Capillary pressure curve construction method and device

A capillary pressure curve and capillary pressure technology, which is used in instrumentation, design optimization/simulation, electrical digital data processing, etc., can solve the problems of not considering the change of the fluid centrifugal process and the low accuracy of the capillary pressure curve, achieving high accuracy and improving construction. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

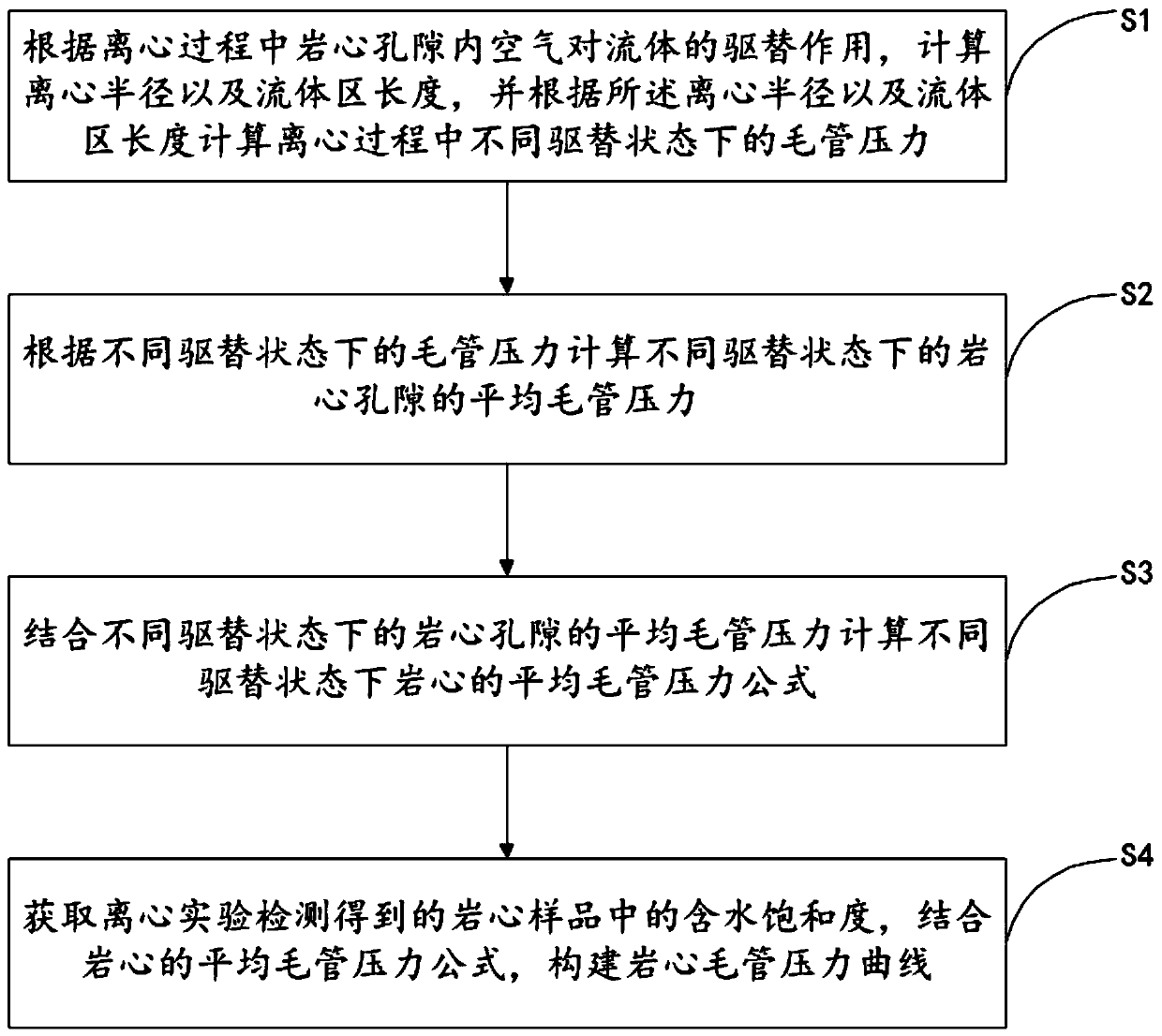

[0020] Such as figure 1 As shown, Embodiment 1 of the present invention provides a method for constructing a capillary pressure curve, which includes the following steps:

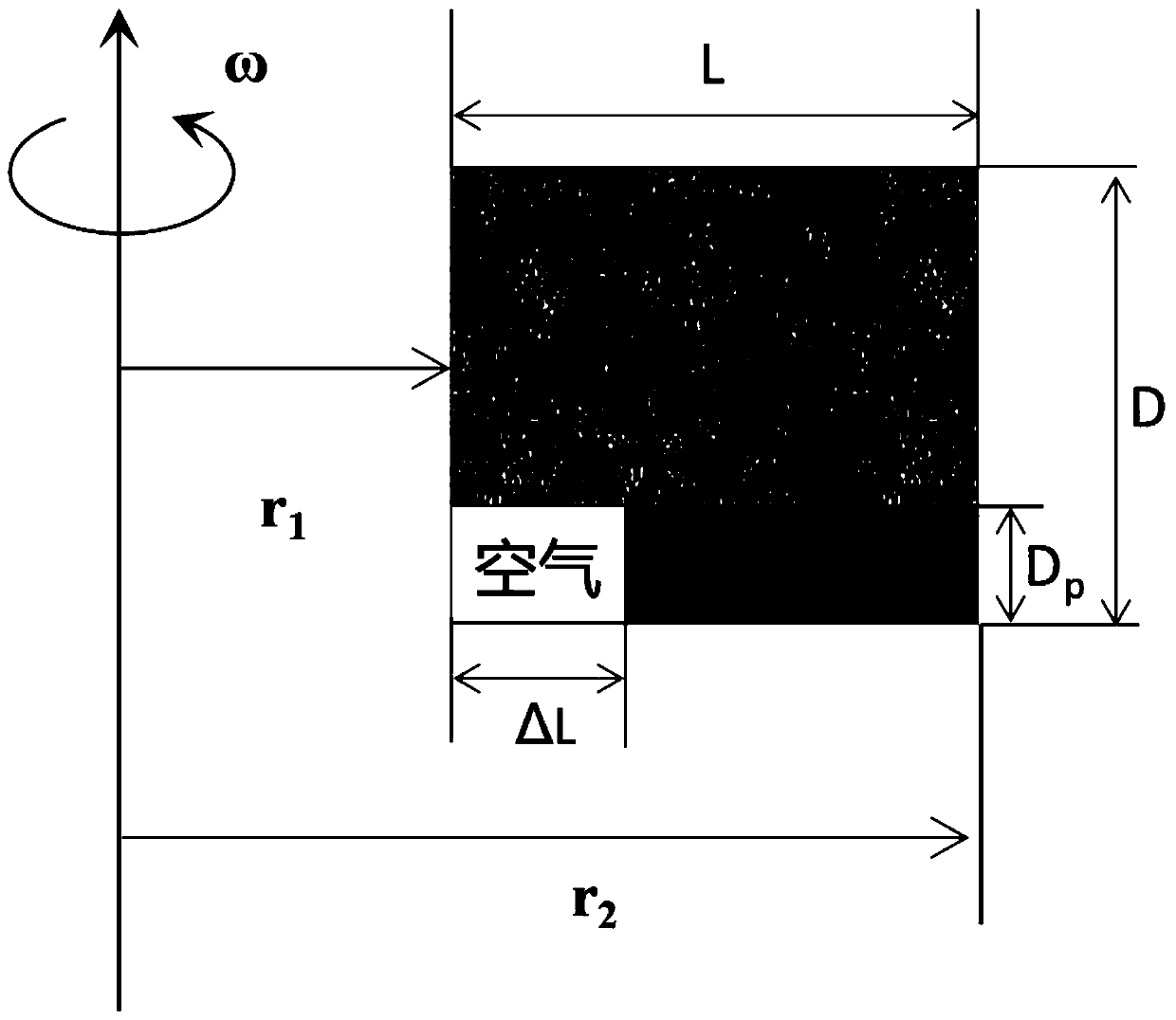

[0021] S1. Calculate the centrifugal radius and the length of the fluid zone according to the displacement effect of the air in the core pores during the centrifugal process on the fluid, and calculate the capillary pressure under different displacement states during the centrifugal process according to the centrifugal radius and the length of the fluid zone;

[0022] S2. Calculate the average capillary pressure of core pores under different displacement states according to the capillary pressures under different displacement states;

[0023] S3. Combining the average capillary pressure of core pores under different displacement states to calculate the average capillary pressure formula of core under different displacement states;

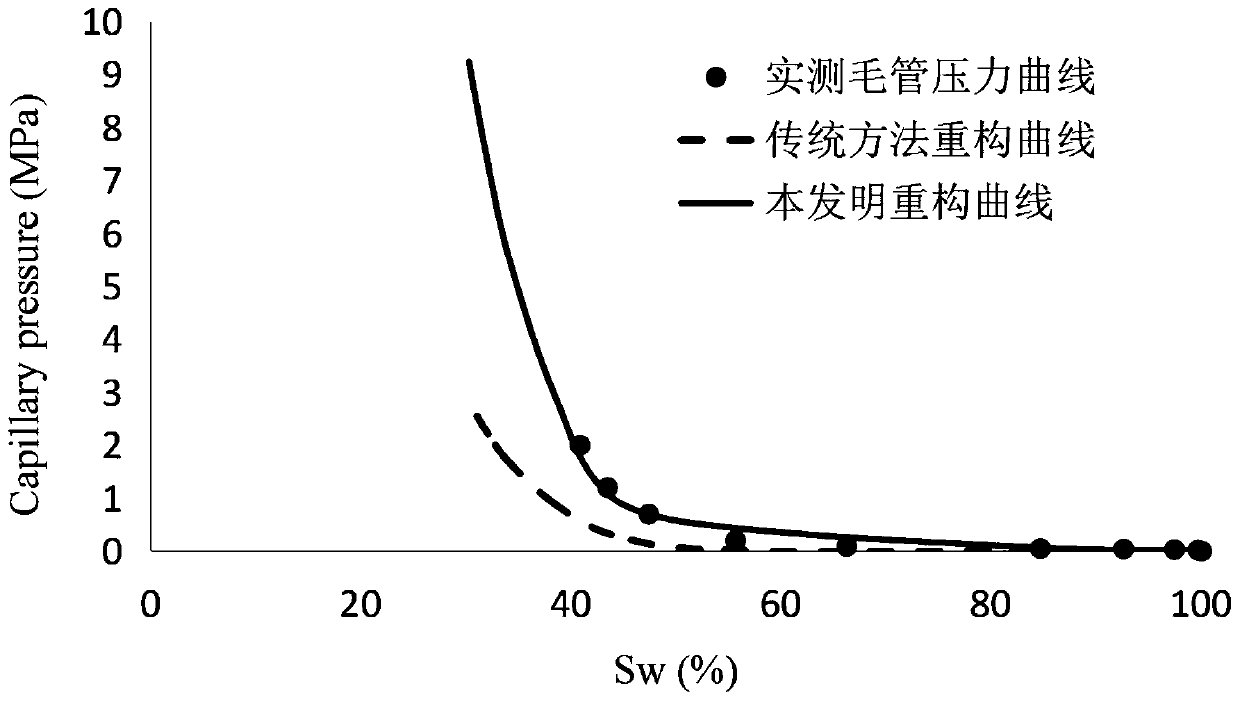

[0024] S4. Obtain the water saturation in the core sample detected by the centrifuga...

Embodiment 2

[0063] Embodiment 2 of the present invention provides a capillary pressure curve construction device, including a processor and a memory, and a computer program is stored on the memory. When the computer program is executed by the processor, the capillary pressure curve provided in embodiment 1 is realized. Construction method.

[0064] The capillary pressure curve construction device provided by the embodiment of the present invention is used to implement the capillary pressure curve construction method. Therefore, the capillary pressure curve construction device also has the technical effects of the capillary pressure curve construction method, and will not be repeated here.

Embodiment 3

[0066] Embodiment 3 of the present invention provides a computer storage medium on which a computer program is stored, and when the computer program is executed by a processor, the method for constructing a capillary pressure curve provided in Embodiment 1 is realized.

[0067] The computer storage medium provided by the embodiment of the present invention is used to implement the capillary pressure curve construction method. Therefore, the computer storage medium also has the technical effects of the capillary pressure curve construction method, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com