Electromagnetic contactor

A technology of electromagnetic contactors and moving contacts, which is applied in the direction of electromagnetic relays, relays, detailed information of electromagnetic relays, etc., and can solve a large number of processing steps and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

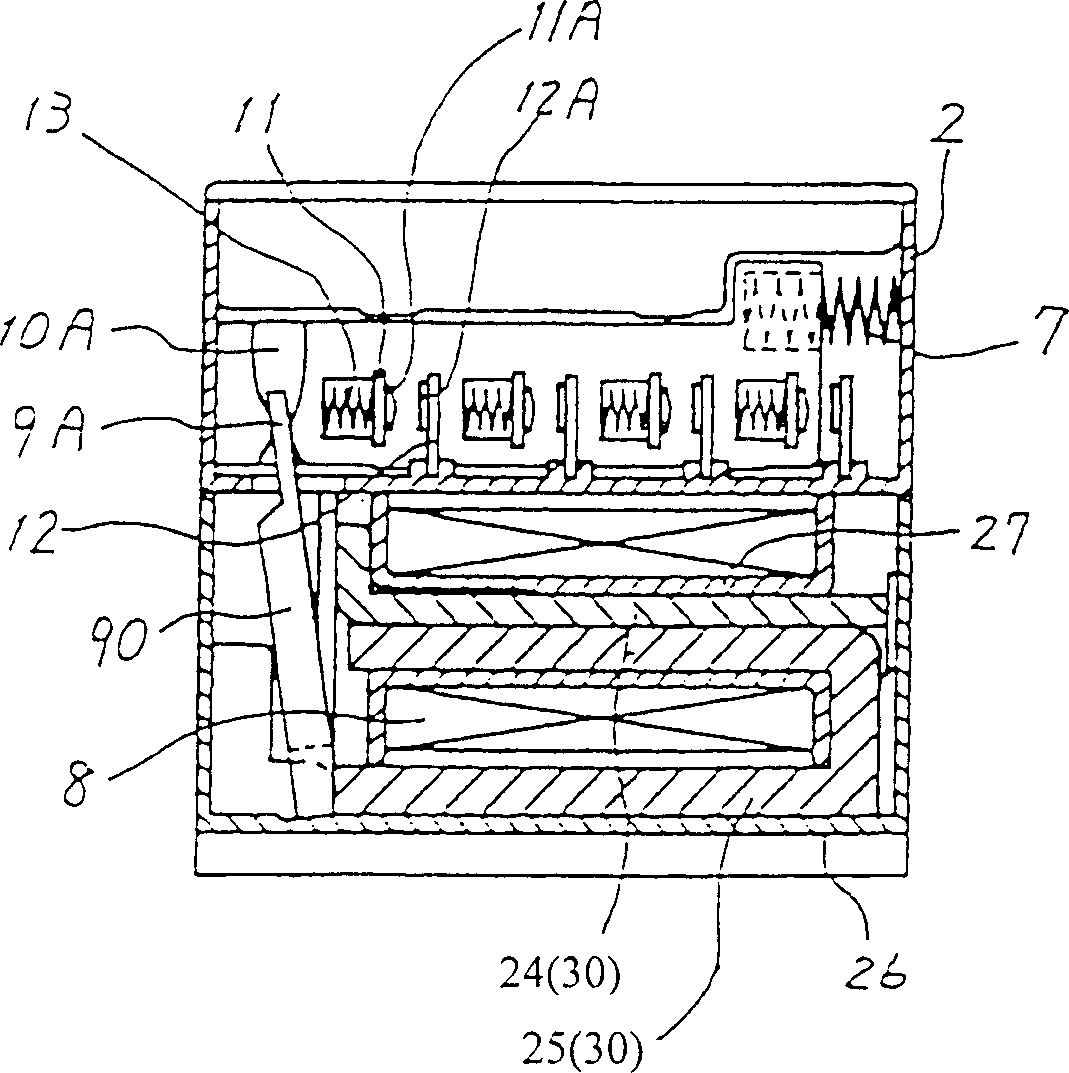

[0032] Hereinafter, it will be described through the embodiments of the present invention. figure 1 A cross-sectional view of a structure of an electromagnetic contactor according to an embodiment of the present invention is shown. The difference between this electromagnetic contactor and the similar traditional technology is that the iron core 30 includes a first iron core 25 shaped like a letter "U" and a second iron core 24 bent like a letter "L", and the first iron core and the second iron core The left sides of the iron cores 24 and 25 face the iron sheet 90, and the first iron core 25 is placed on the bottom of the lower casing 26. Other parts of the structure are the same as those of conventional devices. Therefore, the same components are denoted by the same reference numerals, and their detailed descriptions are omitted here.

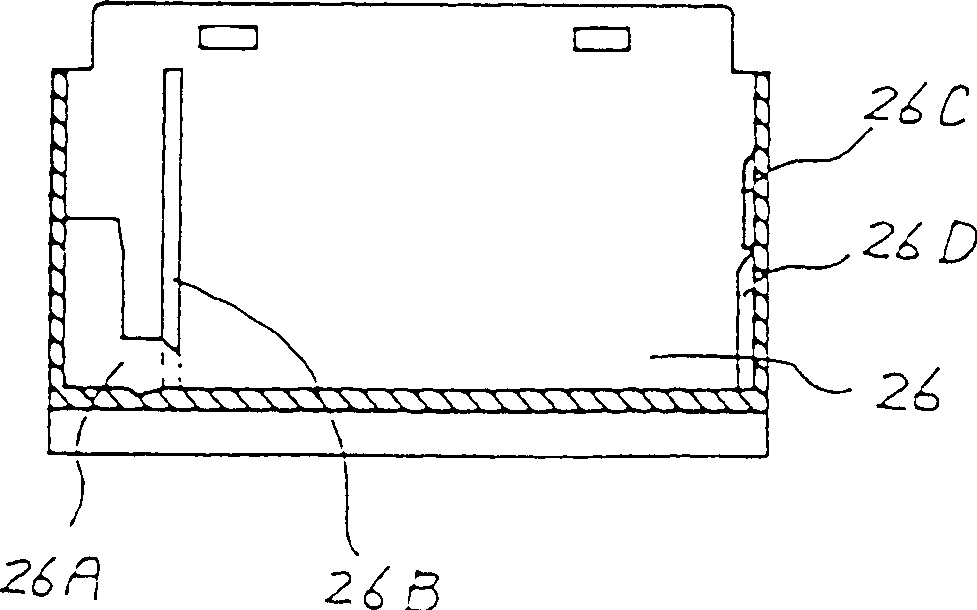

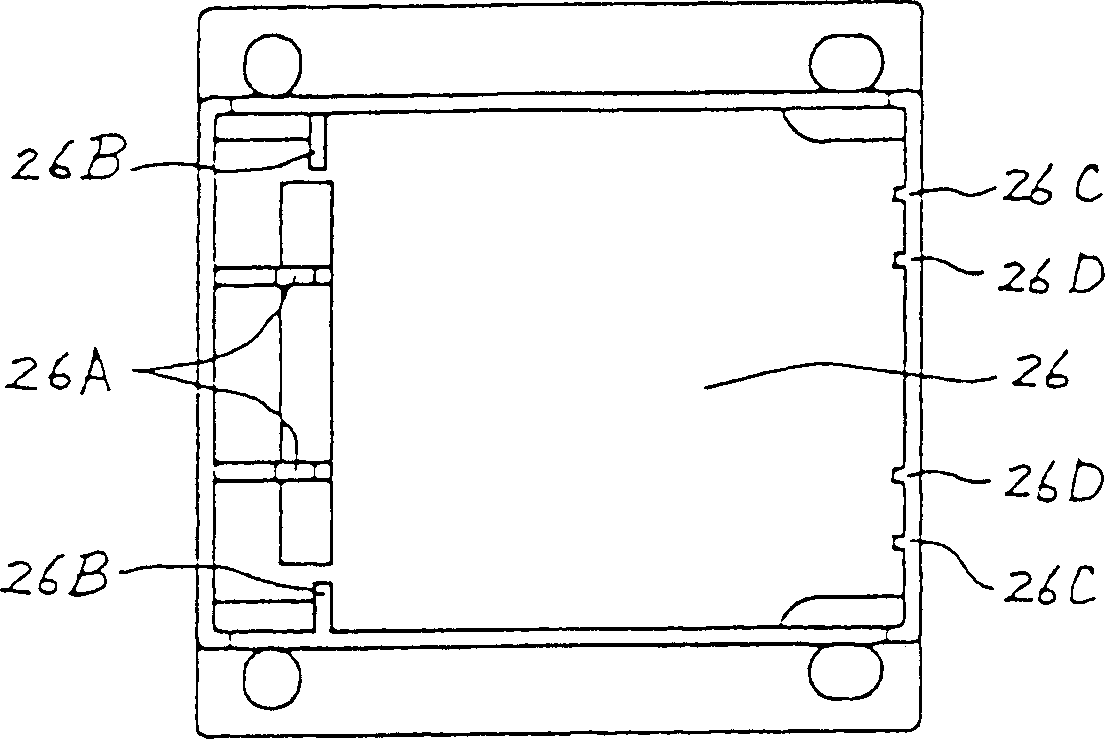

[0033] figure 2 , 3 and 4 are figure 1 Sectional view, plan view and perspective view of the middle and lower casing 26. In each figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com