MIG/MAG electric-arc motion track control method

A technology of motion trajectory and control method, which is applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of asymmetric melting of welding pool, poor anti-interference ability, large randomness, etc., and achieve changing crystallization direction, Improving the quality of weld seam and suppressing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

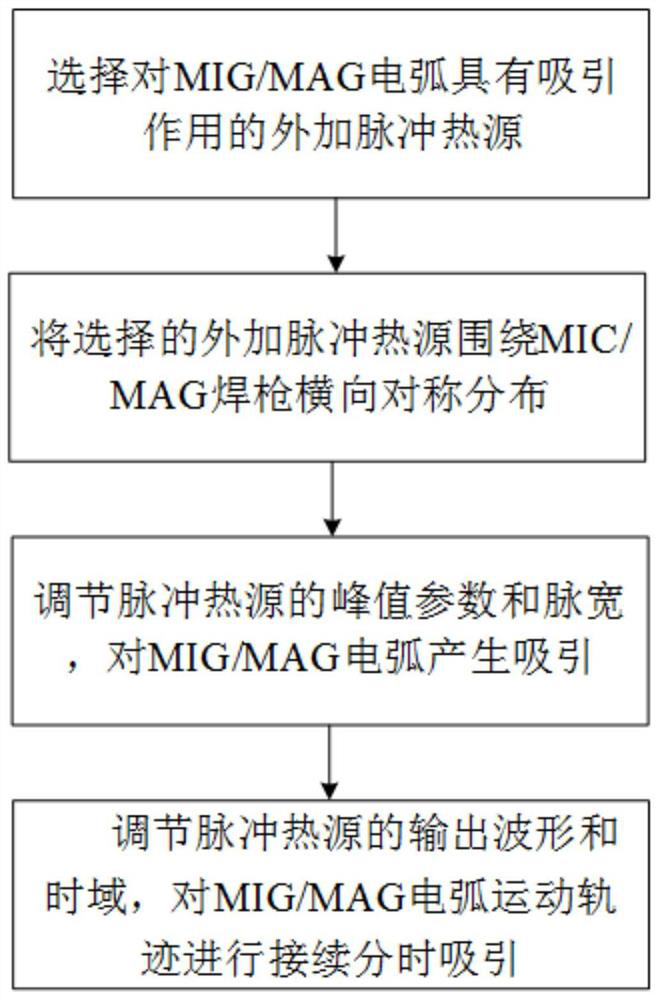

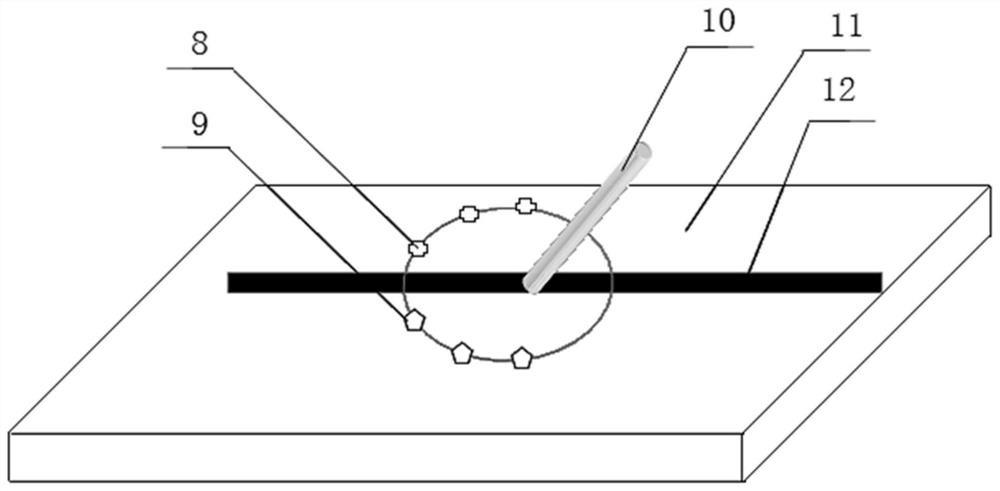

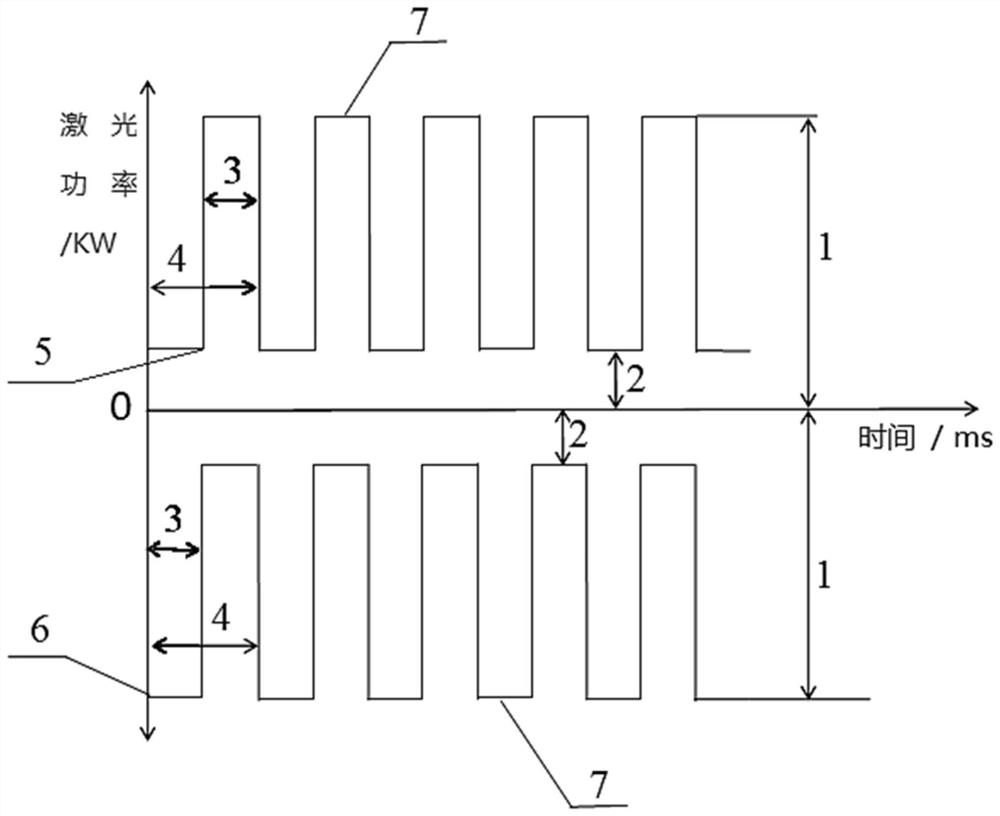

[0024] The invention relates to a MIG / MAG arc motion trajectory control method. During welding, the MIG / MAG arc motion trajectory is controlled by the action point of a pulse heat source, and the time-sharing output characteristics of the pulse heat source are used to adjust the MIG / MAG arc motion trajectory. , according to the number, position and pulse parameters of the external pulse heat source, the precise control of the MIG / MAG arc motion trajectory can be realized. The specific technical steps of the method include:

[0025] Step 1. Select an external pulse heat source that has an attractive effect on the MIG / MAG arc. The number of additional pulse heat sources includes 2, 4 or 6. The number of heat sources is selected according to the hardware conditions and the accuracy of the arc motion trajectory. The greater the number of heat sources, the higher the control accuracy of the arc motion trajectory. Pulsed heat sources can be lasers, plasmas or electron beams.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com