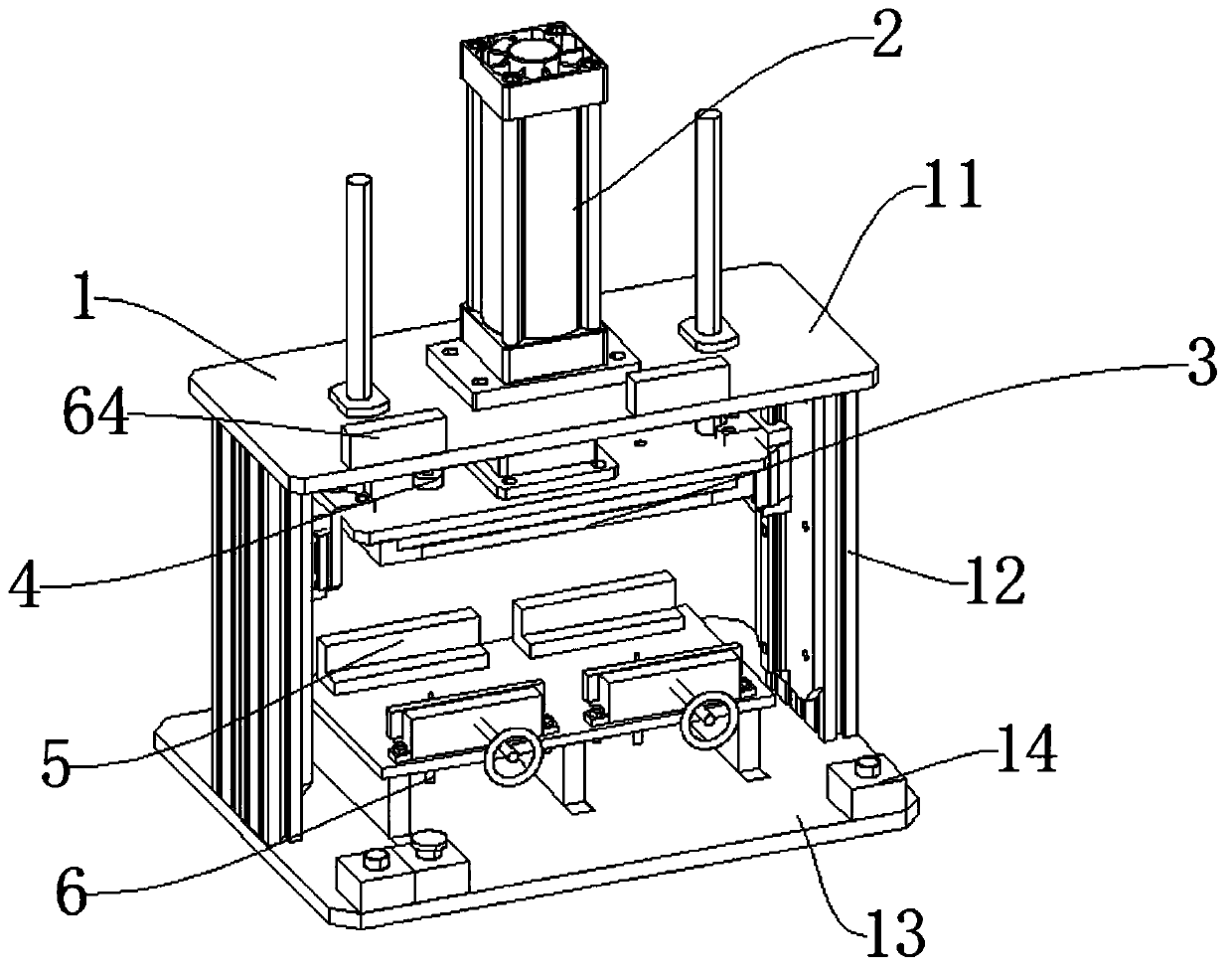

Building material compression resistance comparison detection device

A detection device and anti-pressure technology, which is applied in the direction of measuring device, using stable tension/pressure to test the strength of materials, analyzing materials, etc., can solve the cumbersome testing process and the inability to simultaneously detect intuitive observation and understand the strength comparison of different building materials, etc. problem, achieve the effect of intuitive experimental results and improve practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

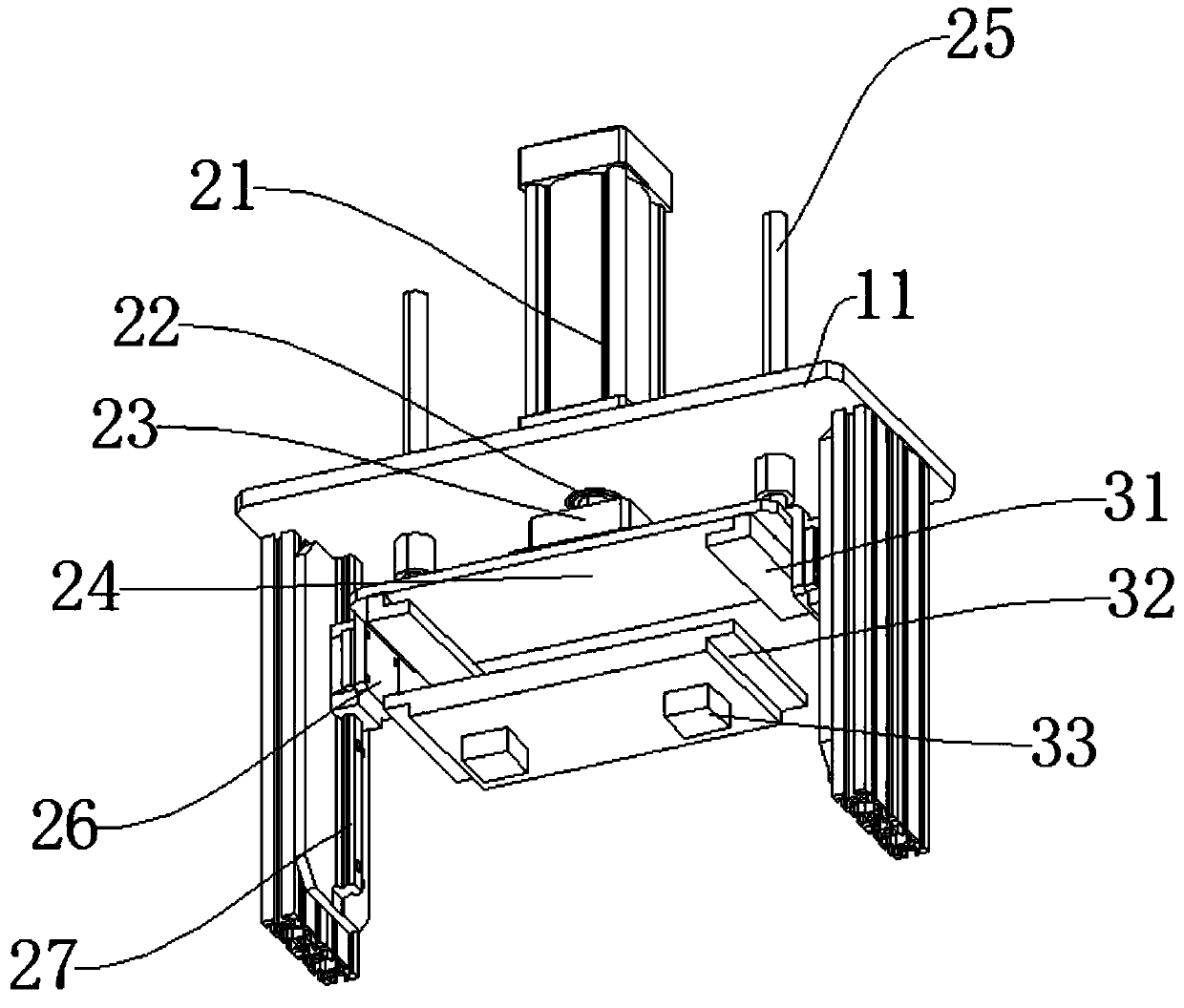

Embodiment 1

[0041] like Figure 1-Figure 6 As shown, the connecting mechanism 4 includes a first lock bar 41, a lifting plate 42, a fixed seat 43, and a first limit ring 44. The fixed seat 43 is connected to the upper end of the lifting seat 24 of the pressurizing mechanism 2, and the inner side of the fixed seat 43 is provided with a second A lock bar 41, the first lock bar 41 one end is connected with lifting plate 42, the first lock bar 41 other end passes through the lifting seat 24 of pressurizing mechanism 2 and connects the impact plate 32 of impact mechanism 3, the first lock bar 41 and fixed A first stop ring 44 is provided between the seats 43, a first return spring 45 is provided at the lower end of the first stop ring 44, and a first lock groove 46 is provided between the first lock bar 41 and the impact mechanism 3, when it needs to be replaced When the first impact head 33 or the second impact head 34, the first lock bar 41 is lifted, the first lock bar 41 is separated from ...

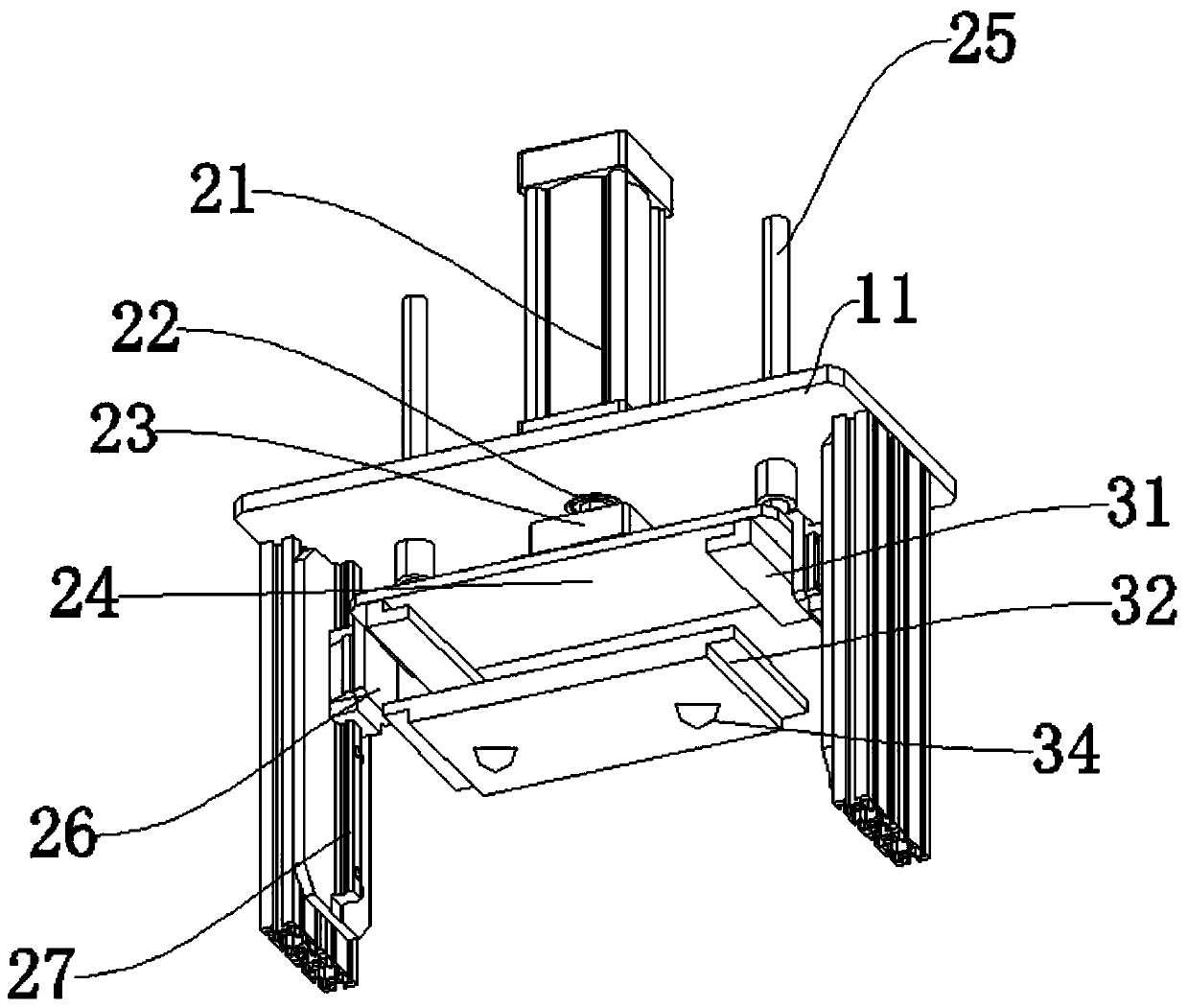

Embodiment 2

[0044] like Figure 7 The difference between this embodiment and Embodiment 1 is that the connecting mechanism 4 includes a second locking lever 411, a second limit ring 412, a second return spring 413, and a second locking groove 414, and the second locking lever 411 is arranged on the impact mechanism 3, a second lock groove 414 is provided between the second lock bar 411 and the lifting seat 24 of the pressurizing mechanism 2, and a second stop ring 412 is provided on the second lock bar 411. The second stop ring 412 A second return spring 413 is arranged between the ring 412 and the impact mechanism 3. When the impact plate 32 needs to be replaced, the impact plate 32 is pulled, and the second locking lever 411 retracts into the inner side of the impact plate 32. After replacement, the second locking lever 411 is locked. into the inner side of the second locking groove 414.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com