Performance monitoring and fault diagnosis method for high-pressure EGR cooler

A technology of EGR cooler and fault diagnosis, which is applied in the direction of machines/engines, charging systems, mechanical equipment, etc., and can solve problems such as low reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

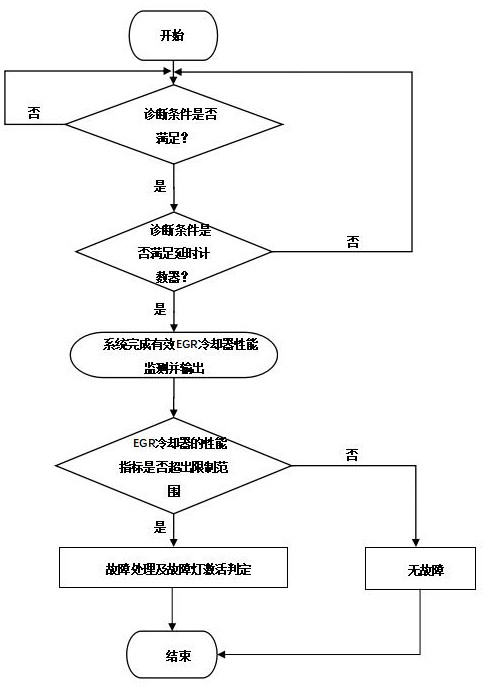

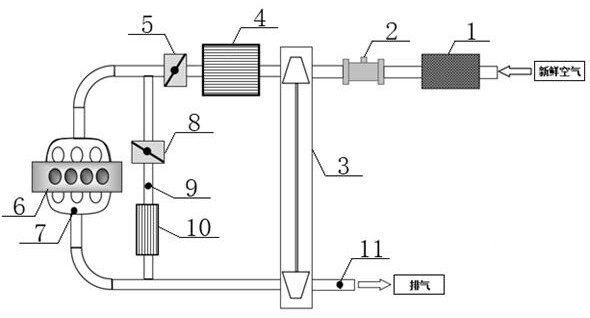

[0074] see figure 1 , figure 2 , a high-pressure EGR cooler performance monitoring and fault diagnosis method, comprising the following steps:

[0075] S1. Turn on the performance diagnosis function of the EGR cooler;

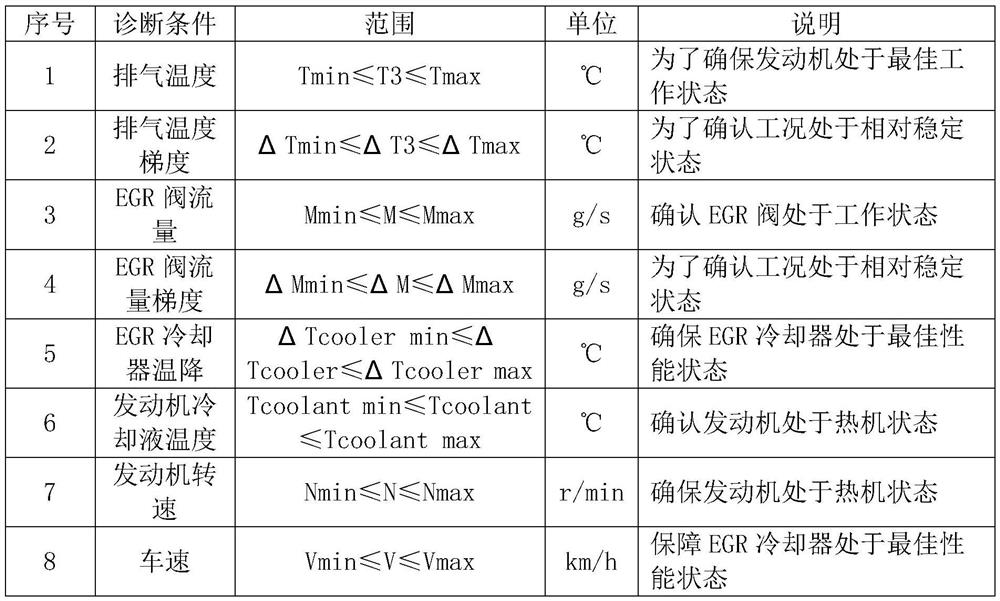

[0076] When the following diagnostic conditions are met at the same time, the EGR cooler performance diagnostic function is enabled:

[0077] (1) The engine exhaust temperature is within the calibrated exhaust temperature range to ensure that the engine is in the best working condition;

[0078] (2) The engine exhaust temperature gradient is within the calibrated exhaust temperature gradient range to ensure that the engine operating condition is relatively stable;

[0079] (3) The EGR valve flow rate is within the calibrated EGR valve flow range to ensure that the EGR valve is in working condition;

[0080] (4) The flow gradient of the EGR valve is within the range of the calibrated EGR valve flow gradient, so as to ensure that the working condition of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com