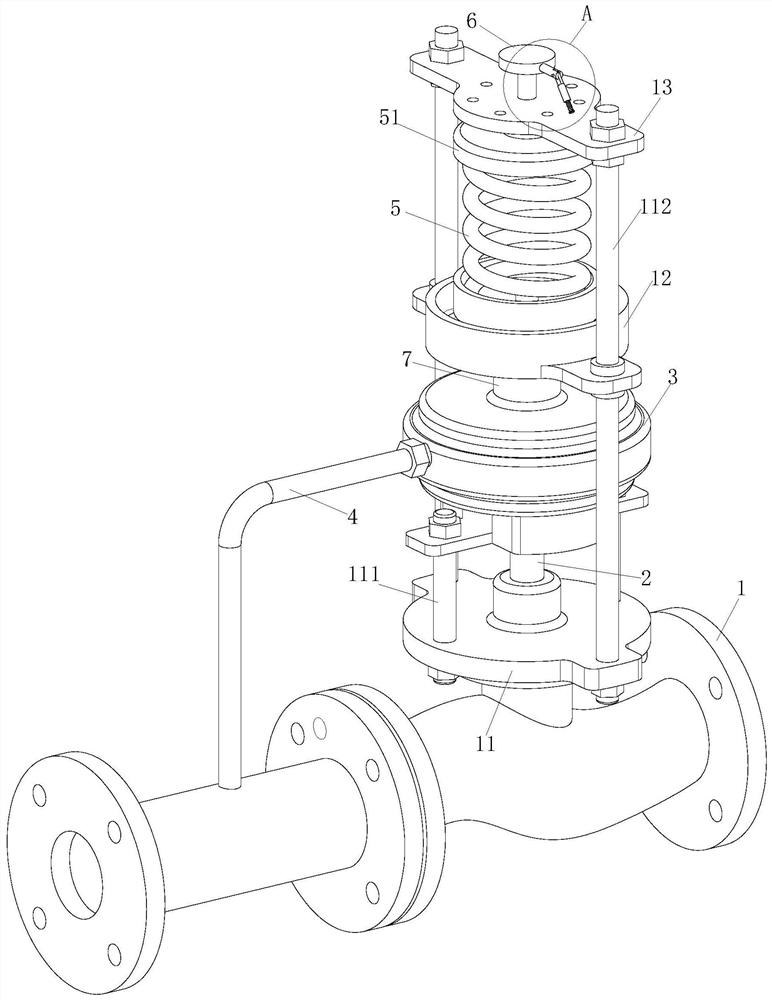

Supermicro-pressure self-operated pressure regulating valve

A pressure-regulating, self-operated technology, applied in the field of regulating valves, can solve problems such as the limitation of the adjustment angle of the regulating seat, and achieve the effect of increasing the sticking extrusion force, convenient adjustment and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

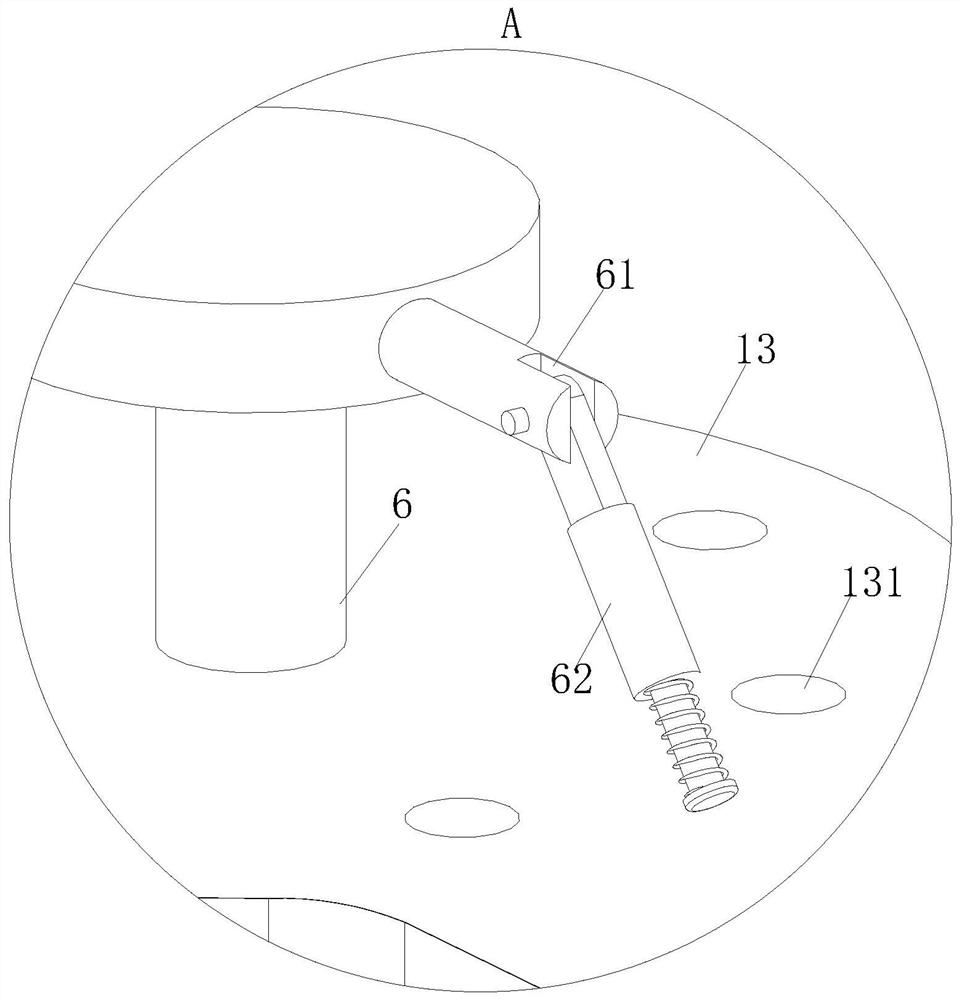

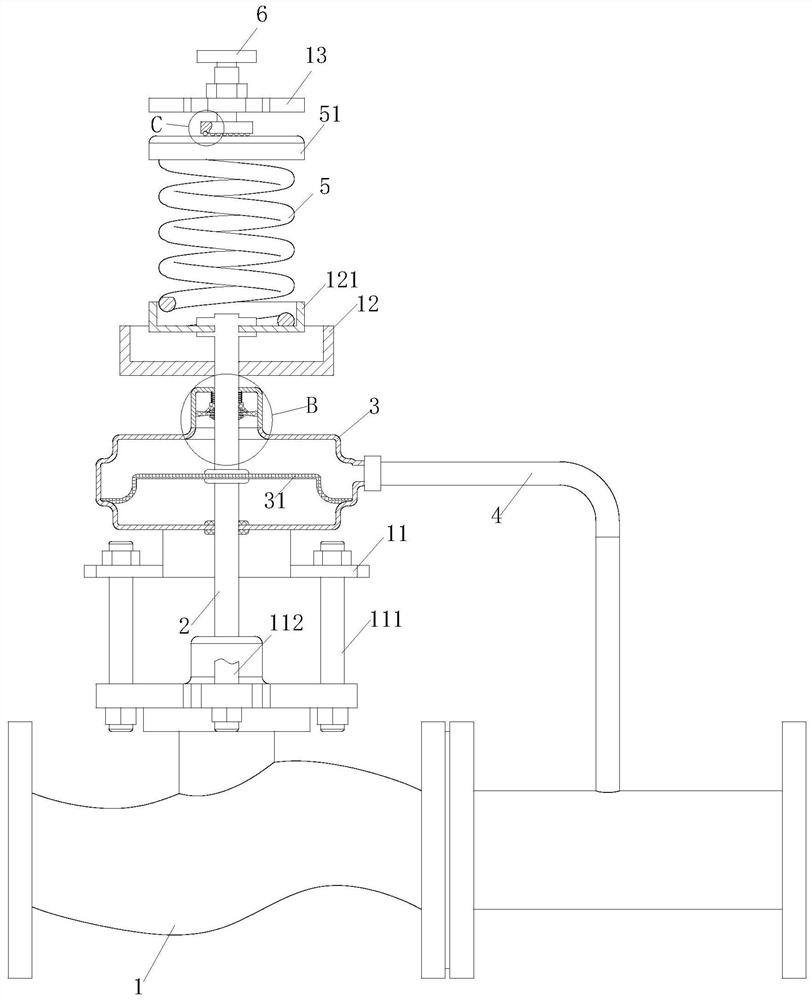

[0025] As a specific embodiment of the present invention, a sealing unit 7 is provided between the actuator 3 and the No. 1 pallet 12; the sealing unit 7 includes a housing 71, a No. 1 rubber ring 72 and a retaining ring 73; The lower end of the casing 71 is fixedly connected to the upper end surface of the actuator 3, and the outer ring of the valve stem 2 located in the casing 71 is provided with a No. 1 rubber ring 72, and the cut surface of the No. 1 rubber ring 72 is M-shaped. The recess of the ring 72 is attached to the inner ring of the retaining ring 73, and the outer ring of the retaining ring 73 is fixed on the inner side wall of the housing 71; the seal between the valve stem 2 and the actuator 3 is realized through the sealing unit 7; Place the No. 1 spring 5 on the upper end of the actuator 3, so that the upper end of the valve stem 2 slides up and down through the upper end of the actuator 3, and the cavity enclosed by the membrane 31 in the actuator 3 and the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com