A control method for adjusting the amount of fuel into the boiler by using the oxygen content signal of the flue gas

A flue gas oxygen content and signal adjustment technology, which is applied in the direction of adjusting fuel supply, combustion method, and control of combustion, can solve problems such as poor anti-disturbance ability, single control loop, and simple model, so as to improve safety and stability The effects of improving performance, improving response speed, and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] It should be pointed out that the following detailed description is intended to provide further explanation to the application, and the terms used are only for describing specific implementations, and are not intended to limit the exemplary implementations based on the application.

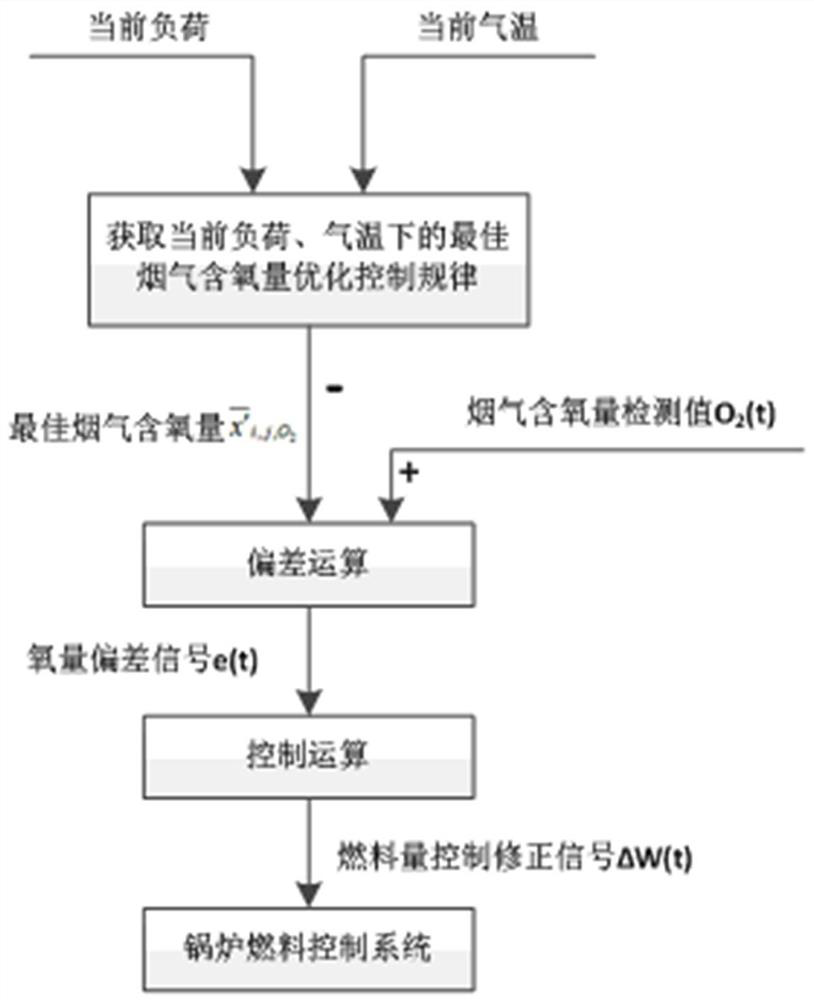

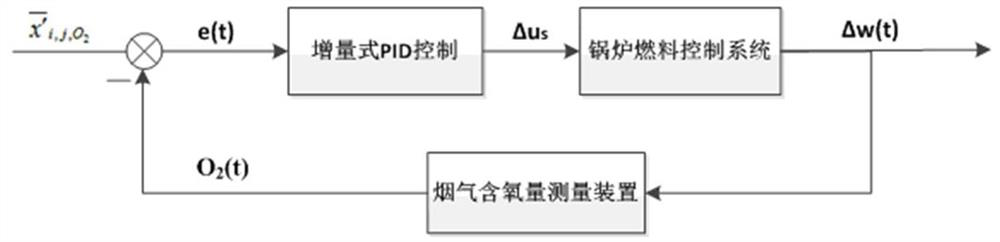

[0066] figure 1 and figure 2 As shown, the present invention relates to a method for controlling the amount of fuel fed into the boiler by using the flue gas oxygen content signal, comprising the following steps:

[0067] 1) Establish a control law that is better than the optimization target according to the distribution of load and temperature:

[0068] ① Obtain historical operation data of coal-fired units:

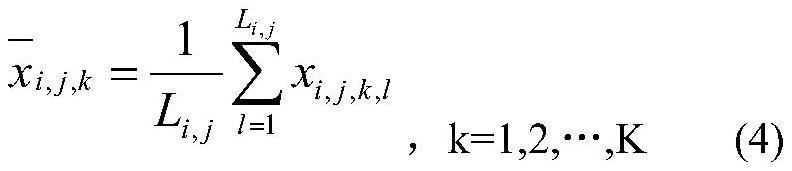

[0069] 1a. Determine the parameter x extracted from the DCS historical database k , the parameter types include: actual load, total fuel volume, fuel volume of coal feeders in each layer, primary air volume of coal pulverizers in each layer, total amount of secondary air, opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com