Sampling method for improving alloy quality inspection sampling representativeness

A quality inspection and representative technology, applied in the direction of sampling devices, etc., can solve problems such as insufficient randomness of package selection, economic loss of enterprises, and poor sampling representativeness, so as to improve the management level of sampling inspection, protect legitimate interests, and prevent violations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A sampling method for improving the representativeness of alloy quality inspection sampling, which includes the following steps: In the first step, the supplier performs sequential package numbers on the ton-bag packaging alloy and sprays the package number on the packaging bag; each packaging bag has a unique Package number.

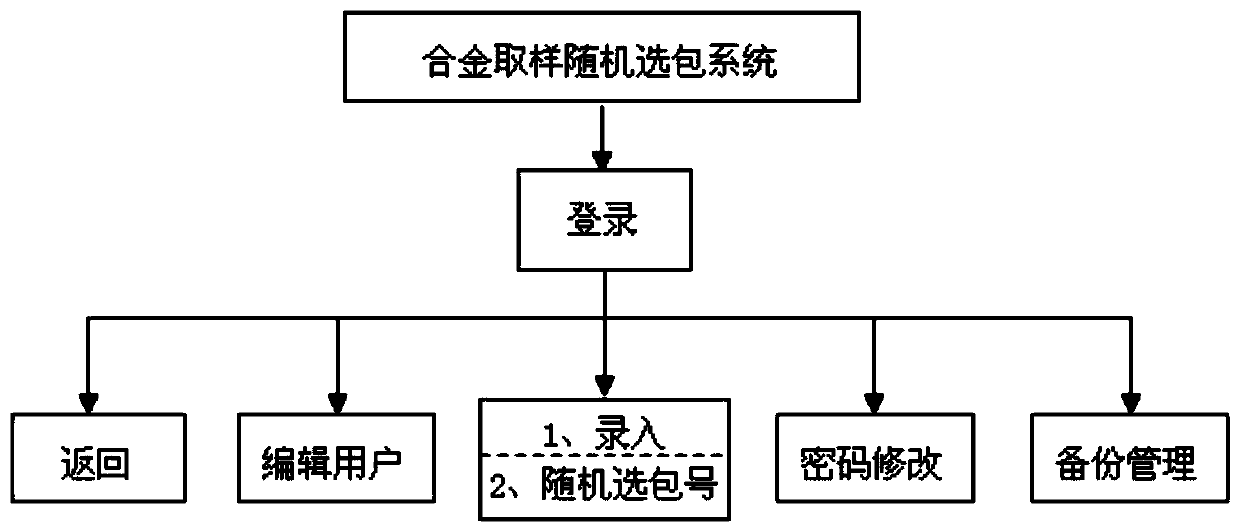

[0023] The second step is to compile a computer random package selection program, and set the number of packages for sampling ton bags according to the sampling rules stipulated by the inspection standards; namely INDEX(A:A,MATCH(SMALL(,ROW(A1)),B:B, 0)), and the randomness function RANDBETWEEN (starting package number, ending package number), input the starting package number, and after terminating the package number, the program automatically generates the sampling package number that cannot be changed at will.

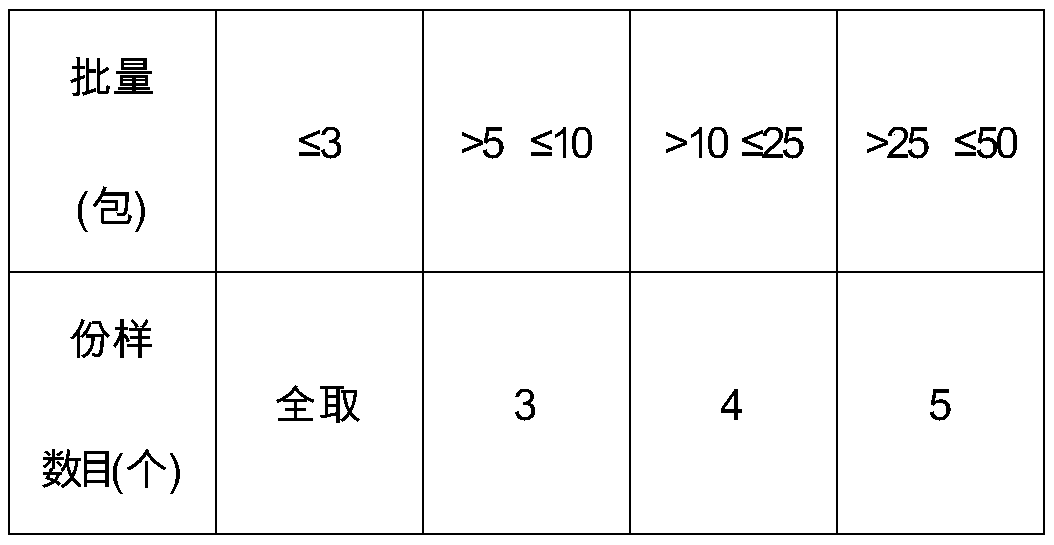

[0024] The following table shows the sampling rules for the specific inspection standards for ton-bag packaging alloys:

[0025]

[0026] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com