Refurbishing device for small electric appliance shell

A technology for electrical enclosures and refurbishment devices, applied in the directions of injection devices, chemical instruments and methods, grinders, etc., can solve the problems of speeding up, fragile metal enclosures, affecting the safety of electrical equipment, etc., and achieve the effect of increasing cleaning capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

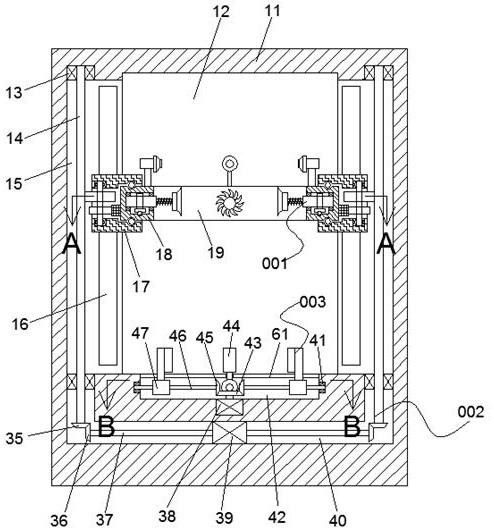

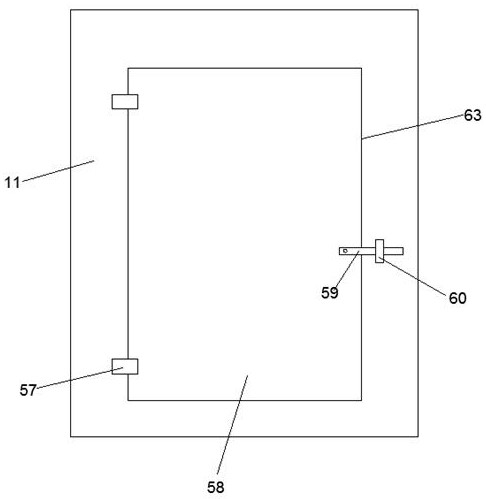

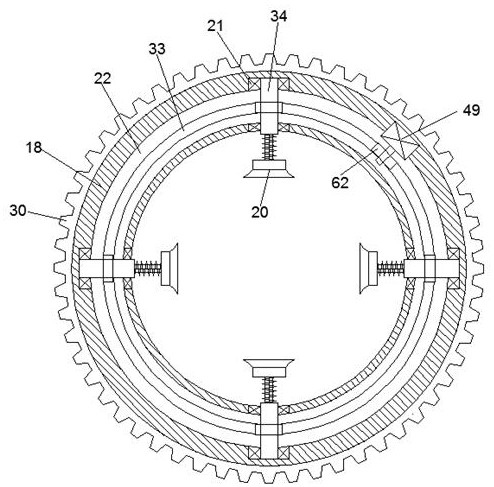

[0018] Combine below Figure 1-6 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are consistent.

[0019] refer to Figure 1-6 , according to an embodiment of the present invention, a device for refurbishing a housing of a small electrical appliance includes a device body 11, a working chamber 12 is provided in the device body 11, and lifting grooves 15 are correspondingly provided in the left and right walls of the working chamber 12, and the left and right The front and rear walls of the corresponding lifting groove 15 are correspondingly provided with a No. 1 sliding groove 16, and the lifting base 17 is slid up and down between the corresponding No. 1 sliding groove 16, and the left and right end faces of the corresponding lifting base 17 are connected. There is a rotating cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com