A pipeline repair device

A pipeline repair and transmission wheel technology, applied in the pipeline field, can solve problems such as difficult to cut the protective layer, and achieve the effects of low repair cost, delayed aging, and less waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

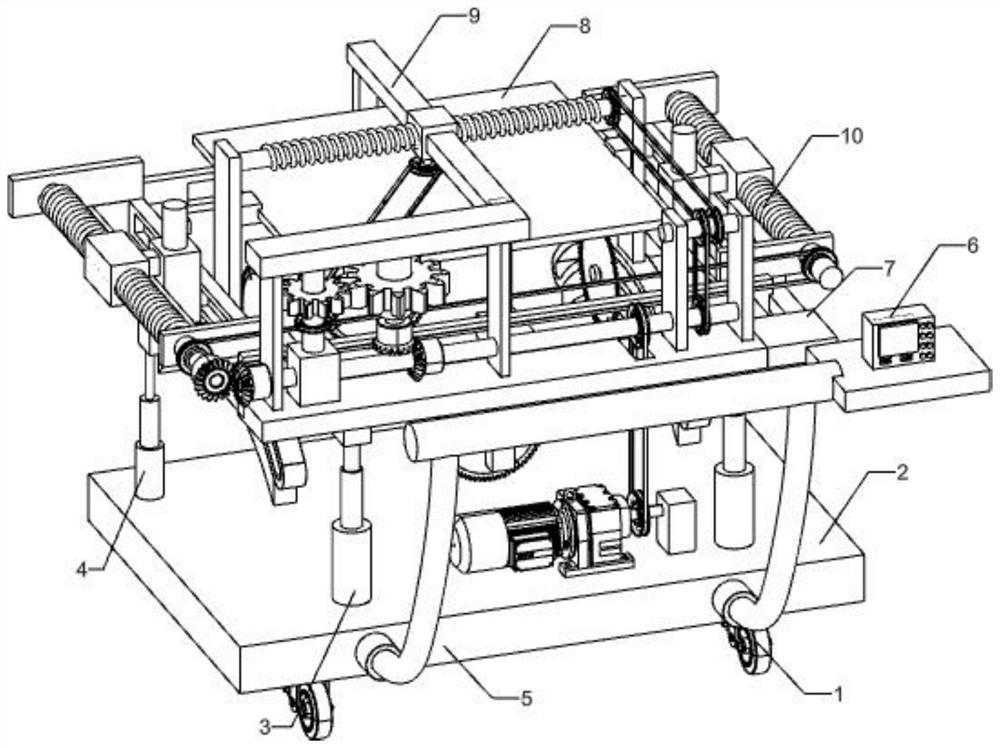

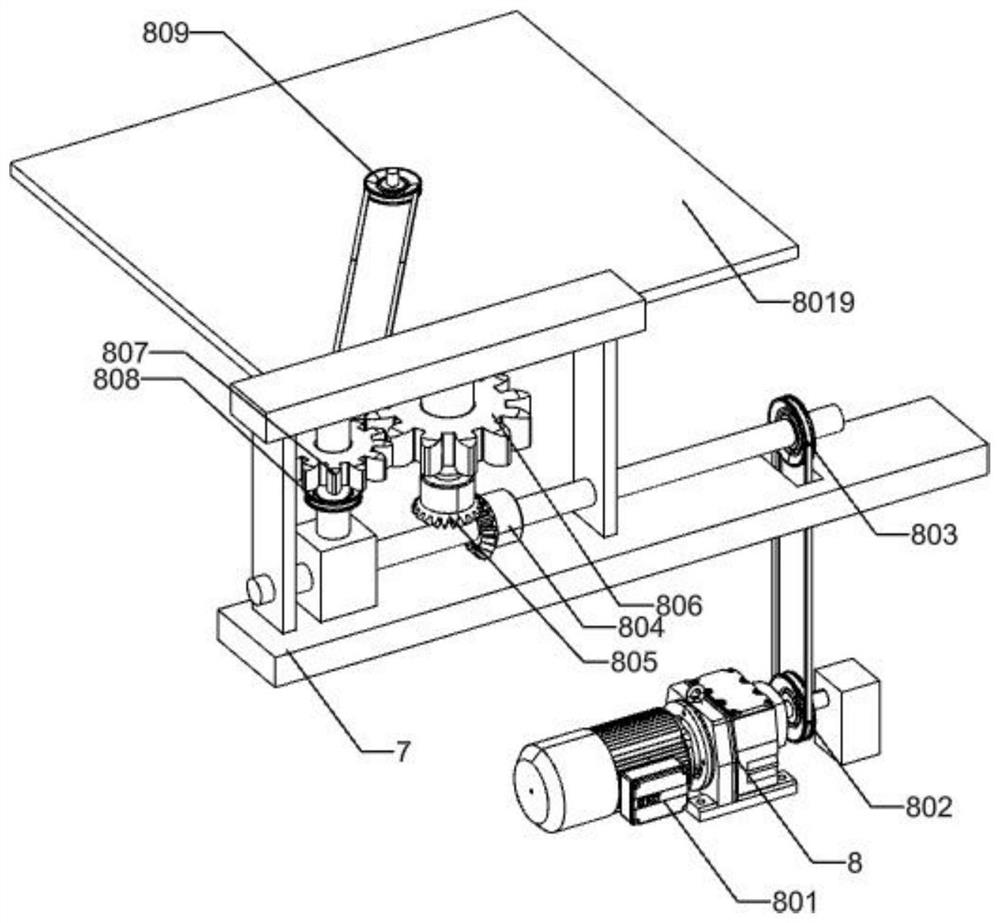

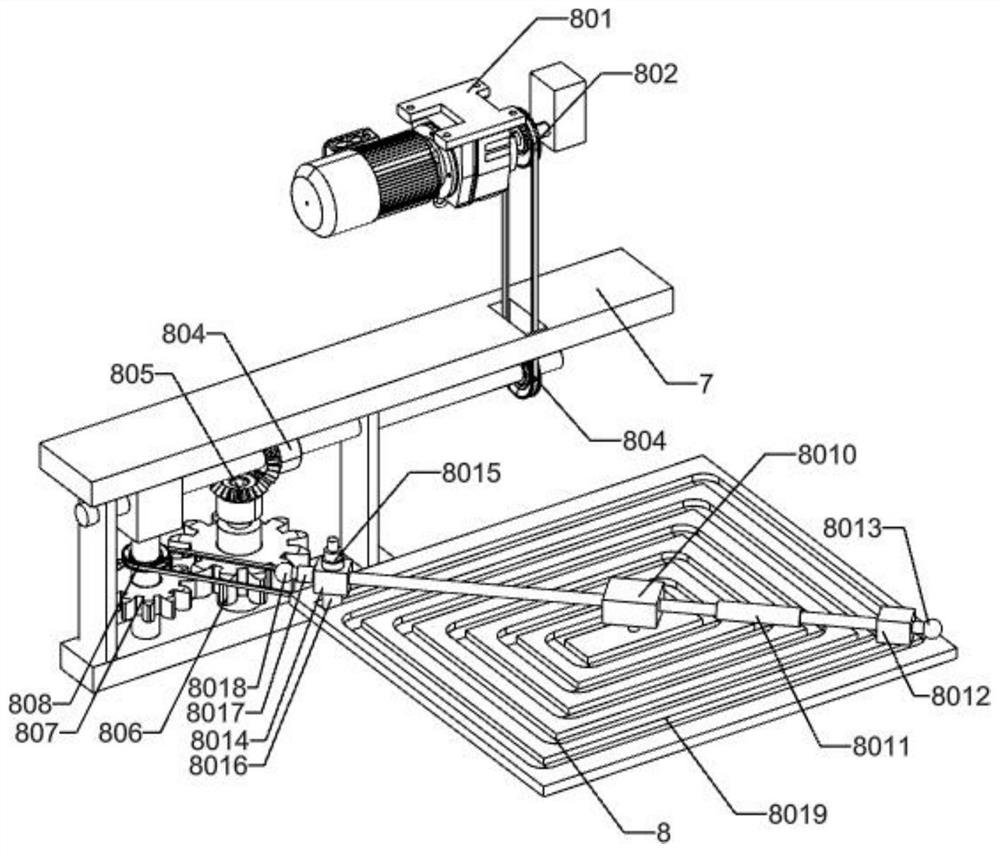

[0026] A pipeline repair device such as Figure 1-5 As shown, it includes caster 1, bottom plate 2, main fixed cylinder 3, auxiliary cylinder 4, push handle 5, control panel 6, main combined lifting plate 7, loop repair device 8, flat knife device 9 and curved knife device 10; casters The top of the bottom plate 1 is bolted to the bottom plate 2; the top left rear side of the bottom plate 2 is bolted to the main fixed cylinder 3; the top left front side of the bottom plate 2 is bolted to the auxiliary cylinder 4; the rear middle of the bottom plate 2 is welded to the push handle 5; The top of the fixed cylinder 3 is bolted to the main combination lifting plate 7; the top of the auxiliary cylinder 4 is connected to the curved knife device 10; the right top of the push handle 5 is connected to the control panel 6 through a flat plate; the left side of the top of the main combination lifting plate It is connected with the loopback repair device 8, and the rear middle part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com