3D printer and printing method thereof

A 3D printer and print head technology, applied in the field of 3D printing, can solve problems such as deformation, cracking and warping of printed workpieces, and achieve the effects of high density, extended service life, and easy temperature accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

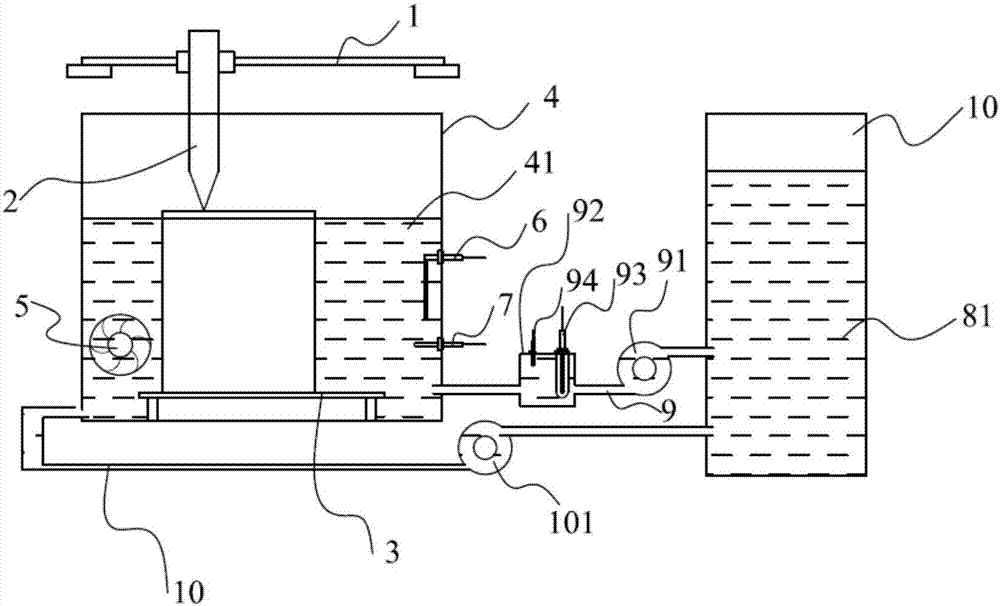

[0039] The second embodiment of the present invention provides a printing method of the above-mentioned 3D printer: obtain the 3D model of the printing workpiece through self-built model or 3D scanning. Import the 3D model of the printed workpiece into slicing software to perform slicing operations, and transmit the generated code to the above-mentioned 3D printer. The heated liquid is injected into the high-temperature printing container, so that the bottom surface of the printing platform is immersed in the high-temperature liquid in the high-temperature printing container, and the top surface of the printing platform exposes the liquid surface of the high-temperature liquid. The moving platform drives the print head to perform single-layer printing on the printing platform to obtain the first layer of printed pattern layer, and to perform single-layer printing on the top of the obtained first layer of printed pattern layer to obtain the second layer of printed pattern layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com