Method for removing fault of vibration value of engine

A troubleshooting and engine technology, applied in machine/structural component testing, static/dynamic balance testing, measuring devices, etc., can solve problems such as long troubleshooting period, large decomposition depth, and many troubleshooting inspection items, etc. Achieve the effects of shortening the troubleshooting cycle, saving repair costs and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

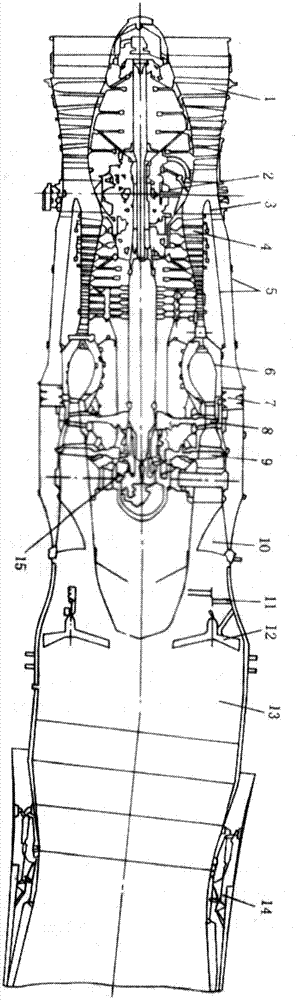

[0018] For an engine with a vibration change fault, the method for eliminating the vibration value change fault provided by the present invention is adopted, and the specific process steps are as follows:

[0019] (1) Partially disassemble the engine: divide the lower half of the outer duct and the first half of the high-pressure stator casing to expose the high-pressure compressor rotor;

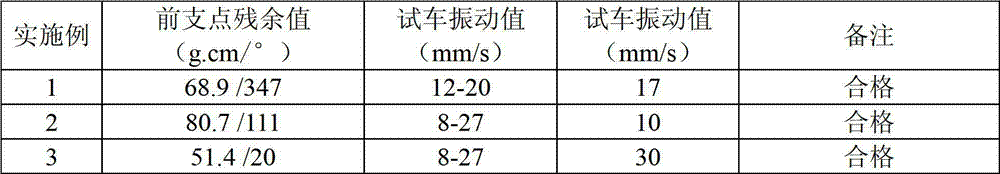

[0020] (2) Query balance data: query the balance data of the high-pressure compressor rotor of the engine before the test run, see Table 1, and find out the actual light-point position of the high-pressure compressor rotor through the light-point position displayed by the balance data;

[0021] Table 1: Balance data before test run

[0022] Implementation number

High pressure rotor unbalance value (g.cm)

Tap the phase angle (°)

1

68.9

347

2

80.7

111

3

51.4

20

[0023] (3) Adjust the unbalance of the high-pressure compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com