Direct current motor with constant voltage electric brush

A DC motor and brush technology, applied in the direction of DC commutator, circuit, collector, etc., can solve the problems of brush wear, slow cooling, fast brush wear, etc., to achieve flexible and convenient control, fast response speed, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

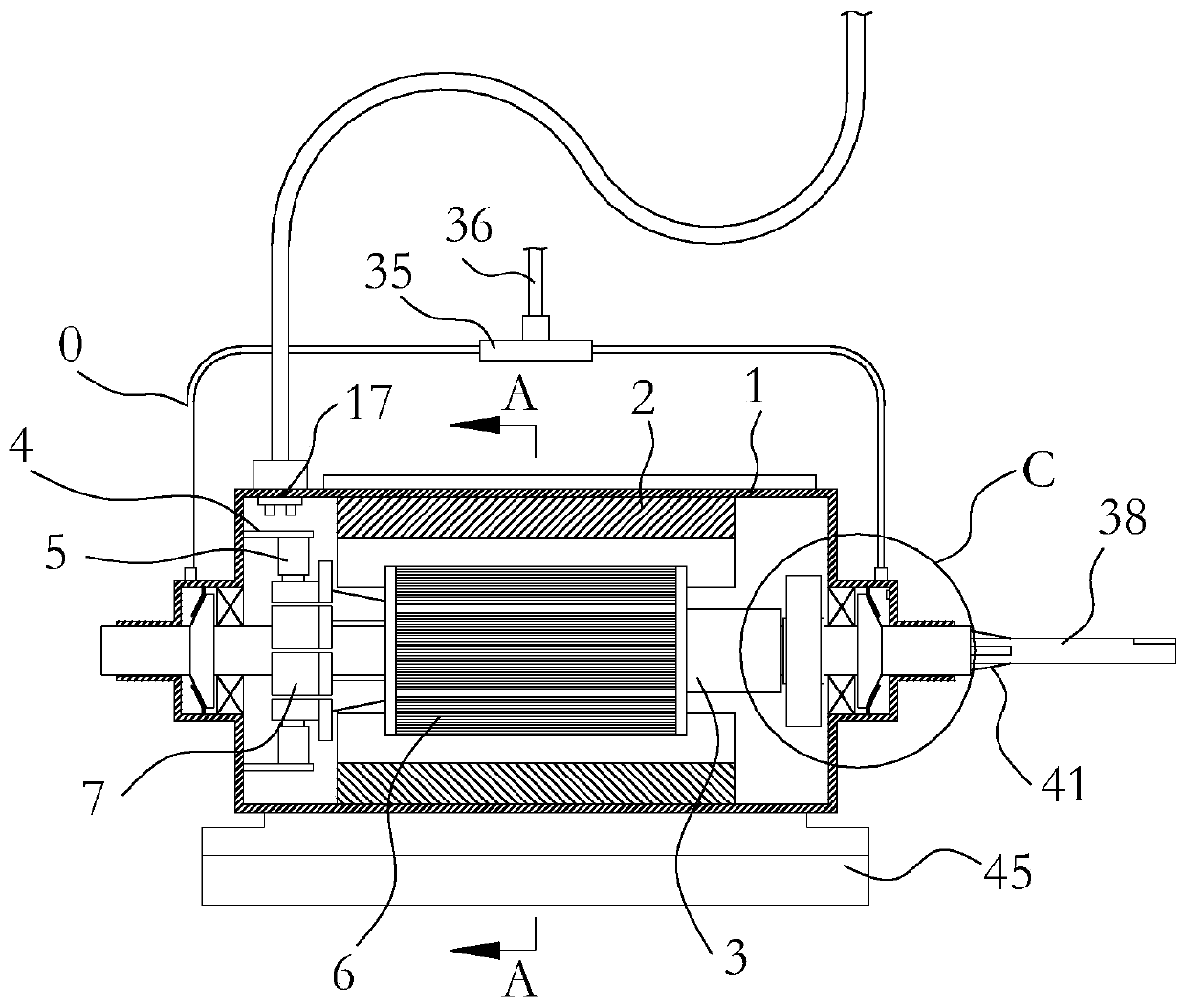

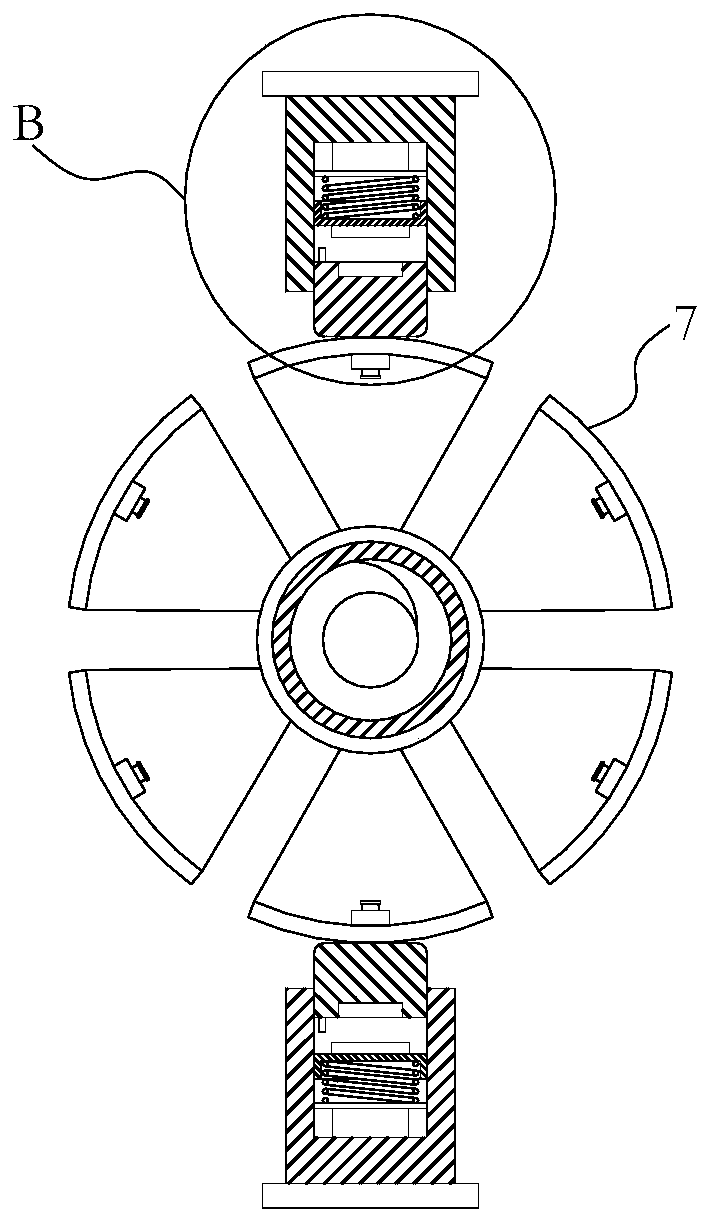

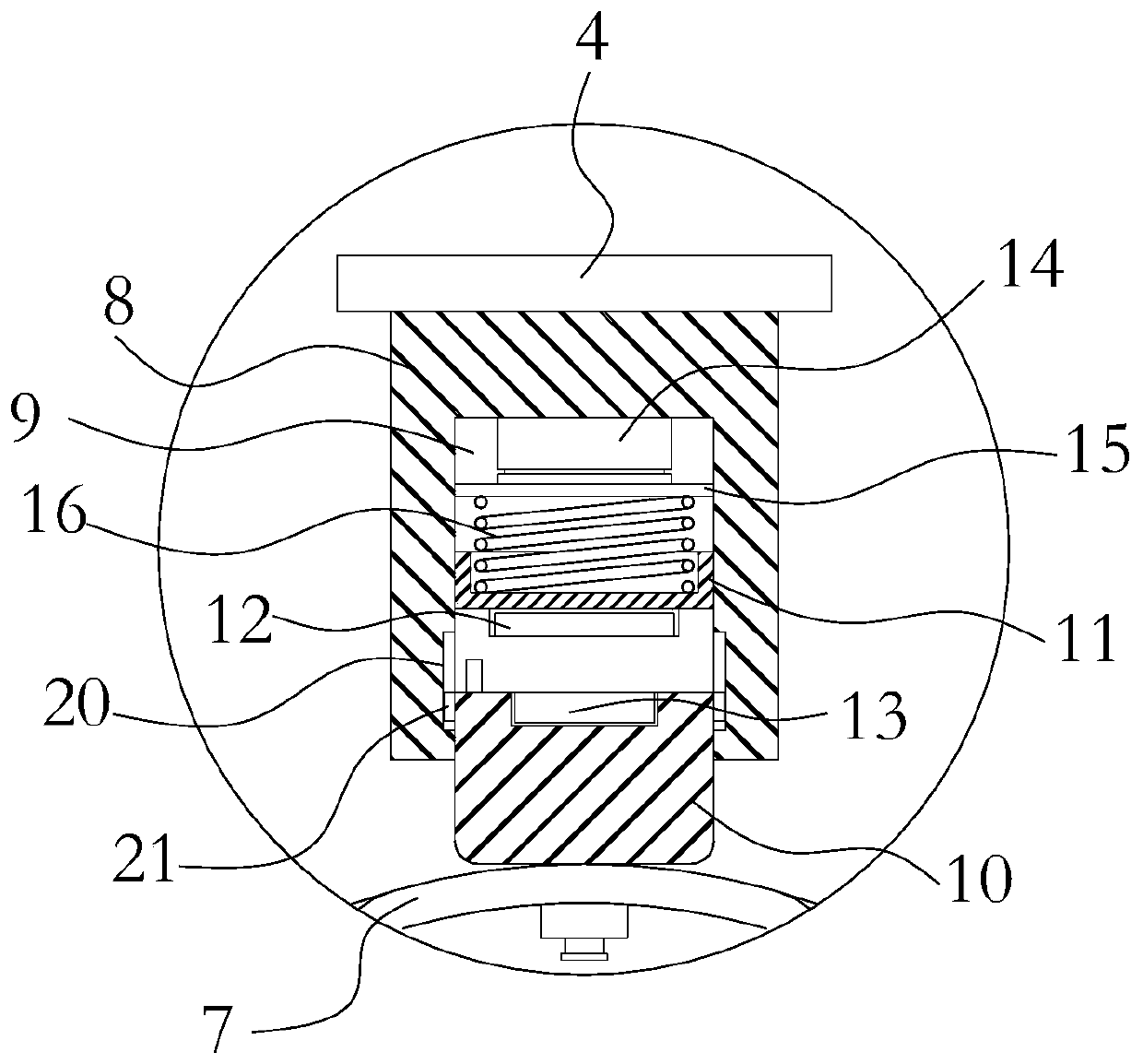

[0030] like Figure 1-10 The motor shown is the same as the conventional DC motor in that it also includes a casing 1 , a pair of stators 2 fixedly arranged on the inner wall of the casing 1 , and a rotating shaft 3 installed between the pair of stators 2 . A mounting bracket 4 is provided on the inner wall of the housing 1 corresponding to one end of the rotating shaft 3, such as figure 1 As shown in the figure, that is, the inner wall of the housing 1 at the left end of the rotating shaft 3 is provided with a mounting frame 4 , and a brush 5 is provided on the mounting frame 4 . A rotor 6 consisting of a magnetic core and an electromagnetic coil is arranged on a section of the rotating shaft 3 between the stators 2 , and the electromagnetic coil is wound on the magnetic core. After the rotor 6 is energized, the rotor 6 is affected by the magnetic force of the stator 2 and continues to rotate in the casing 1 . A commutator 7 is disposed on the rotating shaft 3 at a position...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap