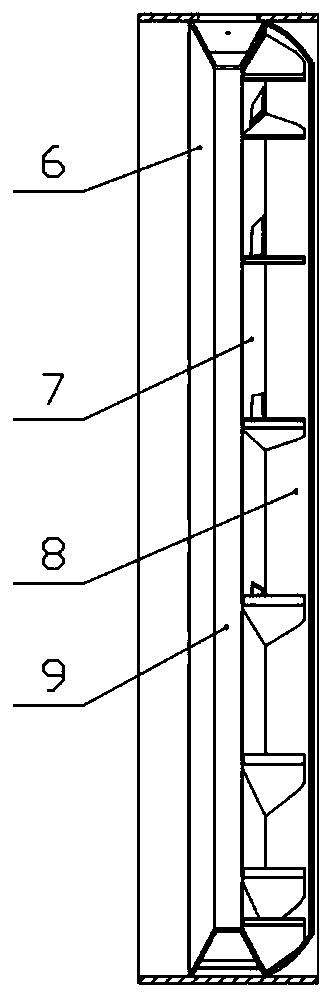

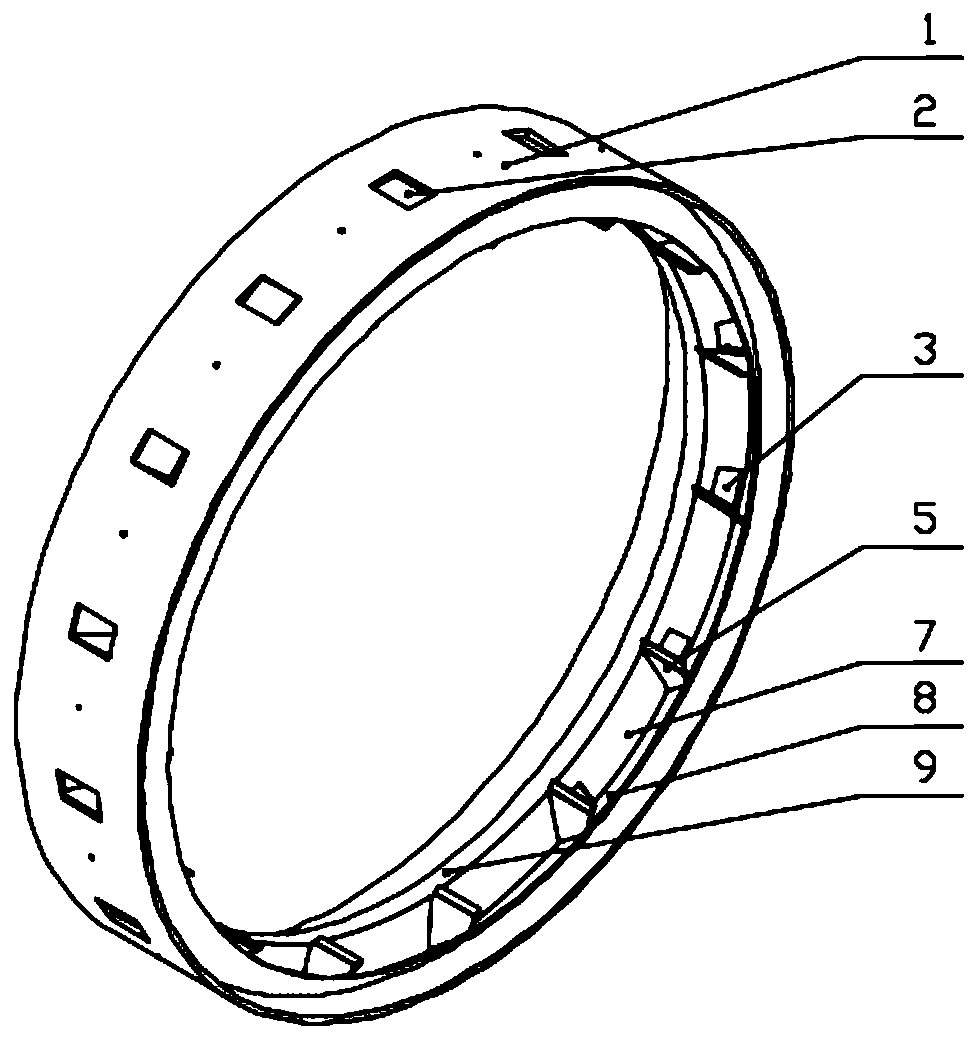

[0033] As a typical implementation of the present invention, please refer to Figure 1a ~ Figure 2 , this embodiment discloses a secondary seeding mechanism for a drum-type hole seeder, which includes a cylindrical seeding body, the seeding body specifically includes a cylindrical outer wall 1, and the inner side of the outer wall 1 is connected to As for the side panels, it can be understood that the side panels are ring-shaped, and the inner side of the outer side wall 1 is connected to three side panels including the first side panel 6 , the second side panel 7 and the third side panel 8 .

[0034] In this embodiment, considering the trajectory requirements of the seeds 12, the first side plate 6, the second side plate 7 and the third side plate 8 are not arranged in parallel, and the first side plate 6 and the second side plate 7 are arranged from the inner edge to the The direction of the outer edge gradually moves away. It can be understood that the second side plate 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com