Cooked food packaging device

A technology for cooked food and packaging, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of not being able to eat while hot, affecting the quality of packaging, skin elasticity, and dry and rough sliding mouth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

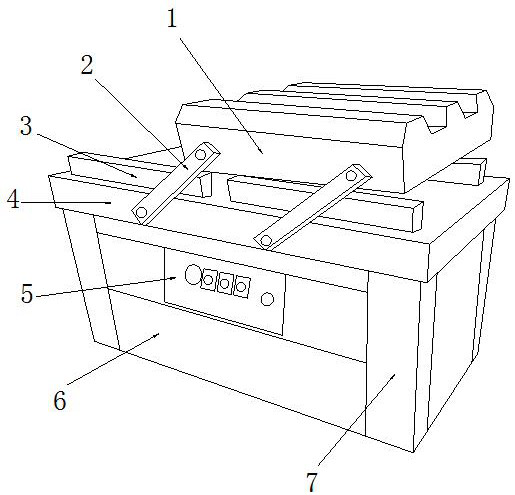

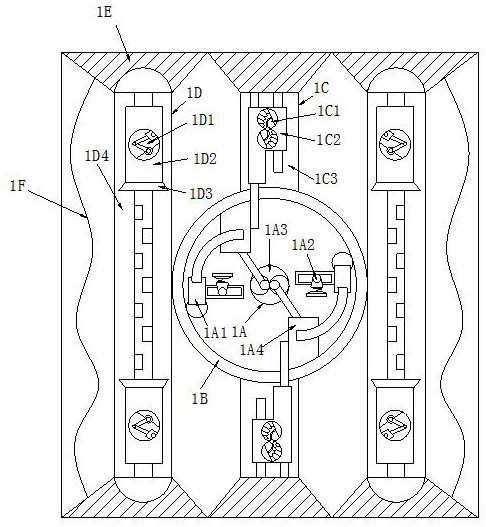

[0032] See Figure 1-Figure 6 , The present invention provides a cooked food packaging device, the structure of which includes: shuttle tray cover 1, swing arm frame 2, sealing strip block 3, packaging workbench 4, industrial control panel 5, packaging chassis 6, pillar block 7 , The shuttle disk rack cover 1 is mechanically connected to the sealing strip block 3 through the swing arm frame 2. The sealing strip block 3 is tightly attached to the top surface of the packaging worktable 4 and is on the same level. The panel 5 is closely attached to the front side of the packaging box 6 and is on the same vertical surface. The packaging workbench 4 is nested on the top of the packaging box 6 and is perpendicular to each other. The packaging box 6 and the pillar block 7 are an integral structure And on the same vertical plane, the shuttle plate frame cover 1 is provided with a counterweight sliding support frame 1A, a roulette slot 1B, a torque sliding column frame 1C, a monorail po...

Embodiment 2

[0039] See Figure 1-Figure 6 , The present invention provides a packaging device for cooked food. The other aspects are the same as Embodiment 1, except that:

[0040] See figure 2 The monorail pole 1D is composed of a connecting rod brush holder 1D1, a shuttle block 1D2, a trapezoidal pad 1D3, and a monorail pole 1D4. The connecting rod brush holder 1D1 is installed inside the shuttle block 1D2. The pad 1D3 and the shuttle block 1D2 are nested into one body. The monorail pole 1D4 is mechanically connected with the shuttle block 1D2 and is on the same vertical surface. The trapezoidal pad 1D3 is driven by the shuttle block 1D2 to press up and down to collide to form a spark plug effect , To ensure sufficient friction between the pressure line of the internal combustion cylinder.

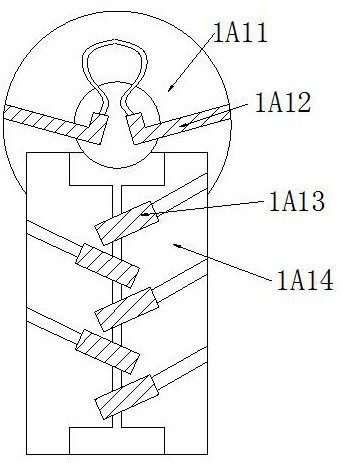

[0041] See Image 6 The connecting rod disc brush holder 1D1 is composed of a pneumatic hole disc slot 1D11, a connecting rod holder 1D12, a wheel buckle column block 1D13, and a piston fan plate 1D14....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com