Method for designing blanking opening degree of hot-base galvanized square tube

A design method and technology of opening degree, applied in computer-aided design, calculation, special data processing applications, etc., can solve problems such as unsuitable calculation of cutting opening degree, large extrusion amount, surface damage, etc., and achieve considerable social and economic benefits. benefit, achieve fit, performance and dimensional deviation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

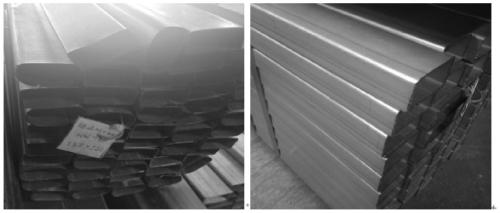

Image

Examples

Embodiment

[0028] Embodiment: Adopt the 1.35mm system square tube section specification 4in*2in (1in=2.54mm) material: SGHC.

[0029] (1) Technological requirements: the square pipe adopts the process of reaming and sizing, and the welding seam does not make a bending angle; according to the technological requirements, n=4.

[0030] (2) Material performance requirements: The material SGHC is a Japanese standard product, and the yield strength is: 205MPa≤Rel≤245MPa; n=3 according to the process requirements.

[0031] (3) When the two n values are inconsistent, take the maximum n=4 as the calculation coefficient,

[0032] Substitute into the formula W=A×2+B×2-nT.

[0033] W=4×2.54×2+2×2.54×2-4×1.35=25.08mm

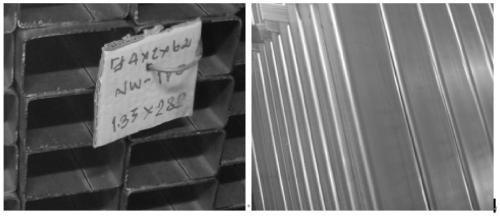

[0034] The final product is as figure 2 As shown, the finished product rate is high, and there is no black line on the surface.

[0035] By adopting the calculation method for the blanking opening of heat-based thin gauge galvanized pipe (square pipe) provided by the present inv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap