One-button seeding machine and work method thereof

A working method and seeder technology, which is applied in the direction of interval quantitative sowing machinery, planting methods, and seeder parts, can solve the problems of wasting seeds and inability to achieve precise seeding, and achieve the effect of avoiding the phenomenon of multi-seeding and missing seeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

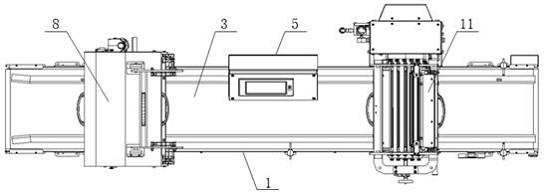

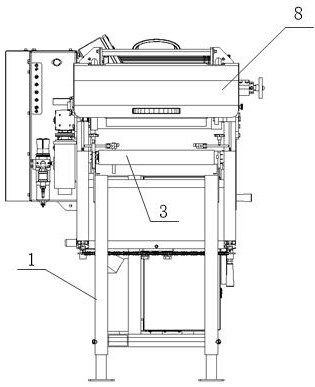

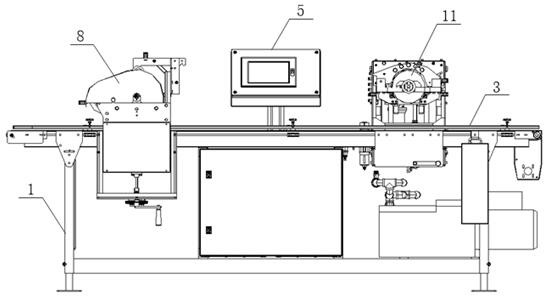

[0042] Such as Figure 1-8 As shown, this embodiment provides a one-button planter, including a frame 1, a tray 2 and a control mechanism, the frame 1 includes a conveyor belt 3, a substrate pressing hole unit arranged at the front end, and a The vacuum seeding unit at the end, the tray 2 includes a number of storage compartments, the storage compartments store substrates, the control mechanism includes a processor 4, a touch device 5, a drive device 6 and a data storage device 7, the Processor 4 is respectively connected with described touch control device 5, driving device 6 and data storage device 7, and described data storage device 7 is used for storing different sowing programs, and described sowing program comprises tray 2 model, seed type and vacuum For the parameters of the pressure value, the touch device 5 is external, and the operator edits and saves the parameters through the touch device 5;

[0043] The conveyor belt 3 is connected to the driving device 6 for tr...

Embodiment 2

[0057] Such as Figure 1-7 , 9, the present embodiment provides a working method of a one-button planter, including the following working steps:

[0058] S101: The processor 4 outputs a transmission signal to the driving device 6, and the driving device 6 drives the conveyor belt 3 to start;

[0059] S102: The processor 4 outputs a first rolling signal to the driving device 6, and the driving device 6 drives the first electric drum 8 to start;

[0060] S103: the processor 4 outputs a second rolling signal to the driving device 6, and the driving device 6 drives the second electric drum 11 to start;

[0061] S104: The processor 4 outputs an adsorption signal to the driving device 6, and the driving device 6 drives the vacuum nozzle 12 to start;

[0062] S105: the electromagnetic valve sensing device 10 senses the position of the tray 2 and sends a corresponding sensing signal to the processor 4;

[0063] S106: The processor 4 determines whether the tray 2 enters under the se...

Embodiment 3

[0081] Such as Figure 8 As shown, when replacing a different type of tray 2, the operator sets a new seeding program in the data storage device 7, and the processor 4 sets the spacing of the punching nails 9 according to the new tray 2 model;

[0082] The processor 4 calculates the moving distance of each electric slider 16 , and outputs a movement signal to the driving device 6 , and the driving device 6 drives each electric slider 16 to move a corresponding distance.

[0083] Specifically, when different types of trays 2 are replaced, the size of the storage compartment of the tray 2 also changes, and parameters such as the rotational speed of the first electric drum 8, the distance between the punching nails 9, and the rotational speed of the second electric drum 11 need to be changed. .

[0084] The operator only needs to change the parameter of the model of the tray 2 in the seeding program, and the processor 4 automatically modifies the parameters such as the rotationa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com