Environment-friendly crusher mining machine

A crusher, an environmentally friendly technology, applied in the field of mining machinery, can solve the problems of high incidence of occupational diseases, low crushing efficiency, and increased production costs, so as to increase safety and environmental protection, improve crushing efficiency, and increase screening speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

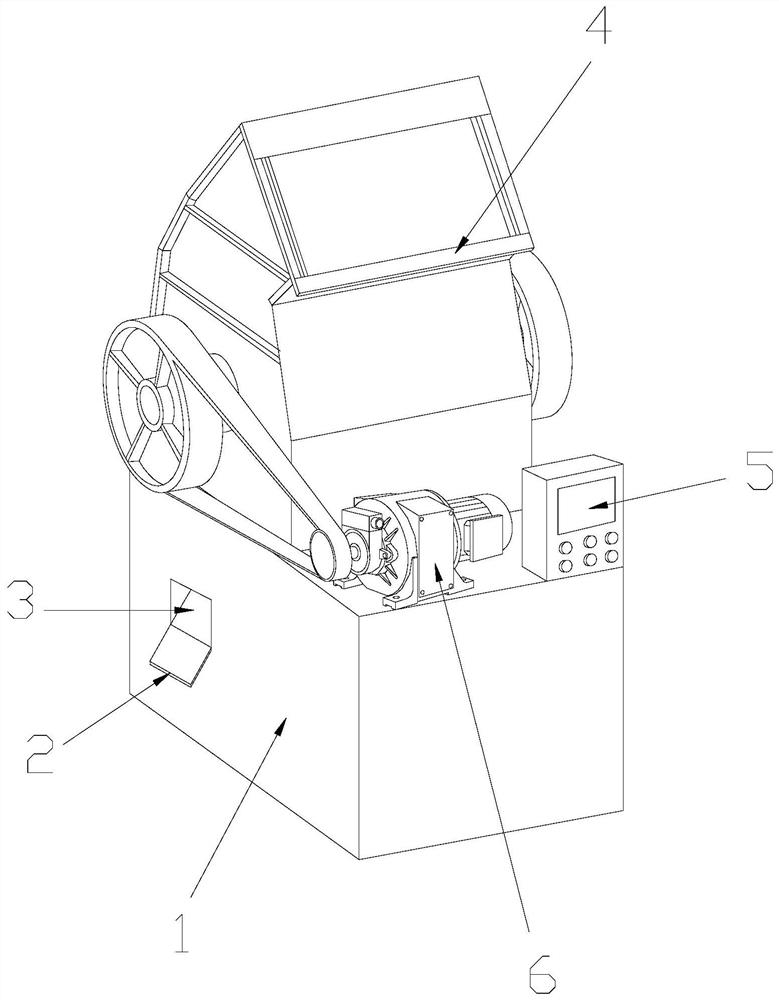

[0027] see Figure 1-Figure 3 , the present invention provides an environmentally friendly crusher mining machine, the structure of which includes a bracket 1, a material guide plate 2, a discharge port 3, a crusher 4, an electric controller 5, and a power device 6. The bottom of the crusher 4 is There is a bracket 1 under the end, the crusher 4 and the bracket 1 are welded by electric welding, the surface of the bracket 1 is provided with a discharge port 3, and a material guide plate 2 is provided under the discharge port 3, so that The material guide plate 2 is fixedly connected with the support 1, the top of the support 1 is provided with a power device 6, the support 1 is connected with the power device 6, and the power device 6 is connected with the crusher 4 in transmission, An electric controller 5 is installed on the top of the bracket 1;

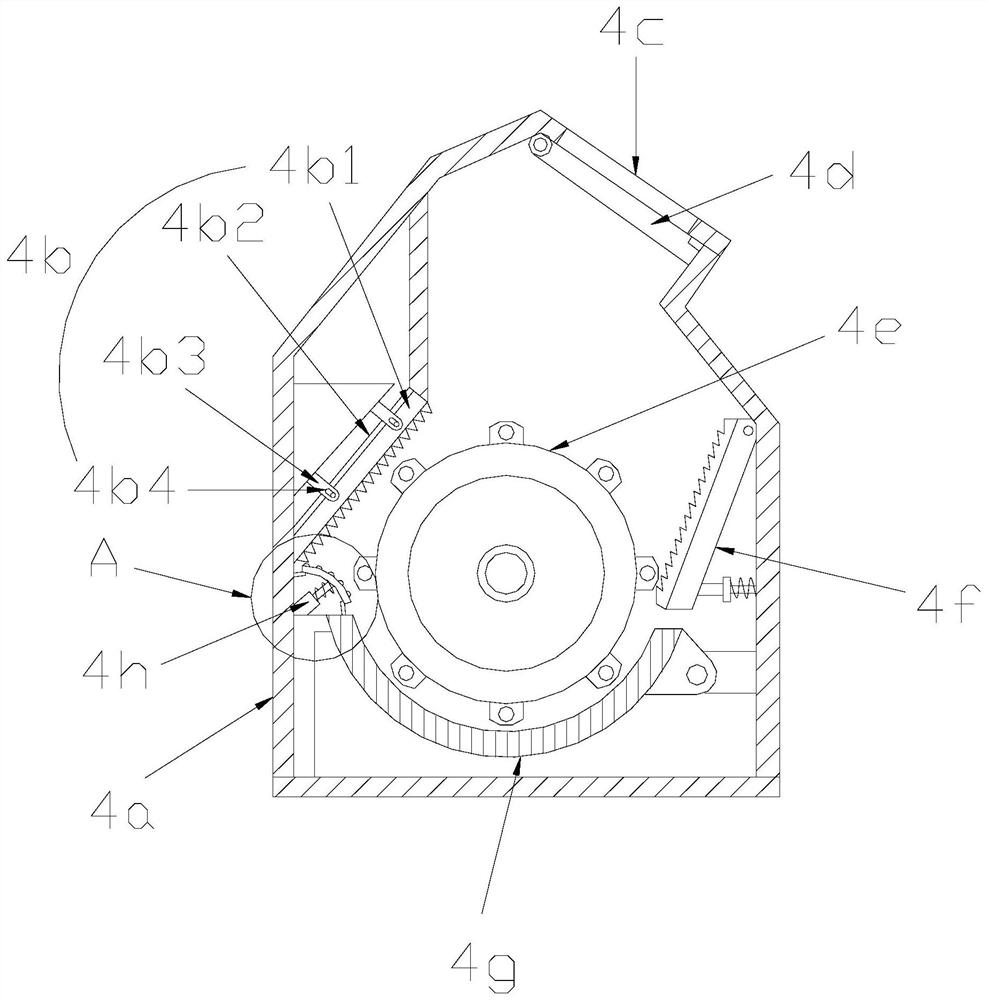

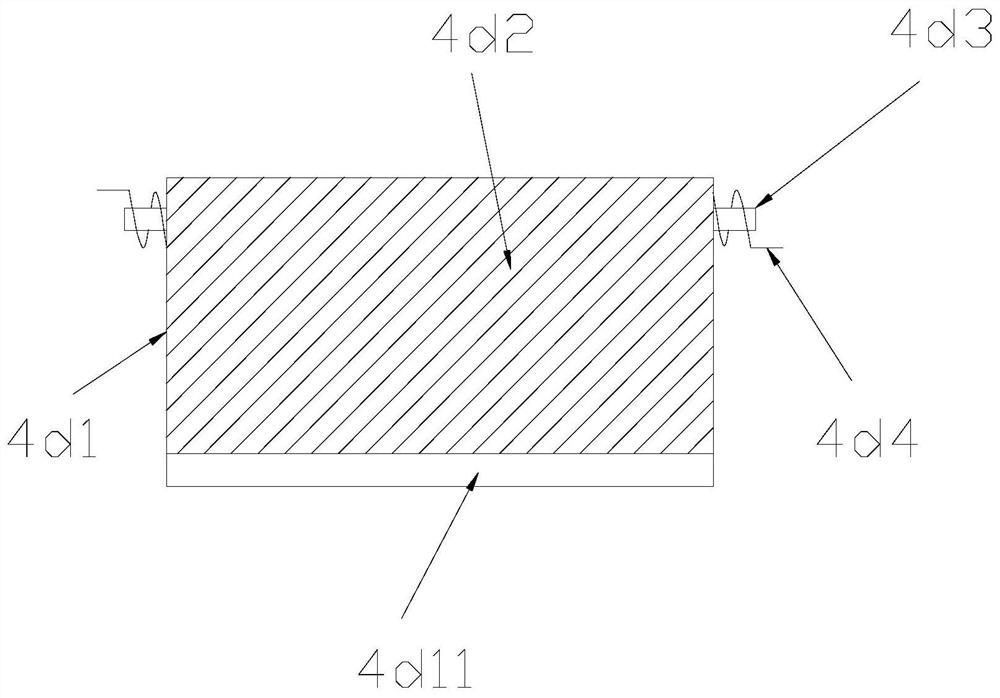

[0028] The crusher 4 is composed of a body 4a, a secondary auxiliary crushing mechanism 4b, a feed port 4c, a splash guard 4d, a...

Embodiment 2

[0035] see Figure 1-Figure 5 , the present invention provides an environment-friendly crusher mining machine. The sliding screening mechanism 4g is composed of a screen bracket 4g1, a sliding support plate 4g2, a screen 4g3, a movable slider 4g4, and a connecting rod 4g5. A screen 4g3 is installed on the inner side of the screen support 4g1, and a sliding support plate 4g2 is provided under the left end of the screen support 4g1, and the sliding support 4g1 and the sliding support plate 4g2 are slidably matched, and the right end of the screen support 4g1 is A movable slider 4g4 is arranged on it, and one end of the screen bracket 4g1 is fixedly connected with the movable slider 4g4, and the other end of the movable slider 4g4 is provided with a connecting rod 4g5, and the movable slider 4g4 is connected with the connecting rod 4g5 slip fit.

[0036] The pop-up mechanism 4h is composed of a telescopic sleeve 4h1, a telescopic support rod 4h2, a pop-up plate 4h3, and a coil s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap