A control method based on standardization-based split-type high-precision liquid cooling source system

A liquid cooling source, high-precision technology, used in coolers, household refrigeration devices, cooling fluid circulation devices, etc., can solve the problem of not meeting the temperature accuracy requirements of external equipment, unable to meet the target temperature temperature accuracy control, affecting compressor life, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

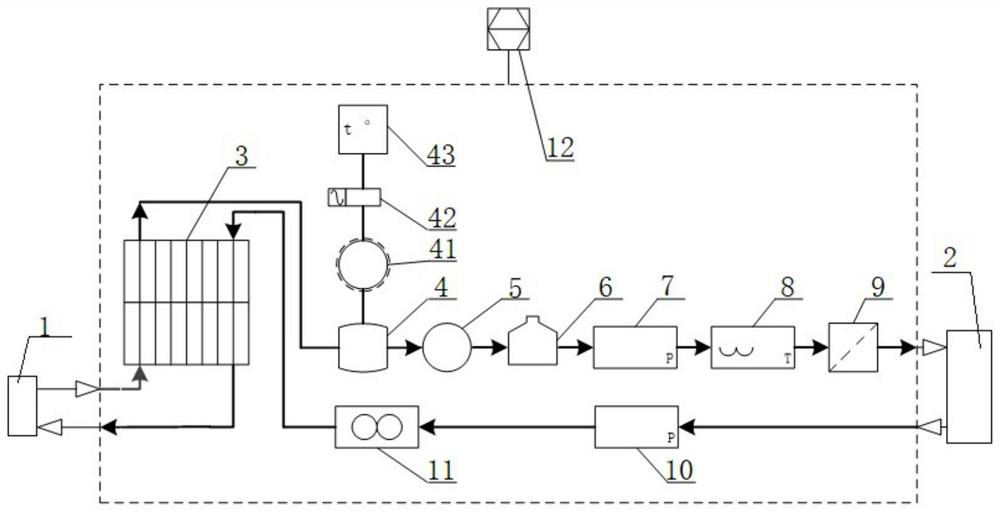

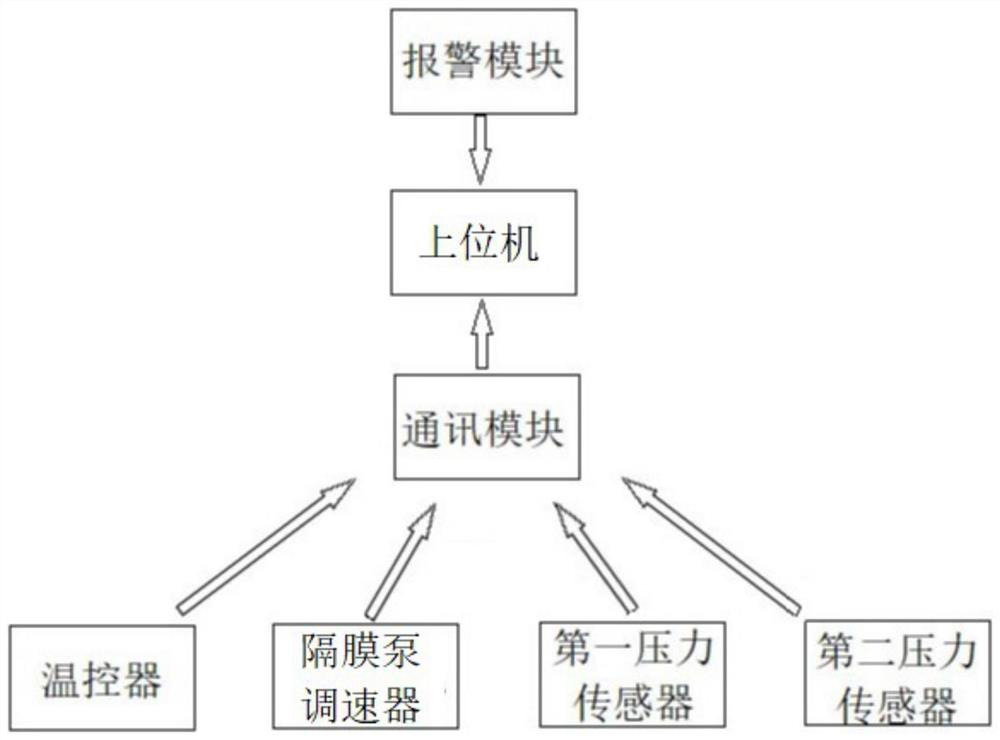

[0030]Embodiment: A method for regulating and controlling a split high-precision liquid cooling source system based on standardization, including the following steps:

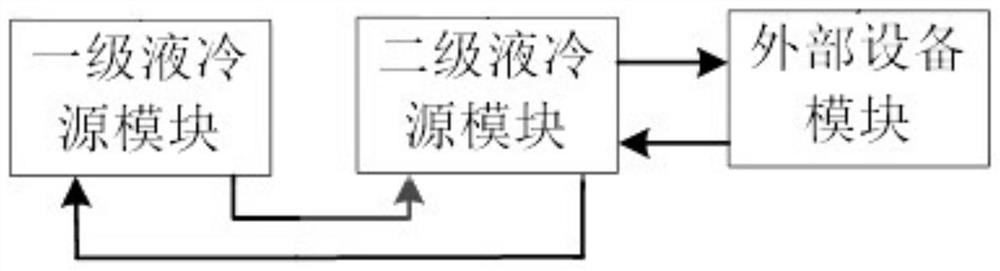

[0031]Step 1: Configure the secondary liquid cooling source module for temperature control for the external equipment module, configure the primary liquid cooling source module for the cooling cycle working medium of the secondary liquid cooling source module, and configure the primary liquid cooling source module for the secondary liquid cooling source The cooling cycle of the module is cooled down according to the target temperature T of the external device module0, Set the temperature of the secondary liquid cooling source module to T0, The set temperature of the primary liquid cooling source module is less than the set temperature of the secondary liquid cooling source module, set to T1, Initial setting △T=T0-T1=3;

[0032]Step 2: After the initial temperatures of the first-level liquid cooling source module and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com