Batter stirring device for cake processing

A mixing device and batter-using technology, which is applied in the direction of mixing/kneading with vertical installation tools, structural components of mixing/kneading machines, etc., can solve problems such as waste, easy residue of flour, and human hands affecting follow-up work, etc. Achieve the effect of avoiding waste and avoiding sore hands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

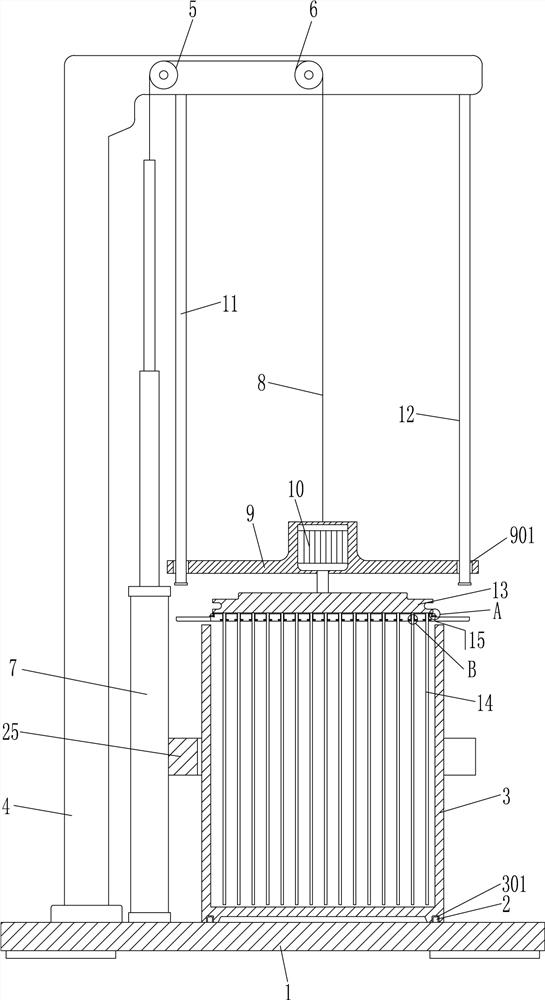

[0018] A batter stirring device for cake processing, such as Figure 1-2 As shown, it includes a bottom plate 1, a block 2, a bucket 3, a frame 4, a first pulley 5, a second pulley 6, a cylinder 7, a wire rope 8, a mounting plate 9, a motor 10, a first slide bar 11, a second pulley Two slide bars 12, stirring disc 13, stirring rod 14 and scraper plate structure 15, the left and right sides of the top of the base plate 1 are provided with blocks 2, the left side of the top of the base plate 1 is provided with a frame 4, and the base plate 1 is connected with the The frame 4 is connected, the frame 4 is located on the left side of the left block 2, the first pulley 5 and the second pulley 6 are installed on the front side of the upper part of the frame 4, the first pulley 5 is located on the left side of the second pulley 6, and the bottom plate 1 There is a cylinder 7 on the left side of the top, and the bottom plate 1 is connected to the cylinder 7 by means of bolts. The cylin...

Embodiment 2

[0020] A batter stirring device for cake processing, such as Figure 1-2 As shown, it includes a bottom plate 1, a block 2, a bucket 3, a frame 4, a first pulley 5, a second pulley 6, a cylinder 7, a wire rope 8, a mounting plate 9, a motor 10, a first slide bar 11, a second pulley Two slide rods 12, stirring disc 13, stirring rod 14 and scraper plate structure 15, the top left and right sides of the bottom plate 1 are provided with blocks 2, the left side of the top of the bottom plate 1 is provided with a frame 4, and the frame 4 is located at the left block On the left side of 2, a first pulley 5 and a second pulley 6 are installed on the front side of the upper part of the frame 4, the first pulley 5 is located on the left side of the second pulley 6, the left side of the bottom plate 1 is provided with a cylinder 7, and the cylinder 7 is located on the frame 4 and the left block 2, the top of the expansion rod of the cylinder 7 is provided with a wire rope 8, the wire rop...

Embodiment 3

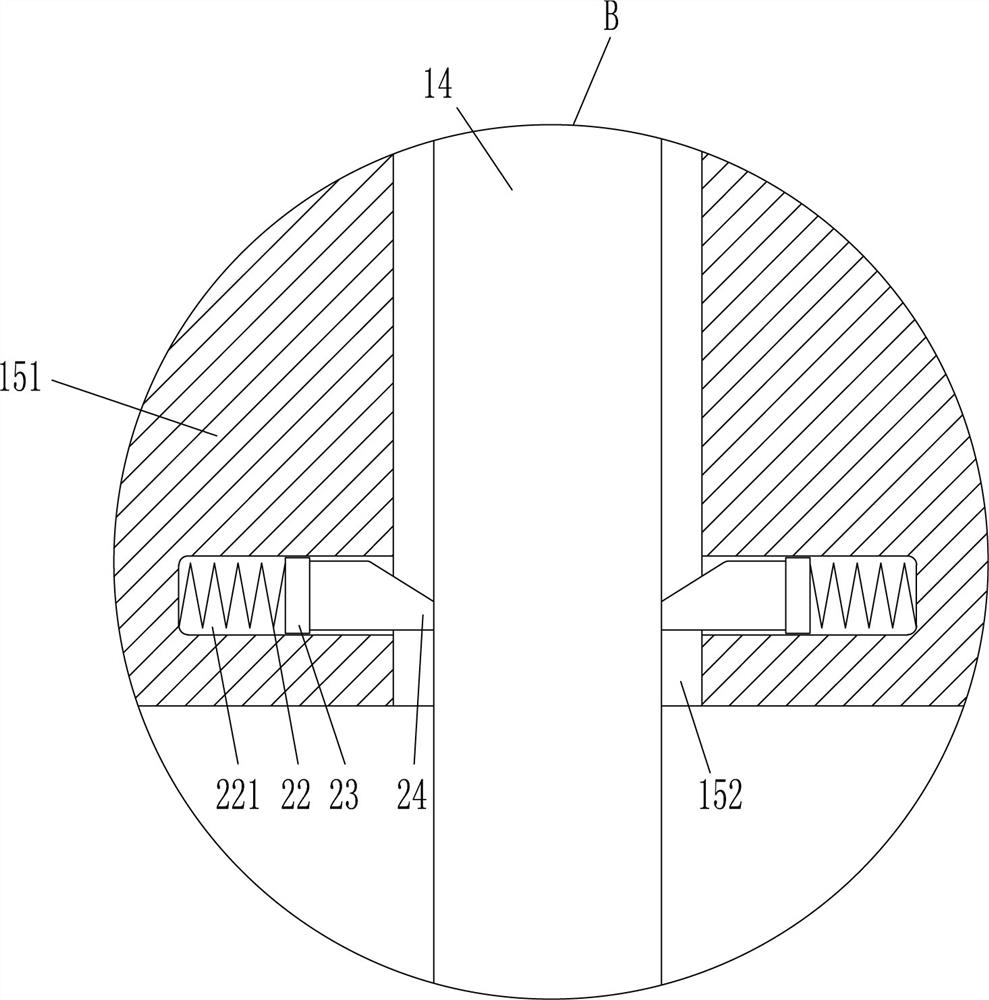

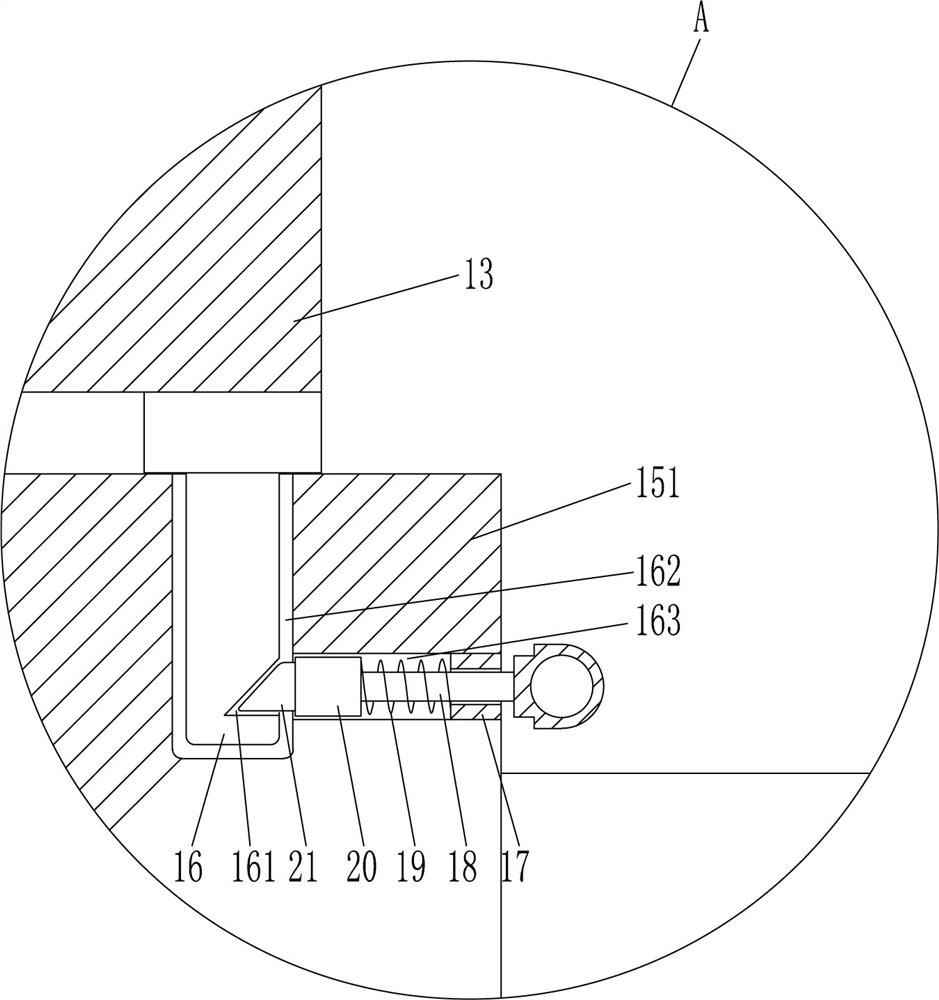

[0023] A batter stirring device for cake processing, such as Figure 1-3 As shown, it includes a bottom plate 1, a block 2, a bucket 3, a frame 4, a first pulley 5, a second pulley 6, a cylinder 7, a wire rope 8, a mounting plate 9, a motor 10, a first slide bar 11, a second pulley Two slide rods 12, stirring disc 13, stirring rod 14 and scraper plate structure 15, the top left and right sides of the bottom plate 1 are provided with blocks 2, the left side of the top of the bottom plate 1 is provided with a frame 4, and the frame 4 is located at the left block On the left side of 2, a first pulley 5 and a second pulley 6 are installed on the front side of the upper part of the frame 4, the first pulley 5 is located on the left side of the second pulley 6, the left side of the bottom plate 1 is provided with a cylinder 7, and the cylinder 7 is located on the frame 4 and the left block 2, the top of the expansion rod of the cylinder 7 is provided with a wire rope 8, the wire rop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com