Automobile gooseneck hinge assembly system

A gooseneck hinge technology, applied in the field of auto parts, can solve the problems of troublesome adjustment, troublesome installation, and high rigidity of the gooseneck hinge 1, and achieve the effects of stable performance, convenient installation and tight coordination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

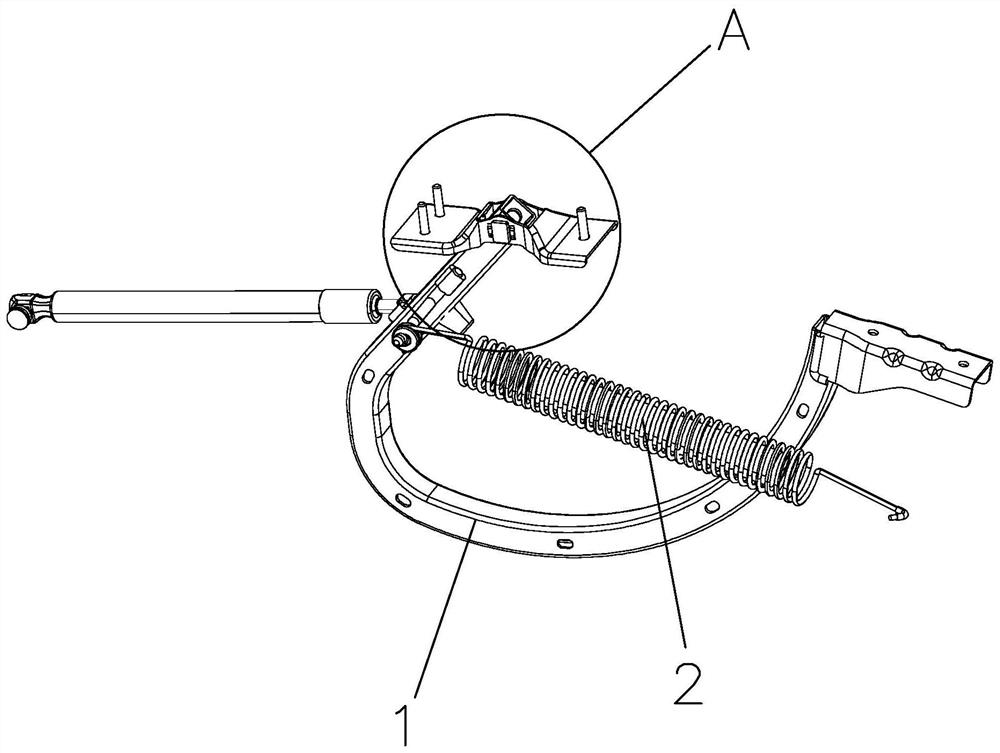

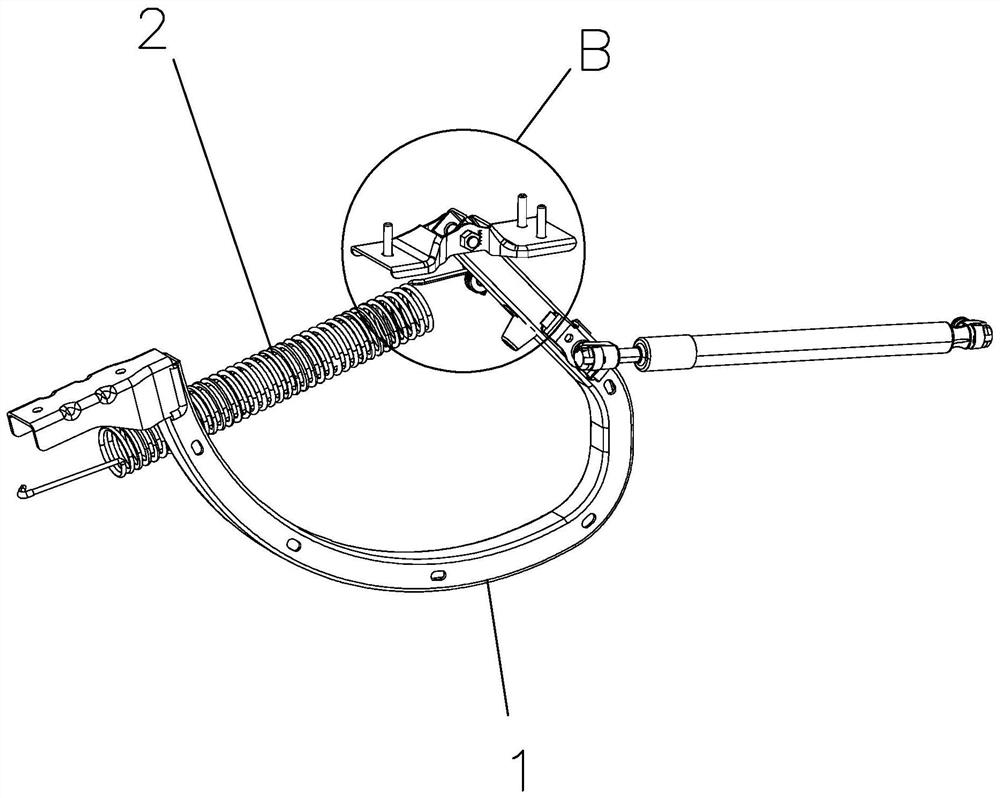

[0029] see Figure 1 to Figure 6 : An automotive gooseneck hinge assembly system, comprising a gooseneck hinge 1, a spring 2 for reducing the opening resistance of a trunk lid 34, a realizable gooseneck hinge 1 fixed on the upper side of the trunk 3 Corresponding to the connecting mechanism for adjusting the end up and down, one end of the gooseneck hinge 1 is hinged on the connecting mechanism, the other end of the gooseneck hinge 1 is connected to the trunk lid 34, and one end of the spring 2 is connected to the gooseneck hinge. On the hinge 1, the other end of the spring 2 is connected to the rear side inside the trunk 3.

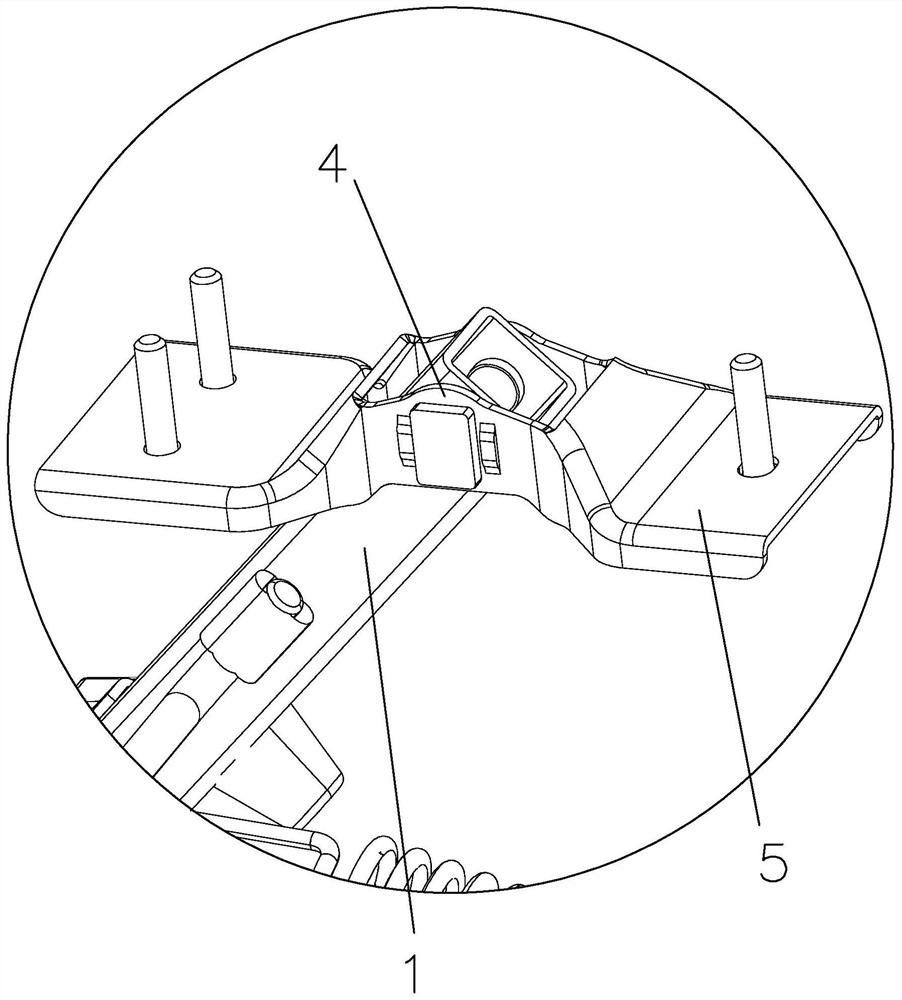

[0030] The connection mechanism includes a support plate 4 located on opposite sides of the end of the gooseneck hinge 1, a support plate 5 affixed to the support plate 4, and a vertical slot 6 arranged on the support plate 4. The gooseneck hinge 1 Bolts 7 are pierced on the end, and the bolts 7 pass through the vertical long holes 6 and are fixedly con...

Embodiment 2

[0034] see Figure 7 to Figure 11 : An automotive gooseneck hinge assembly system, comprising a gooseneck hinge 1, a spring 2 for reducing the opening resistance of a trunk lid 34, a realizable gooseneck hinge 1 fixed on the upper side of the trunk 3 Corresponding to the connecting mechanism for adjusting the end up and down, one end of the gooseneck hinge 1 is hinged on the connecting mechanism, the other end of the gooseneck hinge 1 is connected to the trunk lid 34, and one end of the spring 2 is connected to the gooseneck hinge. On the hinge 1, the other end of the spring 2 is connected to the rear side inside the trunk 3. The spring 2 is pierced with a sponge for reducing the noise when the spring 2 stretches.

[0035]The connection mechanism includes a connecting plate 10 fixed on the upper side of the trunk 3, two sliding blocks 11 that are slidably connected to the lower side of the connecting plate 10, a fixed block 12 fixed on the lower side of the connecting plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com