Low-frequency broadband electromagnetic-piezoelectric-friction combined type vibration energy collector

A vibration energy harvesting, composite technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electric component, etc. Low resonance frequency and other problems, to achieve the effect of enriching power output characteristics, strong environmental adaptability, and reducing collision energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

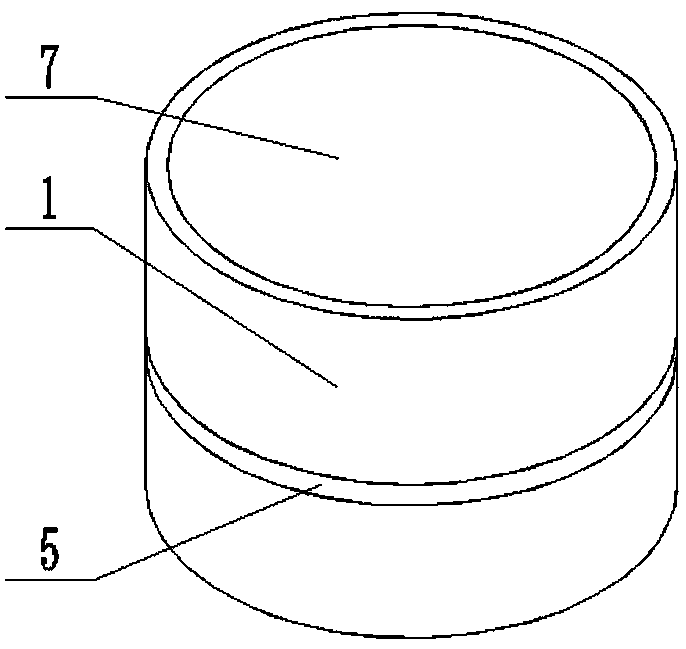

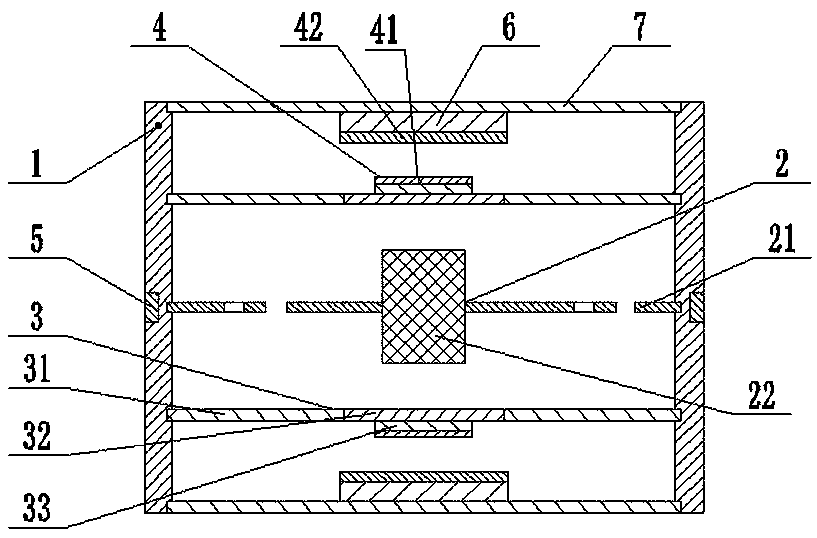

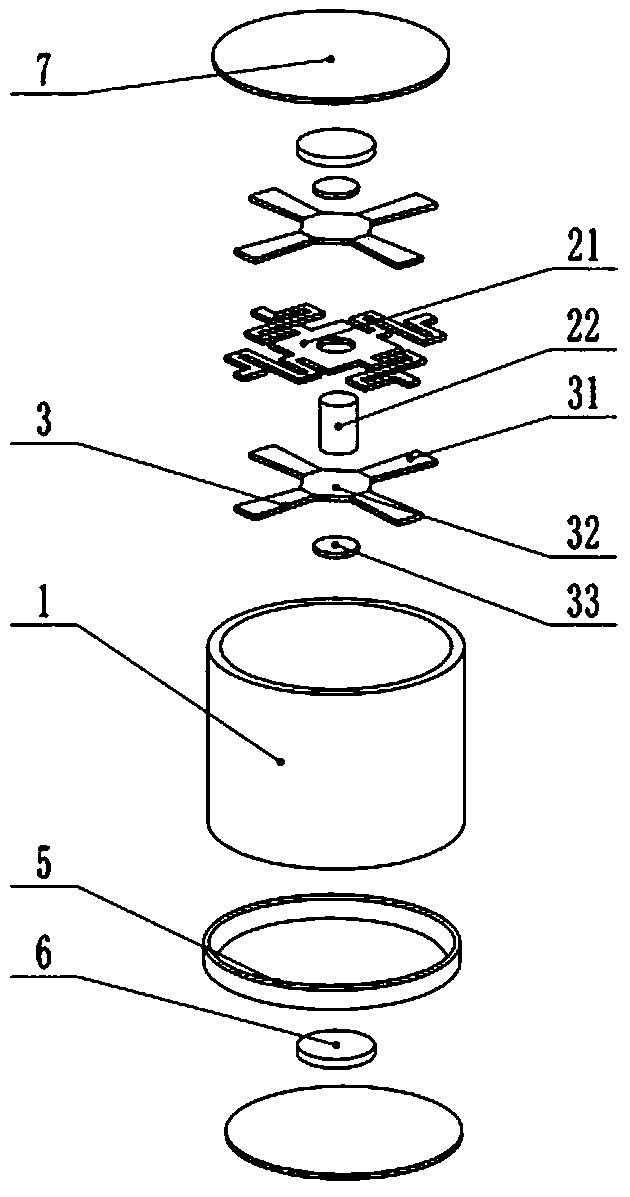

[0023] Such as Figure 1-Figure 4 As shown, a low-frequency broadband electromagnetic-piezoelectric-friction composite vibration energy harvester includes a housing 1, the upper and lower ends of the housing 1 are respectively fixed with end caps 7, and the inner surfaces of the two end caps 7 are fixed A fixed magnet 6 is installed, a moving magnet mechanism 2 is installed in the middle part of the housing 1, and an induction coil 5 is installed at the moving magnet mechanism 2 on the outer peripheral wall of the casing 1, between the moving magnet mechanism 2 and the fixed magnet 6 on the upper side An elastic limit mechanism 3 and a friction generating mechanism 4 are provided in sequence, and an elastic limit mechanism 3 and a friction generating mechanism 4 are also arranged in sequence between the moving magnet mechanism 2 and the fixed magnet 6 on the lower side. The moving magnet mechanism 2 and the elastic There is a gap between the limiting mechanisms 3, the central ...

Embodiment 2

[0035] Such as Figure 1-Figure 4 As shown, a low-frequency broadband electromagnetic-piezoelectric-friction compound vibration energy harvester includes a housing 1, the upper and lower ends of the housing 1 are respectively fixed with end caps 7, and the inner end faces of the two end caps 7 are all fixed A fixed magnet 6 is installed, a moving magnet mechanism 2 is installed in the middle part of the housing 1, and an induction coil 5 is installed at the moving magnet mechanism 2 on the outer peripheral wall of the casing 1, between the moving magnet mechanism 2 and the fixed magnet 6 on the upper side An elastic limit mechanism 3 and a friction generating mechanism 4 are provided in sequence, and an elastic limit mechanism 3 and a friction generating mechanism 4 are also arranged in sequence between the moving magnet mechanism 2 and the fixed magnet 6 on the lower side. The moving magnet mechanism 2 and the elastic There is a gap between the limiting mechanisms 3, the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com