Blast furnace hearth ceramic cup side wall formed by inlaying and laying refractory brick rings

A technology of refractory bricks and ceramic cups, applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problem of displacement, loss of stability, airtightness, entering into the circumferential inter-annular brick seam or direct contact with a large width on the back side, etc. problems, to achieve the effect of improving overall stability, prolonging furnace service life and long functional life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

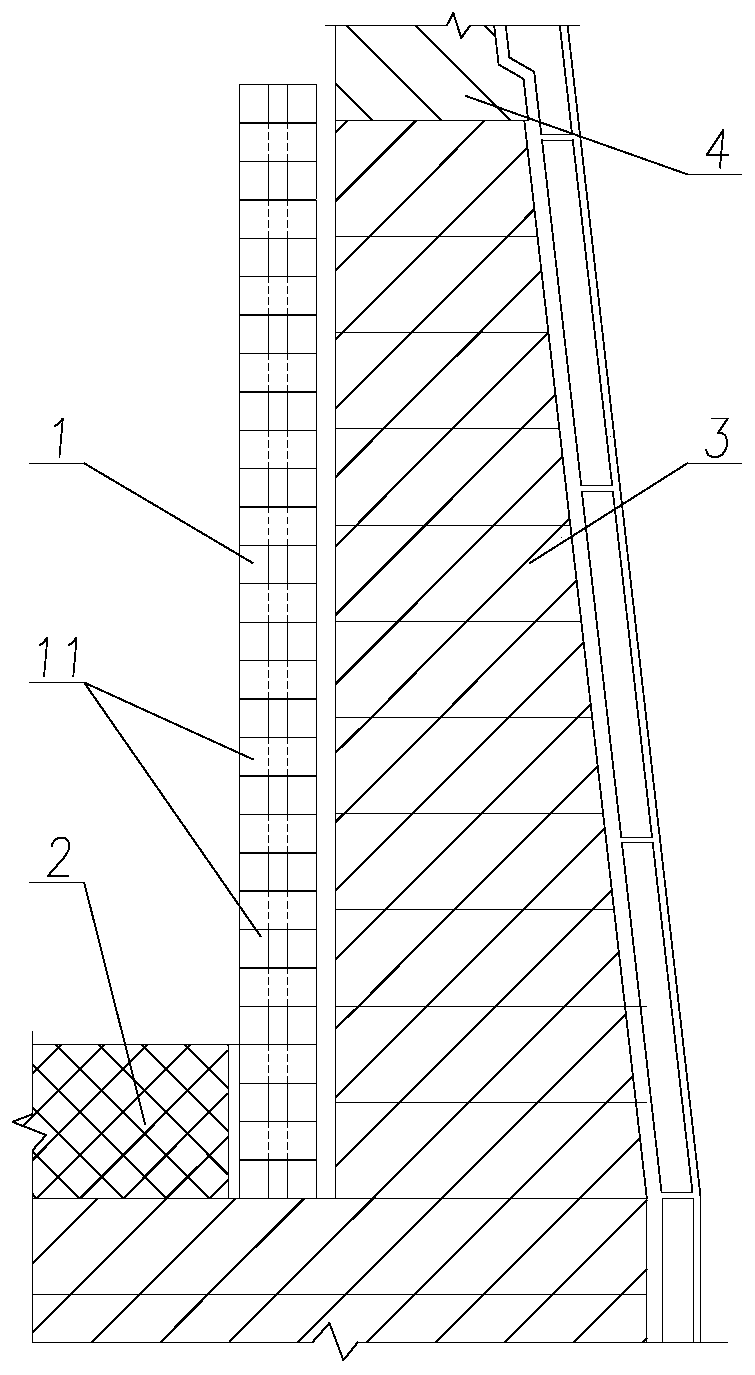

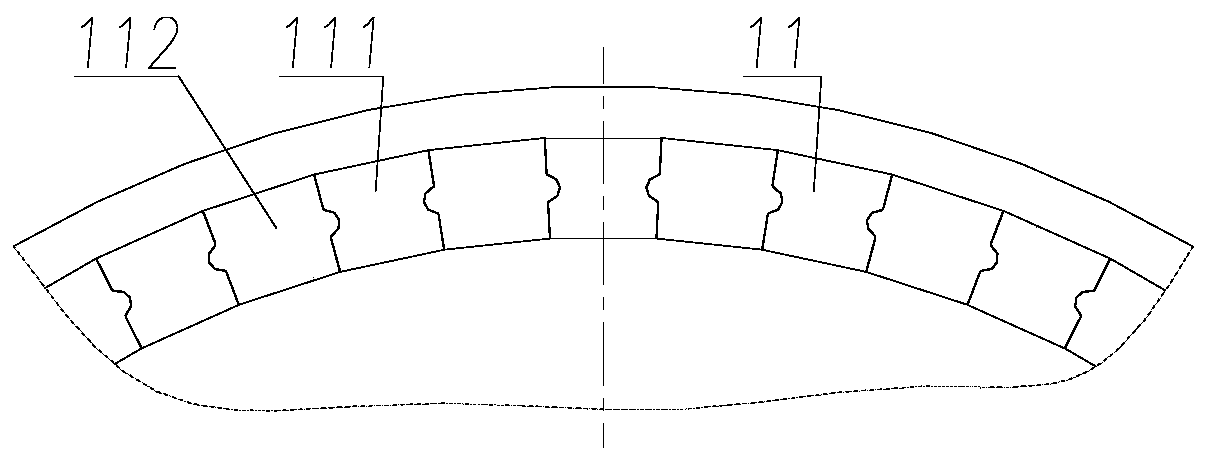

[0035] Embodiment one: see figure 1 , figure 2 , Figure 8 and Figure 9 . A ceramic cup side wall 1 of a blast furnace hearth made of inlaid refractory brick rings 11 according to the present invention is stacked up and down by several layers of refractory brick rings 11 in the height direction of the hearth, and at least one refractory brick is formed in the radial direction of the blast furnace Ring 11, ceramic pad 2 is arranged at the bottom of refractory brick ring 11, carbon brick 3 and tuyere combination brick 4 are arranged on the outside of ceramic cup side wall 1, and refractory brick ring 11 is made of first refractory brick 111 and second refractory brick 112 alternately. Both sides of the first refractory brick 111 have arc-shaped vertical grooves on both sides, and both sides of the second refractory brick 112 have vertical convex bands with an arc-shaped cross-section. The vertical convex band on the side of 112 is embedded in the vertical groove on the sid...

Example Embodiment

[0037] Embodiment two:

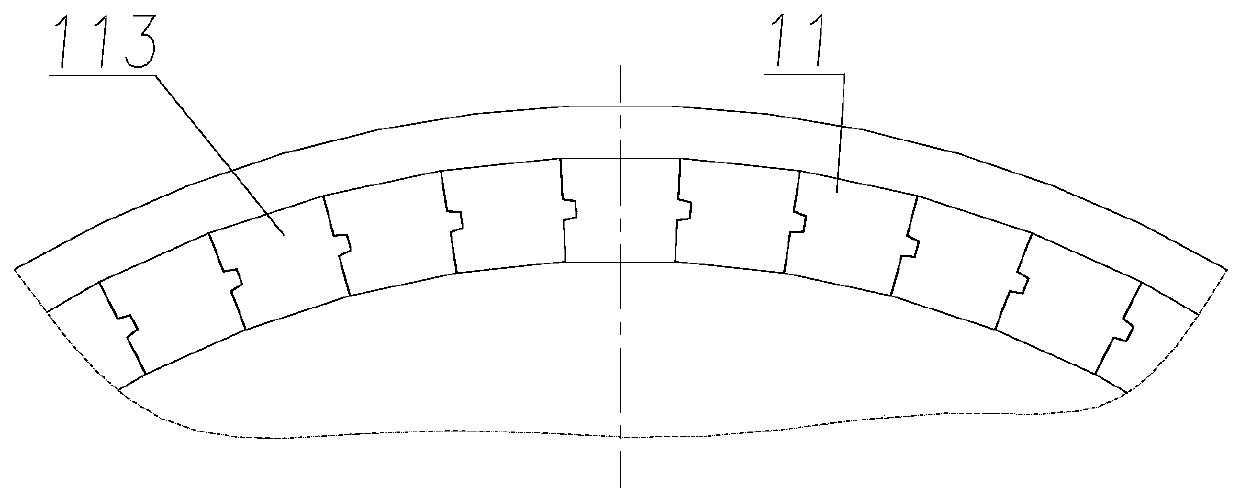

[0038] see figure 1 , image 3 and Figure 10, a ceramic cup side wall 1 of a blast furnace hearth made of inlaid refractory brick rings 11 according to the present invention is stacked up and down by several layers of refractory brick rings 11 in the height direction of the hearth, and at least one refractory brick ring 11 is formed in the radial direction of the blast furnace The brick ring 11, the refractory brick ring 11 is sequentially built by the third refractory brick 113, the two sides of the third refractory brick 113 respectively have a vertical groove and a vertical convex belt with a trapezoidal cross-sectional shape, and the third refractory brick 113 The vertical convex band on the side is embedded in the vertical groove on the side of the adjacent third refractory brick 113;

[0039] The design width of the masonry gap between the third refractory bricks 113 is 0.5mm.

Example Embodiment

[0040] Embodiment three:

[0041] see figure 1 , Figure 4 , Figure 11 . A blast furnace hearth ceramic cup wall 1 composed of inlaid refractory brick rings 11 of the present invention consists of several layers of refractory brick rings 11 stacked up and down in the height direction of the hearth, and at least one refractory brick ring in the radial direction of the blast furnace 11. The refractory brick ring 11 is composed of the first refractory brick 111, the second refractory brick 112 and the first replacement brick 114. The vertical convex belt on the side of the second refractory brick 112 is embedded in the phase. Among the vertical grooves on the adjacent first refractory brick 111 side, one side of the first replacement brick 114 is a plane, and the other side has a vertical protrusion extending into the vertical groove on the first refractory brick 111 side. Belt, the space surrounded by the flat side of the first replacement brick 114 and the vertical groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com