Hot-melt fully-sealed button cell shell and assembly process thereof

A button battery and assembly process technology, applied in battery pack parts, sealing materials, battery covers/end covers, etc., can solve problems such as bulging, sealing ring slipping, sealing structure gaps, etc., to improve production efficiency and increase assembly. Speed, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments:

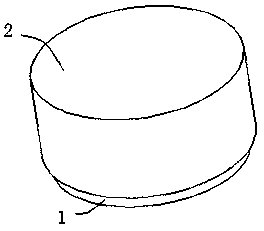

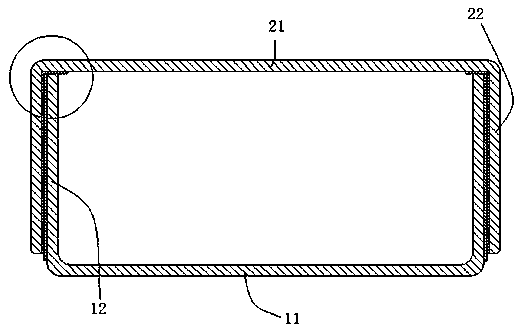

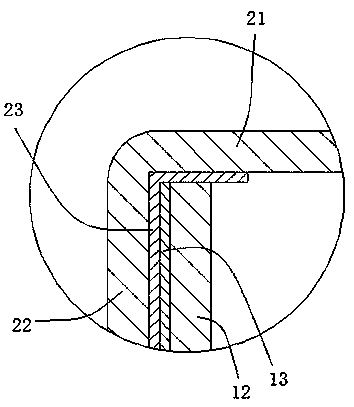

[0040] like Figure 1-5, a hot-melt fully sealed button battery case, comprising an inner case 1 and an outer case 2 covering the inner case 1 , the inner case 1 includes a bottom plate 11 and an edge arranged on the edge of the bottom plate 11 An annular first baffle 12, the housing 2 includes a top plate 21 and an annular second baffle 22 arranged on the edge of the top plate 21, the second baffle 22 surrounds the first baffle 12 The outer side of the first baffle 12 is fixedly provided with the first sealing layer 13, and the inner side of the second baffle 22 is fixedly provided with the second sealing layer. 23 , the second sealing layer 23 is against the first sealing layer 13 .

[0041] In the present invention, the battery casing is formed by the inner shell 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com