A mold structure for installing copper nuts on insulating seats

A technology of copper nut and insulating seat, applied in the direction of coating, can solve the problems of extending the effective thread length of copper nut, insufficient effective thread of copper nut, and high success rate of injection molding of insulating seat, and achieves good injection molding effect and structure. Simple, high injection molding success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further explained in conjunction with the accompanying drawings.

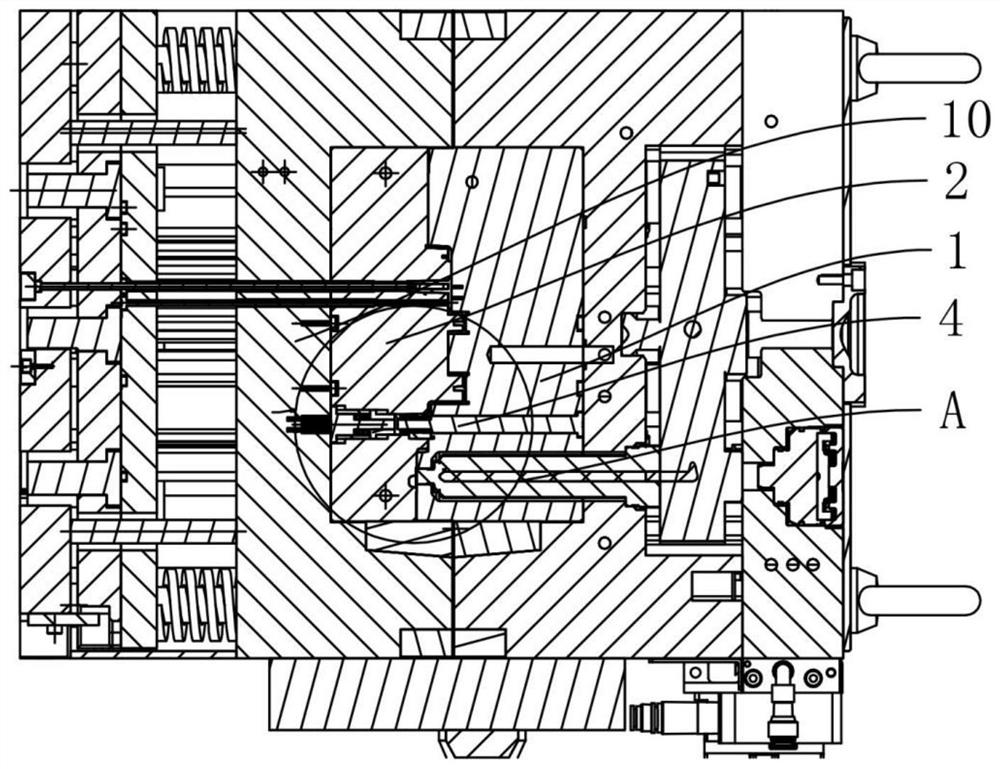

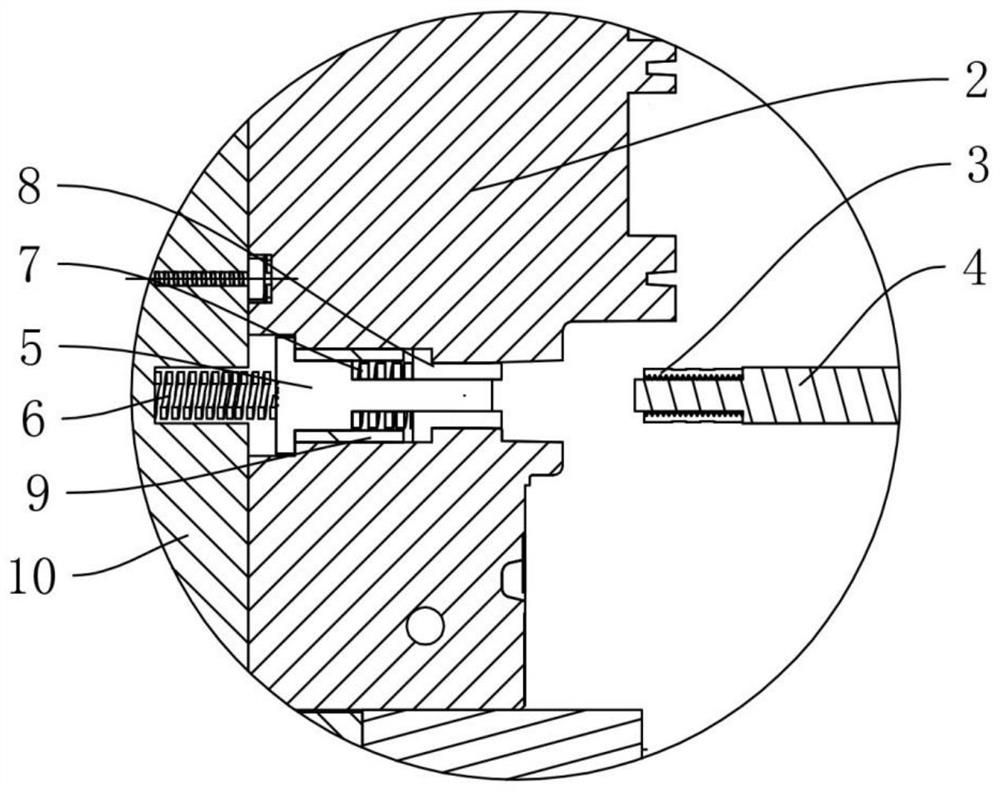

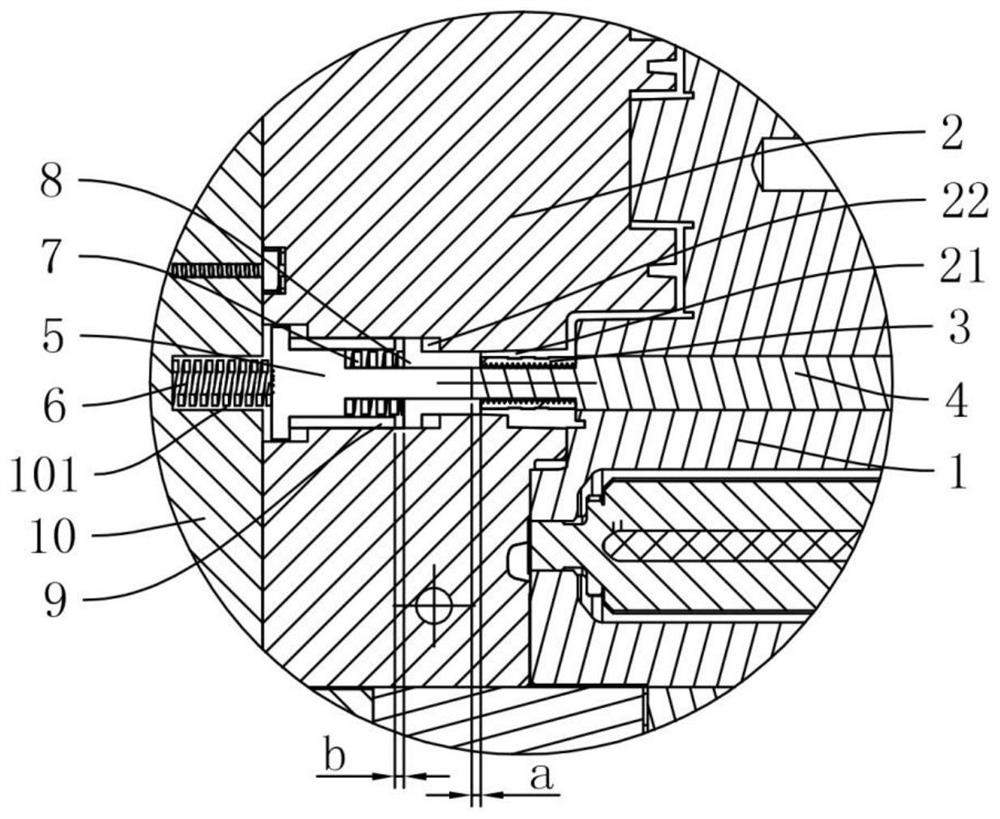

[0022] see Figure 1 to Figure 5 A mold structure for installing a copper nut 3 on an insulating seat is shown, which includes a front mold core 1 and a rear mold core 2 which are arranged oppositely front and back, and a copper nut 3 is installed on the front mold core 1 through a mounting column 4, The copper nut 3 is sleeved on the mounting column 4 and the end of the mounting column 4 protrudes from the copper nut 3, and the mounting column 4 is provided with a stop step that cooperates with the copper nut 3, so that the copper nut 3 can only be to move.

[0023] The rear mold core 2 is provided with a molding hole 21 matched with the copper nut 3 and an installation cavity 22 connected with the molding hole 21. During injection molding, the injection molding medium enters the molding hole 21 to form a product. The mounting cavity 22 is movably provided with a spring post 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com