Reinforced pipeline connecting pipe

A reinforced and connected pipe technology, which is applied in the direction of pipe/pipe joint/pipe fitting, sleeve/socket connection, engine sealing, etc., can solve the problems of inability to disassemble, fall off, disassemble the pipe and re-lay the pipe, etc., to avoid Liquid leakage and shedding phenomenon, simple and convenient installation work, solve the effect of one-time docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

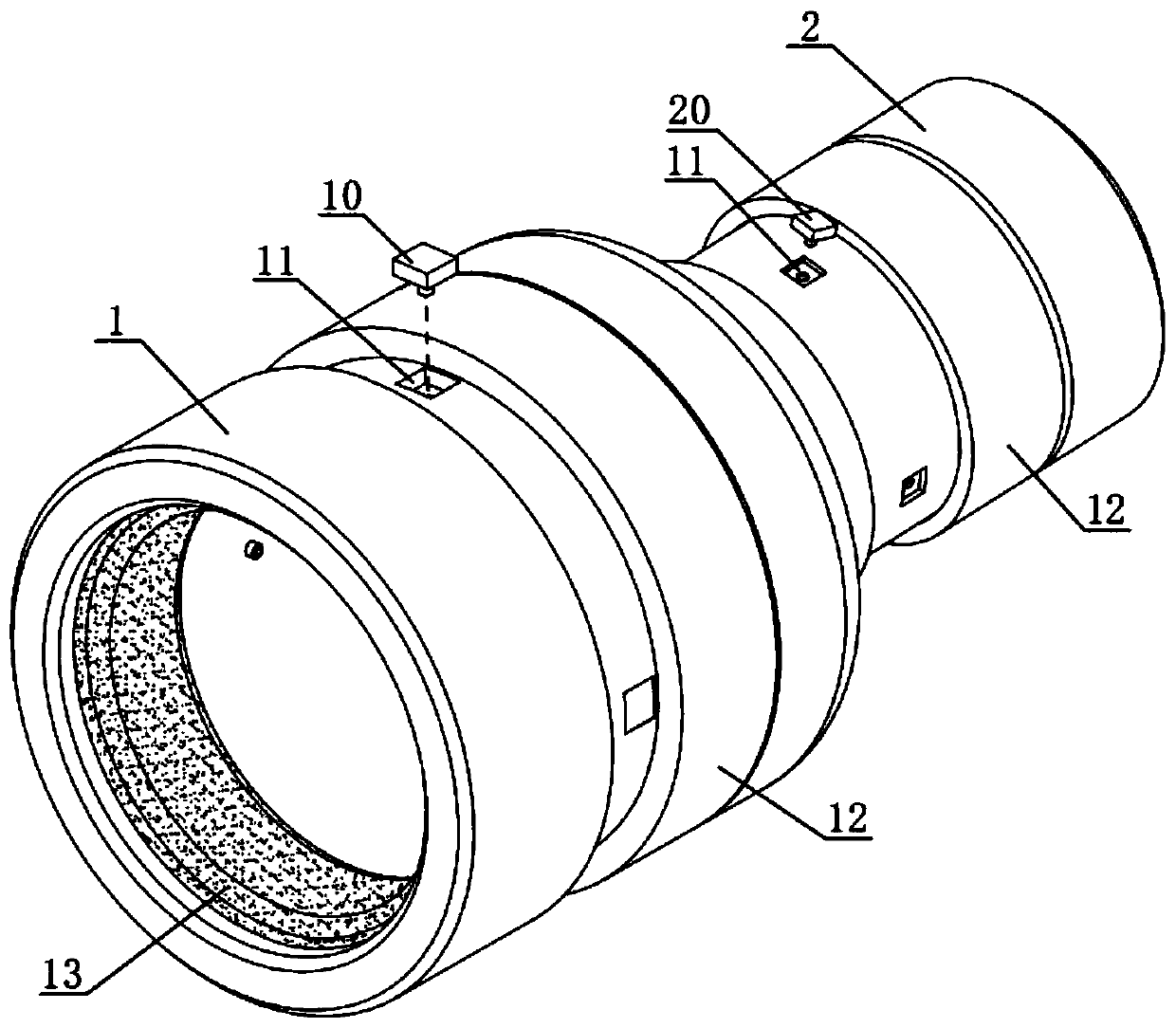

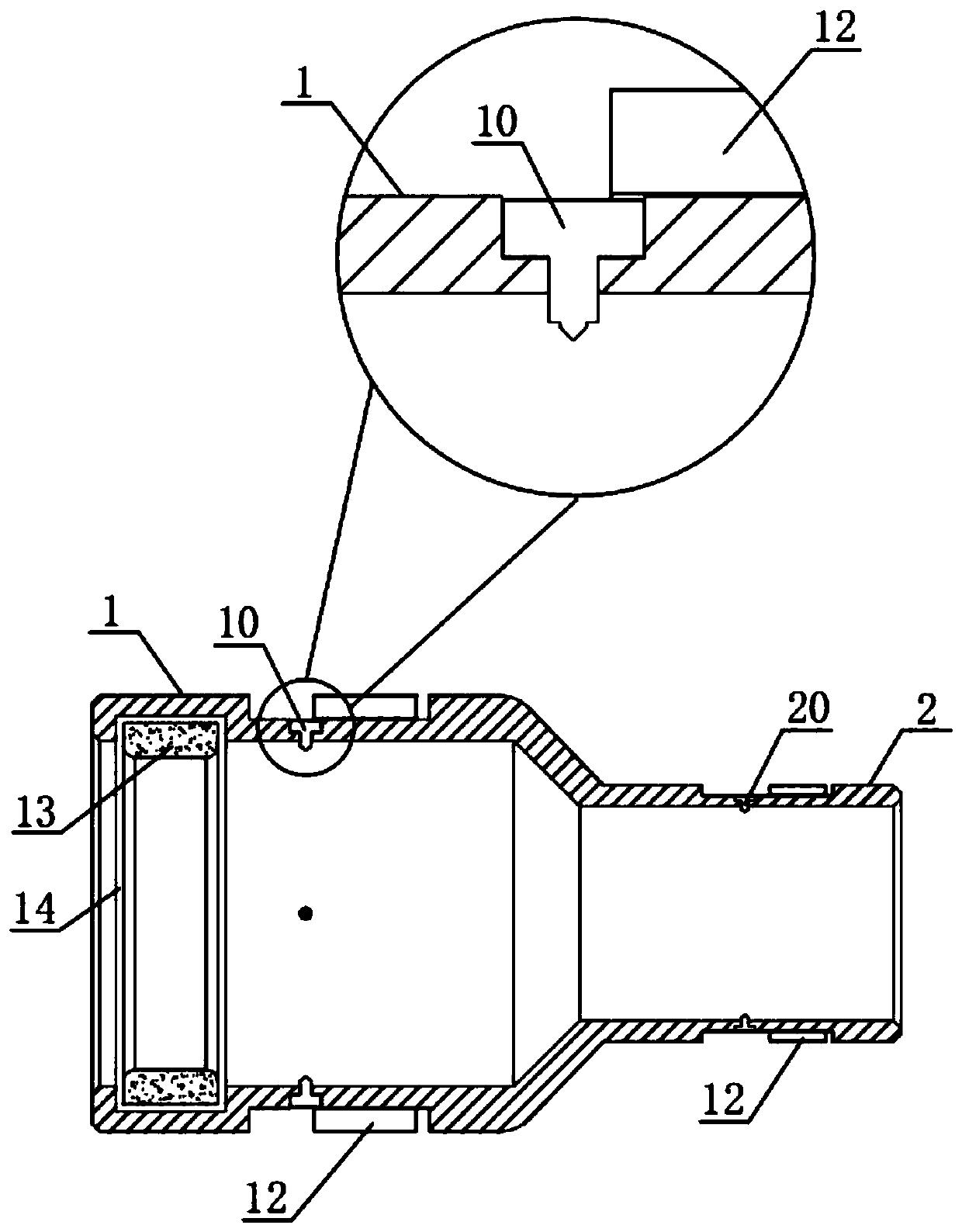

[0024] Such as figure 1 The reinforced pipe connecting pipe shown includes a large tube fixing part 1 and a small tube fixing part 2. Both the large tube fixing part 1 and the small tube fixing part 2 are hollow cylindrical inside, and the large tube fixing part 1 and the small tube fixing part 2 are Integrated and internally connected, the large pipe fixing part 1 is used to insert and fix a larger diameter pipe, and the small pipe fixing part 2 is used to insert and fix a smaller diameter pipe to realize the butt joint of two pipes.

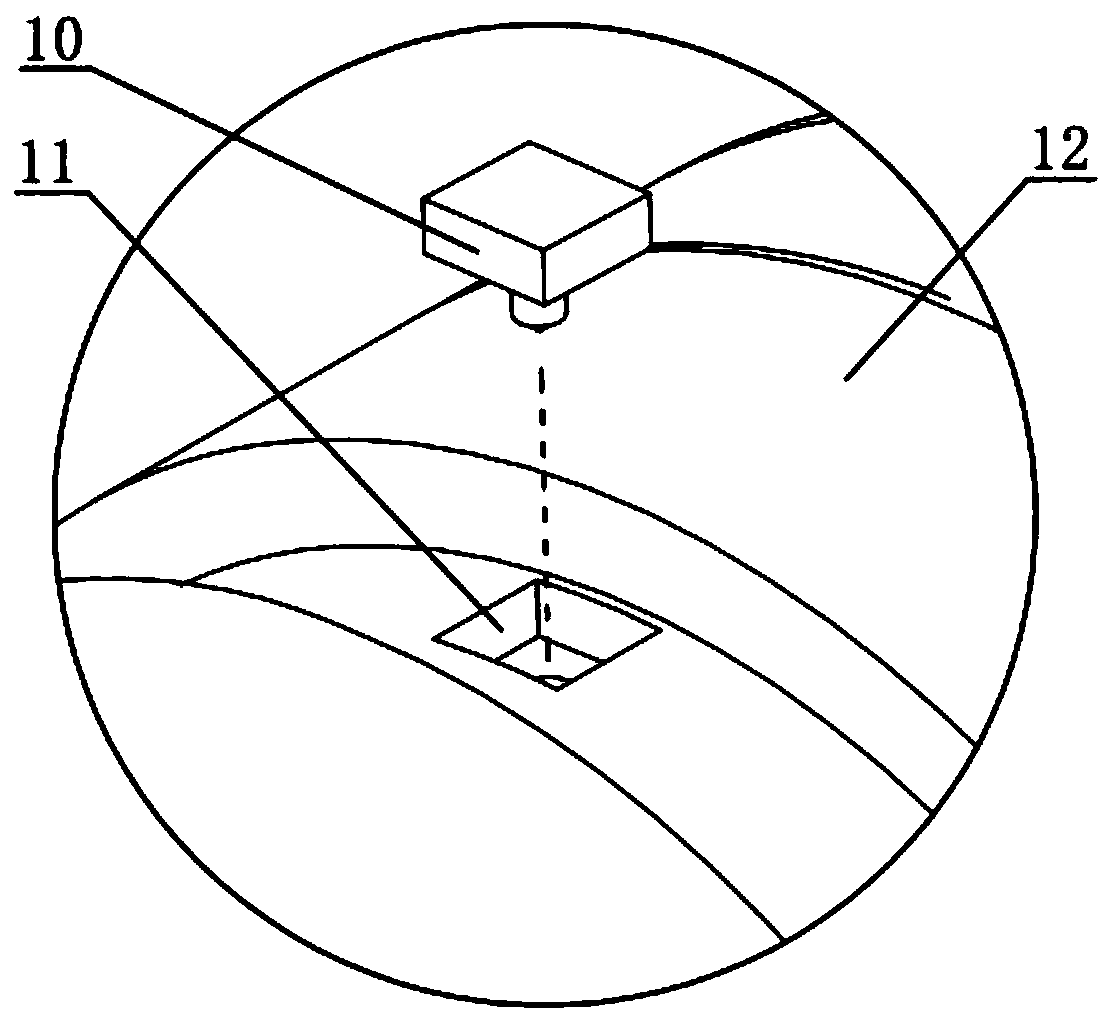

[0025] Such as Figure 1 to Figure 3 As shown, the large tube fixing part 1 is provided with four first tightening devices 10, and the four first tightening devices 10 are arranged equidistantly along the outer wall of the large tube fixing part 1, and each first tightening device 10 It is detachably connected with the large tube fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com