Independent faucet pressure resistance testing device

A pressure test and faucet technology, which is applied in the direction of measuring devices, using stable tension/pressure test material strength, instruments, etc., can solve the problems of long time pressure test, faucet leakage, and inability to measure the pressure of the faucet, etc. problem, to achieve the effect of convenient use of withstand voltage test, satisfying withstand voltage test, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

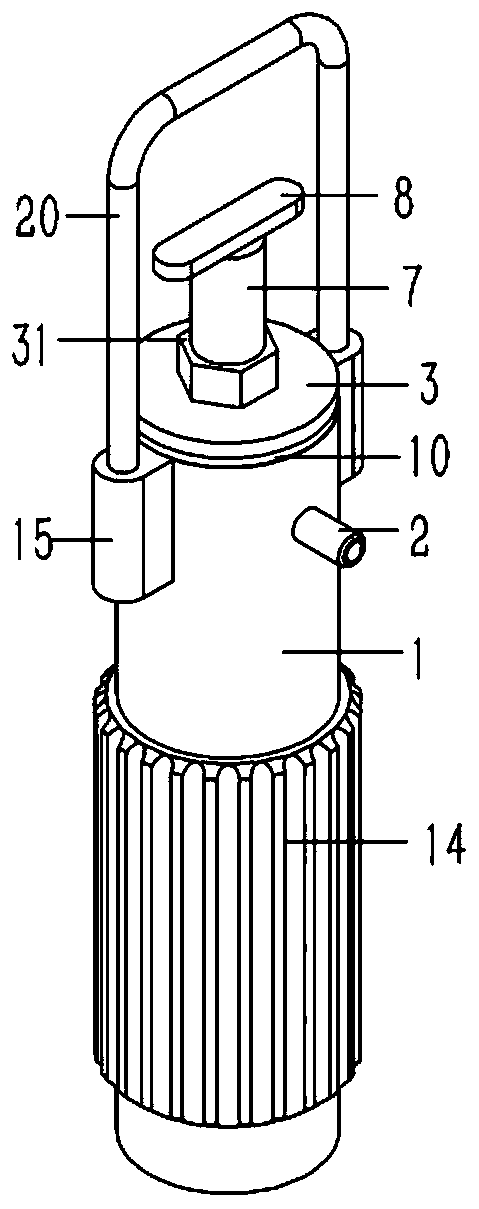

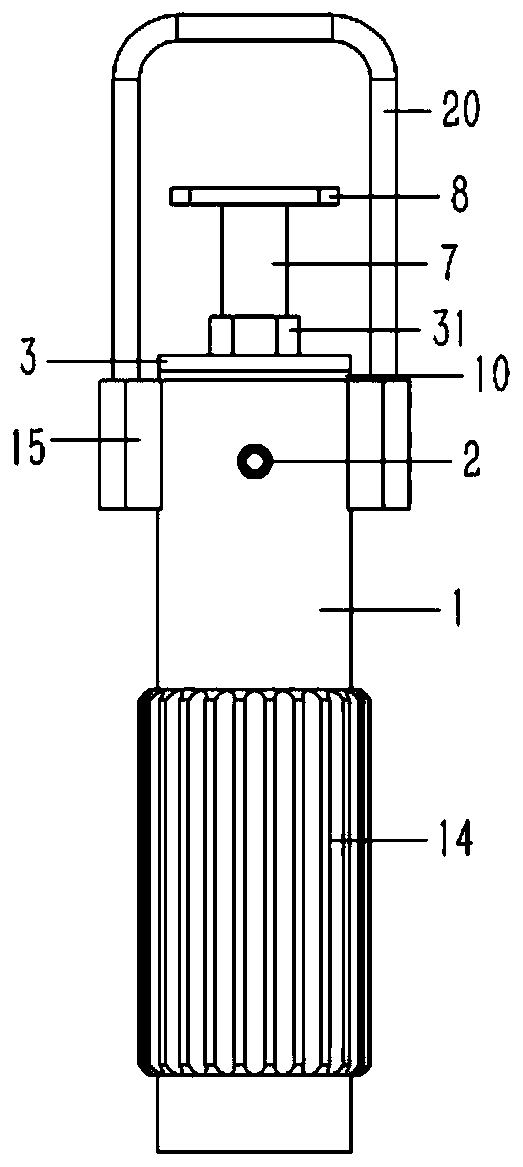

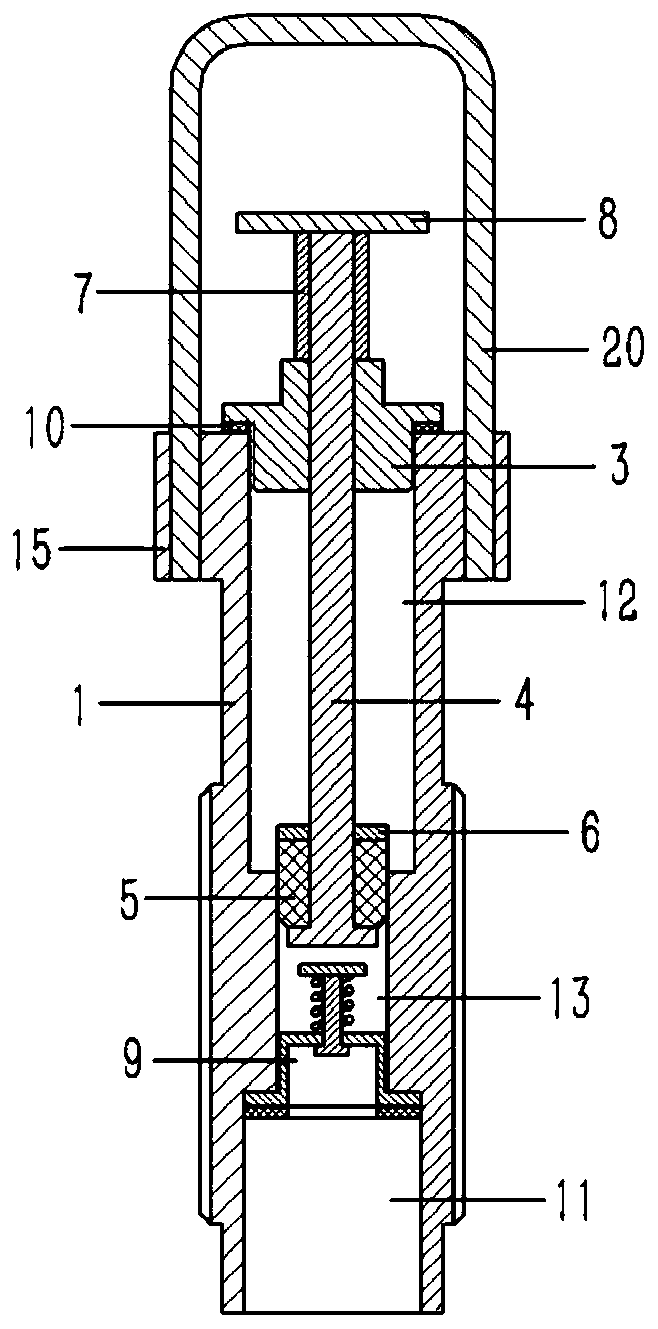

[0018] Example: see Figures 1 to 4 As shown, a self-contained faucet pressure test device includes a cylindrical container 1, the upper part of the container 1 is formed with a pressure chamber 12 passing through the upper end surface of the container 1, and the lower end surface of the container 1 is formed with a threaded connection hole 11, The bottom surface of the threaded connection hole 11 is formed with a guide hole 13 that communicates with the pressure chamber 12. The upper end of the container 1 is inserted and fixed with a valve 2 that communicates with the pressure chamber 12. The guide hole 13 of the container 1 is inserted with an inverted T-shaped The pull rod 4 is fixed with an annular rubber seal sleeve 5 on the upper sleeve of the T-shaped pull rod 4, and the rubber seal sleeve 5 is pressed against the inner wall of the guide hole 13; the upper end of the T-shaped pull rod 4 passes through the end cover 3. A sleeve 7, a horizontal handle 8 is fixed on the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com