Burner and gas range using the same

A technology for burners and gas stoves, which is applied in the direction of burners, gas fuel burners, combustion methods, etc., and can solve problems such as difficult and small burners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, this invention is not limited to the specific example based on the following embodiment.

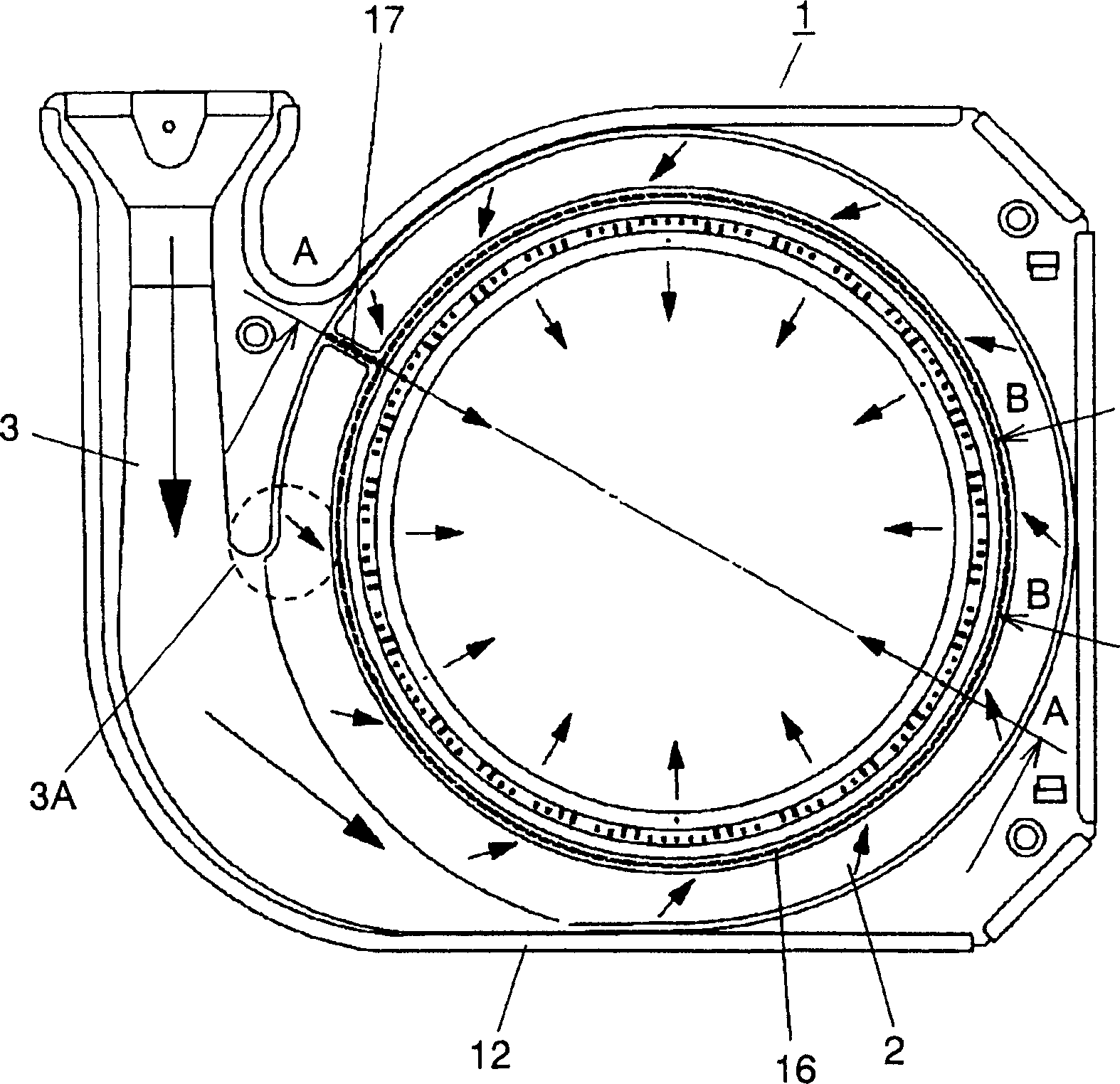

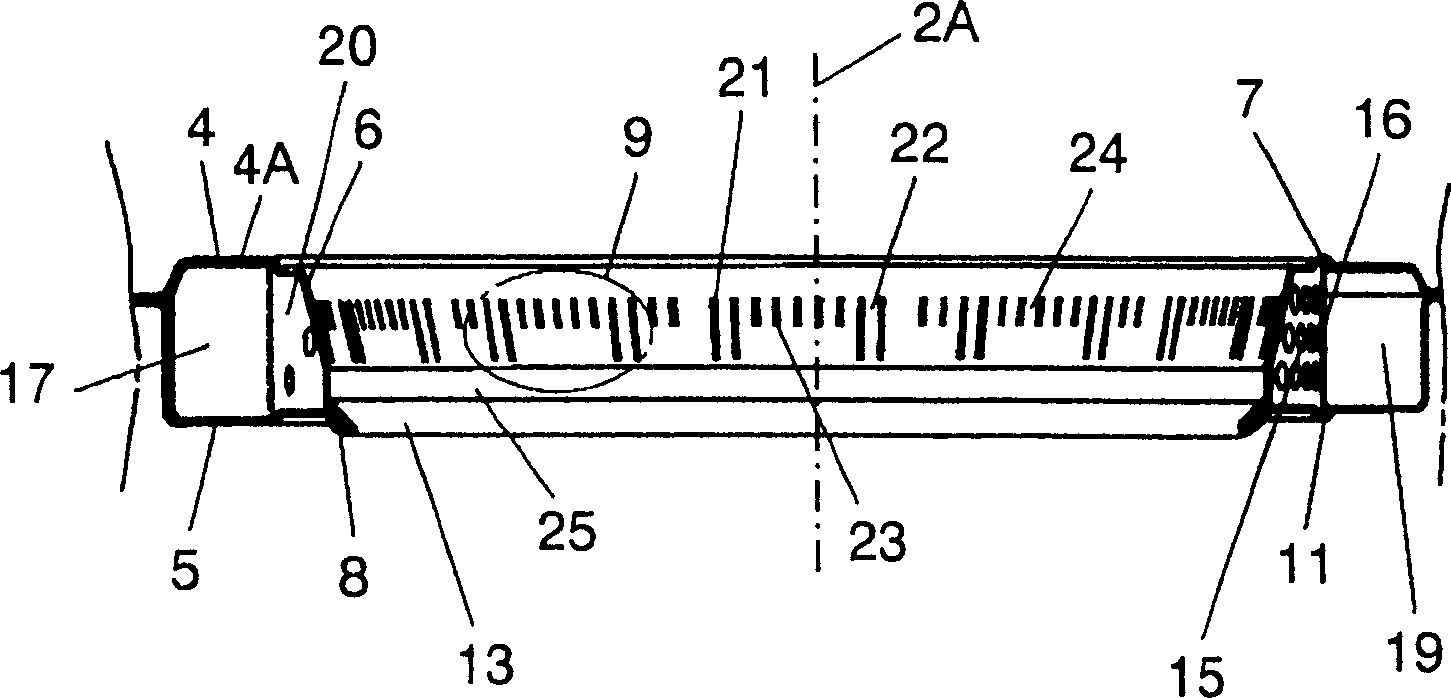

[0045] figure 1 It is a plan view of a burner according to an embodiment of the present invention; figure 2 yes figure 1 Sectional view of line A-A; Figure 3A , Figure 3B They are respectively the top view and the side view of the rectifying body and the blocking body (resistance body). Figure 4A , Figure 4B They are the expansion diagram of the rectifier body and the barrier body and the configuration diagram of the stamping die; Figure 5 yes figure 1 The expanded cross-sectional view of B-B part of .

[0046] The burner 1 is made of a material excellent in heat resistance and corrosion resistance represented by austenitic stainless steel such as SUS304, SUS316, and SUS321, or ferritic stainless steel such as SUS430 and SUS436. The burner 1 is formed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com