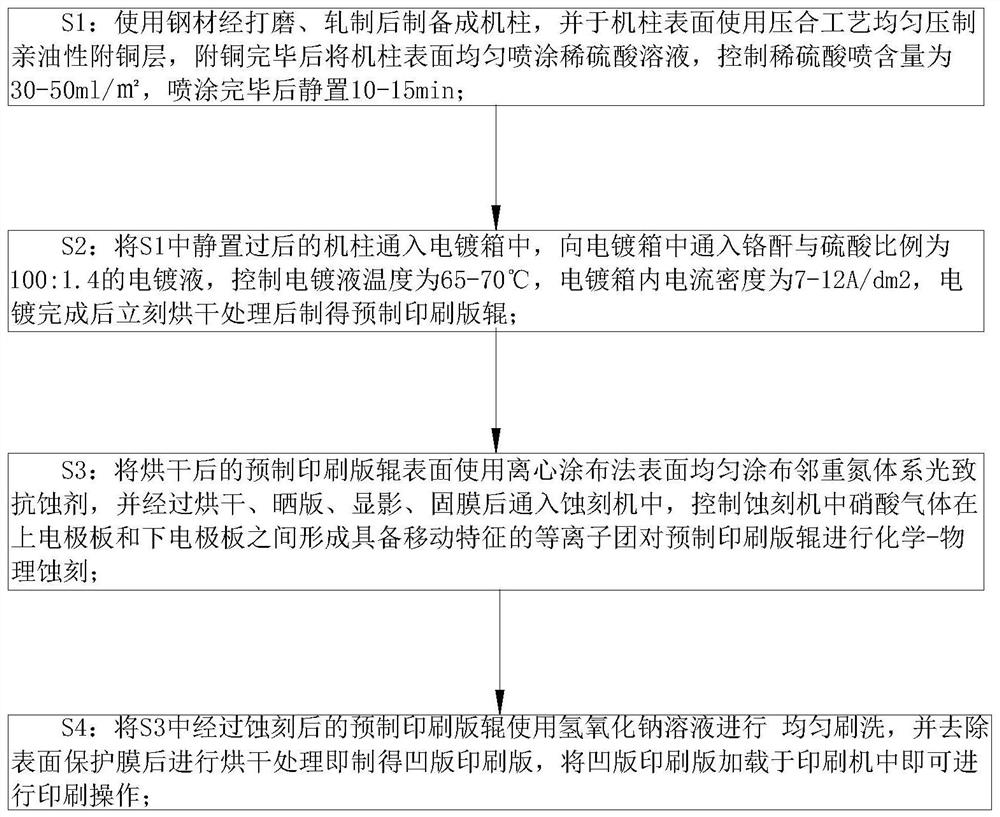

Gravure printing plate and manufacturing method of gravure printing plate

A manufacturing method and printing plate technology are applied in the manufacturing field of gravure printing plates and gravure printing plates, which can solve the problems of different active degree etching uniformity, poor etching effect, different chemical gas flow rates, etc. Good uniformity, enhance the effect of etching uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

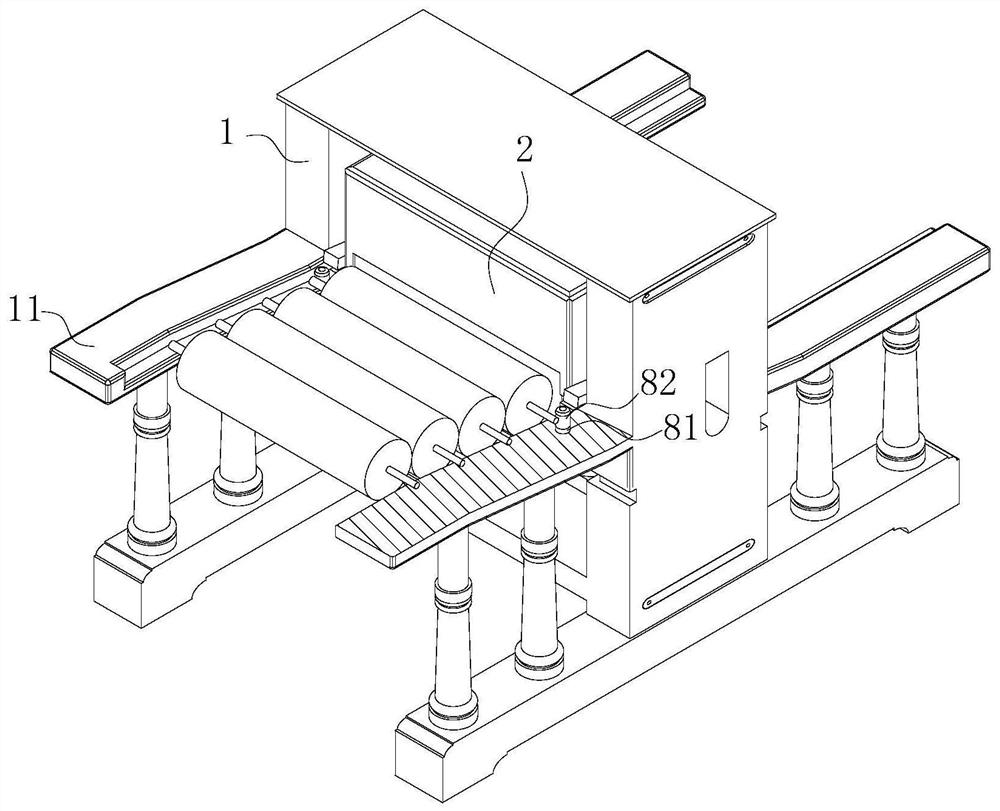

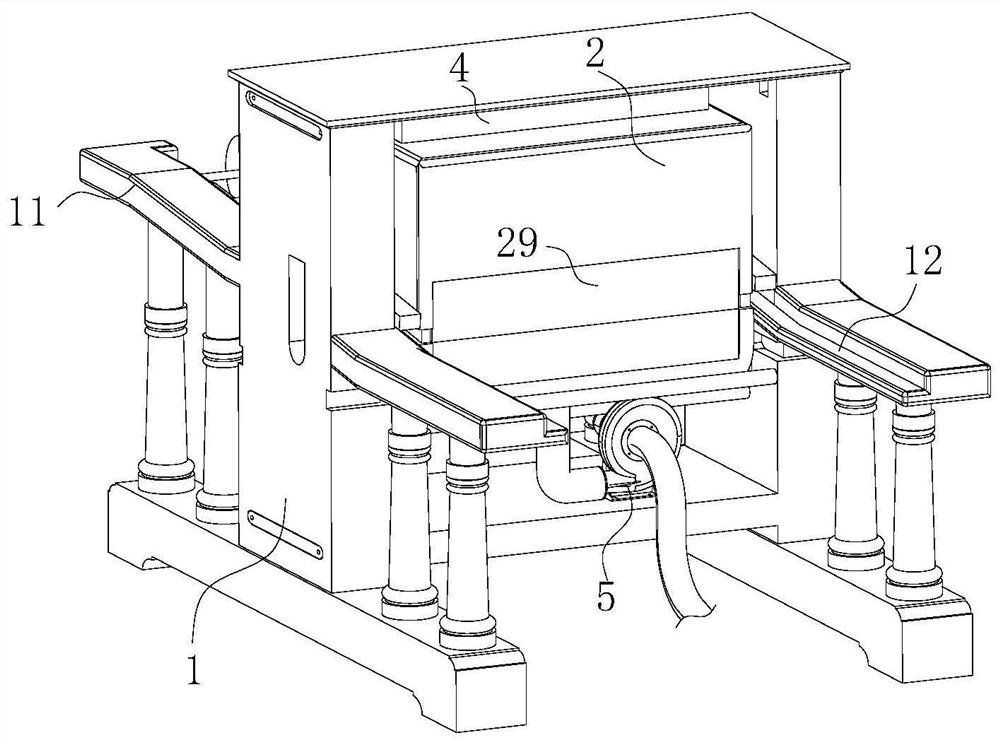

Examples

Embodiment approach

[0036] As an embodiment of the present invention, the first deflector 32 and the second deflector 33 are combined to form an inclined tuyere for stabilizing the rotation direction of the printing plate roll; the first deflector 32 and the second deflector The two deflectors 33 converge the ion flow with acceleration between the upper electrode plate 3 and the lower electrode plate 31, and wash it on the printing plate roller, so that the printing plate roller is subjected to impact force, but due to the vertical impact, not only the impact area is small but also It is not easy to make the printing plate roll form a regular rotation. During work, adjust the inclination angle of the first deflector 32 and the second deflector 33, and then make the direction of the guide through the first deflector 32 and the second deflector 33 The impact between the plasma flow and the printing plate roller is inclined, so that the force of the plasma flow on the printing plate roller is in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com