Double-working-condition gas generator propellant grain

A technology of gas generating agent and dual working conditions, which is applied in the direction of ammunition, projectiles, weapon accessories, etc., can solve the problems of large volume, inconvenient transportation and mobile launch, and achieve low solid particle content, long trend duration, and surface slowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below with reference to accompanying drawing, illustrate the embodiment of the double working condition gas generant grain column related to the invention.

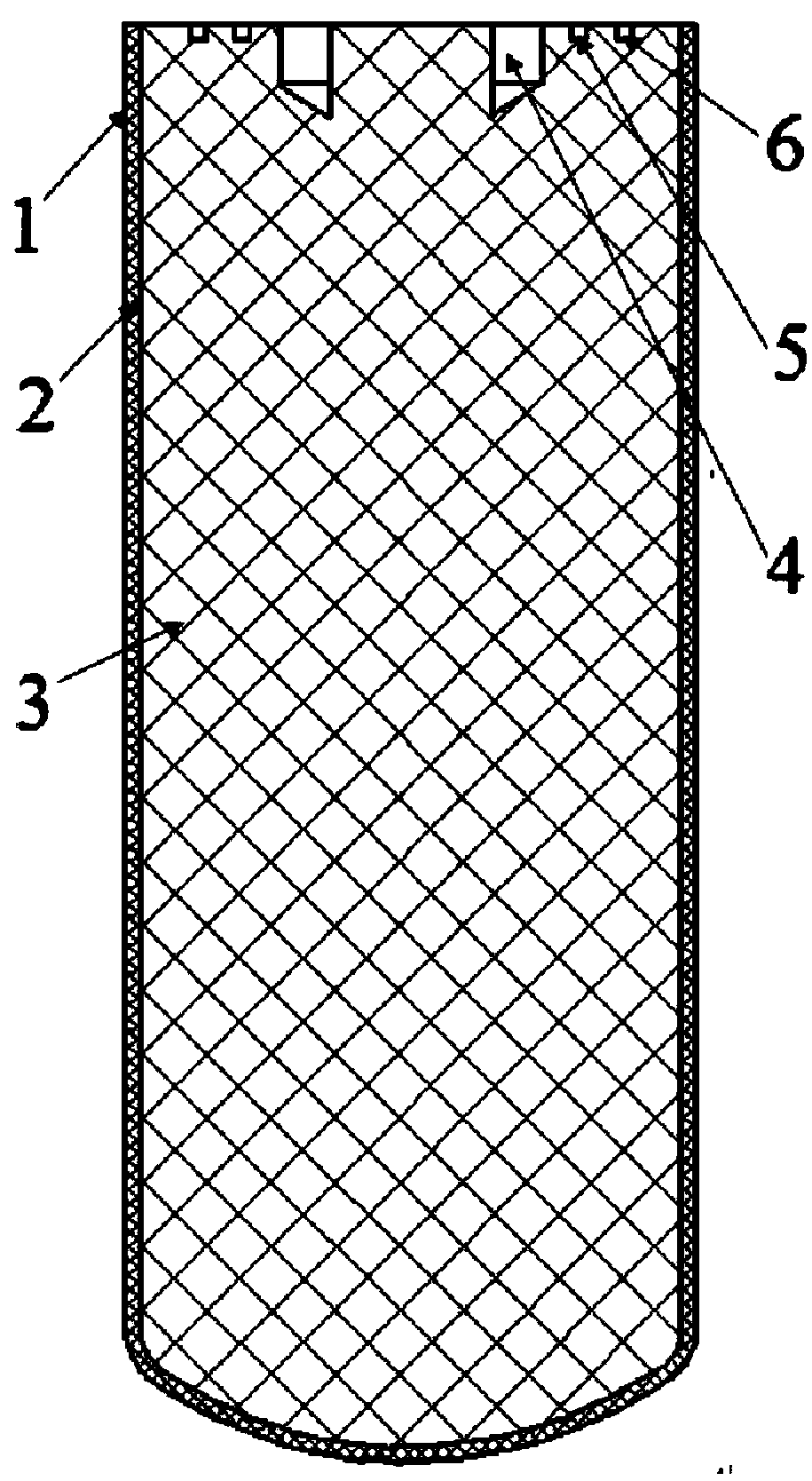

[0029] see figure 1 , a double-working condition gas generating agent powder column, the gas generating agent 3 is installed in the coating sleeve 1, and the middle part of the surface of the gas generating agent 3 is provided with a pointed combustion-supporting groove 4, and the outer sides of the pointed-shaped combustion-supporting groove 4 are successively An inner ring combustion-supporting groove 5 and an outer ring combustion-supporting groove 6 are provided, and a liner 2 is provided at the side of the gas generating agent 3 in contact with the coating sleeve 1 .

[0030] In this embodiment, the gas generating agent 3 is poured into the coating sleeve 1, and the high-burning rate drug rod is placed in the gas generating agent 3. The surface of the gas generating agent is provided with a pointed combustion-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com