A pressure control method for a cvt dual pressure hydraulic system

A technology of pressure control and hydraulic system, applied in fluid pressure actuation system components, transmission device control, fluid pressure actuation device, etc., can solve the problem of high energy consumption, achieve the effect of improving operating efficiency and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

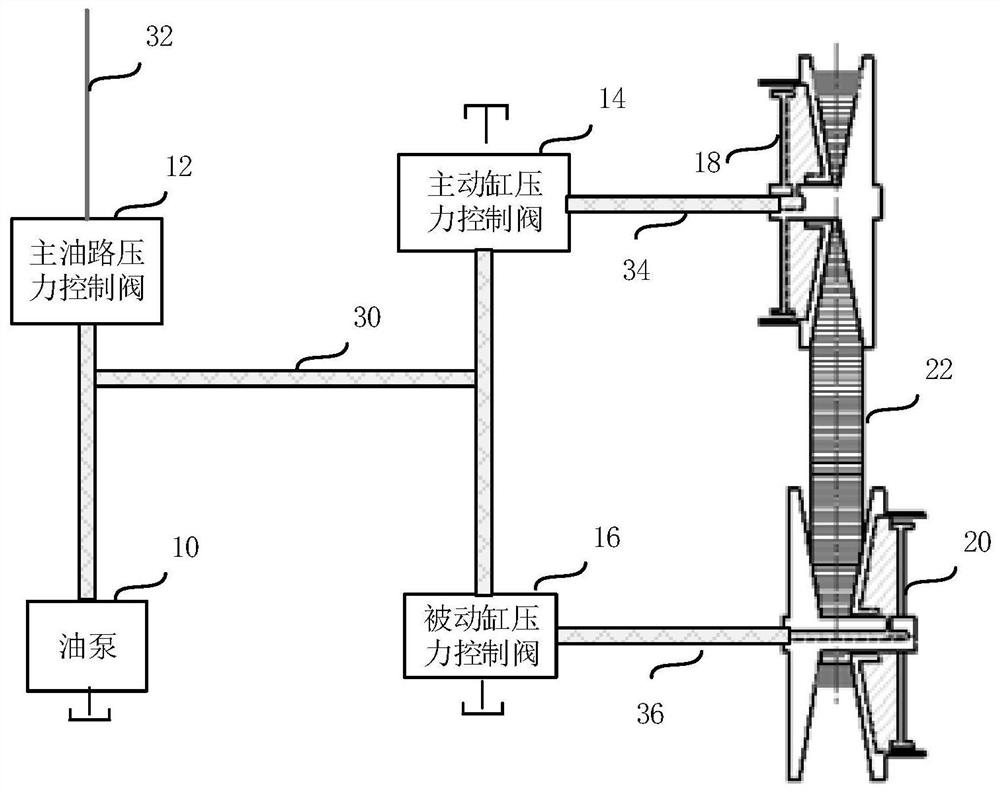

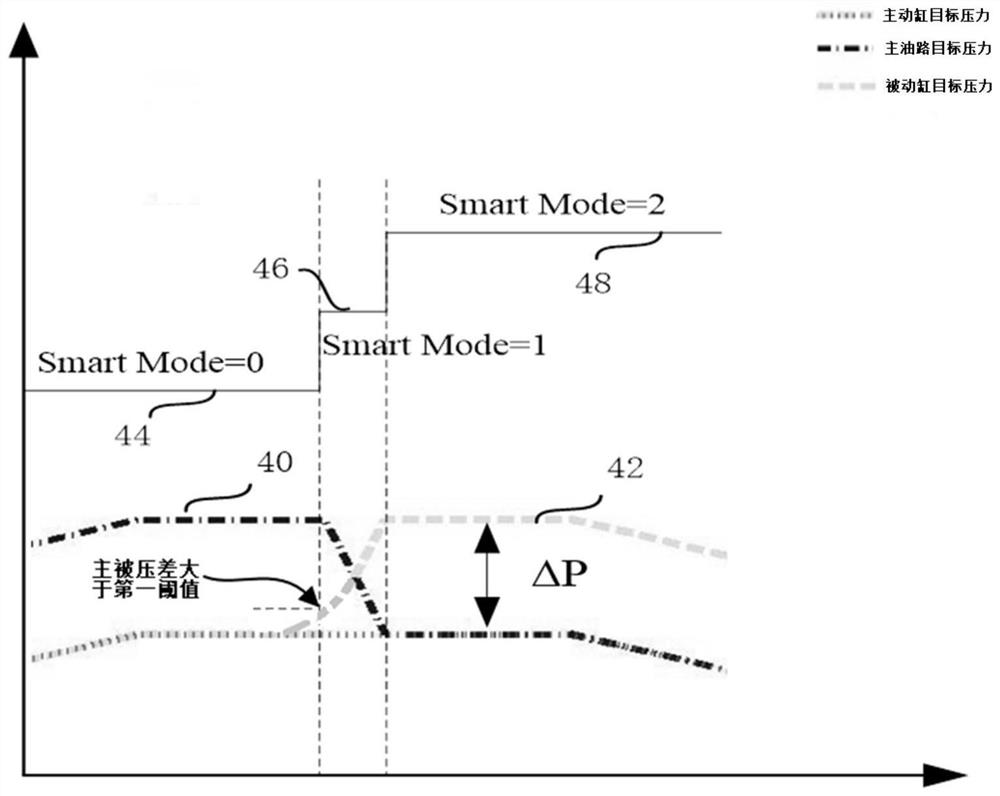

[0040] Embodiment one: figure 2 It is a pressure control method of a CVT dual-pressure hydraulic system in Embodiment 1 of the present invention. In consideration of saving hardware cost and other reasons, in reality, a pressure sensor is often installed at the passive pulley, but not at the driving pulley ( figure 2 represents such a common situation), since the pressure control means of the present invention cannot perform closed-loop control of the main oil circuit pressure control valve based on the target pressure of the active cylinder, so at this time only the target pressure of the passive cylinder P sec Considered as the maximum target pressure Max(P sec , P pri ), and perform closed-loop control or full-open control on the passive cylinder pressure control valve 16 to suppress the pressure of the main oil circuit of the system and reduce losses. figure 2 During the entire control process of the illustrated Smart Mode, the active cylinder pressure control valve ...

Embodiment 2

[0051] Embodiment two: with figure 2 The first embodiment shown is different. In this embodiment, pressure sensors are installed at the passive pulley and the driving pulley of the CVT dual-pressure hydraulic system. At this time, it is necessary to determine in advance which one is the target pressure of the active cylinder or the target pressure of the passive cylinder. is larger, and select the pressure control valve corresponding to the maximum value as the controlled control valve, and the pulley controlled by the controlled control valve is regarded as the controlled pulley (that is, if the target pressure of the active cylinder is greater than the target pressure of the passive cylinder, the active cylinder cylinder pressure control valve as the controlled control valve, otherwise, the passive cylinder pressure control valve as the controlled control valve), and its corresponding target pressure as the controlled target pressure; as for the other pressure control valve,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap