Shaft fork machining clamp

A shaft fork and fixture technology, which is used in manufacturing tools, metal processing equipment, metal processing machinery parts, etc. The problem of low accuracy, etc., to achieve the effect of improving the position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

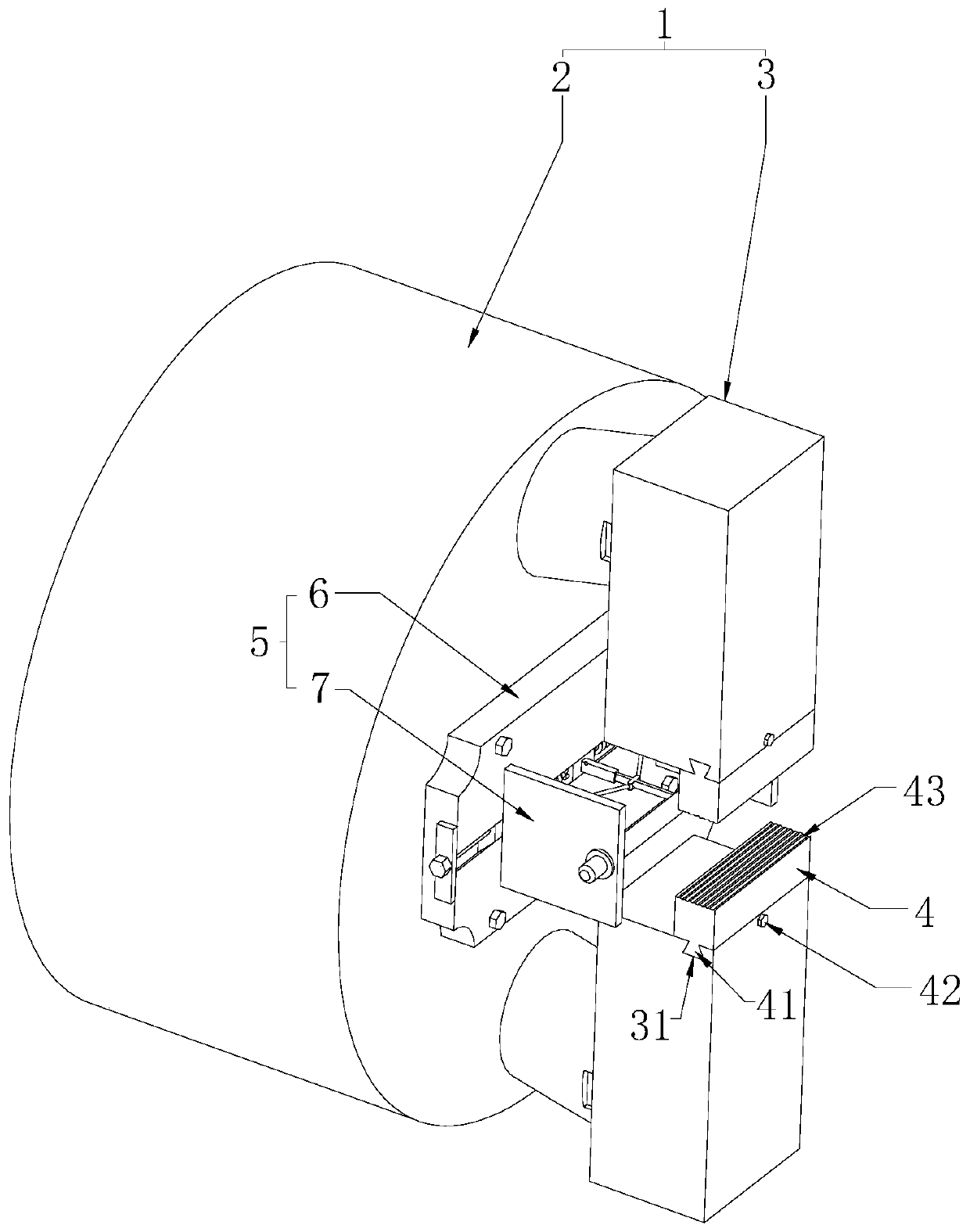

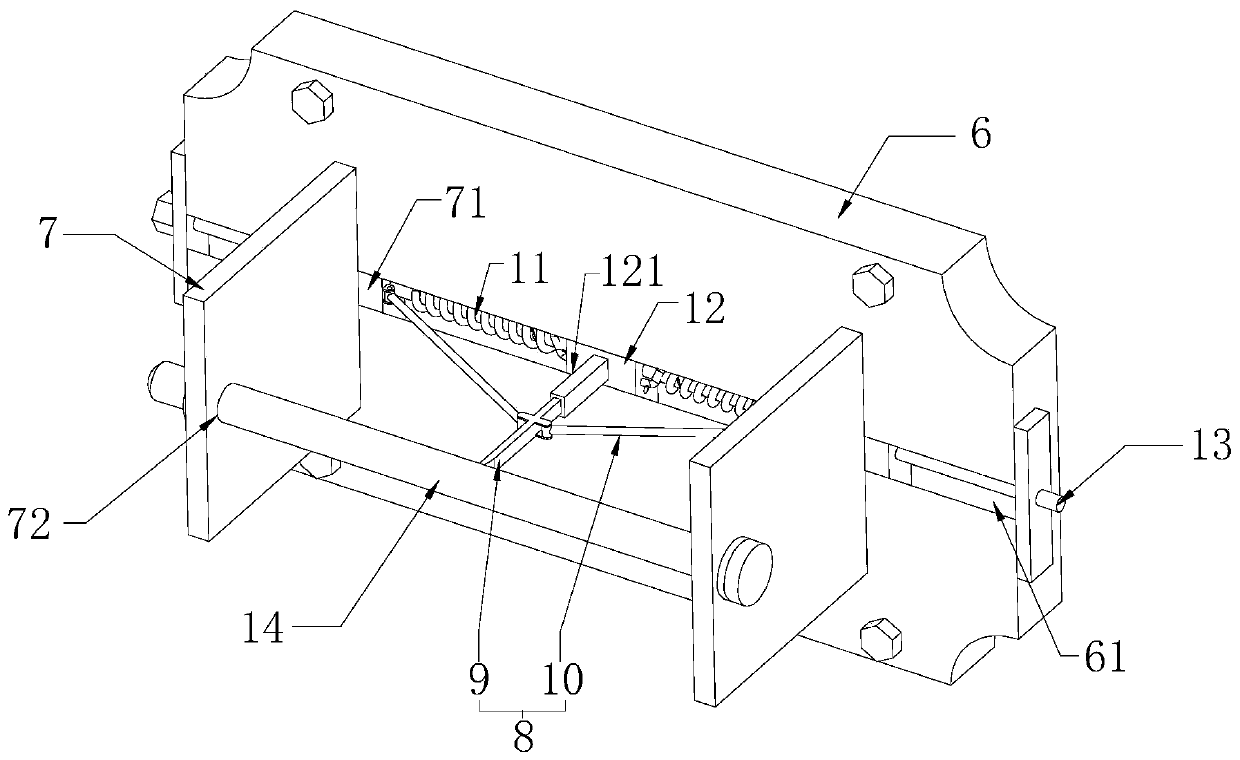

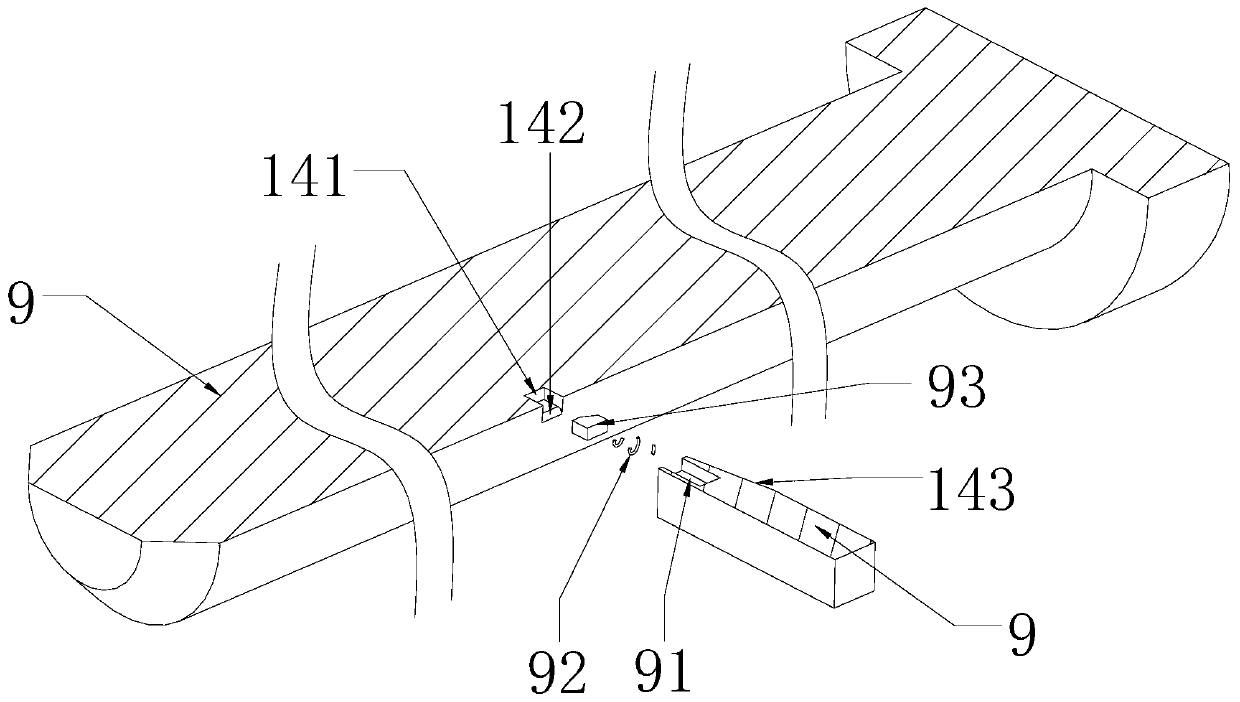

[0031] Such as figure 1 As shown, a jig for processing a shaft fork, including a cable-stayed chuck 1 (refer to the announcement number CN205341973U) and a positioning member 5 for defining the axial position of the shaft fork 15 hole 2 154, wherein the cable-stayed chuck 1 includes a chuck The frame 2 and the fixed claws 3 symmetrically arranged at both radial ends of the chuck frame 2, the fixed claws 3 include a shaft and abutting claws, the shaft slides through the chuck, and the sliding direction of the shaft is the same as that of the chuck frame 2. The axis is provided with an inclination angle; the blank is fixed on the positioning member 5, and the shaft slides so that the abutment claws are relatively close until the abutment claw clamps the blank, realizing the positioning and fixing of the blank before processing.

[0032] Such as figure 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com