Texture depth gradual change process

A technology of texture depth and craftsmanship, applied in coatings, devices for coating liquids on surfaces, special surfaces, etc., can solve the problems of multi-time, complex process and high risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

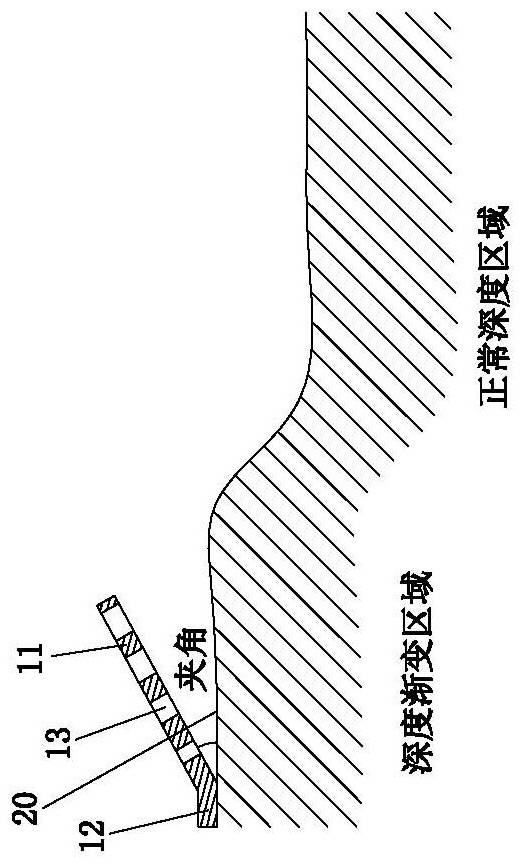

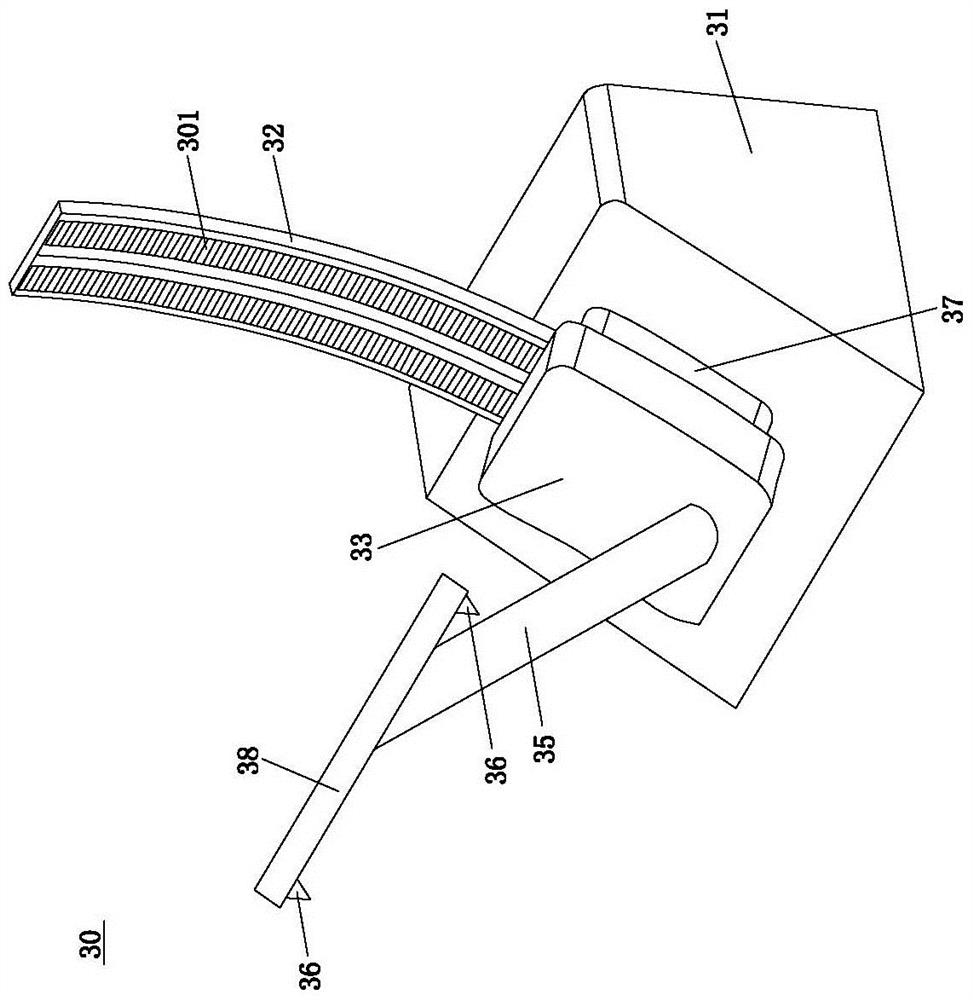

[0034] Please refer to Figure 1 to Figure 4 As shown, it shows the specific structure of the embodiment of the present invention.

[0035] A texture depth gradient process, comprising the steps of:

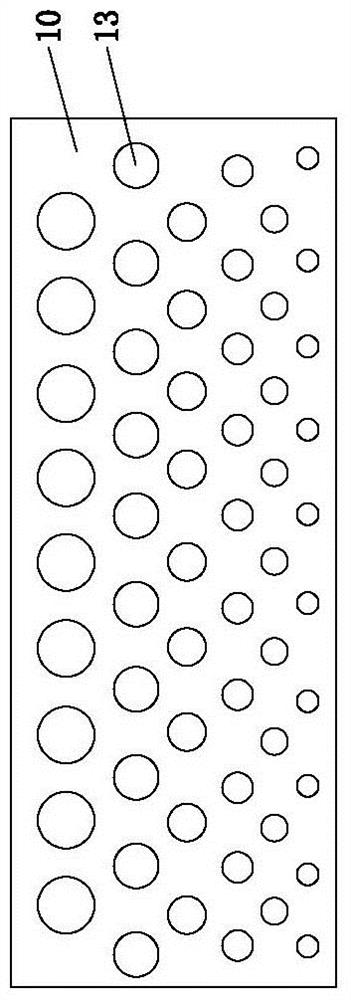

[0036] Step 1: prepare liquid medicine and mold, and make a liquid medicine baffle 10 with a porous structure. The density of the through holes 13 at different positions of the liquid medicine baffle 10 is different, so as to adjust the exchange of the liquid medicine through the different density of the through holes 13 at different positions. Efficiency so as to realize the gradual change of texture depth; here, the more dense the through holes 13 of the liquid medicine baffle 10, the higher the exchange efficiency of the liquid medicine, so the faster the chemical corrosion rate, on the contrary, the sparser the through holes 13 of the liquid medicine baffle 10 The lower the exchange efficiency of the position potion, the slower the chemical corrosion rate;

[0037] Step 2: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com