Patents

Literature

46results about How to "Reduce troubleshooting costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

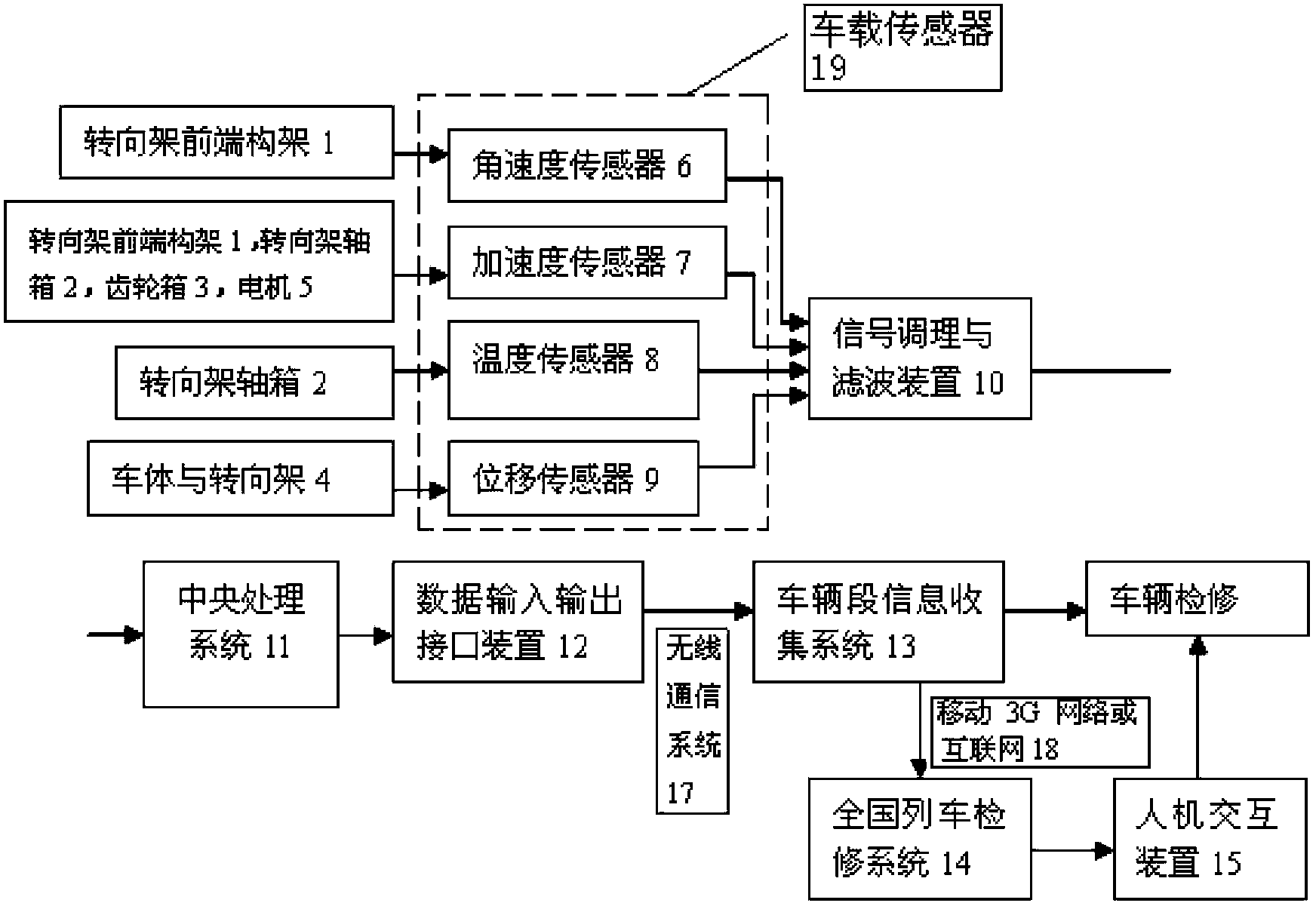

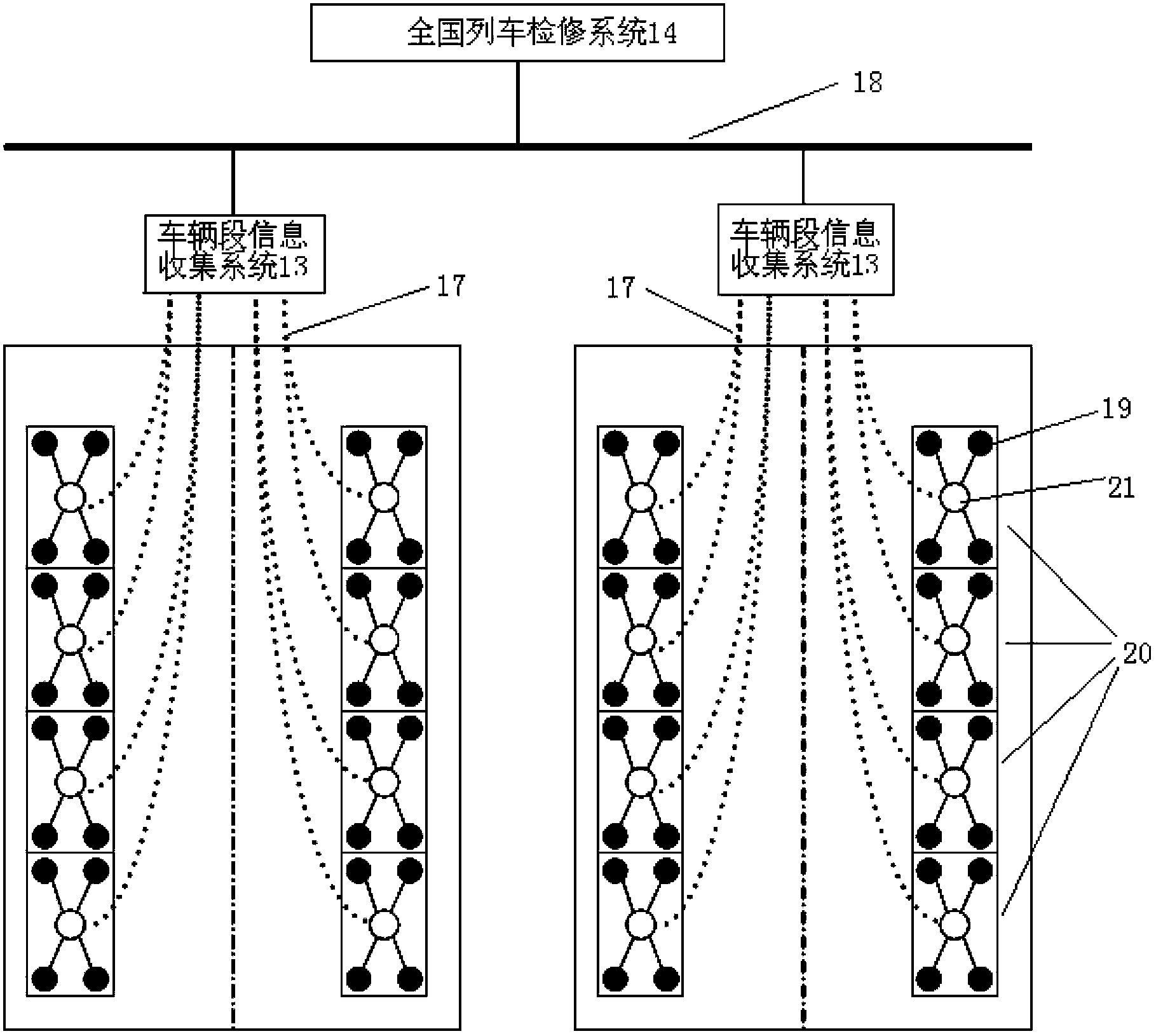

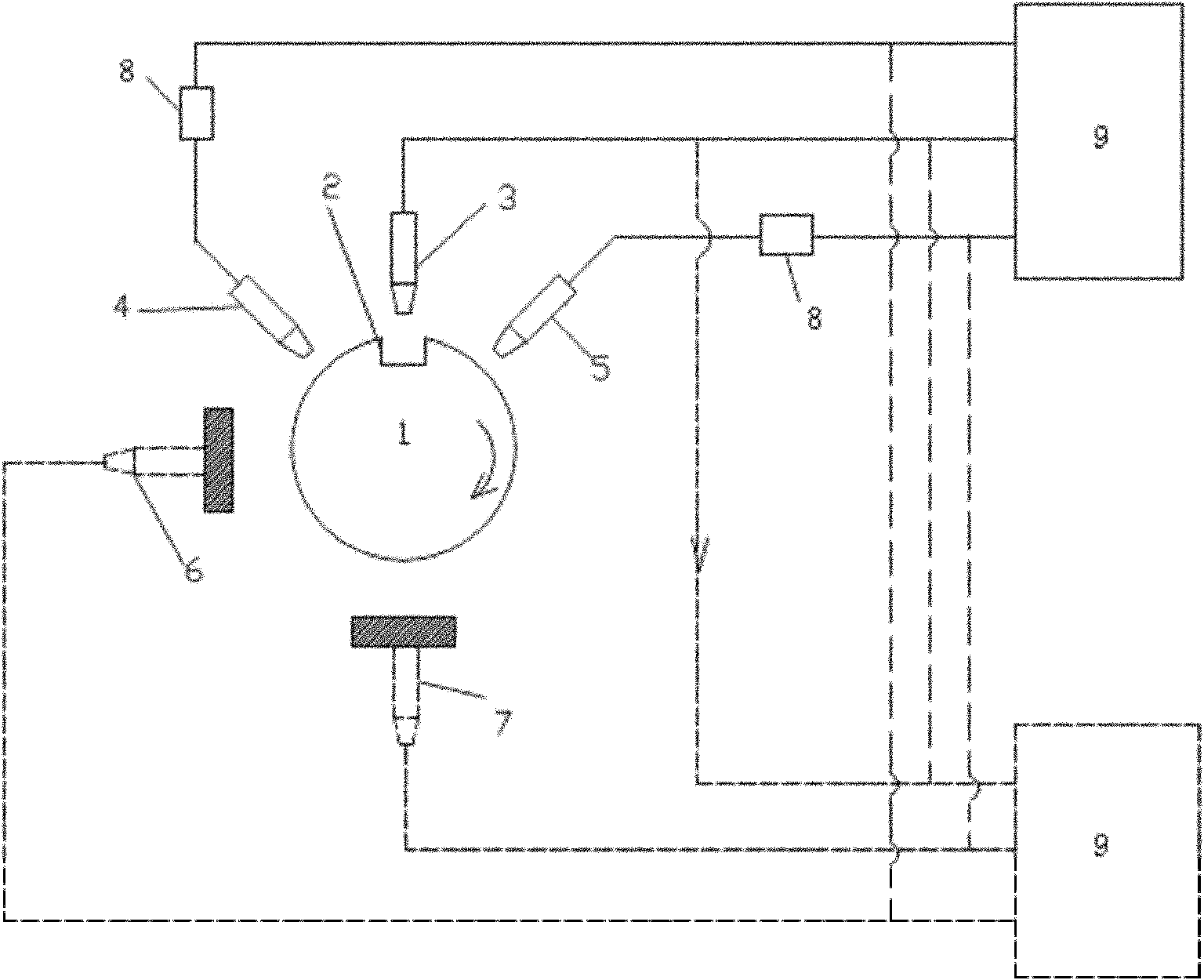

High-speed train running gear fault diagnosis and remote monitoring system based on Internet of Things

ActiveCN103852271AImprove maintenance efficiencyReduce operational riskRailway vehicle testingCollection systemEngineering

The invention relates to a high-speed train running gear fault diagnosis and remote monitoring system based on Internet of Things (IOT). The system provided by the invention comprises vehicle-mounted sensors, a signal conditioning and filtering device, a central processing system, a data input and output interface device, a vehicle depot information collection system, a nationwide train maintenance system and a man-machine interaction device. With the arrangement of a plurality of the vehicle-mounted sensors, accurate fault identification and positioning of key equipment of running gears are realized, prediction of faults is realized, train operational risks are reduced, remote diagnosis of faults is achieved, fault diagnosis cost is lowered, and fault diagnosis cycle is shortened.

Owner:CRRC QINGDAO SIFANG CO LTD

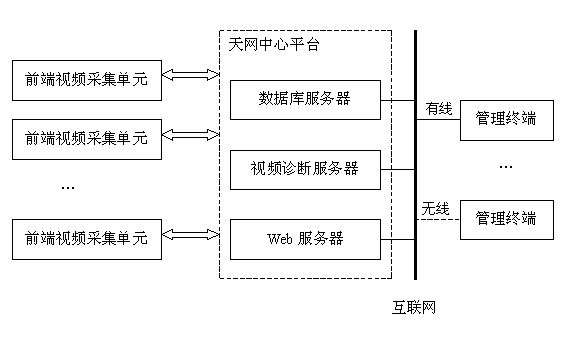

Intelligent skynet video quality diagnostic system

The invention discloses an intelligent skynet video quality diagnostic system which comprises a front end video capture unit, a skynet central platform and a management terminal. The skynet central platform comprises a video diagnostic server, a database server and a Web server, wherein the video diagnostic server adopts the computer vision algorithm to accurately judge spots, rolling, dim, color casting, abnormal luminance and video signal deficiencies of a video image and give out alarm information. The front end video capture unit is connected with the video diagnostic server through a communication network, the video diagnostic server is respectively connected with the database server and the Web server, and the management terminal accesses the Web server through the Internet. The intelligent skynet video quality diagnostic system can automatically detect and distinguish a plurality of video signal failures such as video definition, stripe interference, the abnormal luminance, the color casting and video deficiencies, can test and accurately locate failure situations, is accurate in system testing and can improve processing speed and reliability of processing results.

Owner:四川天翼网络股份有限公司

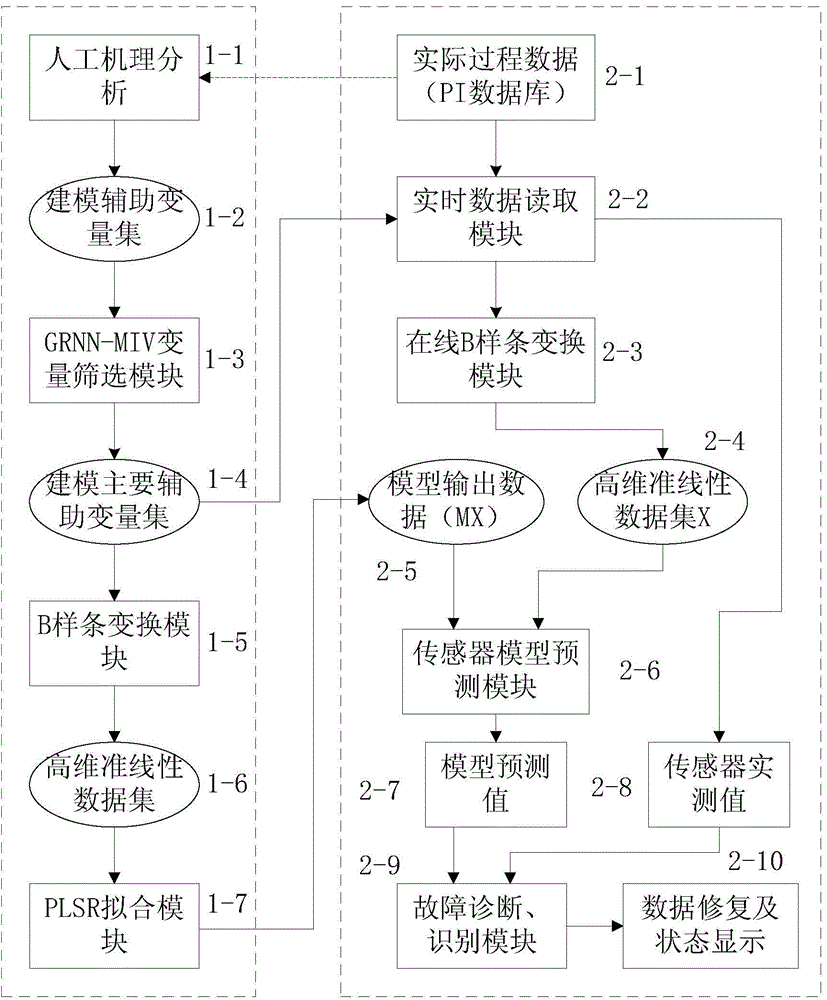

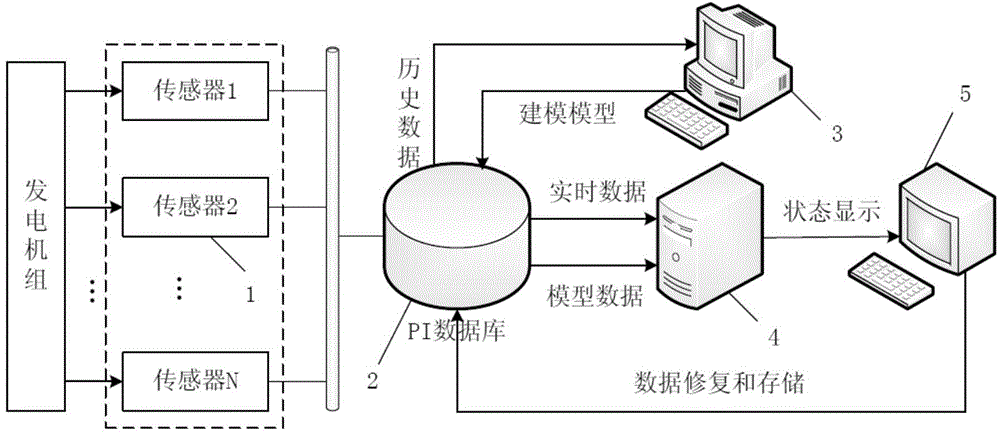

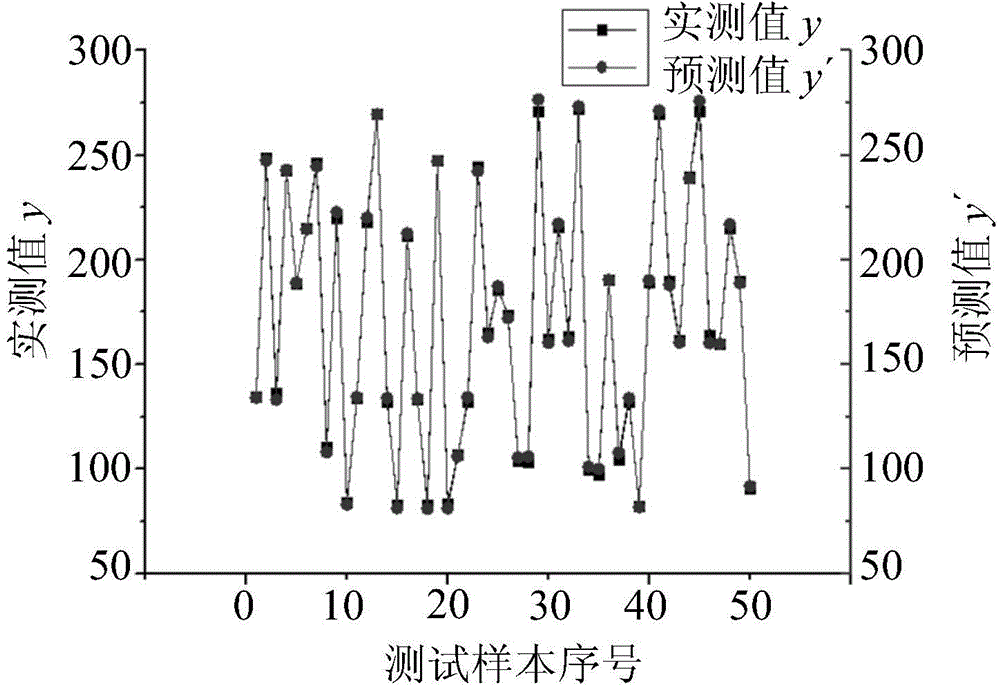

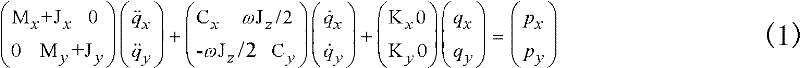

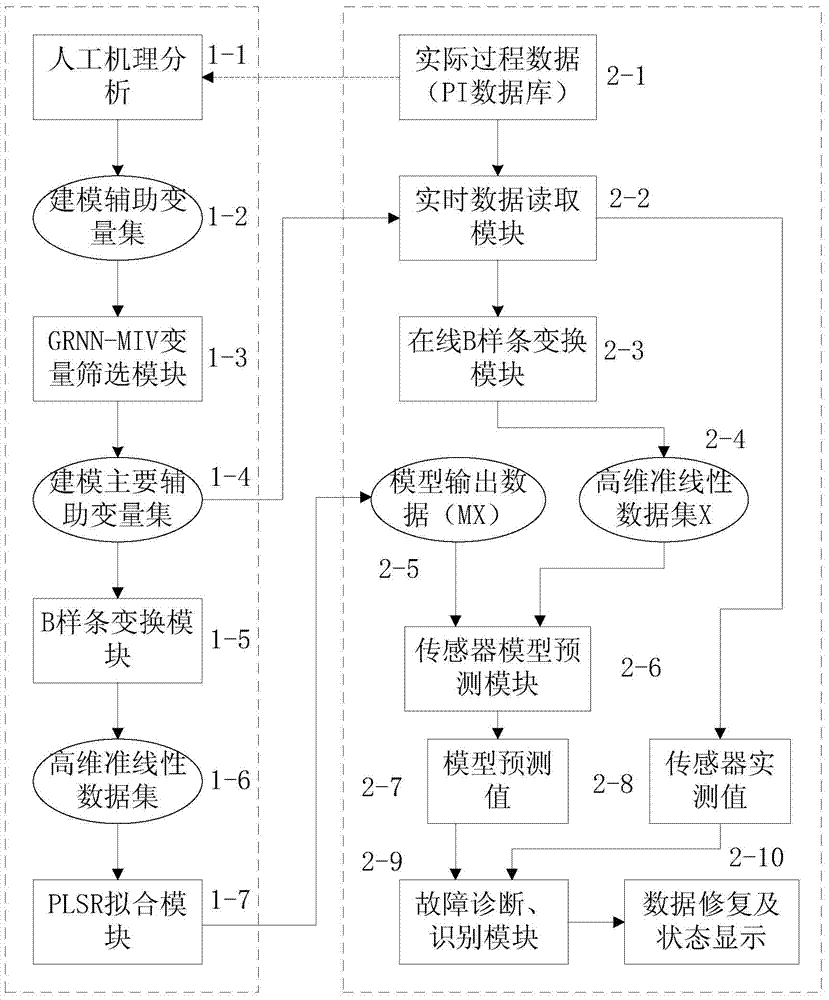

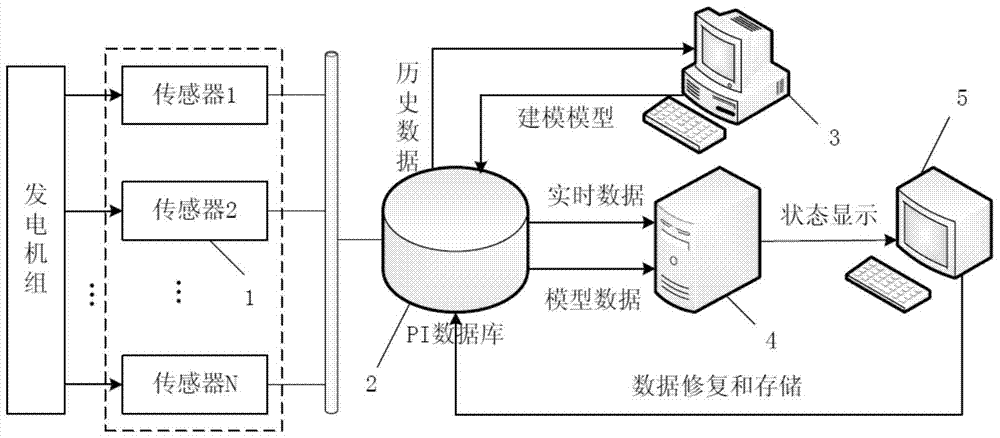

Generator set operating parameter measuring sensor fault diagnosis method and system

ActiveCN104390657AReal-time monitoring of running statusReduce troubleshooting costsInstrumentsFailure diagnosisEngineering

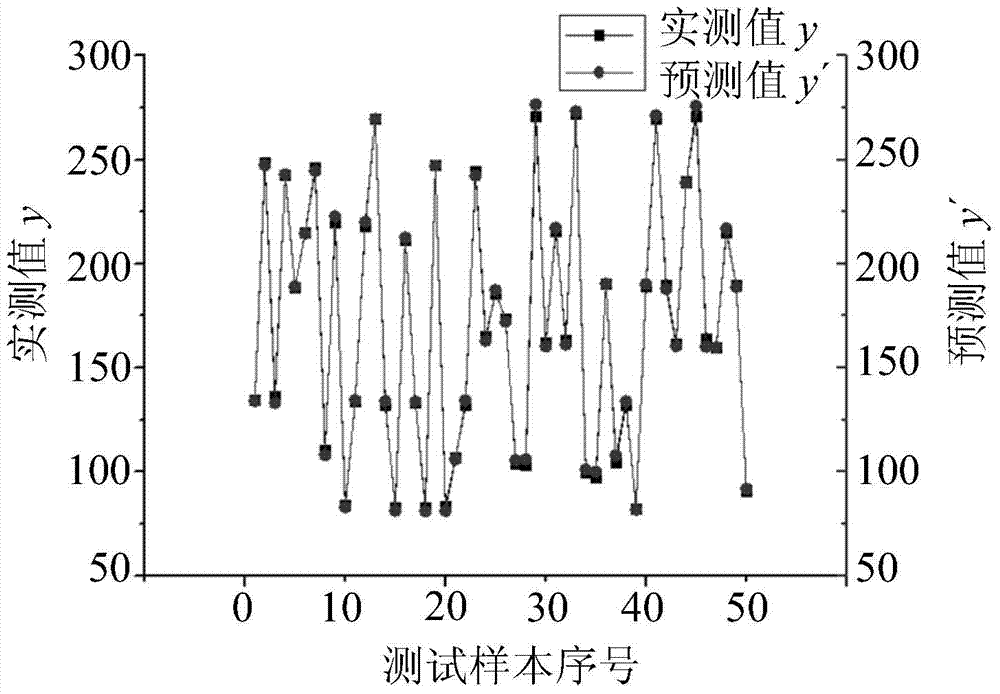

The invention discloses a generator set operating parameter measuring sensor fault diagnosis method. The generator set operating parameter measuring sensor fault diagnosis method can be applied to operating parameter measuring sensor fault diagnosis of generator sets. The method includes the following steps that: offline modeling is performed, auxiliary variables related to a parameter to be measured are obtained through mechanism analysis, and quantitative screening is performed on all the auxiliary variables according to the degree of dependencies, so that main auxiliary variables which have strong dependencies with the parameter to be measured can be obtained; a model for online diagnosis and coefficients of the model are obtained through a B spline transform-based PLSR modeling method; and online diagnosis is performed, and online B spline transformation is performed on real-time data, and the predicted value of the parameter to be measured Y can be obtained through loading the mathematical model between the parameter to be measured and the main auxiliary variables, and statistical characteristics of model predicted data and actually measured data are compared through a window moving method, and therefore, diagnosis on the faults of a sensor and identification of the types of the faults can be realized. The invention also discloses a generator set operating parameter measuring sensor fault diagnosis system.

Owner:ZHEJIANG UNIV

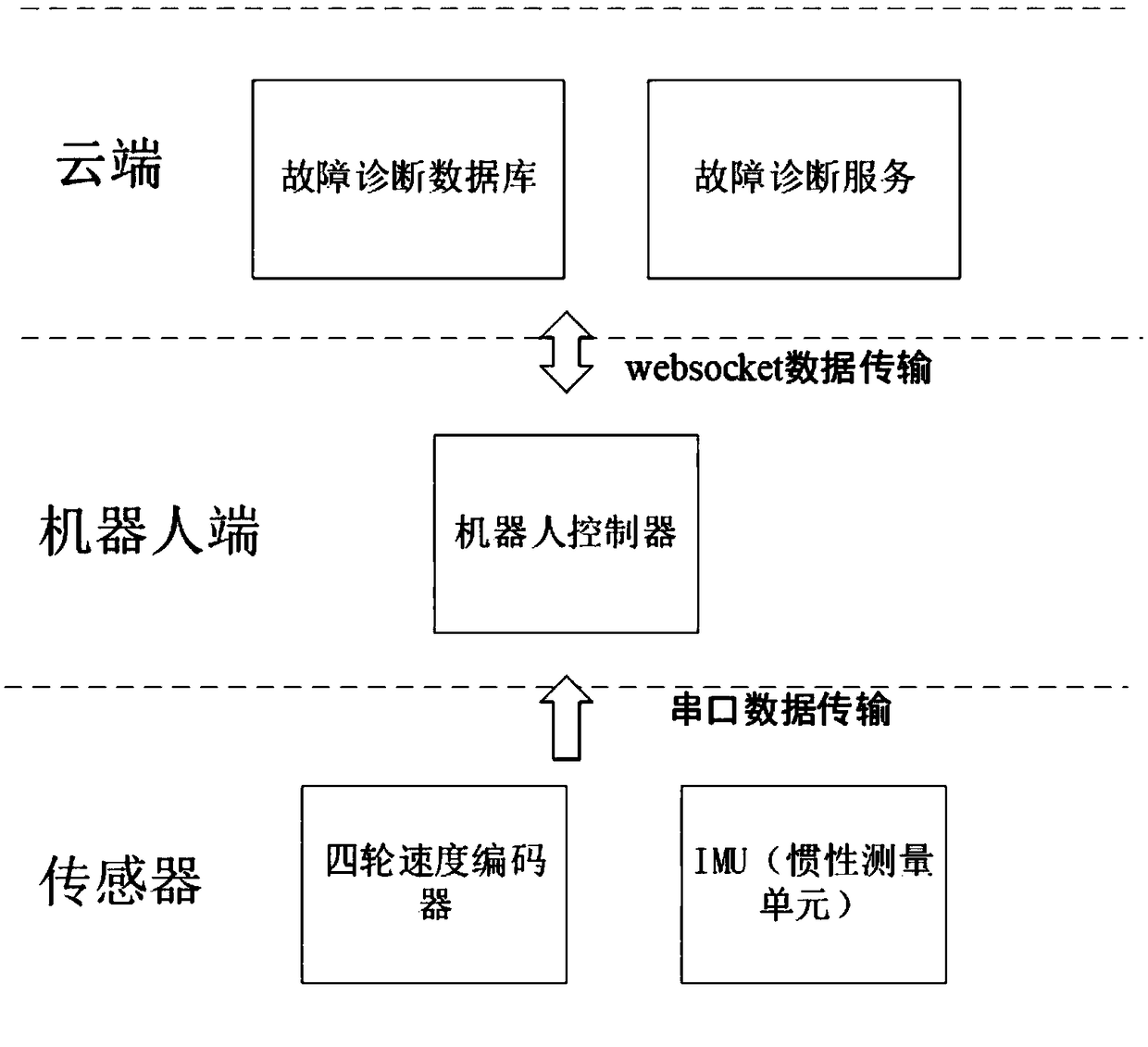

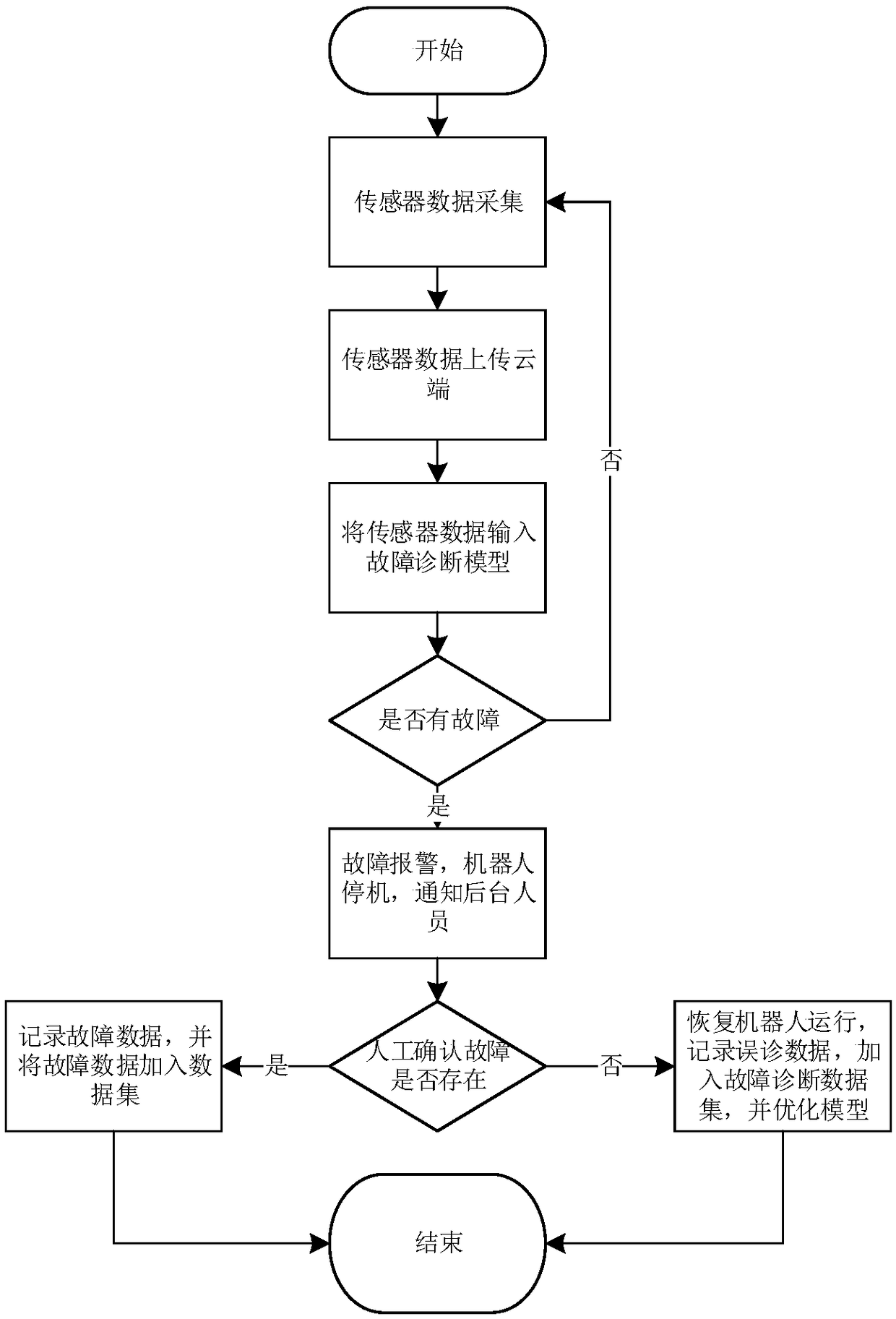

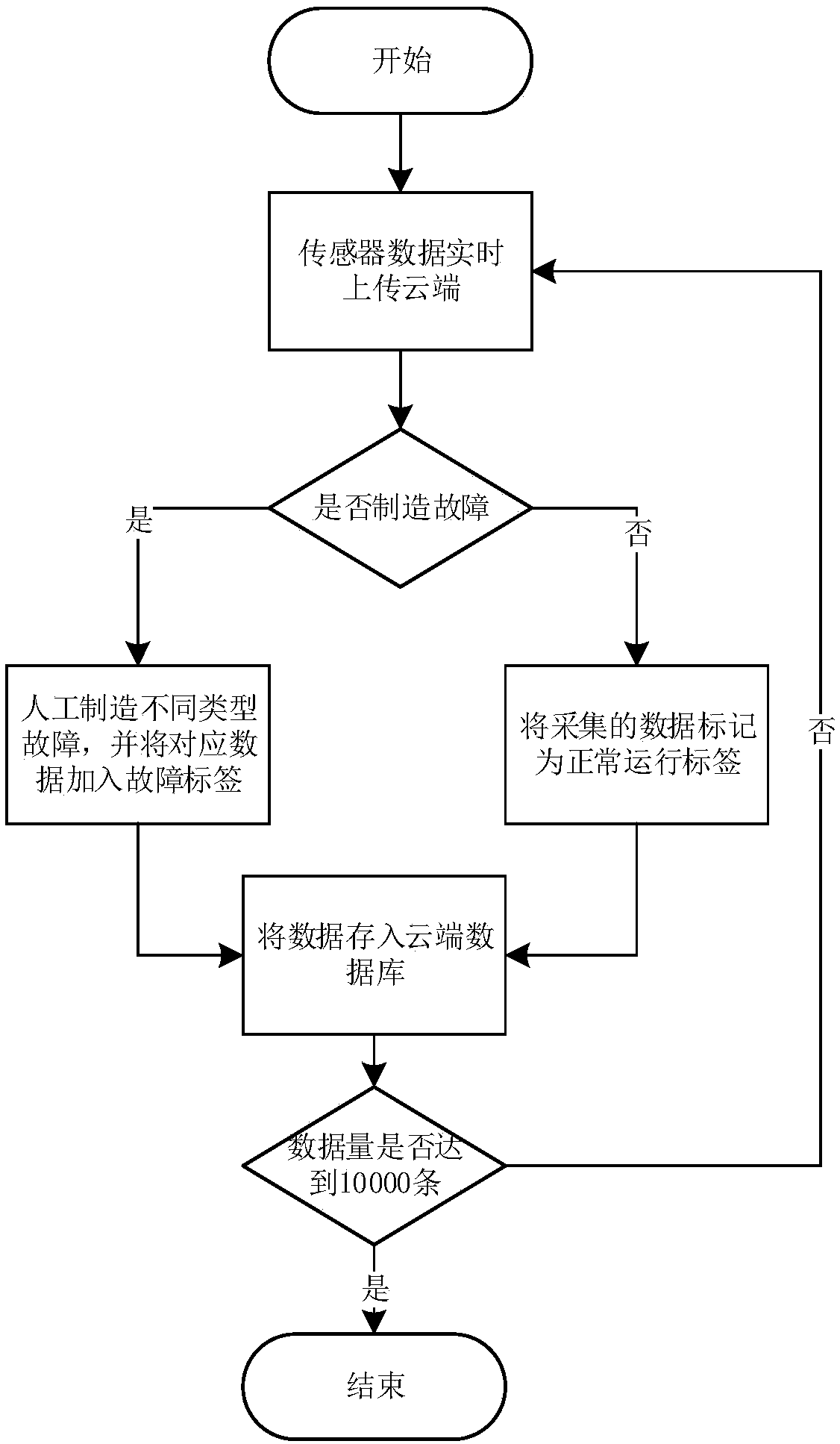

Service robot movement system cloud end fault diagnosis system and method

ActiveCN109129574AImprove computing powerImprove real-time performanceNeural architecturesManipulatorSimulationComputer module

The invention discloses a service robot movement system cloud end fault diagnosis system and method. The service robot movement system cloud end fault diagnosis system comprises a sensor module, a robot controller and a robot fault diagnosis cloud end; the sensor module collects the movement data of a robot in real time; the robot controller is configured to receive the data collected by the sensor module, gather the data and transmit the data to the robot fault diagnosis cloud end through the network; and the robot fault diagnosis cloud end is configured to diagnose the faults of the robot according to the received data and feed the diagnosis result back to the robot controller. A speed encoder and an inertial measurement unit are adopted for data fusion, fault modeling is conducted through a deep studying model, the model is deployed on a cloud end server with high operational capability, and the advantages of high diagnosis real-time performance, high model robustness and high practicability are achieved.

Owner:SHANDONG UNIV

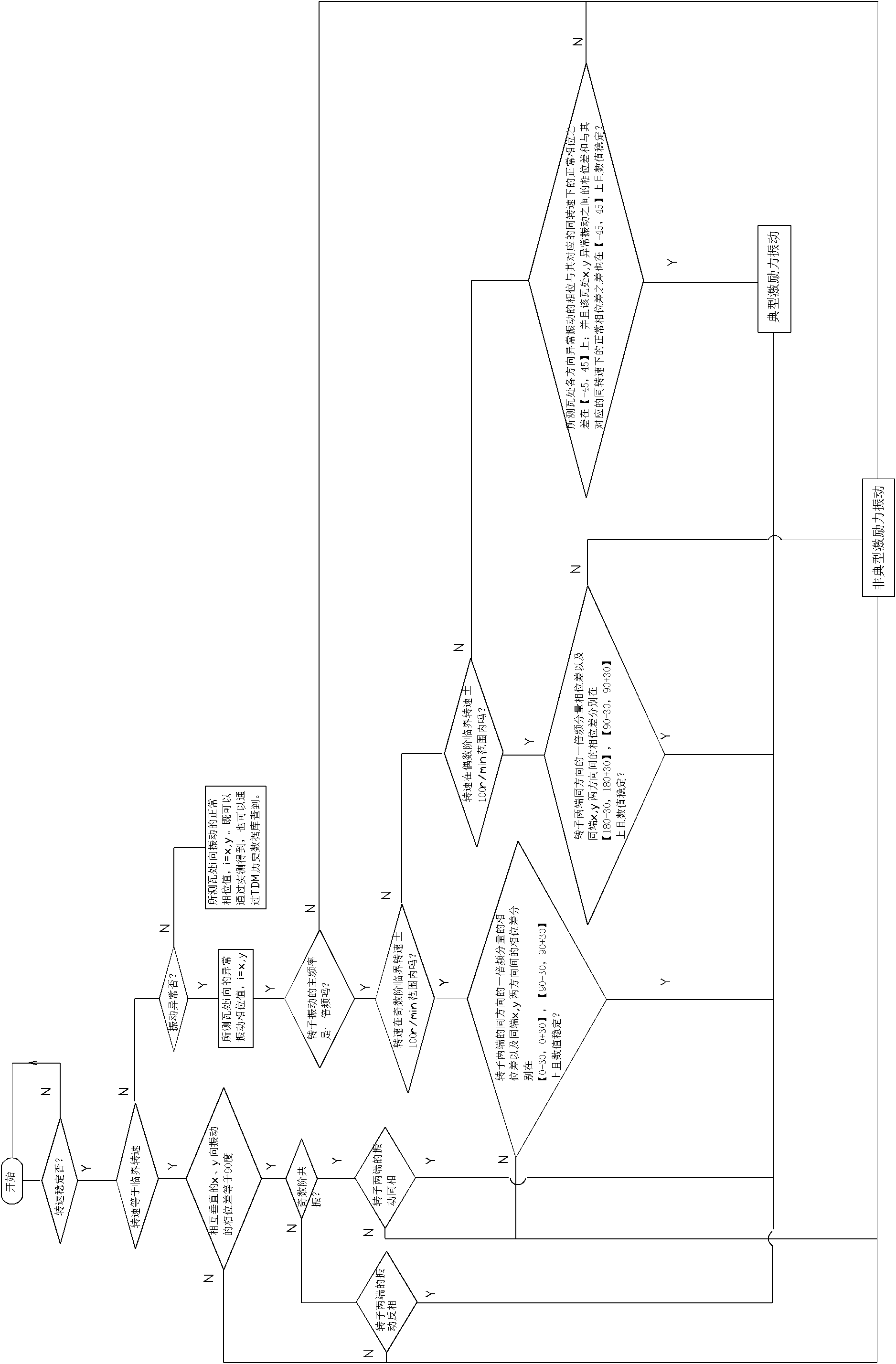

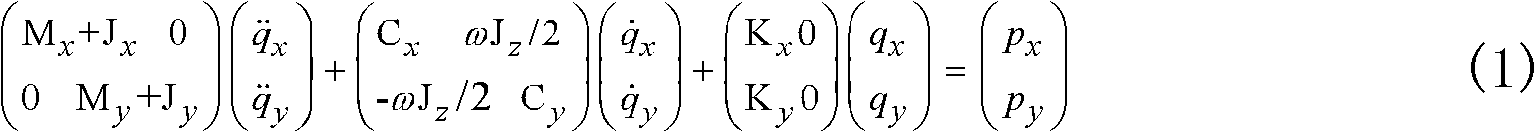

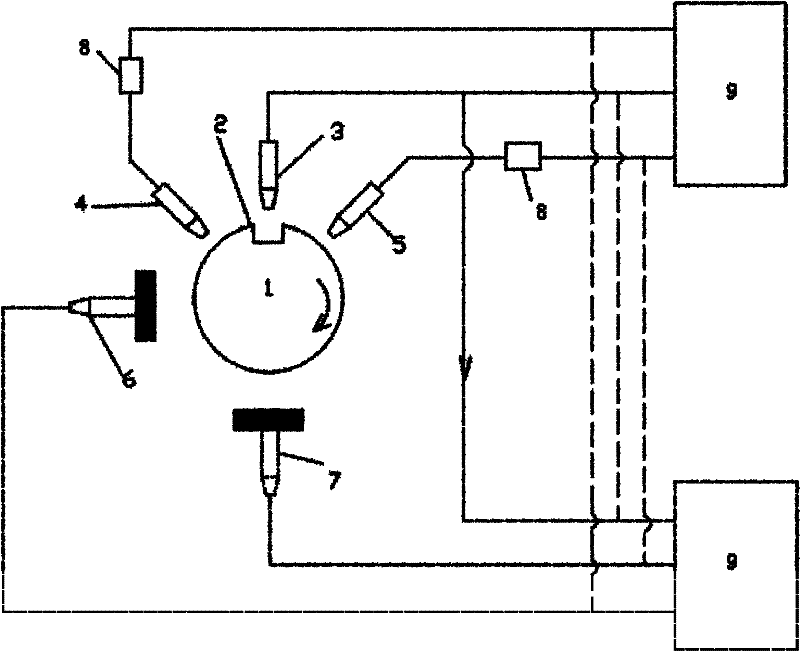

Phase difference aided diagnosis method for shafting vibration of turbo generator unit and system thereof

InactiveCN101915607AQuickly and accurately determineReduce troubleshooting costsSubsonic/sonic/ultrasonic wave measurementUsing electrical meansTurbo generatorPhysics

The invention relates to a phase difference aided diagnosis method for shafting vibration of a turbo generator unit and a system thereof. The method comprises the following steps: setting a plurality of measuring points on a rotor, identifying and judging phases among vibration signals at the measuring points, taking vibration caused by pure mass unbalance as typical excitation force vibration and vibration caused by other factors as atypical excitation force vibration, wherein, the vibration signals at the bearing bushes of a turbo generator unit shafting generated under the action of an atypical excitation force generate abnormal vibration phase difference which is different from a pure dynamic unbalance fault, otherwise, the vibration signals at the bearing bushes only generated under the action of the typical excitation force maintain phase difference normality for the pure dynamic unbalance fault; and if the phase difference meets the conditions, judging that a rotor is only applied with the typical excitation force, otherwise, judging that the shafting is applied with an obvious atypical excitation force.

Owner:SHANDONG ZHONGSHI YITONG GRP

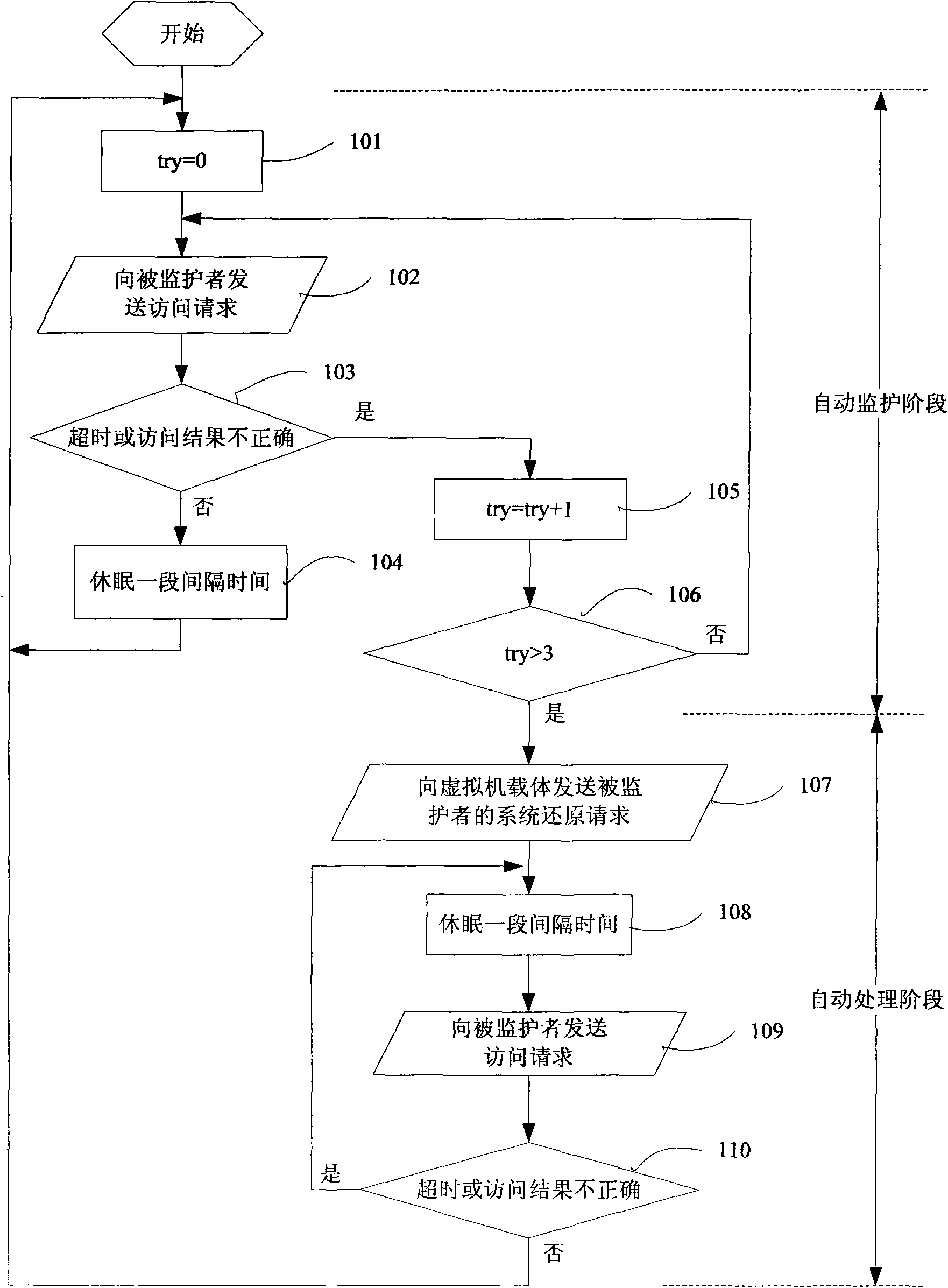

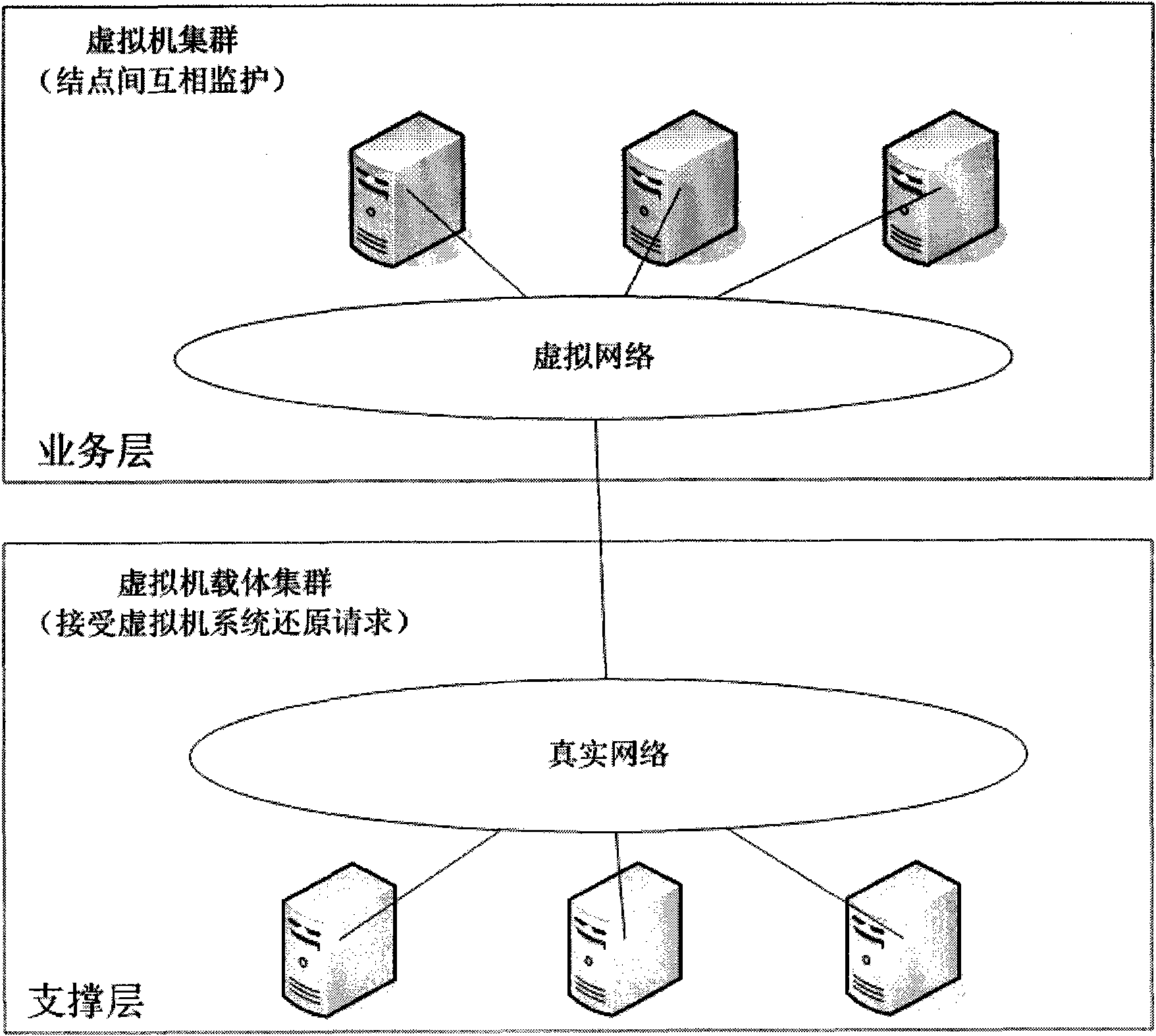

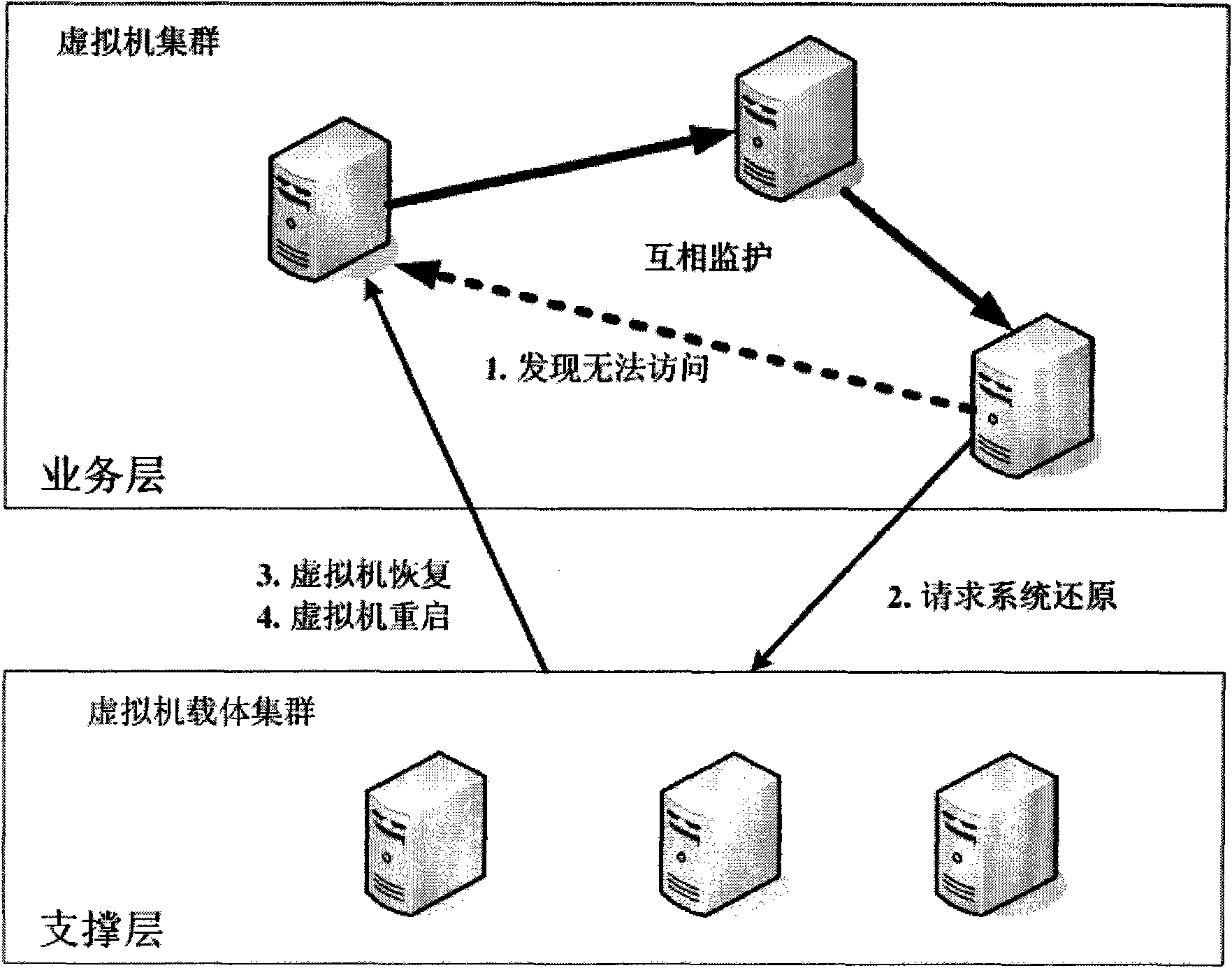

Automatic monitoring method and device for unattended system

InactiveCN102111303AImprove troubleshooting efficiencyReduce troubleshooting costsNetworks interconnectionAutomatic processingSoftware fault

The invention discloses an automatic monitoring method for an unattended system. The method comprises the following steps of: establishing the unattended system by using a virtual machine, and mutually monitoring, discovering a fault and repairing the fault in time by using nodes of the virtual machine; performing real-time fault processing; maintaining the normal operation of the system by using a redundant node; automatically repairing a fault point, namely recovering the system aiming at a software fault; automatically processing the fault point, namely isolating and automatically alarming aiming at a hardware fault; and performing automatic regress after repairing the fault point (including software recovery and hardware replacement) and the addition of a new node by the automatic monitoring and the automatic processing of the system. By using the method, the problems that the prior art cannot repair automatically and process automatically, and cannot perform real automatic recovery are solved. The invention also discloses the automatic monitoring method and an automatic monitoring device for the unattended system.

Owner:BEIJING SAFE CODE TECH

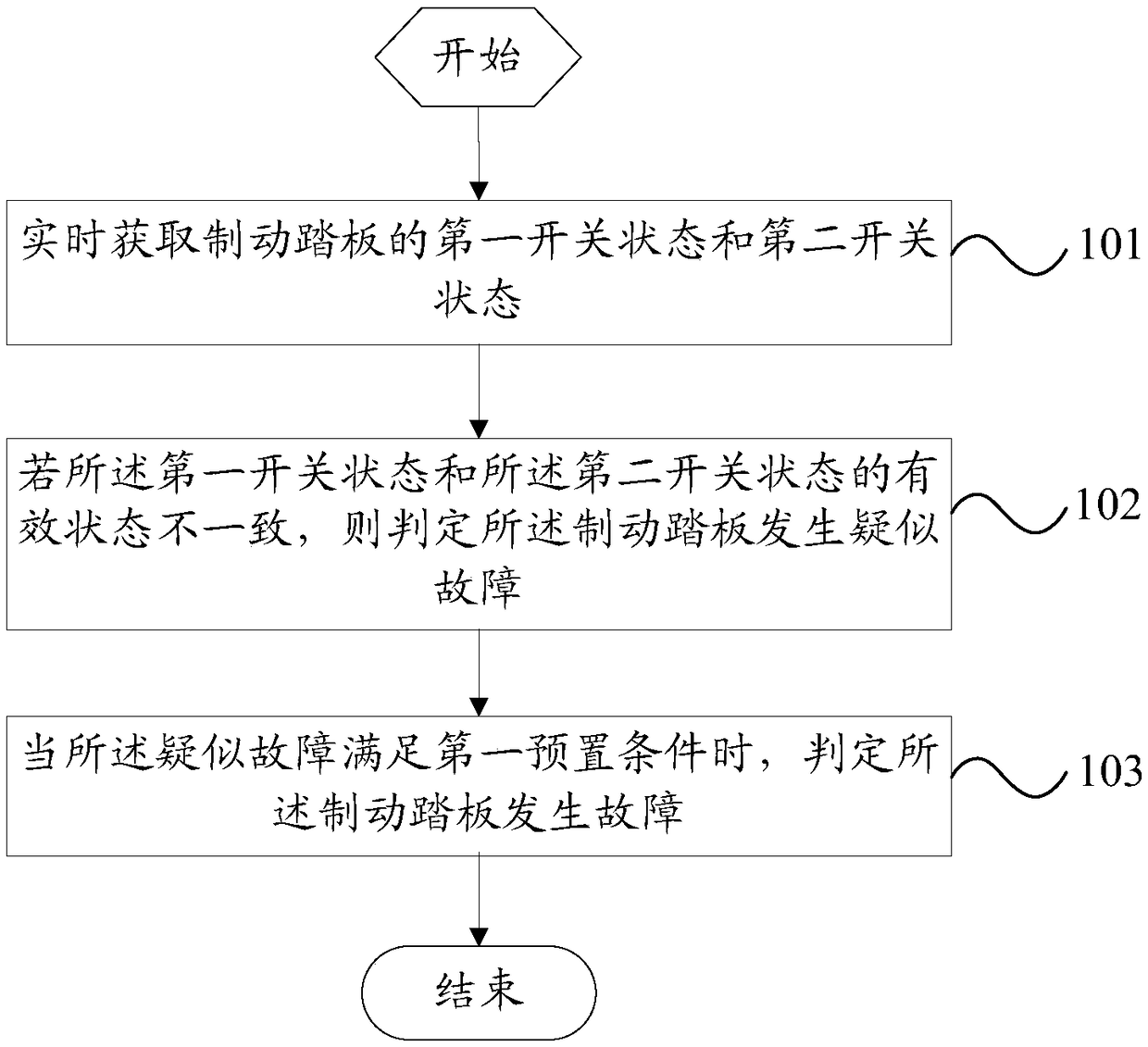

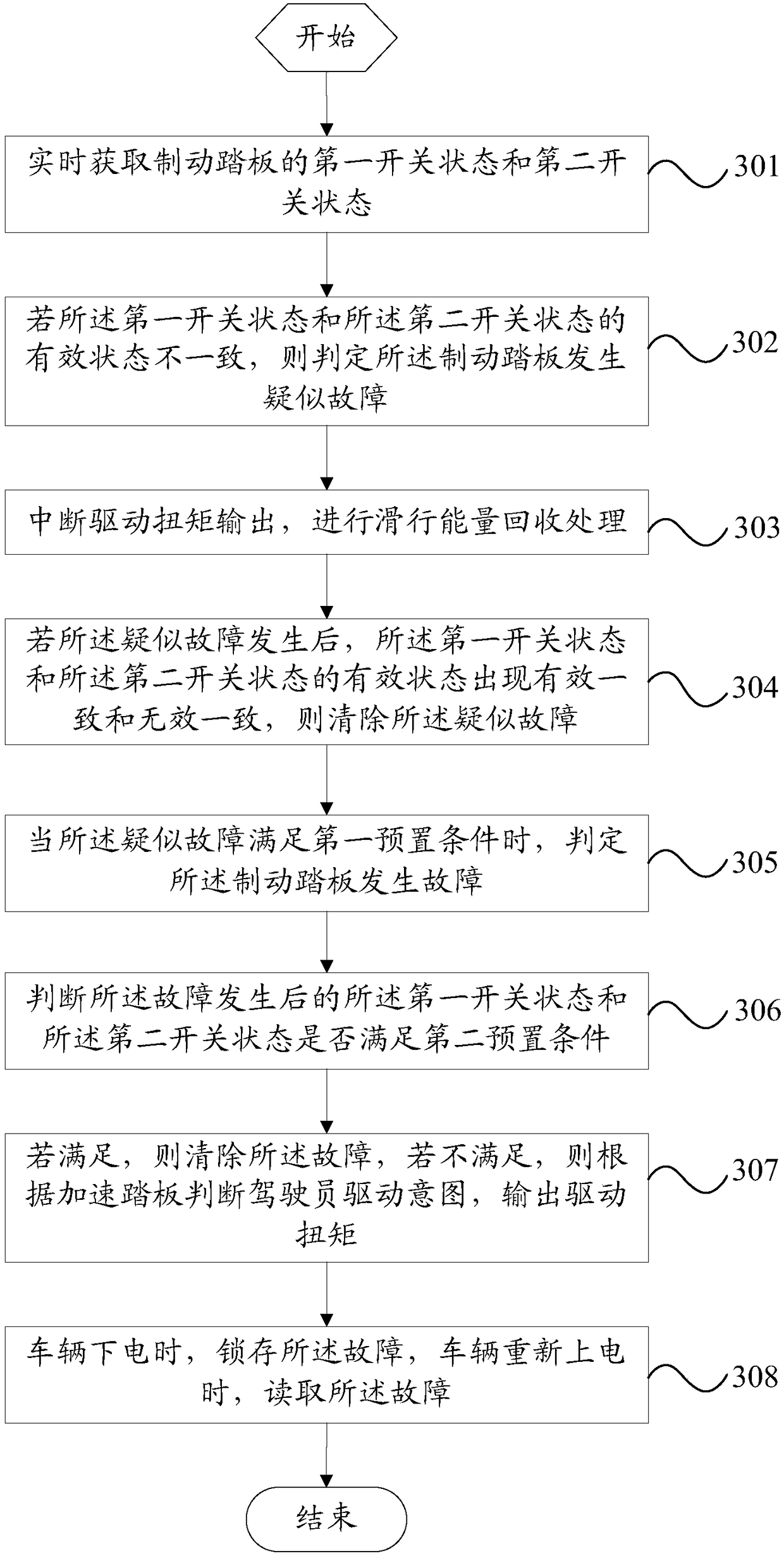

Brake pedal fault diagnosis method and device

ActiveCN109421686AReduce troubleshooting costsImprove reliabilityBrake safety systemsDiagnosis methodsReliability engineering

The invention provides a brake pedal fault diagnosis method and device. The brake pedal fault diagnosis method includes the steps that a first on-off state and a second on-off state of a brake pedal are obtained in real time; if the effective states of the first on-off state and the second on-off state are not identical, it is judged that a suspected fault happens to the brake pedal; and when thesuspected fault meets a first preset condition, it is judged that a fault happens to the brake pedal. By the adoption of the brake pedal fault diagnosis method, fault diagnosis of the brake pedal canbe achieved through a simple structure, the fault diagnosis cost of the brake pedal is reduced, fault misjudgment can be avoided to a certain degree, and the fault diagnosis reliability of the brake pedal is improved.

Owner:GREAT WALL MOTOR CO LTD

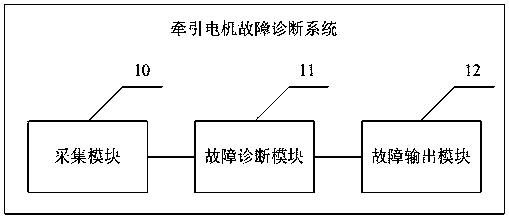

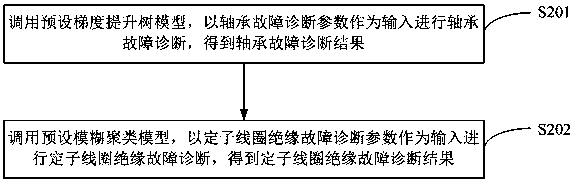

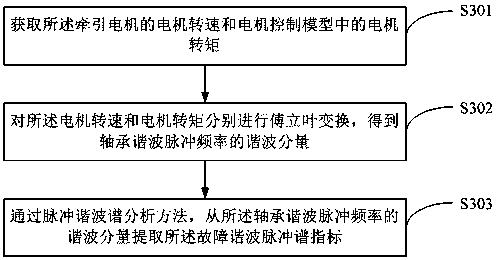

Traction motor fault diagnosis method and device

ActiveCN111208427AReduce troubleshooting costsImplement fault diagnosisSpeed controllerTesting dielectric strengthElectric machineStator coil

The invention provides a traction motor fault diagnosis method and device. The method is applied to a traction motor fault diagnosis system. In the method, a train traction motor is used as an object,on the premise of not additionally arranging a sensor and not additionally carrying out equipment transformation on a train traction system, and by utilizing the bearing fault diagnosis parameter andthe stator coil insulation fault diagnosis parameter of the traction motor, a preset gradient boosting tree model and a preset fuzzy clustering model are respectively called to realize fault diagnosis of a traction motor bearing and fault diagnosis of stator coil insulation, thereby reducing the fault diagnosis cost of the traction motor.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

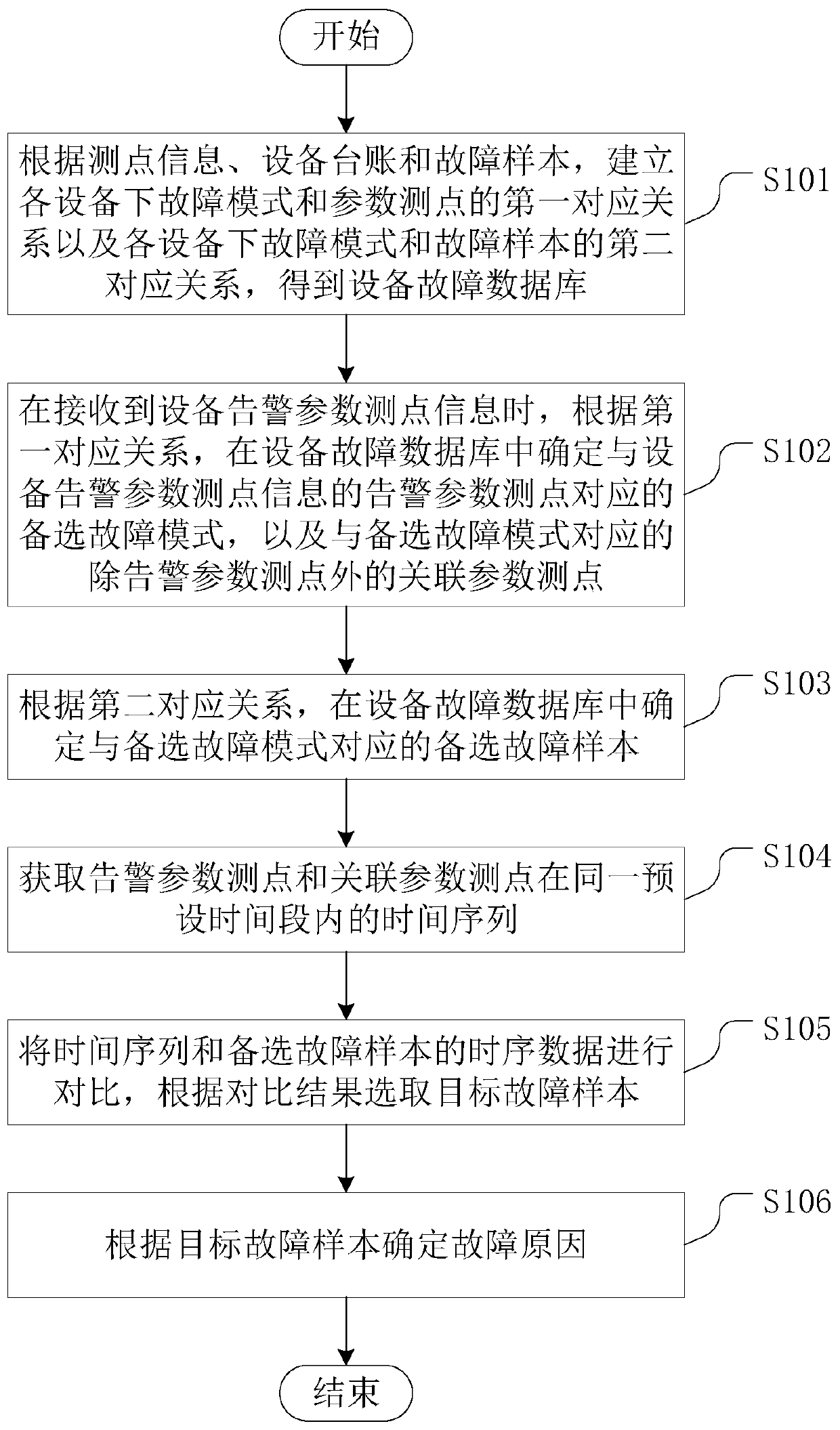

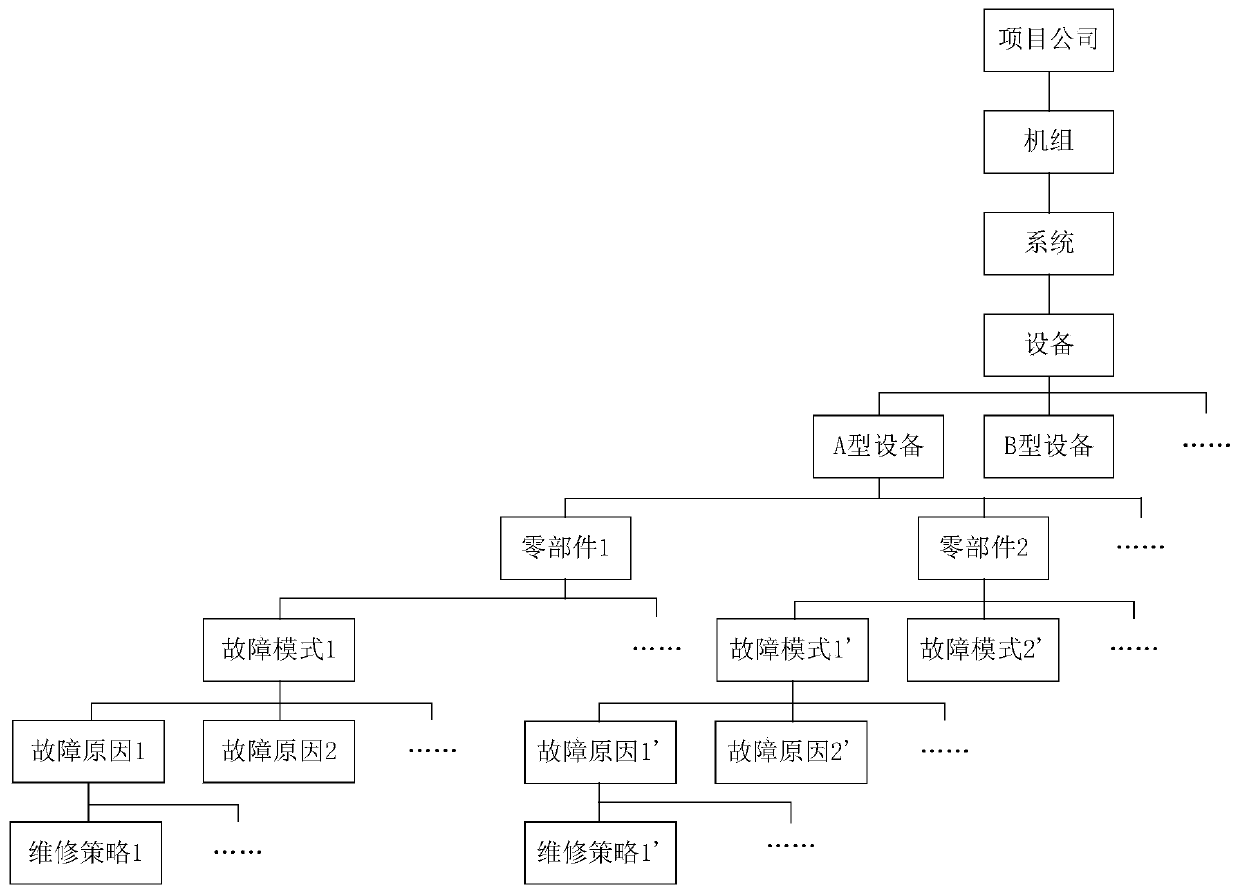

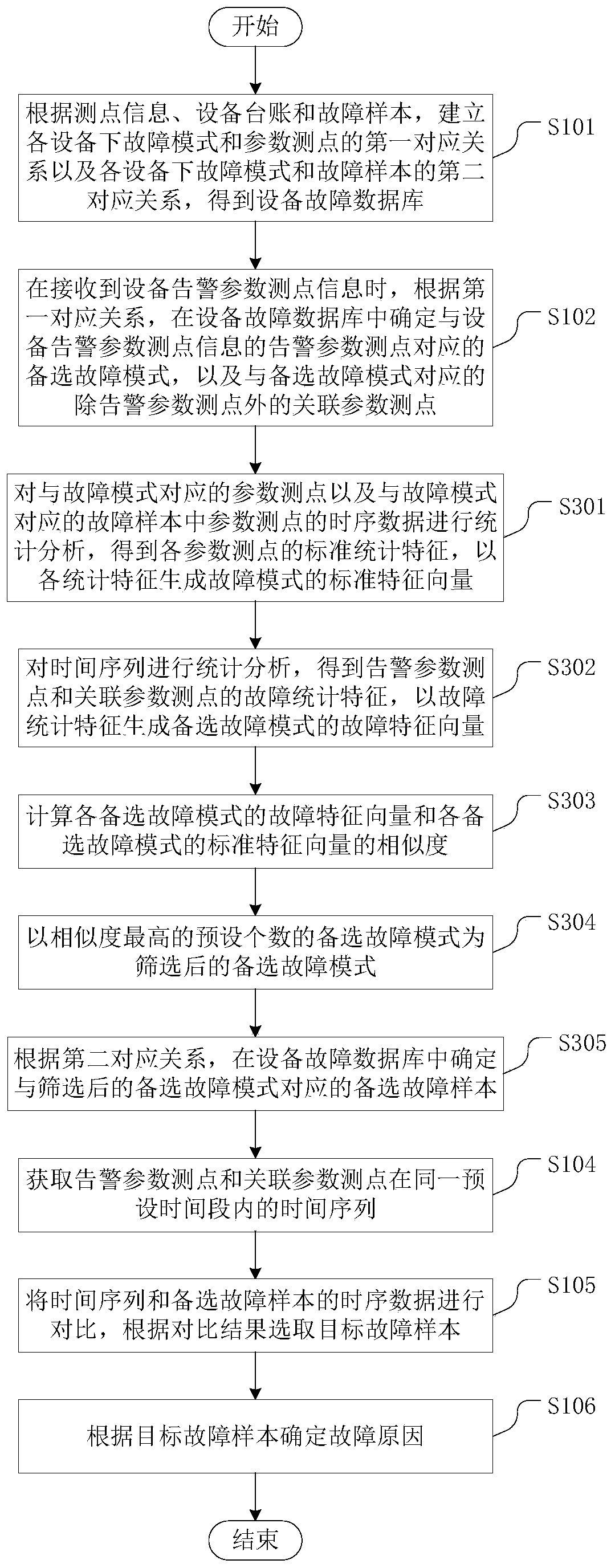

Equipment fault diagnosis method, diagnosis device, diagnosis equipment and storage medium

ActiveCN111459700AReduce dependencyReduce troubleshooting costsDigital data information retrievalFault responseData libraryReliability engineering

The invention discloses an equipment fault diagnosis method and device, diagnosis equipment and a storage medium. An equipment fault database of a first corresponding relationship between a fault modeand a parameter measuring point under each piece of equipment and a second corresponding relationship between the fault mode and a fault sample under each piece of equipment is established; complex expert experience does not need to be added; when the equipment alarm parameter measuring point information is received, alternative fault modes and associated parameter measuring points correspondingto the alarm parameter measuring points of the equipment alarm parameter measuring point information are determined according to the first corresponding relation, alternative fault samples are determined according to the second corresponding relation, a time sequence of the alarm parameter measurement point and the associated parameter measurement point are obtained in the same preset time period;and the time sequence is compared with the time sequence data of the alternative fault samples, i.e., the association between the equipment alarm parameter measurement point information and the faultsamples is obtained through simple analysis of the basic data, a target fault sample is determined according to a comparison result, and further a fault reason is determined.

Owner:华润电力技术研究院有限公司

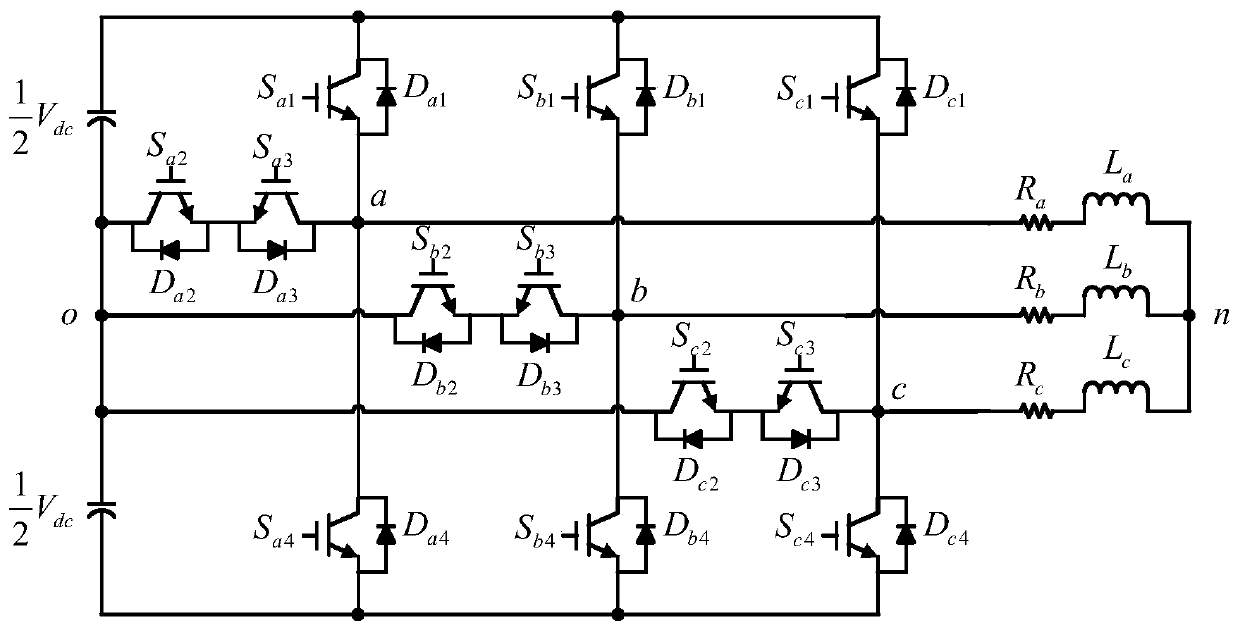

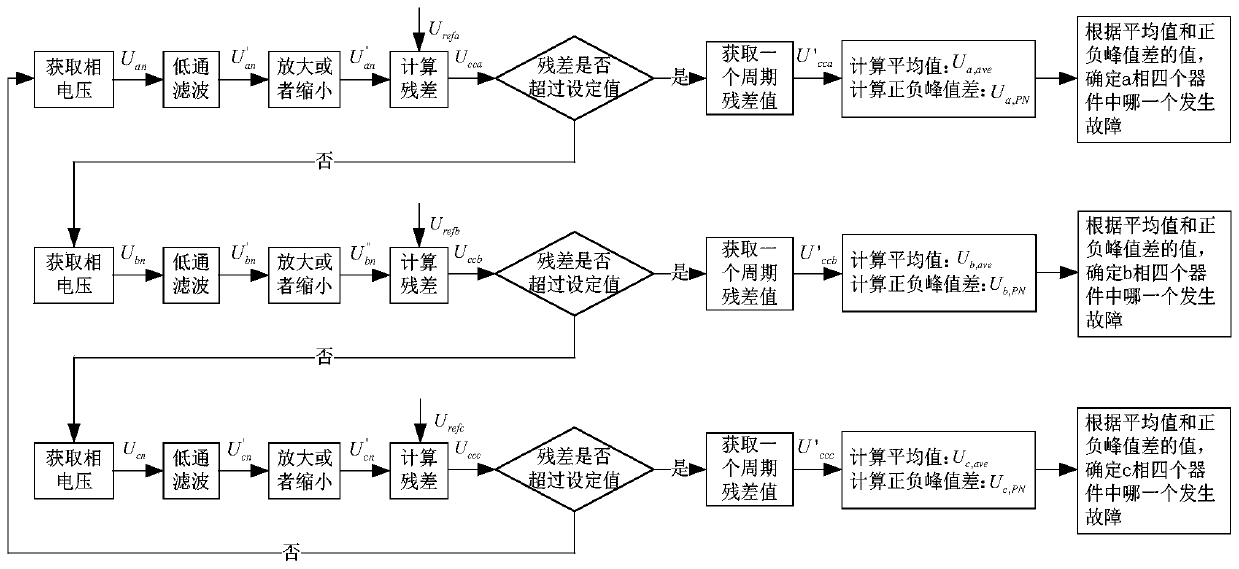

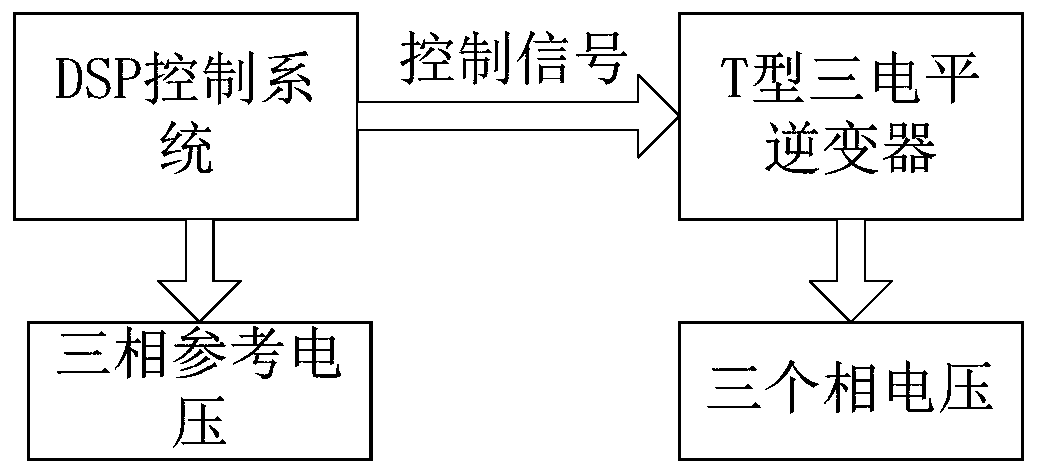

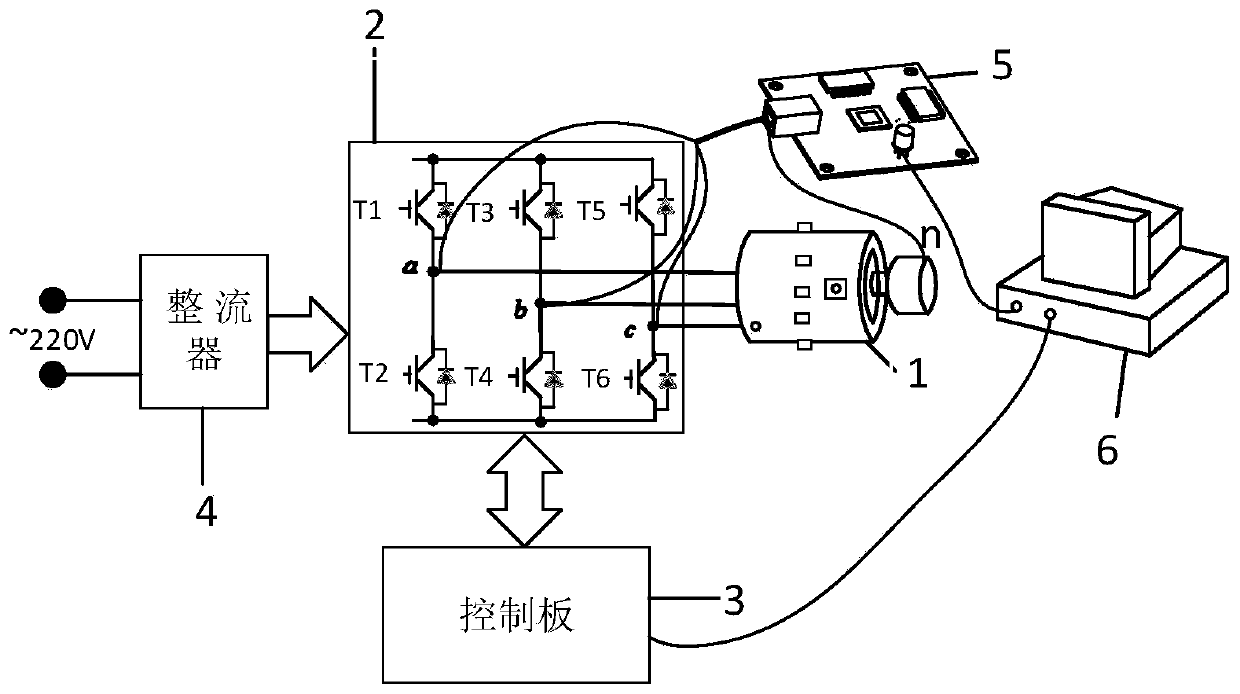

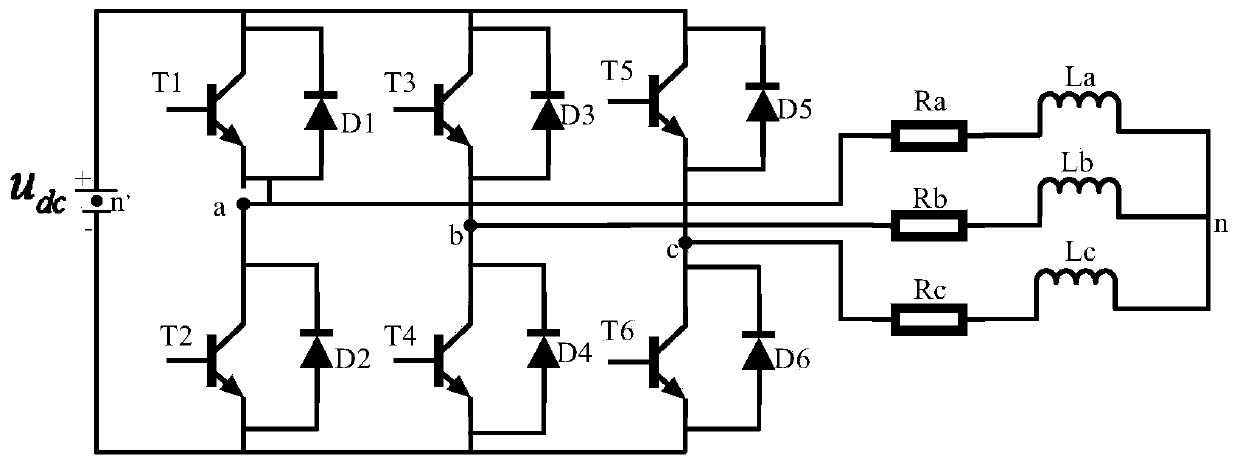

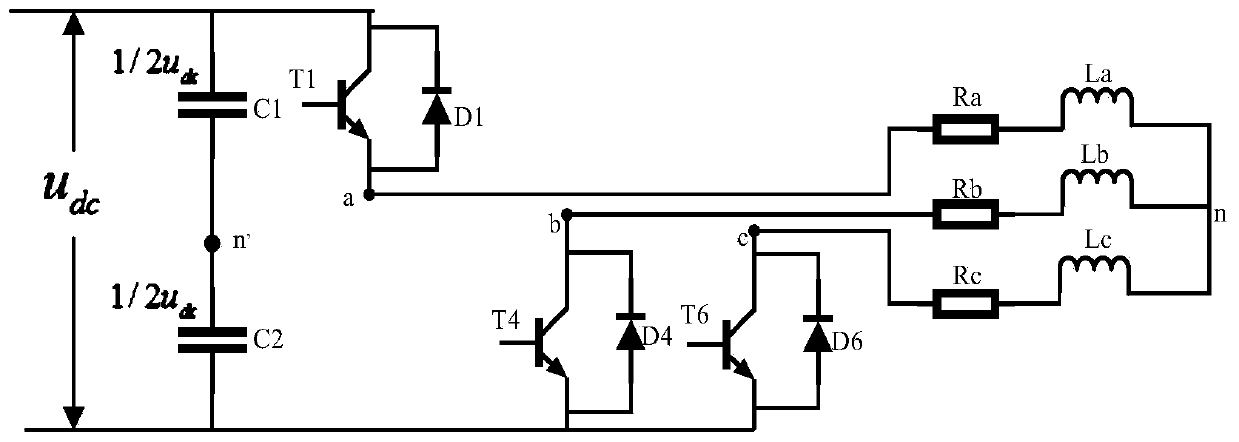

T-type three-level inverter fault diagnosis method based on phase voltage residual

ActiveCN110058111AHigh working reliabilityRaw information needs lessElectrical testingReduction treatmentDiagnosis methods

The invention discloses a T-type three-level inverter fault diagnosis method based on phase voltage residual. In the method, firstly, three-phase voltage of a to-be-diagnosed T-type three-level inverter is obtained, and the three-phase voltage is subjected to filtering and amplification or reduction treatment; residual voltage between reference voltage of each phase and treated voltage of each phase is calculated; whether a circuit of each phase has fault is judged according to a sampling voltage value in the residual voltage of each phase; under the premise that the fault happens, an averagevalue of the residual voltage in one time cycle of starting of sampling moment of the sampling voltage value varying abnormally and a positive and negative peak difference value are calculated; then,specifically, which device has an open circuit fault is judged according to the average value and the positive and negative peak difference value. The method provided by the invention has the advantages that only voltage of three phases needs to be acquired, original information of fault diagnosis is relatively less, moreover, fault diagnosis cost is low, fault diagnosis accuracy is high, the specific device can be located automatically through the fault diagnosis result, and consequently, work reliability of the T-type three-level inverter can be improved effectively.

Owner:合肥九州龙腾科技成果转化有限公司

Open-circuit fault detection method of three-phase inverter power tube

InactiveCN111537914AReduce troubleshooting costsRobustCurrent/voltage measurementContinuity testingPermanent magnet synchronous motorControl theory

The invention discloses an open-circuit fault detection method of a three-phase inverter power tube in the field of motor-driven dynamic system fault detection. Phase voltages of a three-phase inverter during normal and fault operation are acquired in a permanent magnet synchronous motor for experiments; phase voltage data under normal and fault conditions are obtained; six fault state functions are constructed; a fault state function of a to-be-tested motor is solved by using the same method; zero values and non-zero values in six sectors which are correspondingly divided are listed in each fault state function; and finally, the state values in the six sectors in the fault state functions of the to-be-detected motor are determined, if the state values are all non-zero values, the three-phase inverter has no fault, the fault state function of the to-be-detected motor is compared with the six fault state functions one by one in sequence, and if the state values are correspondingly equal, an open-circuit fault is detected to occur in the corresponding tube. According to the method, the phase voltages under the normal working condition and the fault working condition serve as fault diagnosis characteristic values, and good robustness and high accuracy are achieved.

Owner:JIANGSU UNIV

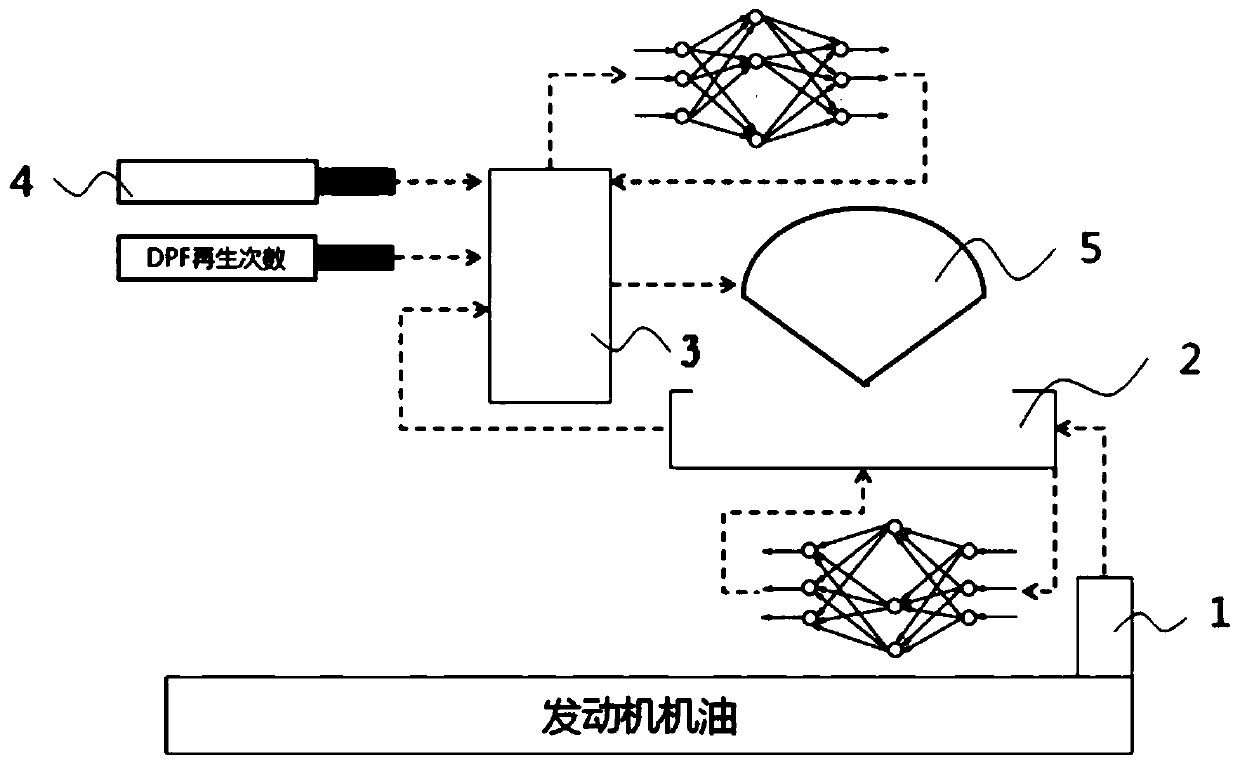

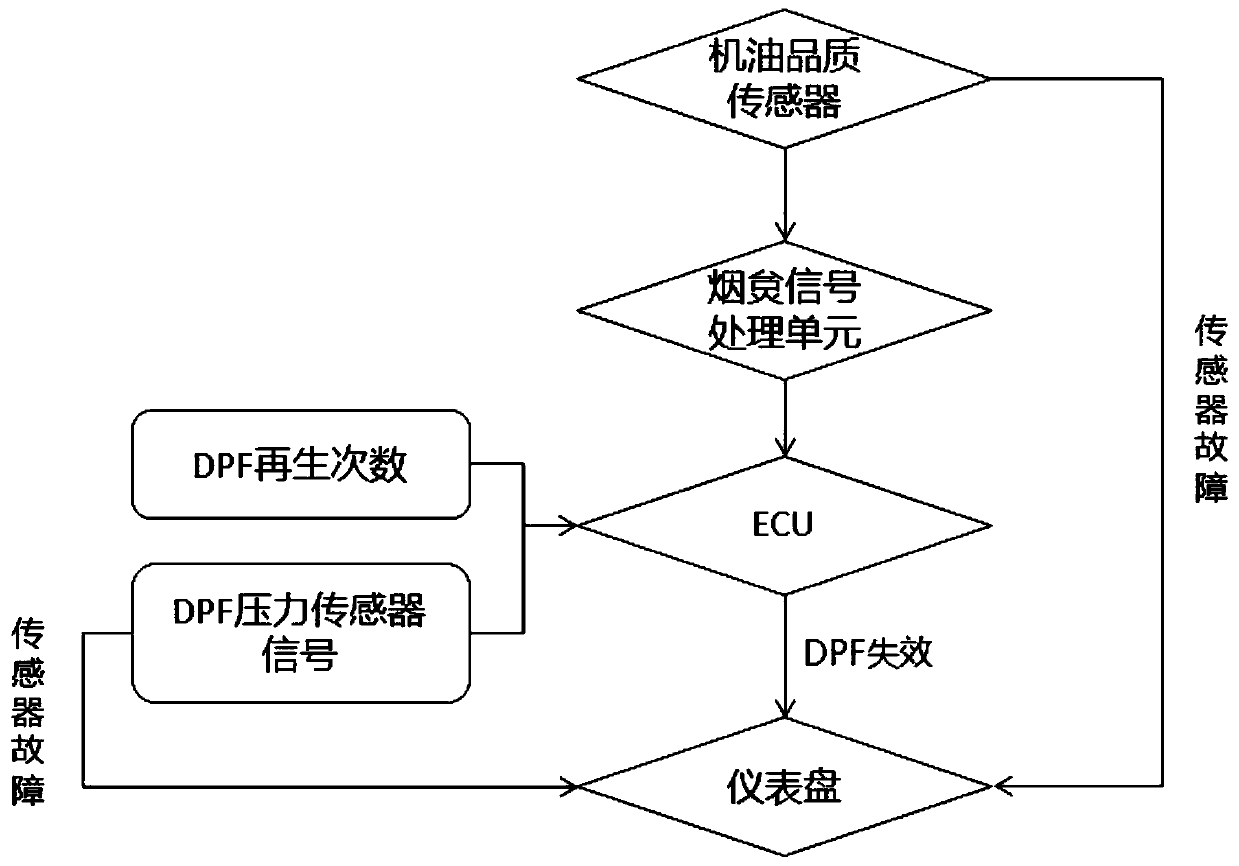

DPF system OBD fault diagnosis method based on engine oil quality sensor

InactiveCN110107387ALow costReduce Interfering SignalsInternal combustion piston enginesExhaust treatment electric controlDifferential pressureOil quality

The invention discloses a DPF system OBD fault diagnosis method based on an engine oil quality sensor. The OBD fault diagnosis method comprises the engine oil quality sensor, a soot signal processingunit, an ECU (electronic control unit), a DPF differential pressure sensor and an instrument panel, wherein the engine oil quality sensor is connected with the soot signal processing unit through electric signal transmission, the soot signal processing unit sends the soot content to the ECU, and the DPF pressure sensor is electrically connected with the instrument panel through the ECU. Accordingto the DPF system OBD fault diagnosis method based on the engine oil quality sensor, a modeled DPF filtering precision algorithm is used for detecting the content of the soot in engine oil, interference signals are few, and the precision degree is high; and in addition, the system is simple in structure, and the false alarm probability is reduced. Meanwhile, the engine oil quality sensor is low incost, and the existing DPF system OBD fault diagnosis cost can be greatly reduced.

Owner:苏州艾思泰车辆科技有限公司

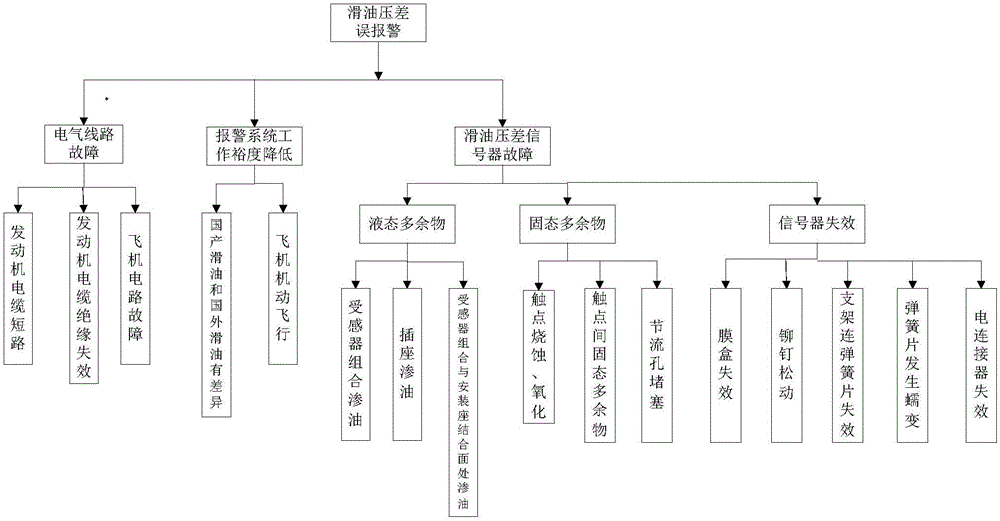

Method for locating failure causes for main gearbox lubrication systems in helicopters

InactiveCN103062614AFind out the cause of the failureEasy to findLubrication elementsReduction driveFailure causes

The invention relates to a method for locating failure causes for main gearbox lubrication systems in helicopters. Checking direction and steps are determined by monitoring instrument parameters, and failure causes are located quickly and conveniently, so that failure of a lubrication system is eliminated quickly. The method is evidently effective in practical application and can be used to effectively locate failure causes for the main gearbox lubrication systems in helicopters, troubleshooting cycle is shortened and troubleshooting cost is lowered.

Owner:HARBIN DONGAN ENGINE GRP

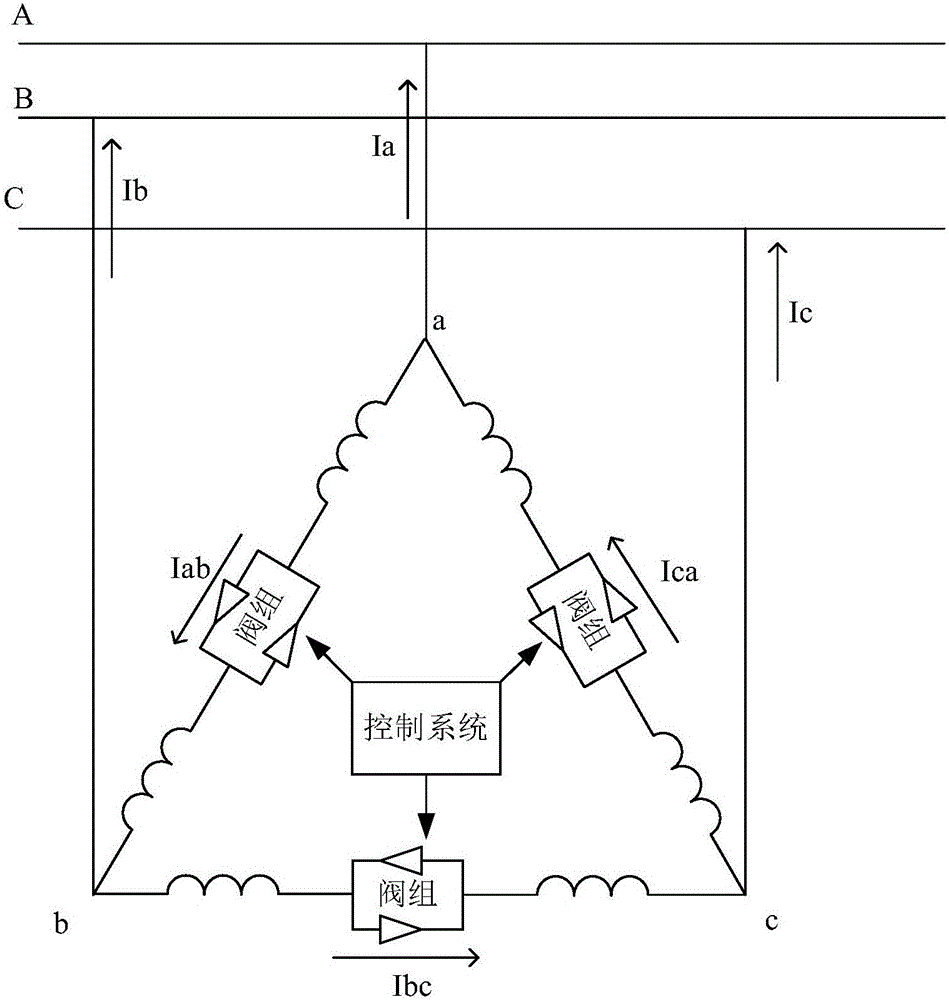

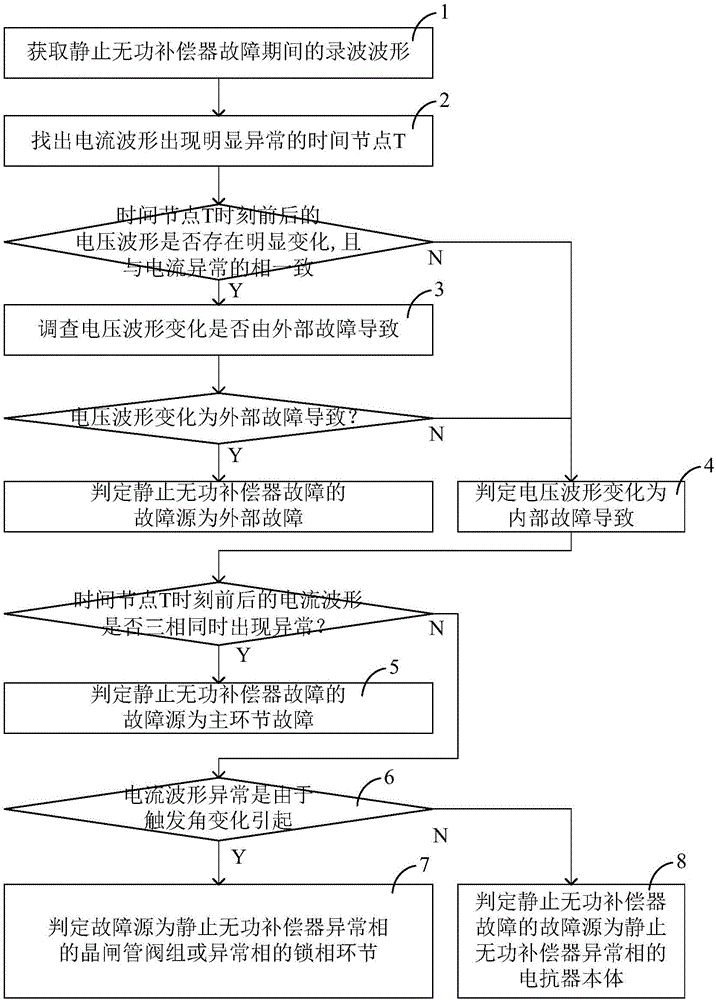

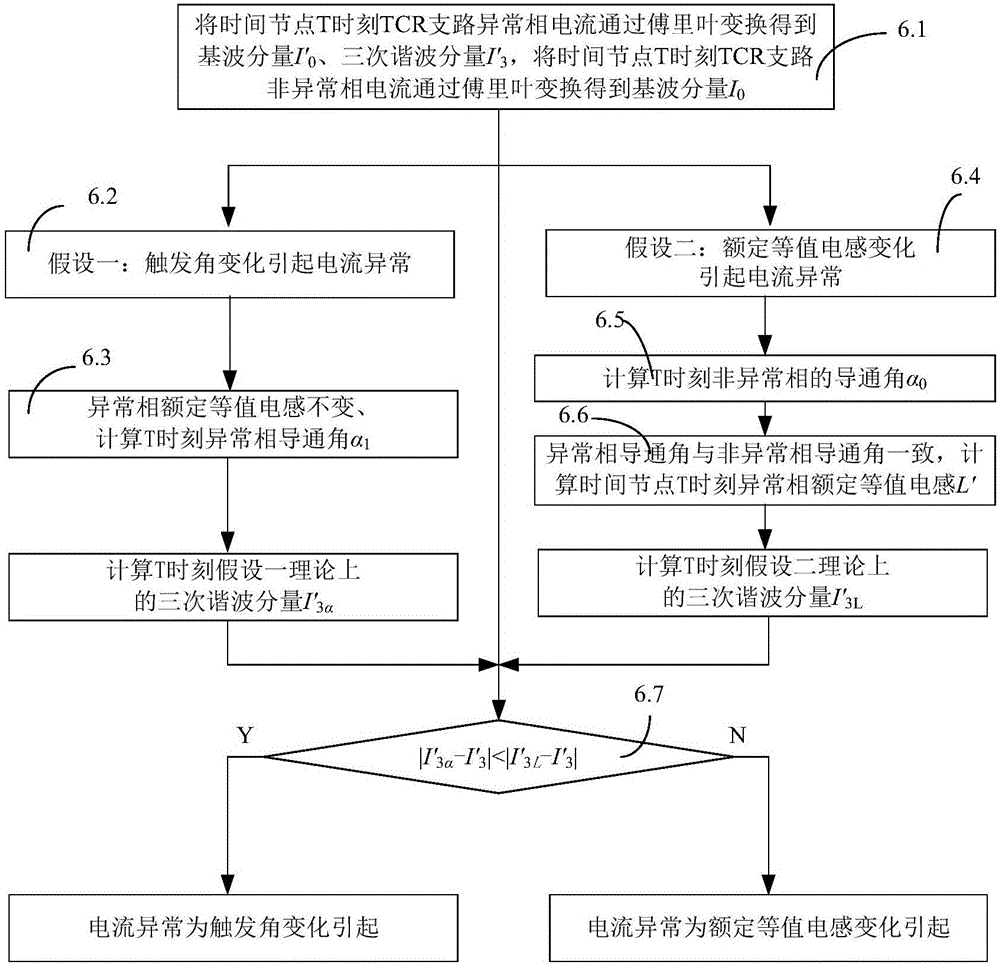

Method for fault analysis and location of thyristor controlled reactor of static var compensator

ActiveCN106353637AQuick analysisFast analysis and positioningFault locationThree-phaseDevice failure

The invention discloses a method for fault analysis and location of thyristor controlled reactor of static var compensator,which comprises the step of identifying and locating a fault source gradually by analyzing and calculating the waveform recorded during the fault period,analyzing the abnormalities of the bus line voltage to distinguish the internal fault from the external fault, distinguishing the main link fault or other link / equipment faults in the control system by analyzing whether the three-phase current is abnormal at the same time, and calculating the third-harmonic component in the current to distinguish thyristor valve block control failure from reactor failure. The invention analyzes and locates the fault source of the static var compensator rapidly without relying on laboratory detection or fault simulation, and has the advantages of simplified fault analysis, shortened outage time, improved efficiency, reduced cost and wide application range.

Owner:STATE GRID CORP OF CHINA +2

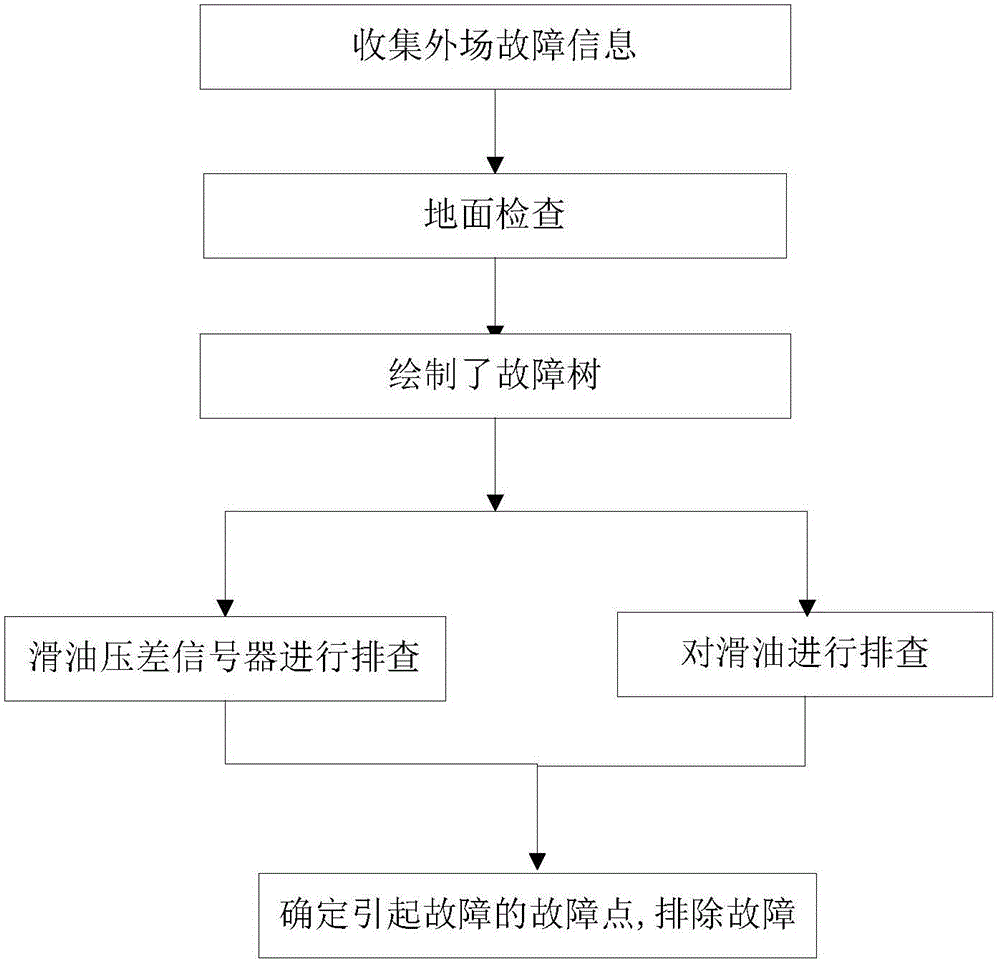

Lubricating oil pressure difference false alarm fault point searching method

The invention provides a lubricating oil pressure difference false alarm fault point searching method. The method includes performing airplane ground electrical line inspection after eliminating the airplane maneuvering flight faults, drawing a fault tree, and performing verification and checking according the fault tree; checking a lubricating oil pressure difference signal device; 3.2) checking the lubricating oil; performing the contrast test of different types of lubricating oil on the engine and eliminating the faults caused by the pressure of the different types of lubricating oil; performing classification analysis to determine the fault points of the faults; and for the reasons of the fault points, taking measures to eliminate the faults. The method of the invention improves the accuracy and effectiveness of the fault diagnosis, reduces the over-reliance on the operators' level in the fault analysis and fault positioning carried in the product testing process, and prevents repeated and disordered work, thereby reducing the labor intensity, and improving the work efficiency.

Owner:AECC AVIATION POWER CO LTD

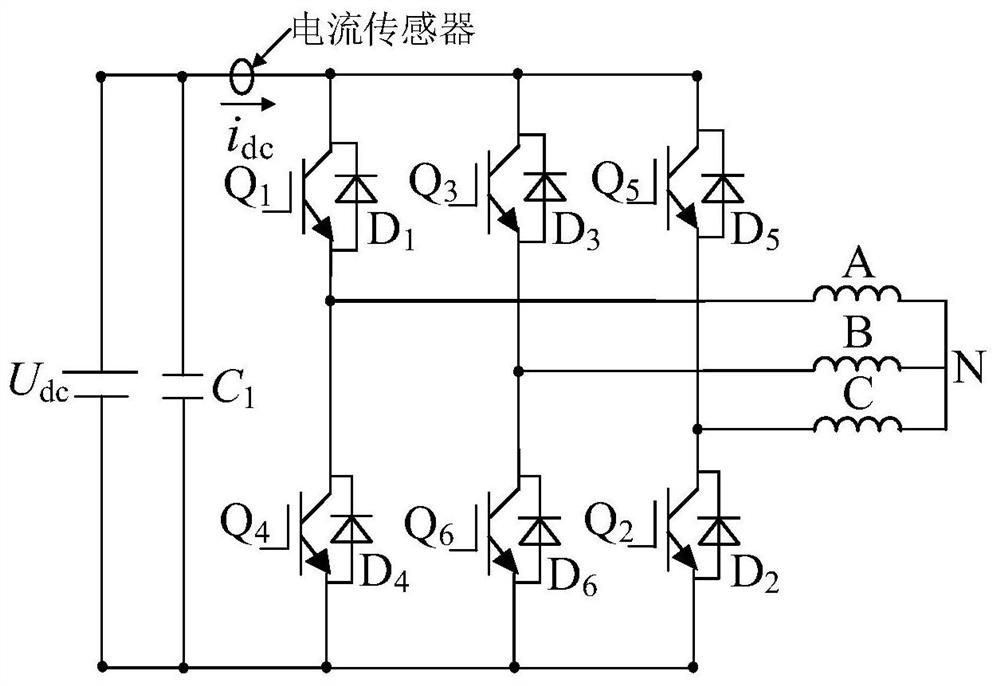

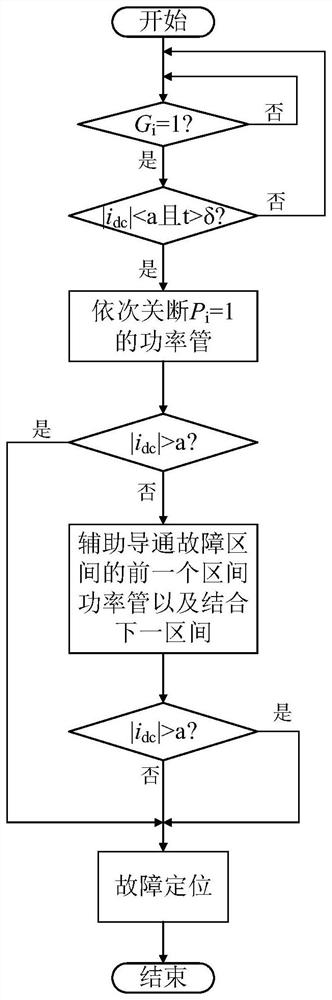

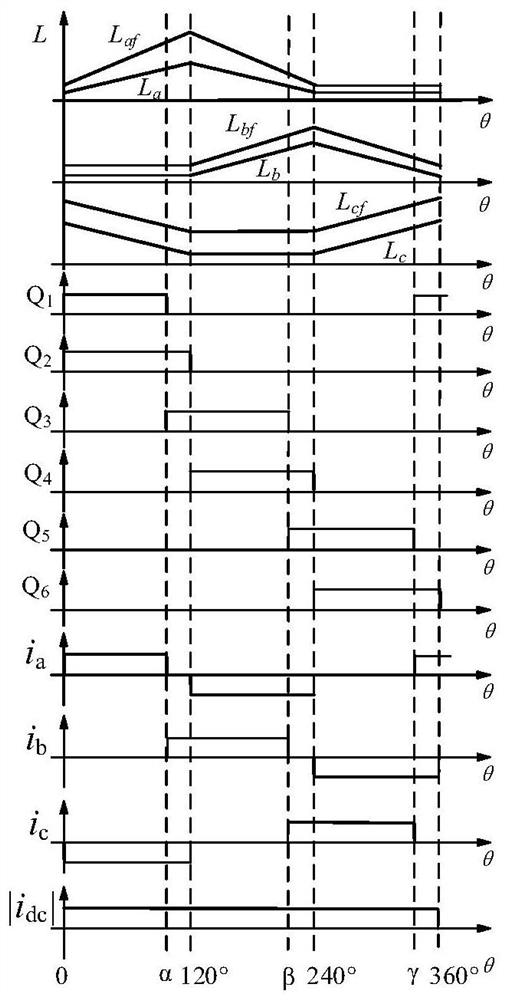

Doubly salient motor power converter open-circuit fault diagnosis method based on bus current

ActiveCN113687271AReduce troubleshooting costsShorten the timeContinuity testingElectric machineControl engineering

The invention discloses a doubly salient motor power converter open-circuit fault diagnosis method based on bus current, and relates to the technical field of motor control, and the method comprises the steps: obtaining a DC bus current absolute value and a position signal of a motor rotor; determining the working state of the power converter according to the position signal; if the absolute value of the direct-current bus current is smaller than the zero current threshold value and the duration time exceeds the time threshold value, determining that the power converter has an open-circuit fault; sequentially turning off the power tubes with high-level driving signals in the current working state, and sequentially comparing whether the absolute value of the current of the direct-current bus is still smaller than a zero-current threshold value or not; if not, determining that the other power tube is in an open circuit when the power tube is turned off; and if the two comparison results are yes, conducting the power tube to be driven in the previous working state, and observing the current change of the direct current bus in combination with the next working state to assist in positioning the fault position. The method is low in fault diagnosis cost, shortens the fault diagnosis time, and is not influenced by rotation speed and load changes.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

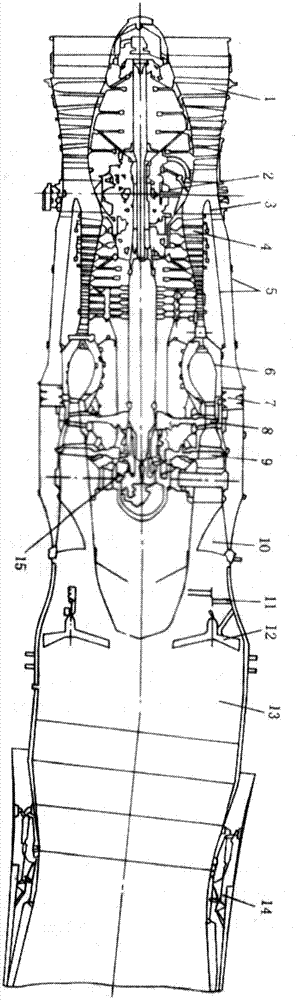

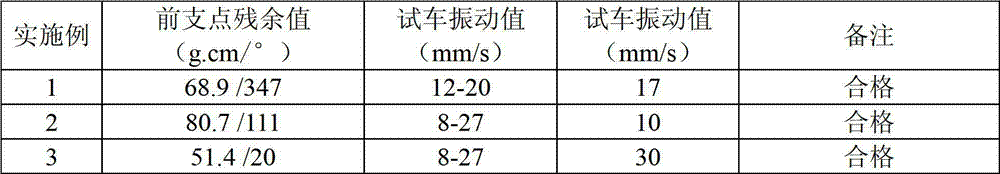

Method for removing fault of vibration value of engine

InactiveCN102928161AShorten troubleshooting cycleReduce repair costsStatic/dynamic balance measurementEngineeringHigh pressure

The invention provides a method for removing a fault of a vibration value of an engine. The method is characterized in that residual unbalance of a high-pressure rotor is changed by a method for adjusting the quality of a high-pressure air injection primary rotor blade, so that the vibration fault is removed. The adjustment scheme of the high-pressure air injection primary rotor blade is characterized in that the mass difference of an I level light key point blade of the high-pressure rotor according to a phase of front balance of an engine test, so that the increased unbalance is obtained; and the mass of the blade to be adjusted is equal to dividing a rotation radius of a mass center of the high-pressure air injection I level rotor blade by the increased unbalance. The method acts on an engine using an elastic oil membrane damping manner, so that the vibration fault can be effectively removed through little resolving depth. Therefore, the vibration value of the engine meets working requirements; meanwhile, the damping period of the engine can be reduced; the fault removing cost of the engine can be reduced; and the labor intensity of the operator can be reduced.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

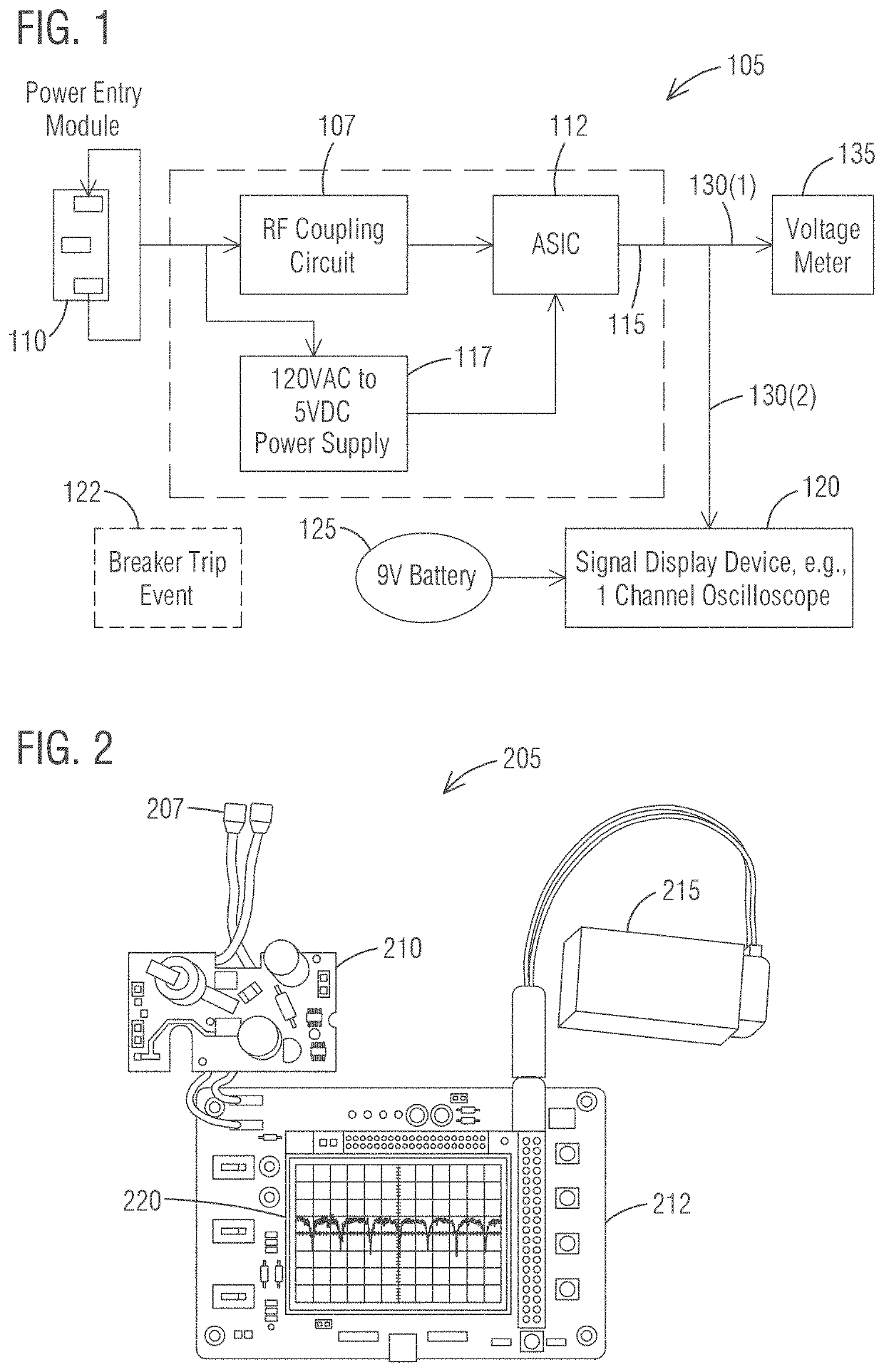

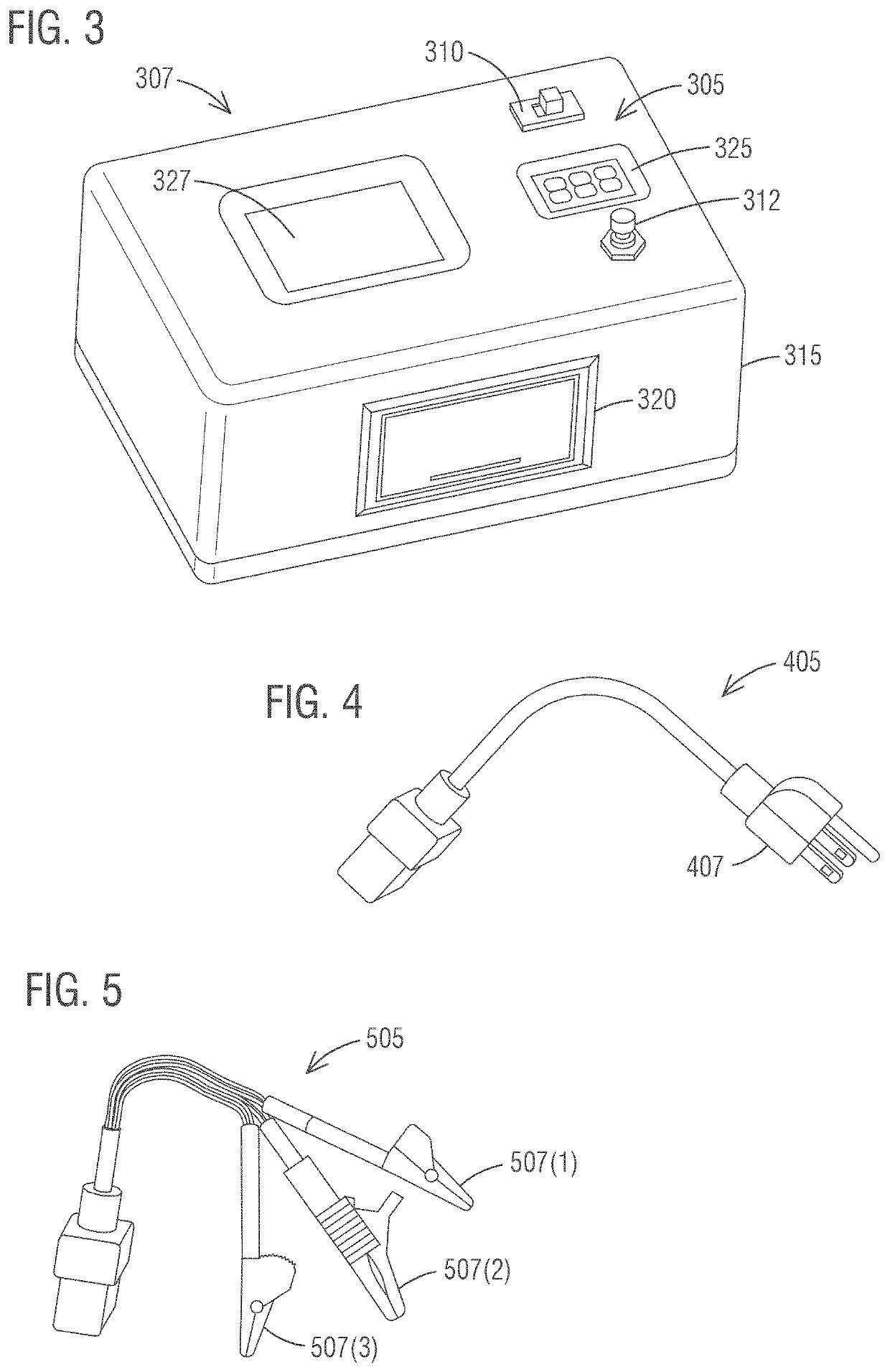

Nuisance arc fault circuit interrupter (AFCI) circuit breaker tripping diagnostic tool

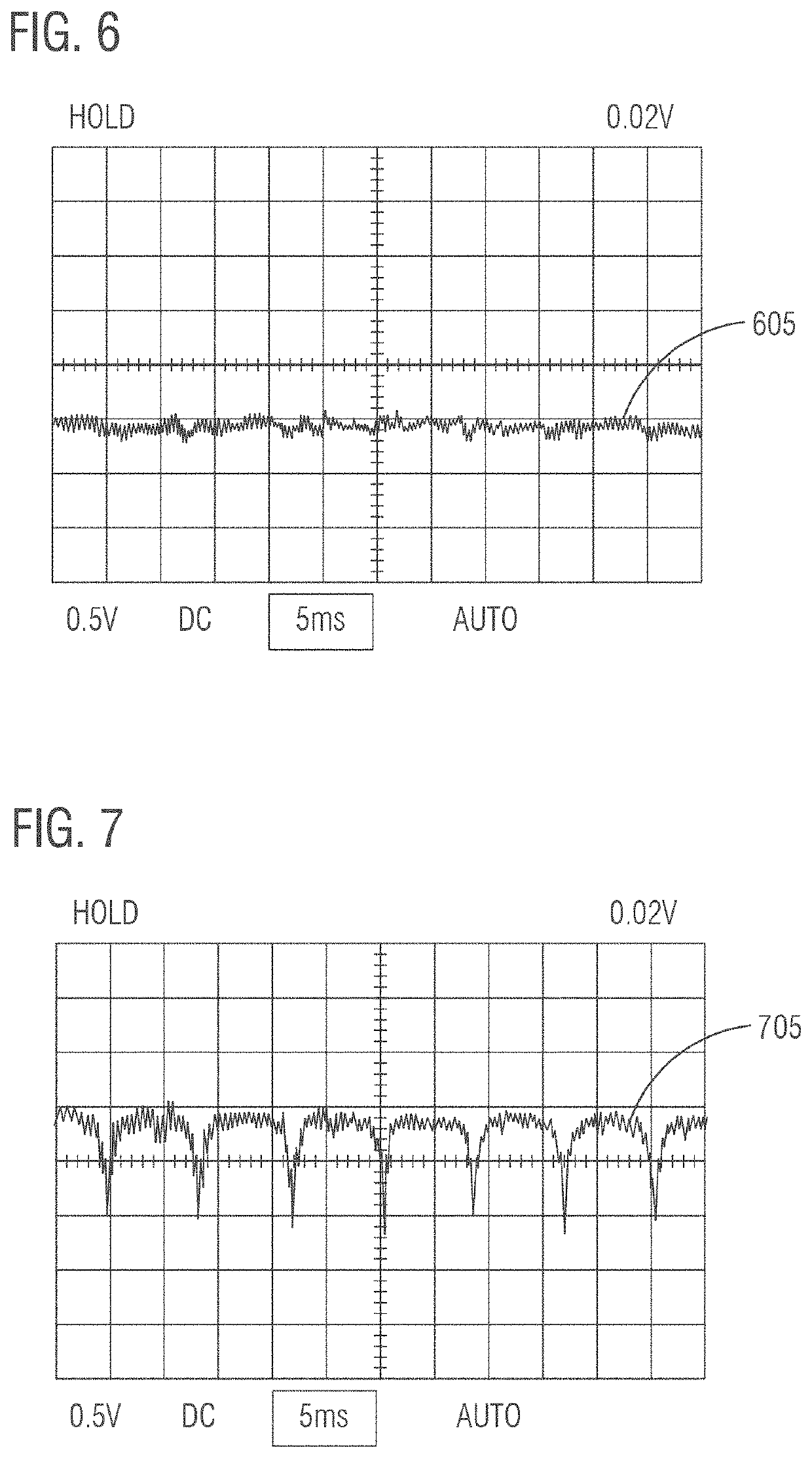

ActiveUS20210278453A1Shorten the timeReduce troubleshooting costsEmergency protective arrangement detailsTesting using acoustic measurementsNoise (radio)Signal on

An arc-like radio frequency (RF) noise detector device is configured to detect and display RF noise on a residential circuit branch that cause or contribute to an arc fault circuit interrupter (AFCI) circuit breaker tripping. It comprises a power cord with a plug to connect to a receptacle on a branch circuit of the AFCI circuit breaker to detect RF noise. It further comprises a RF noise coupling circuit to receive power from a power entry module and coupled to an Application Specific Integrated Circuit (ASIC) to generate a Received Signal Strength Indicator (RSSI) signal from the detected RF noise. It further comprises a power supply, a signal display device configured to receive and display the RSSI signal on a display screen to determine nature of a breaker trip event or likelihood of the breaker trip event and a battery to power the signal display device.

Owner:SIEMENS IND INC

Helicopter main speed reducer oil leak troubleshooting method

ActiveCN103542095AShorten troubleshooting cycleReduce troubleshooting costsEngine sealsGearing detailsTroubleshootingPetroleum engineering

The invention relates to a helicopter main speed reducer oil leak troubleshooting method. The method includes that an oil leak position is determined, state of a sealing member is examined, an oil leak mode of a main speed reducer is determined, and then oil leak reasons can be quickly and conveniently found. The helicopter main speed reducer oil leak troubleshooting method has the advantages of simplicity and high efficiency, oil leak fault reasons of the main speed reducer of a helicopter can be quickly and effectively found, and troubleshooting period and cost are reduced.

Owner:HARBIN DONGAN ENGINE GRP

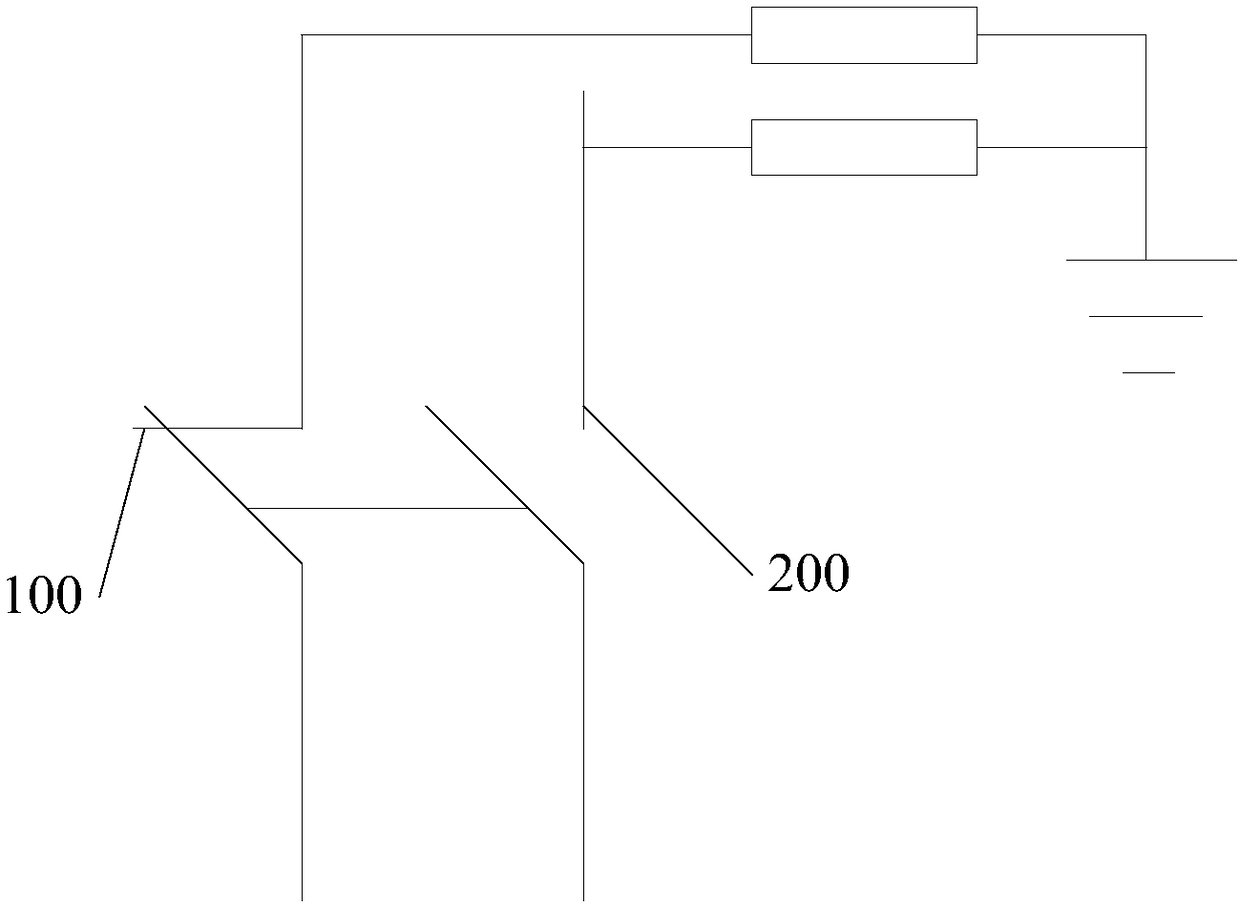

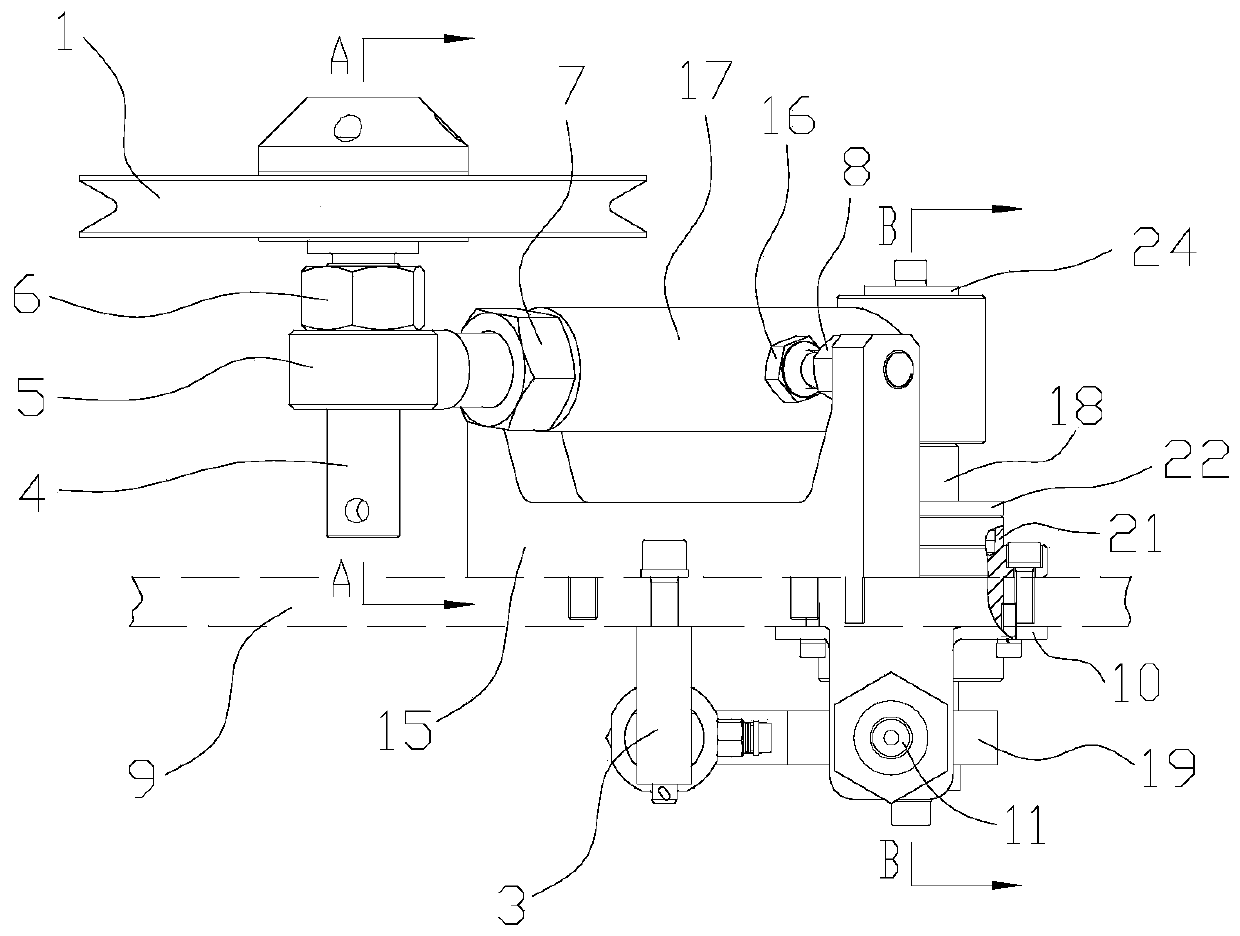

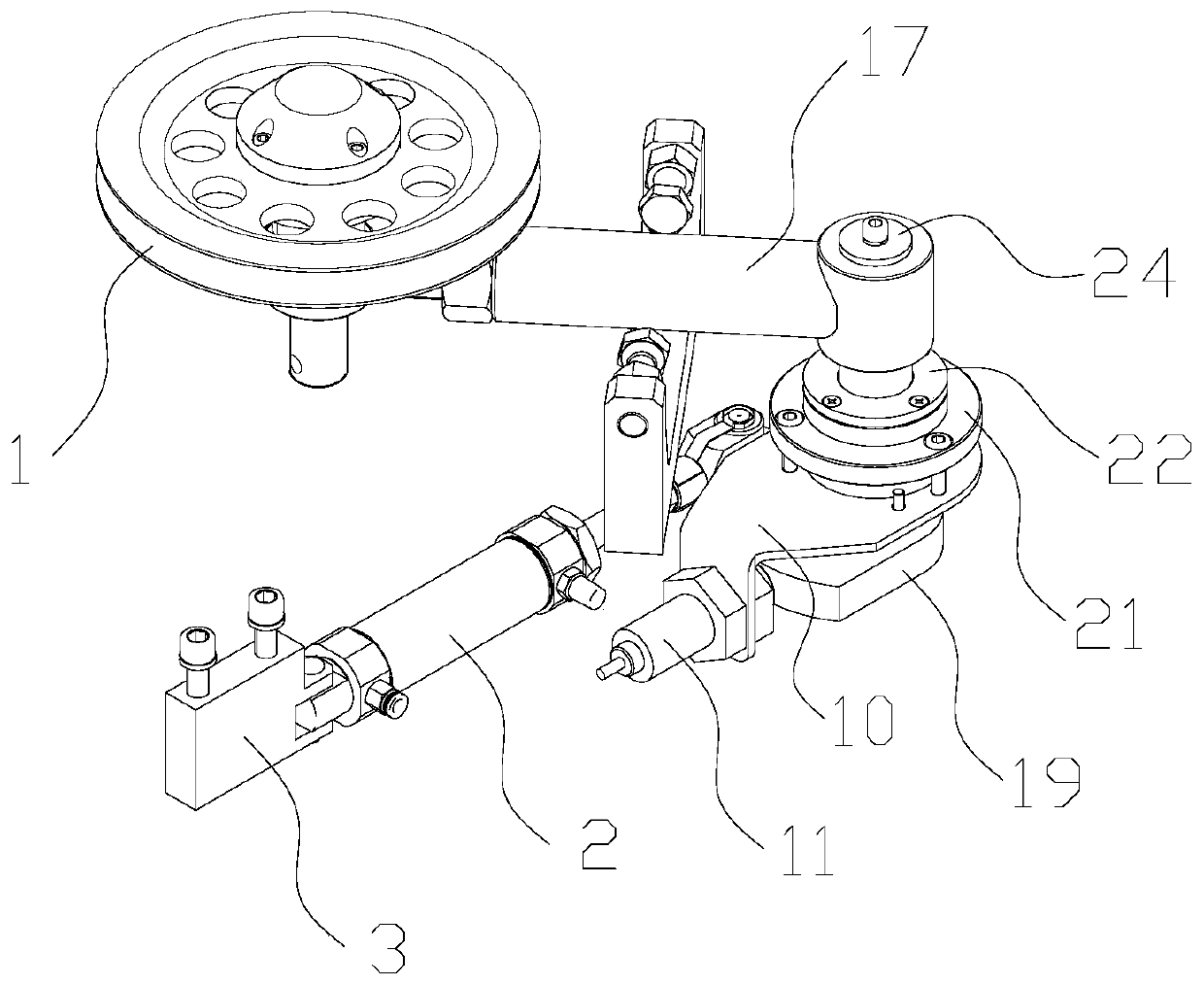

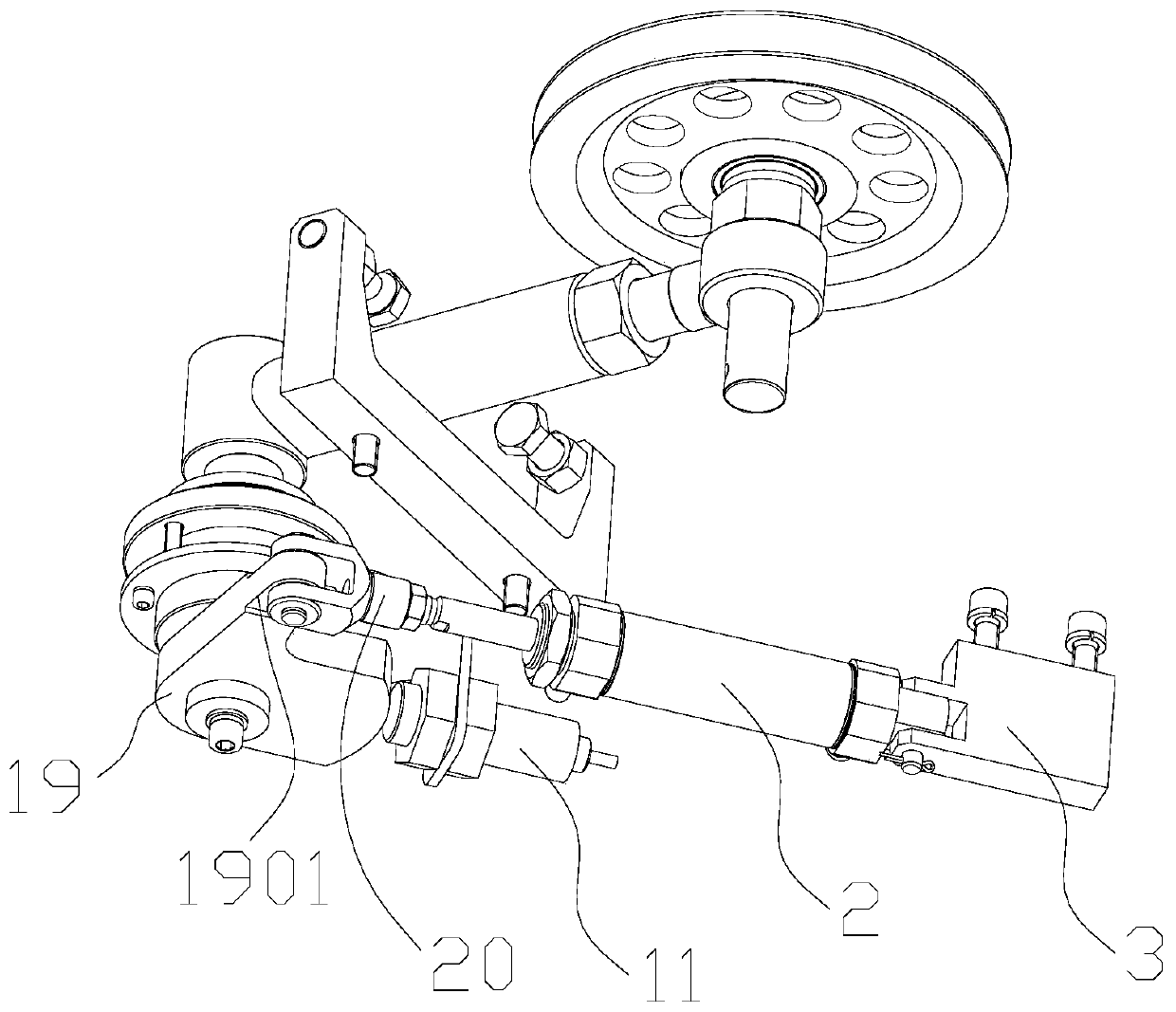

Guide wheel device with three adjustable degrees of freedom

PendingCN110802119AStable supportGuaranteed production efficiencyThree degrees of freedomControl engineering

The invention provides a guide wheel device with three adjustable degrees of freedom. The guide wheel device comprises a guide wheel, a steering mechanism, a limiting mechanism, a transmission mechanism, a monitoring mechanism, an air cylinder and a fixing plate, wherein one end of the steering mechanism is provided with the guide wheel, the other end of the steering mechanism is connected with one end of the transmission mechanism, the transmission mechanism comprises a monitoring plate, the other end of the transmission mechanism is connected with the air cylinder, the monitoring mechanism comprises a support and a sensor, the support is fixed to a machine table panel, the sensor is fixed to the support, and a detection head of the sensor is opposite to the monitoring plate. According tothe guide wheel device, the adjustment function of the guide wheel position in three degrees of freedom is realized, the guide wheel can be conveniently adjusted to the optimal position, and the operation is convenient and rapid. The guide wheel position can be dynamically controlled in the production process, the guide wheel can be kept in the optimal position range all the time in the production process, the processed metal wire is stable in stress, high in consistency and high in pretreatment quality, and the quality and competitiveness of the enterprise product are improved.

Owner:GUIZHOU AEROSPACE NANHAI SCI & TECH

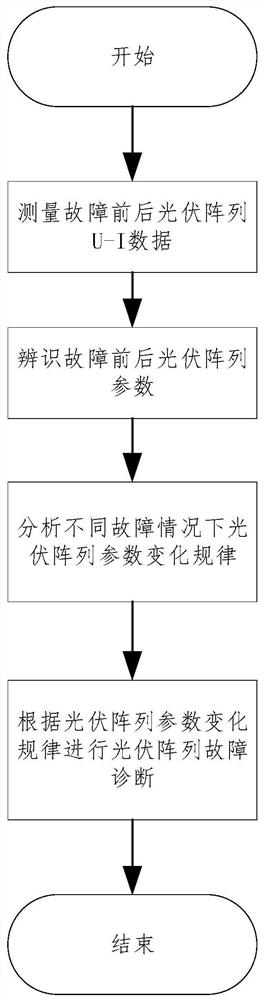

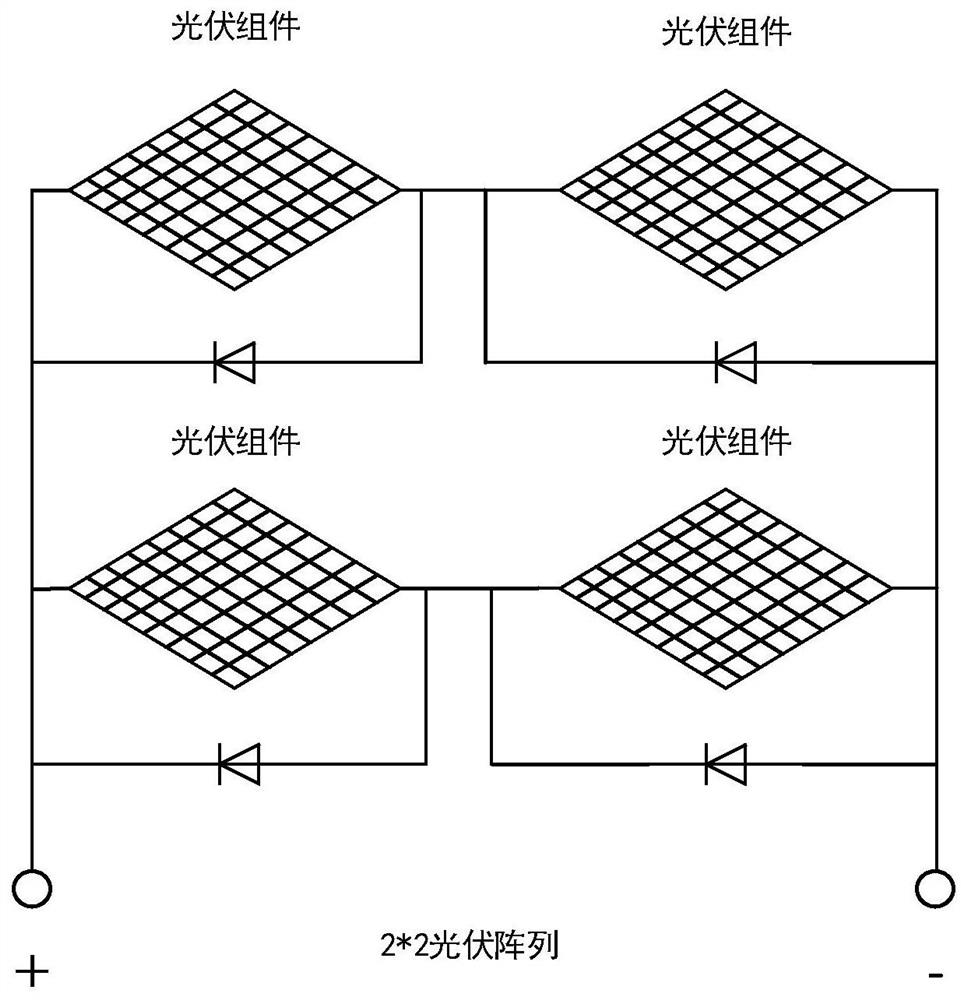

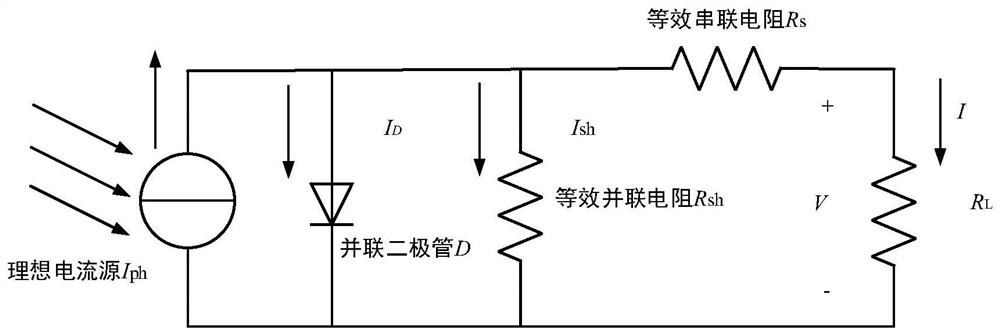

Photovoltaic array fault diagnosis method based on improved salp swarm algorithm

ActiveCN113191075AReduce troubleshooting costsFew samples of current dataPhotovoltaic monitoringCharacter and pattern recognitionIntelligent algorithmsAlgorithm

The invention discloses a photovoltaic array fault diagnosis method based on an improved salp swarm algorithm, and belongs to the field of photovoltaic power generation. The method includes: a photovoltaic array parameter identification module based on the improved salp swarm algorithm and a photovoltaic array fault diagnosis module based on internal parameter change. Then the photovoltaic array parameter identification module identifies five parameter values of the photovoltaic array single-diode model according to the voltage and current output by the photovoltaic array. Finally, the photovoltaic array fault diagnosis module carries out photovoltaic array fault diagnosis according to the change range of five parameters of the photovoltaic array before and after the fault. According to the invention, based on the improved salp swarm algorithm, compared with a traditional dogvessel goblet swarm optimization algorithm and other intelligent algorithms, the photovoltaic array parameter identification speed is faster, and the precision is higher; moreover, the photovoltaic array fault diagnosis module carries out fault diagnosis through the parameter change of the photovoltaic array before and after the fault, and compared with other photovoltaic array fault diagnosis methods, the photovoltaic array fault diagnosis method is low in required cost and high in diagnosis speed.

Owner:ZHEJIANG UNIV

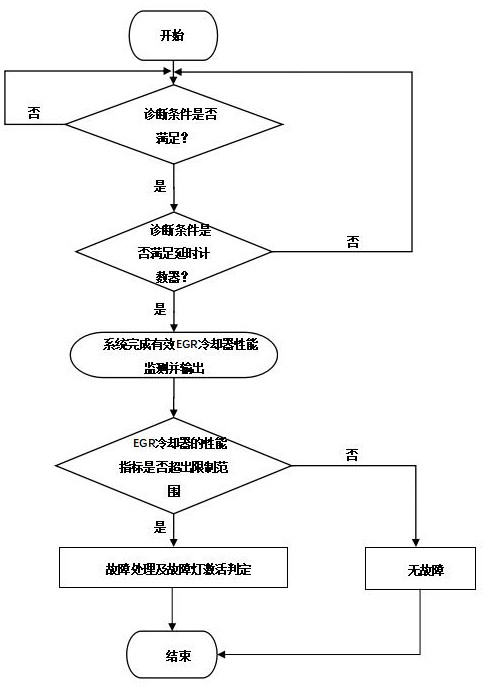

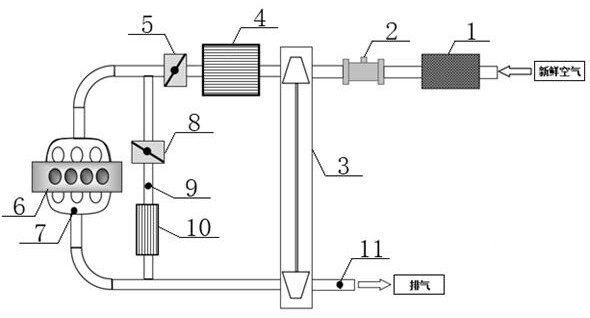

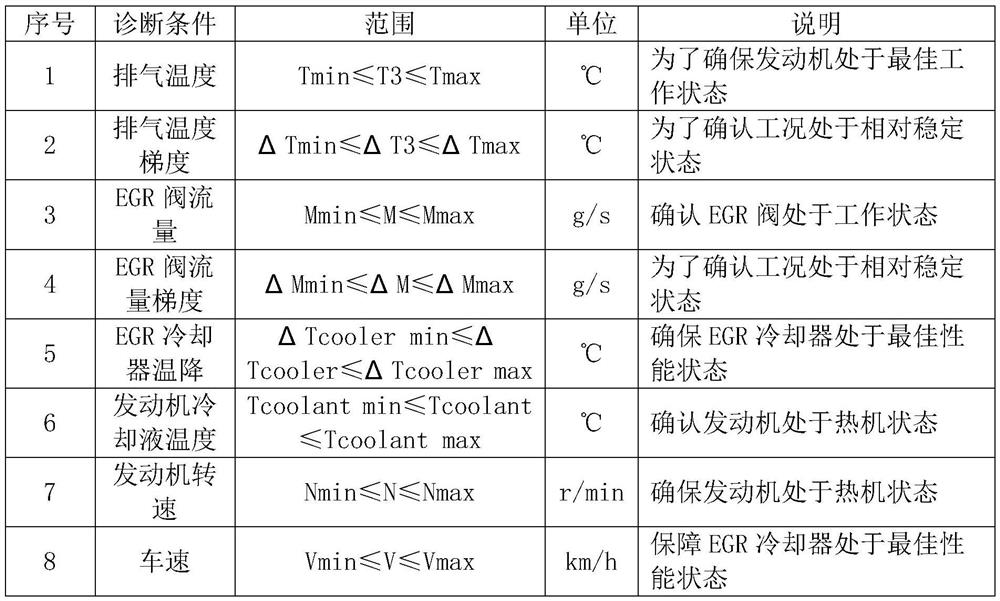

Performance monitoring and fault diagnosis method for high-pressure EGR cooler

ActiveCN113389667AImprove reliabilityGuaranteed reliabilityExhaust gas recirculationMachines/enginesControl engineeringFalse alarm

The invention discloses a performance monitoring and fault diagnosis method for a high-pressure EGR cooler. The performance monitoring and fault diagnosis method comprises the following steps that S1, when all diagnosis conditions are met, a signal delay counter is added, and after the diagnosis conditions are met and lasts for set time, an EGR cooler performance diagnosis function is started; S2, the cooling efficiency of the EGR cooler is monitored and diagnosed according to the ratio of the EGR cooler front and back temperature drop calculated based on the measured value of an EGR cooler outlet temperature sensor to the EGR cooler temperature drop calculated based on an EGR cooler outlet temperature model; and S3, if the performance monitoring index of the EGR cooler is lower than a diagnosis threshold value, it is judged that the performance of the EGR cooler fails, and the low cooling efficiency fault of the EGR cooler is reported, and if the performance monitoring index of the EGR cooler is higher than the diagnosis threshold value, it is judged that the performance of the EGR cooler is normal. According to the performance monitoring and fault diagnosis method, the reliability is high, the fault diagnosis robustness is enhanced, and the false alarm risk is reduced.

Owner:DONGFENG AUTOMOBILE COMPANY

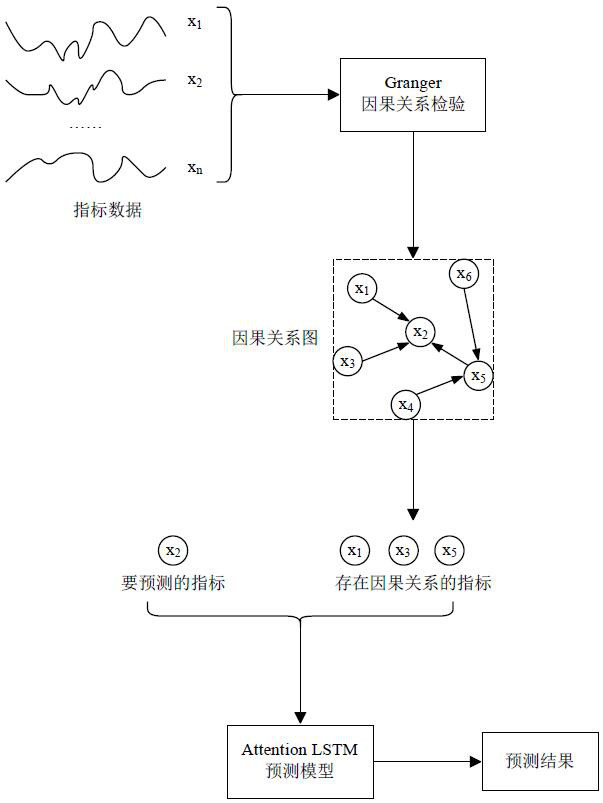

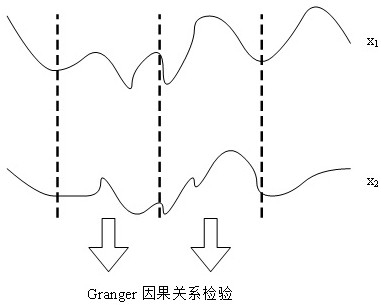

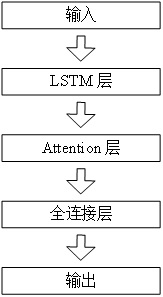

Causal relationship test and micro-service index prediction alarm method

ActiveCN114579407AImprove accuracyImprove discovery efficiencyHardware monitoringNeural architecturesData miningComputer science

The invention relates to a causal relationship test and micro-service index prediction alarm method. The method comprises service index causal relationship discovery based on Granger causal relationship test and multi-index prediction based on Attention LSTM. According to the method, the indexes having the causal relationship with the to-be-predicted index are found through the Granger causal relationship test and jointly participate in prediction, so that the prediction accuracy is improved. And meanwhile, aiming at the problems that the index sequence in the micro-service scene is relatively long, the causal relationship exists locally among the indexes, and the overall causal relationship is not strong, the Granger causal relationship test is improved, and the causal relationship is calculated in a segmented increment manner. In the practical application of the method, when a new value is added into the time sequence, only the causal relationship of the increment needs to be calculated, and the historical data does not need to be re-calculated, so that the calculation amount is reduced, and the causal relationship discovery efficiency in the micro-service scene is improved.

Owner:BEIHANG UNIV

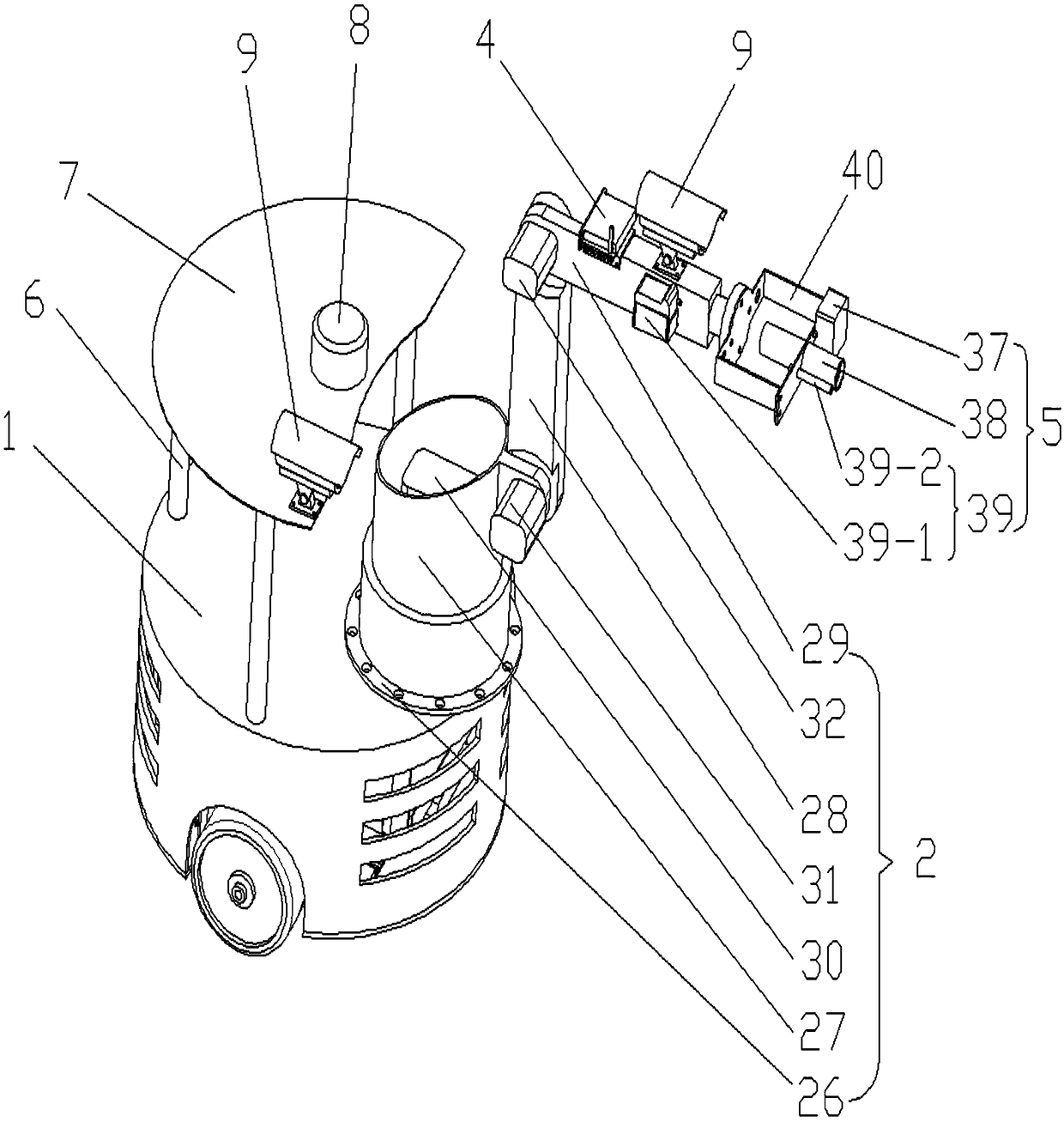

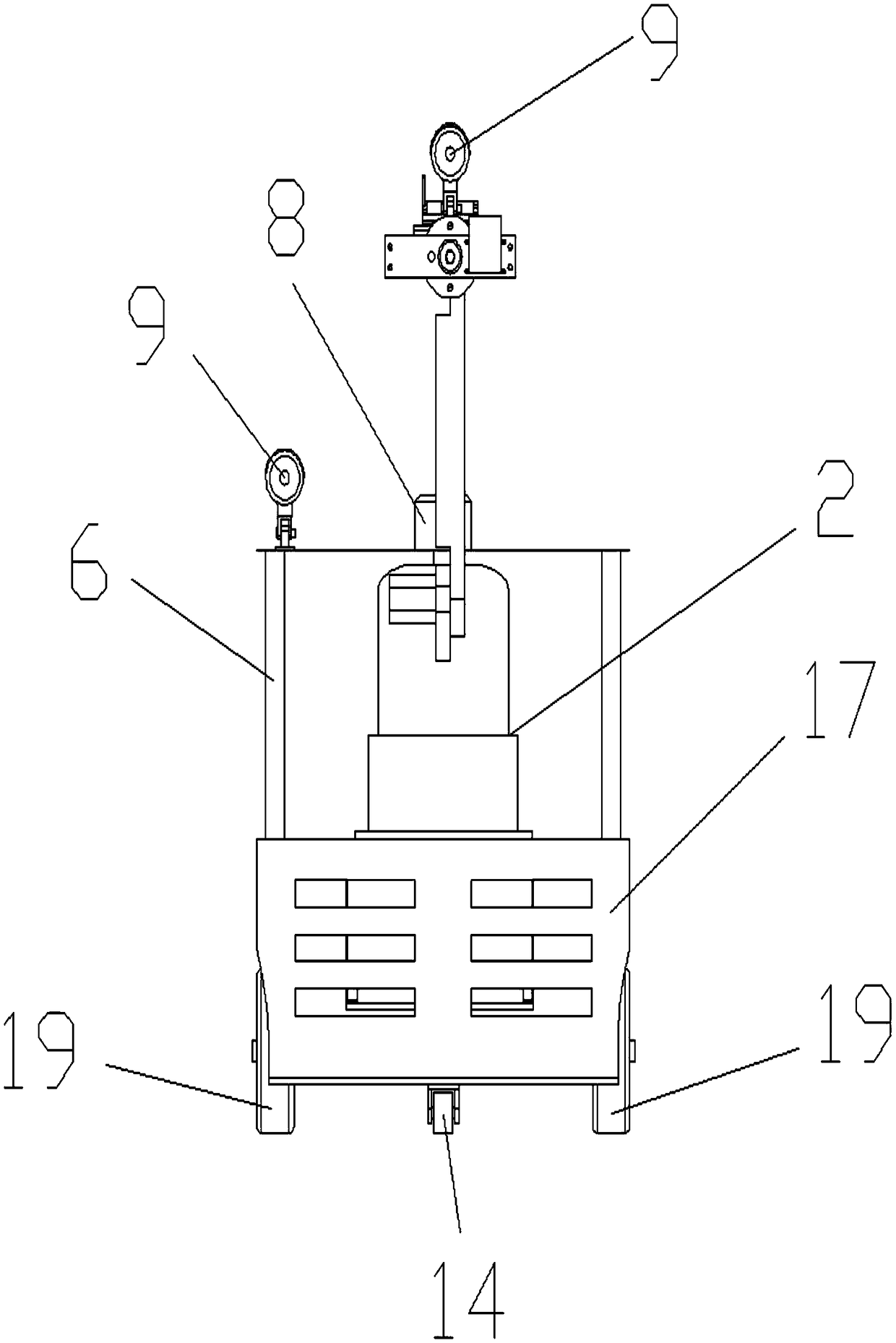

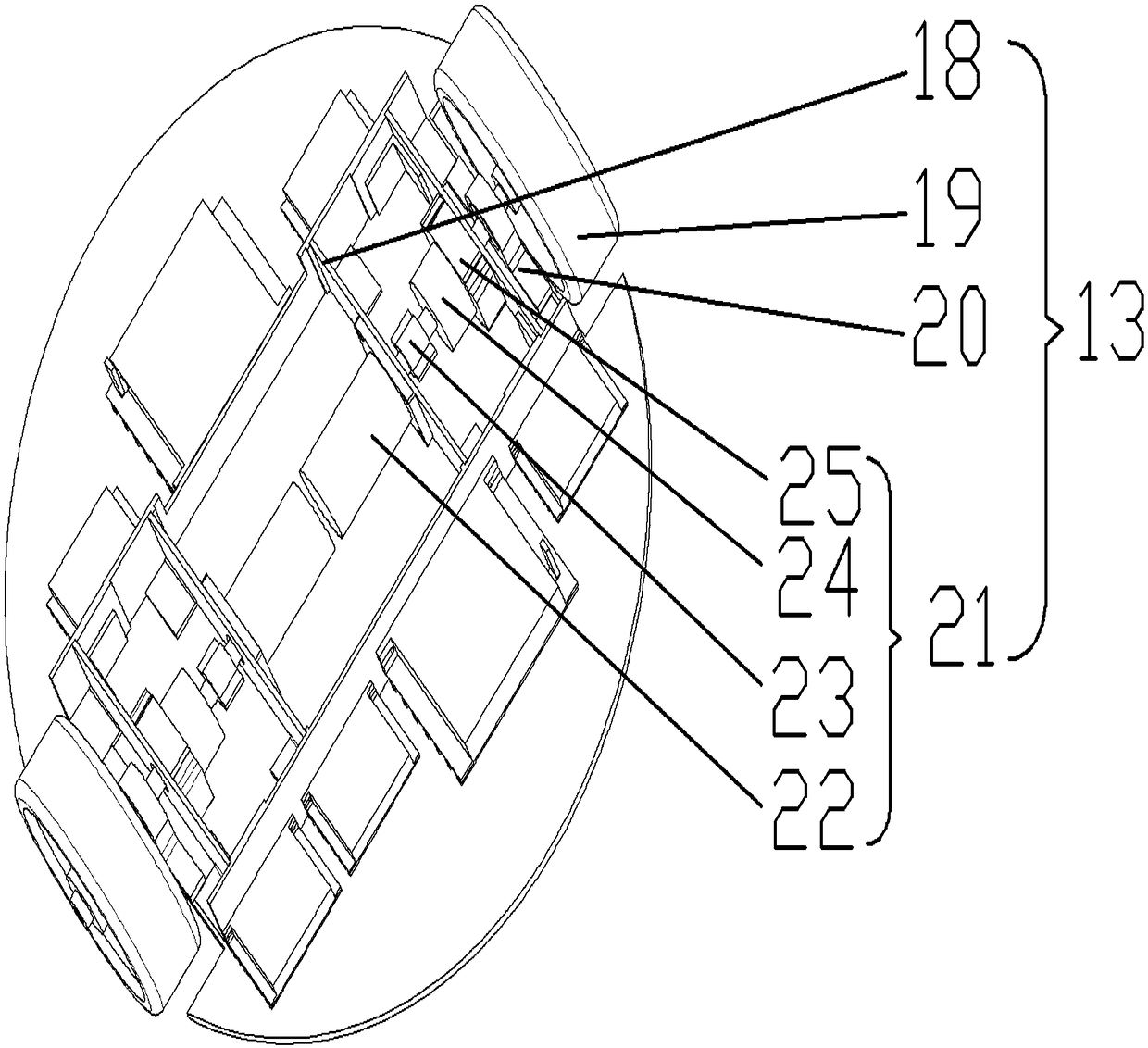

Intelligent-manufacturing-field-oriented mobile machine tool fault diagnosis robot

PendingCN109465675AReduce troubleshooting costsQuick TroubleshootingMeasurement/indication equipmentsDetection diagnosisManipulator

The invention relates to an intelligent-manufacturing-field-oriented mobile machine tool fault diagnosis robot, and belongs to the technical field of machine tool fault detection diagnosis. The intelligent-manufacturing-field-oriented mobile machine tool fault diagnosis robot comprises a movable chassis, a chassis controller fixed to the movable chassis, a mechanical arm module fixed to the movable chassis, a pose adjusting module used for controlling the mechanical arm module, a signal collector, a sensor module and a cloud platform, wherein the signal collector and the sensor module are fixed to the mechanical arm module. The sensor module comprises a noise sensor, a temperature sensor and a displacement sensor, the noise sensor, the temperature sensor and the displacement sensor are insignal connection with the signal collector, and the chassis controller, the pose adjusting module and the signal collector are in WIFI signal connection with the cloud platform. The mobile machine tool fault diagnosis robot can replace the manual work to carry out fault detection on a machine tool, and the machine tool fault information is collected. The mobile machine tool fault diagnosis robotis simple in structure, and the diagnosis efficiency can be improved while the machine tool diagnosis cost is reduced.

Owner:GUANGDONG MECHANICAL & ELECTRICAL COLLEGE

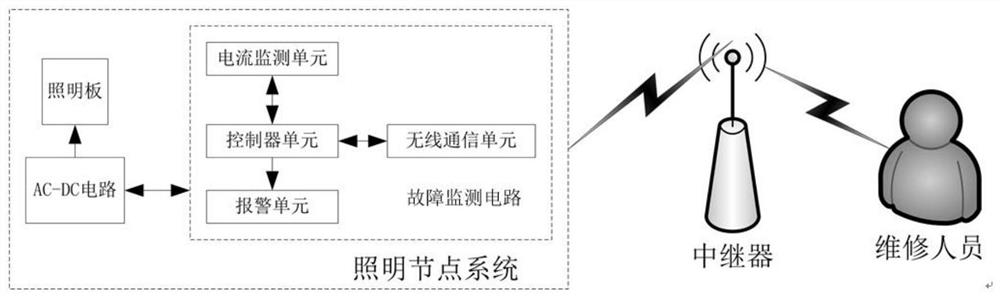

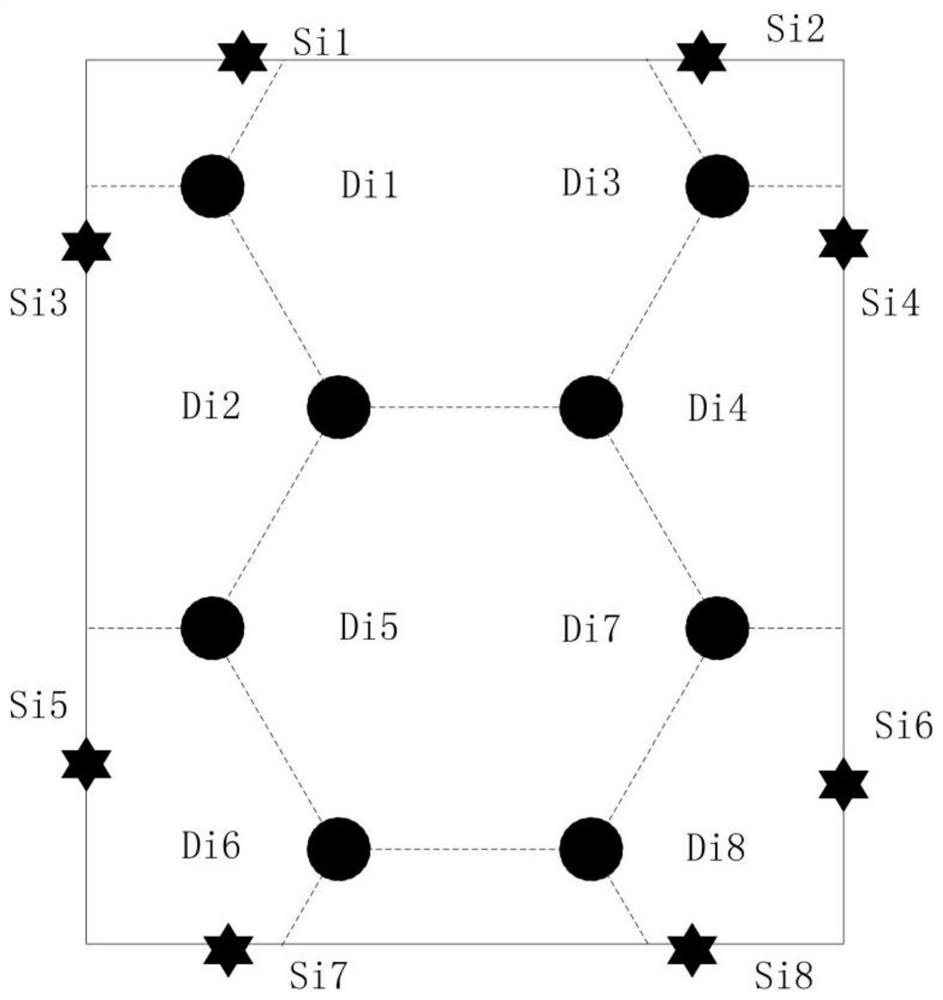

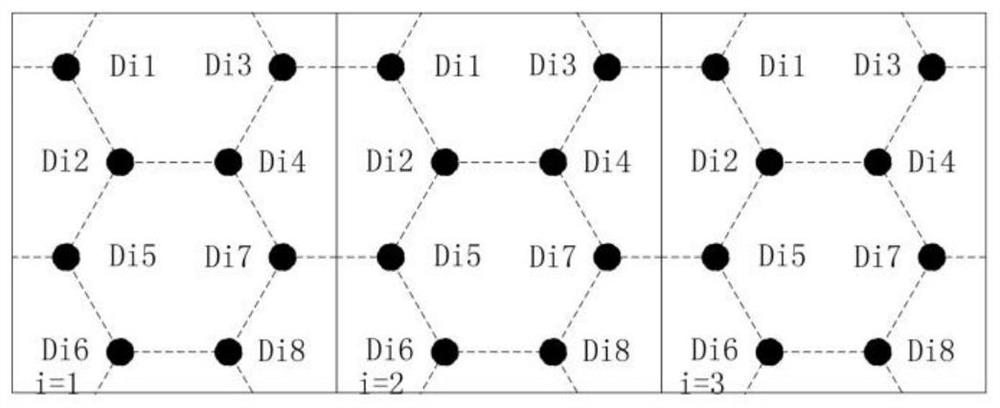

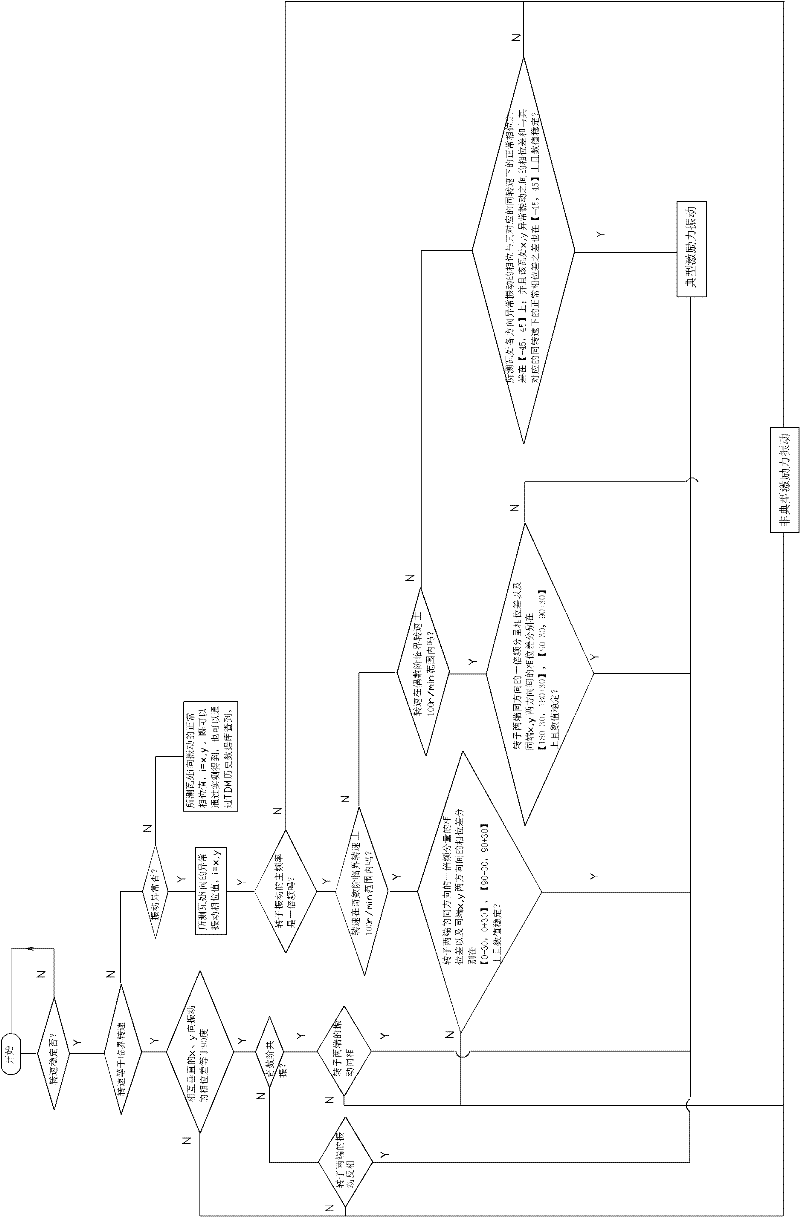

Lighting node system

ActiveCN111800918AImprove stabilityEasy to replaceElectrical apparatusEnergy saving control techniquesLight equipmentDaughterboard

The invention relates to the technical field of intelligent control of lighting equipment. The invention particularly relates to a lighting node system. The system comprises a fault monitoring circuit, an AC-DC circuit and an illumination board. The invention provides the lighting node system, when a local lamp fails, the lamp is turned off, an adopted lighting daughter board can isolate a fault circuit from the lighting board; on one hand, fault chain reaction is reduced, the lighting panel can run normally, and on the other hand, the fault type and the alarm level can be judged according tothe working current value of the lighting panel, the fault lighting panel, the alarm level and the fault type are remotely repaired, the troubleshooting cost is reduced, meanwhile, the modular lighting daughter board can be conveniently replaced, and the field maintenance efficiency and the stability of the lighting node system are improved.

Owner:CHANGZHOU UNIV

Phase difference aided diagnosis method for shafting vibration of turbo generator unit and system thereof

InactiveCN101915607BQuickly and accurately determineReduce troubleshooting costsSubsonic/sonic/ultrasonic wave measurementUsing electrical meansPhase differenceAided diagnosis

The invention relates to a phase difference aided diagnosis method for shafting vibration of a turbo generator unit and a system thereof. The method comprises the following steps: setting a plurality of measuring points on a rotor, identifying and judging phases among vibration signals at the measuring points, taking vibration caused by pure mass unbalance as typical excitation force vibration and vibration caused by other factors as atypical excitation force vibration, wherein, the vibration signals at the bearing bushes of a turbo generator unit shafting generated under the action of an atypical excitation force generate abnormal vibration phase difference which is different from a pure dynamic unbalance fault, otherwise, the vibration signals at the bearing bushes only generated under the action of the typical excitation force maintain phase difference normality for the pure dynamic unbalance fault; and if the phase difference meets the conditions, judging that a rotor is only applied with the typical excitation force, otherwise, judging that the shafting is applied with an obvious atypical excitation force.

Owner:SHANDONG ZHONGSHI YITONG GRP

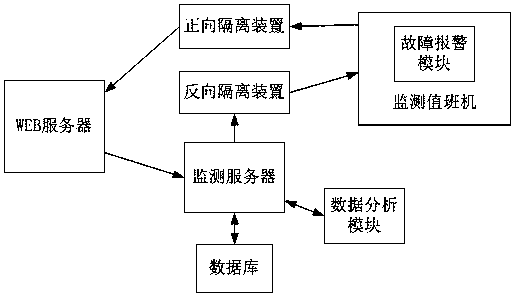

Online monitoring system for intelligent network channel

InactiveCN107786372AImprove troubleshooting efficiencyReduce downtimeData processing applicationsData switching networksWeb serviceProcessing cost

The invention proposes an online monitoring system for an intelligent network channel, and used for solving the problem that the existing system cannot meet the power grid development, and cannot monitor the network channel in real time. The online monitoring system comprises a monitoring server, a database and a data analysis module; the monitoring server is connected with a WEB server; the database and the data analysis module are both connected with the monitoring server; the monitoring server is connected with a monitoring on-duty machine through a reverse isolating device; and the monitoring on-duty machine is provided with a fault alarm device, and the monitoring on-duty machine is connected with the WEB server through the reverse isolating device. The online monitoring system for the intelligent network channel provided by the invention improves the fault processing efficiency of the network channel, greatly reduces the fault processing cost, shortens the network channel fault time, ensures the comprehensive, accurate and real-time monitoring of power grid information, and guarantees the safety of a power grid.

Owner:PUYANG POWER SUPPLY COMPANY STATE GRID HENAN ELECTRIC POWER +1

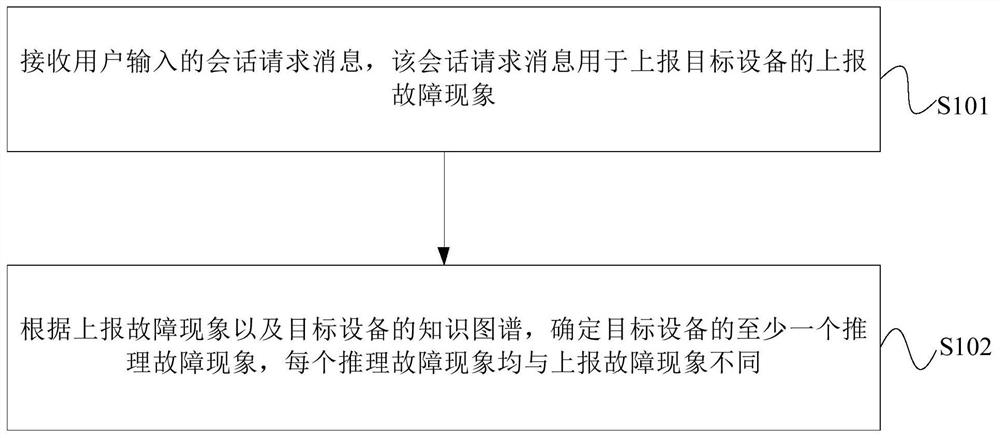

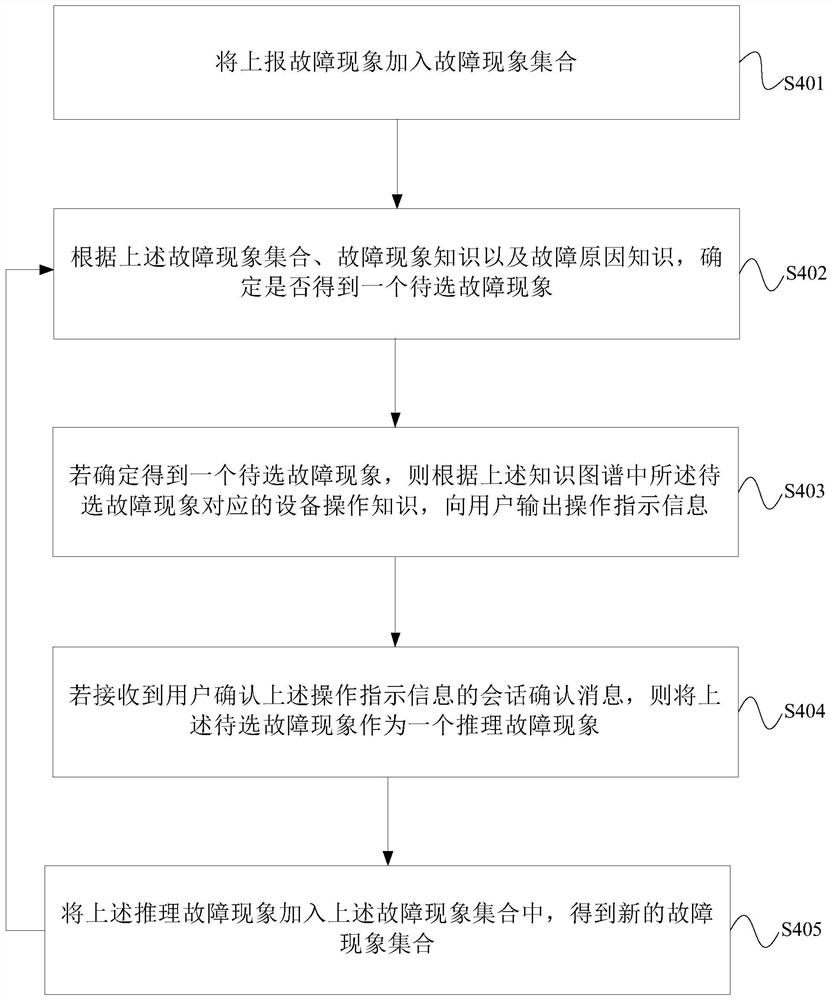

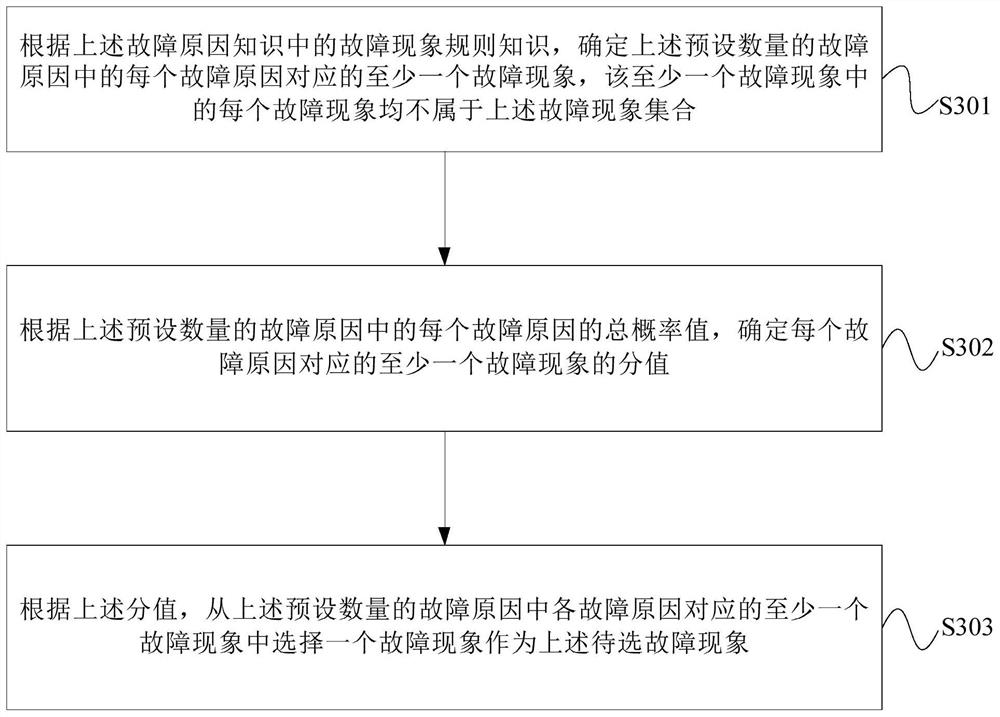

Fault information interaction processing method and device and electronic equipment

InactiveCN111737480AImprove experienceThe fault phenomenon is detailed and accurateCommerceSemantic tool creationUser deviceKnowledge graph

Embodiments of the present invention provide a fault information interaction processing method and apparatus, and an electronic device, the method comprising: receiving a session request message inputby a user, the session request message being used for reporting a reporting fault phenomenon of a target device; determining at least one inference fault phenomenon of the target equipment accordingto the reported fault phenomenon and the knowledge graph of the target equipment, each inference fault phenomenon being different from the reported fault phenomenon; wherein the knowledge graph of thetarget equipment comprises fault phenomenon knowledge, fault reason knowledge and equipment operation knowledge, the fault phenomenon knowledge comprises fault reason rule knowledge and equipment operation rule knowledge, and the fault reason knowledge comprises fault phenomenon rule knowledge. According to the method, more fault phenomena of the user equipment except the fault phenomenon input by the user can be determined, the fault processing cost can be greatly reduced, the fault processing efficiency is improved, and the user experience is improved.

Owner:青岛聚好联科技有限公司

A fault diagnosis method and system for a generator set operating parameter measurement sensor

ActiveCN104390657BReal-time monitoring of running statusReduce troubleshooting costsInstrumentsReal-time dataDiagnosis methods

The invention discloses a fault diagnosis method for a generator set operation parameter measurement sensor, which can be applied to the fault diagnosis method of the generator set operation parameter measurement sensor, including: offline modeling, obtaining auxiliary variables related to the parameters to be measured through mechanism analysis, and for all The auxiliary variables are quantitatively screened according to the degree of dependence, and the main auxiliary variables with strong dependence on the parameters to be measured are obtained; then the model and model coefficients used for online diagnosis are obtained through the PLSR modeling method based on B-spline transformation; Diagnosis, online B-spline transformation of real-time data, by loading the mathematical model between the parameters to be measured and the main auxiliary variables, the predicted value of the parameter Y to be measured is obtained, and the predicted data of the model is compared with the measured data by the "window moving method" The statistical characteristics of the sensor can realize the fault diagnosis of the sensor and identify the fault type of the sensor. The invention also discloses a fault diagnosis system for the measuring sensor of the operating parameters of the generating set.

Owner:ZHEJIANG UNIV

Switch fault handling method and device

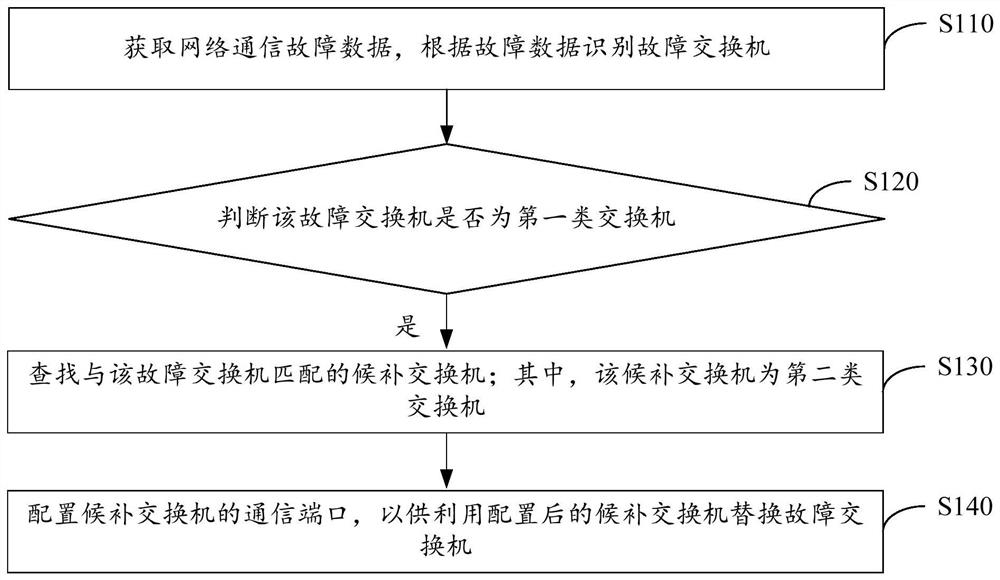

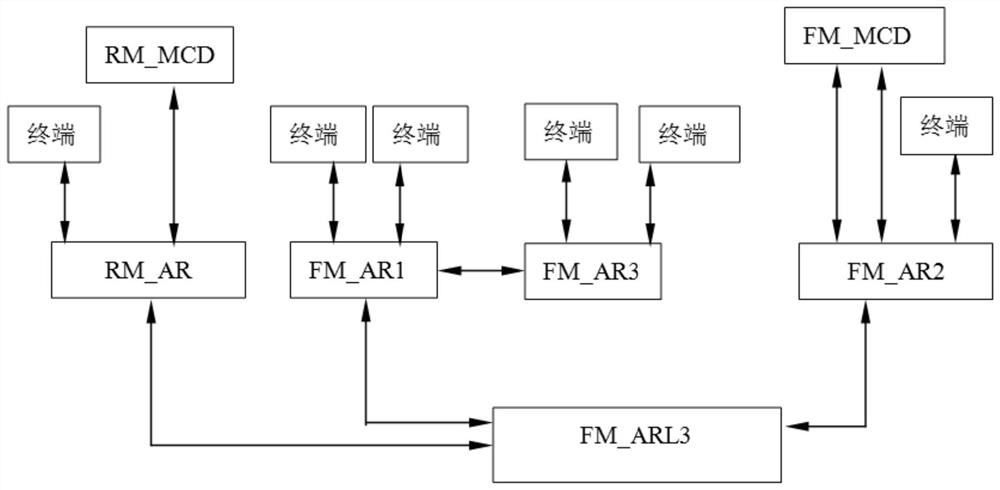

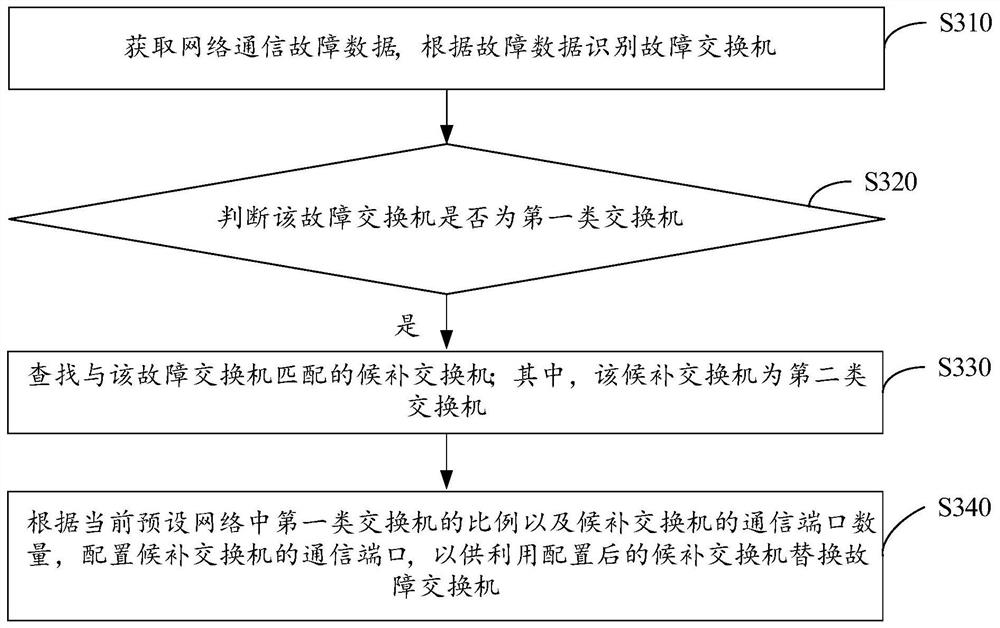

ActiveCN111950640BReduce troubleshooting costsImprove processing efficiencyCharacter and pattern recognitionTransmissionComputer hardwareNetwork communication

The invention discloses a switch fault processing method and device. The method includes: acquiring network communication fault data, identifying the faulty switch according to the fault data; judging whether the faulty switch is a first-type switch; wherein the first-type switch only supports the first communication protocol; if so, searching for a candidate matching the faulty switch switch; wherein, the candidate switch is a second type of switch, and the second type of switch supports the first communication protocol and the second communication protocol; the communication port of the candidate switch is configured to replace the faulty switch with the configured candidate switch; wherein, after the configuration The candidate switch includes a first-type port and a second-type port, the first-type port corresponds to the first communication protocol, and the second-type port corresponds to the second communication protocol. By adopting this solution, when a certain switch fails, there is no need to replace the communication equipment in the entire network, the fault processing cost is low, and the processing efficiency is high.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com