Metal part code pressing mechanism capable of adjusting letters

A metal component and adjustable technology, which is applied in the field of stamping mechanism, can solve problems such as the loosening of the fixed structure of the code sheet, the trouble of mold replacement, and the inability to change the code, so as to achieve the effects of reasonable structural design, improved service life and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

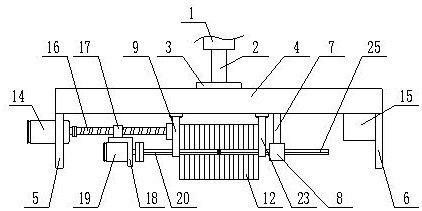

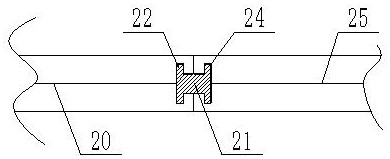

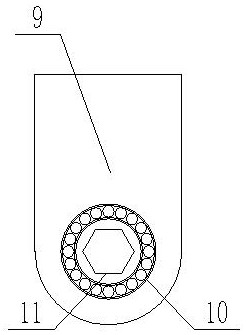

[0029] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6 As shown, the inventive point of the present application is that the vertical rod 7 is fixedly installed on the lower surface of the mounting base, the vertical rod is perpendicular to the lower surface of the mounting base, and the vertical rod is located between the first mounting plate and the second mounting plate. The lower end of the vertical pole is fixedly connected with the outer circular inner hexagonal steel pipe 8, and the lower surface of the mounting seat is fixedly installed with a support plate 9 and a support plate 2 23, and the support plate 1 and the support plate 2 are all parallel to the mounting plate 1, and the support plate 1 and the support plate 2 are all parallel to the mounting plate 1. Plate one and support plate two are positioned between vertical rod and mounting plate one, and support plate one is close to mounting plate one, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com