A Hydraulically Driven Constant Pressure Constant Displacement Friction Stir Welding Spindle Unit

A technology of friction stir welding and constant pressure, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

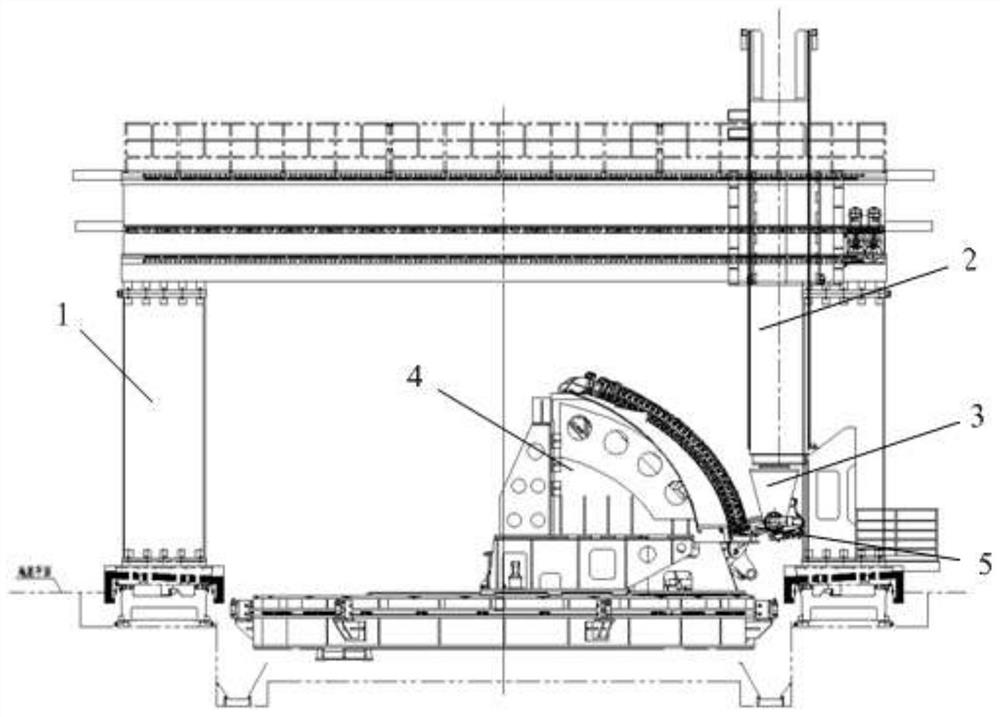

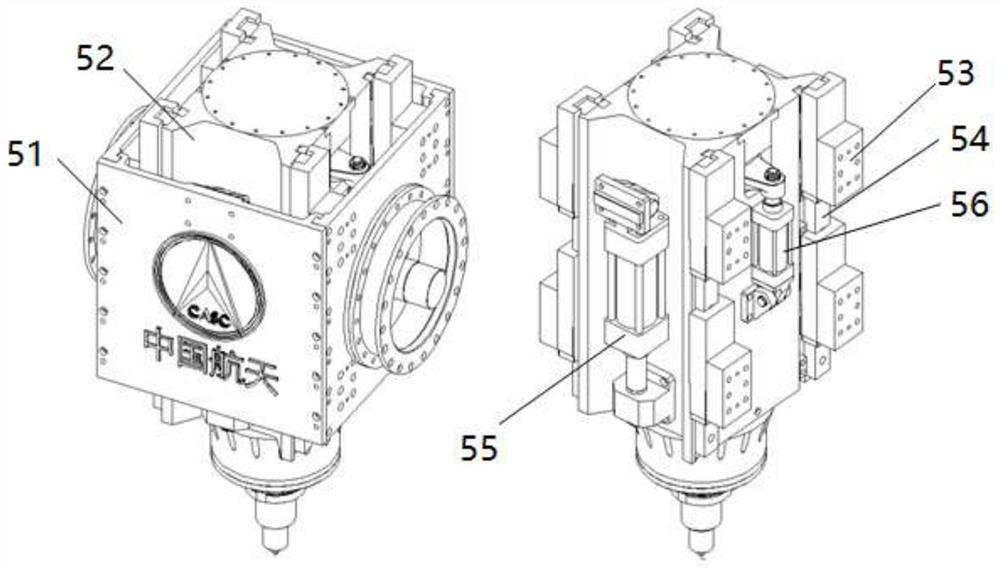

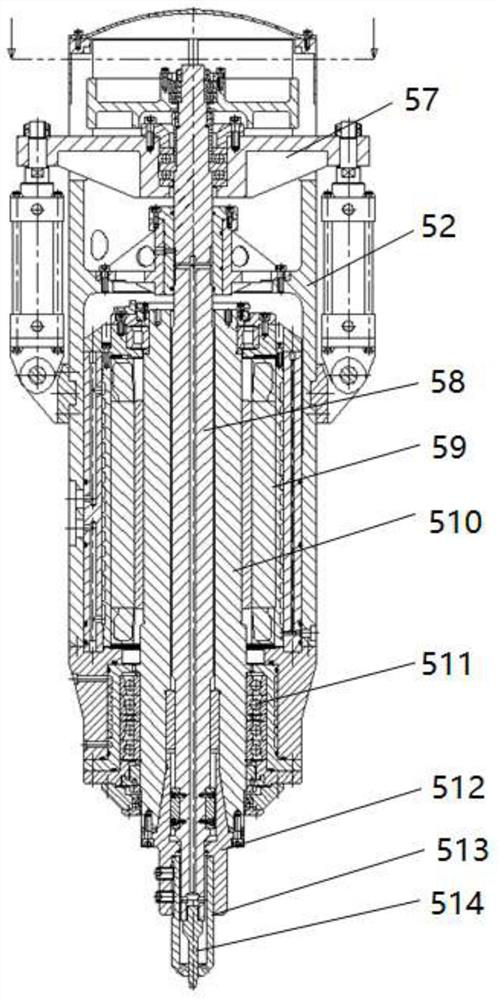

[0029] A hydraulically driven constant pressure and constant displacement friction stir welding spindle unit 5 is used to solve the problem of constant pressure and constant displacement control in the heavy load friction stir welding process, such as figure 1 and figure 2 The friction stir welding spindle unit 5 shown is installed inside the fork-shaped structural member 3 at the end of the ram end of the frame of the gantry main body 1, and completes the welding of the longitudinal seam of the bottom of the box along the welding track through the frame of the gantry main body 1 and the double forks; including: Between the slide box 51 and the main shaft housing 52, two sets of symmetrical shoulders are pressed into the servo cylinder 55 for driving. The tailstock of the servo cylinder body is fixedly connected with the outer slide box 51. 52 is fixedly connected, and the plunger is extended or retracted by controlling the oil cylinder, thereby causing relative movement betw...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap