Patents

Literature

56results about How to "Increased precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

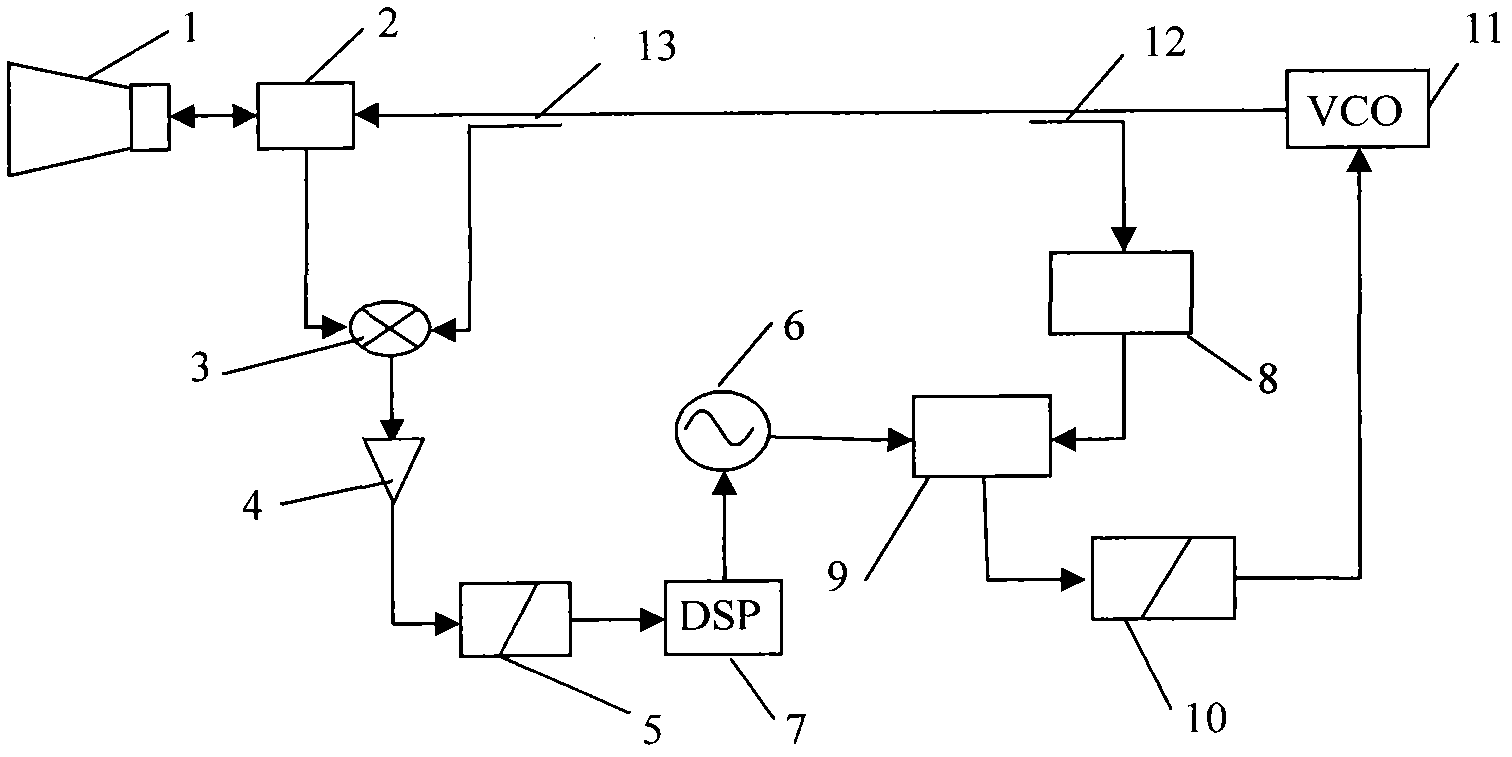

Frequency-modulated continuous wave radar ranging method with high sweep linearity

InactiveCN102565787AIncreased precisionAccurate correctionRadio wave reradiation/reflectionPhase correctionPhase difference

The invention relates to a frequency-modulated continuous wave radar ranging method with high sweep linearity. The frequency-modulated continuous wave radar ranging method at least adopts a distance echo signal processing unit and a voltage-controlled oscillator (VCO) sweep linearity correction unit, and the precision of the sweep linearity can be greatly improved by performing phase correction on sweep frequency of the VCO. The same level with reference frequency can be achieved by performing frequency division on the frequency of the VCO. Then, phases at two frequencies are compared and control voltage of the VCO is adjusted according to phase difference, so that the purpose of precise frequency correction is achieved.

Owner:西安龙之梦网络信息有限公司

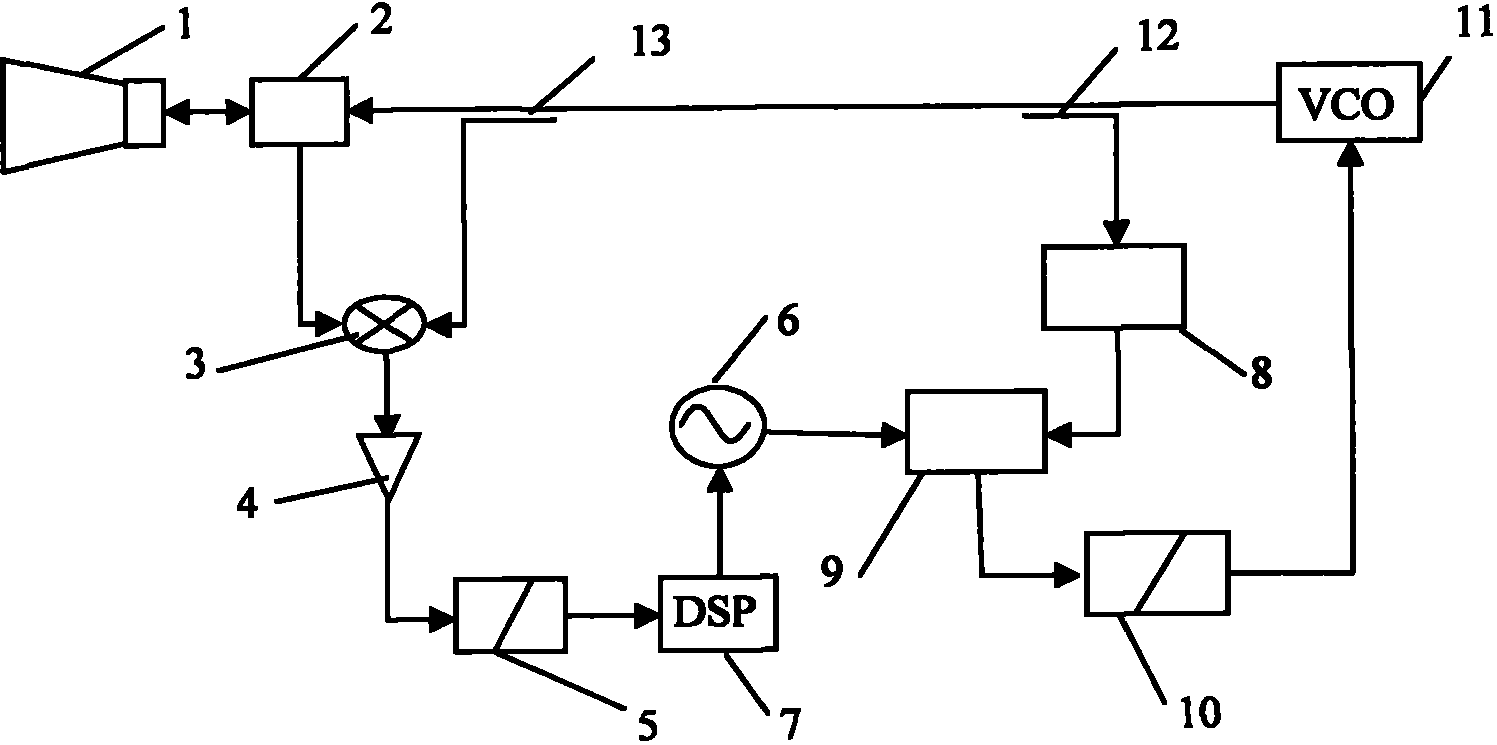

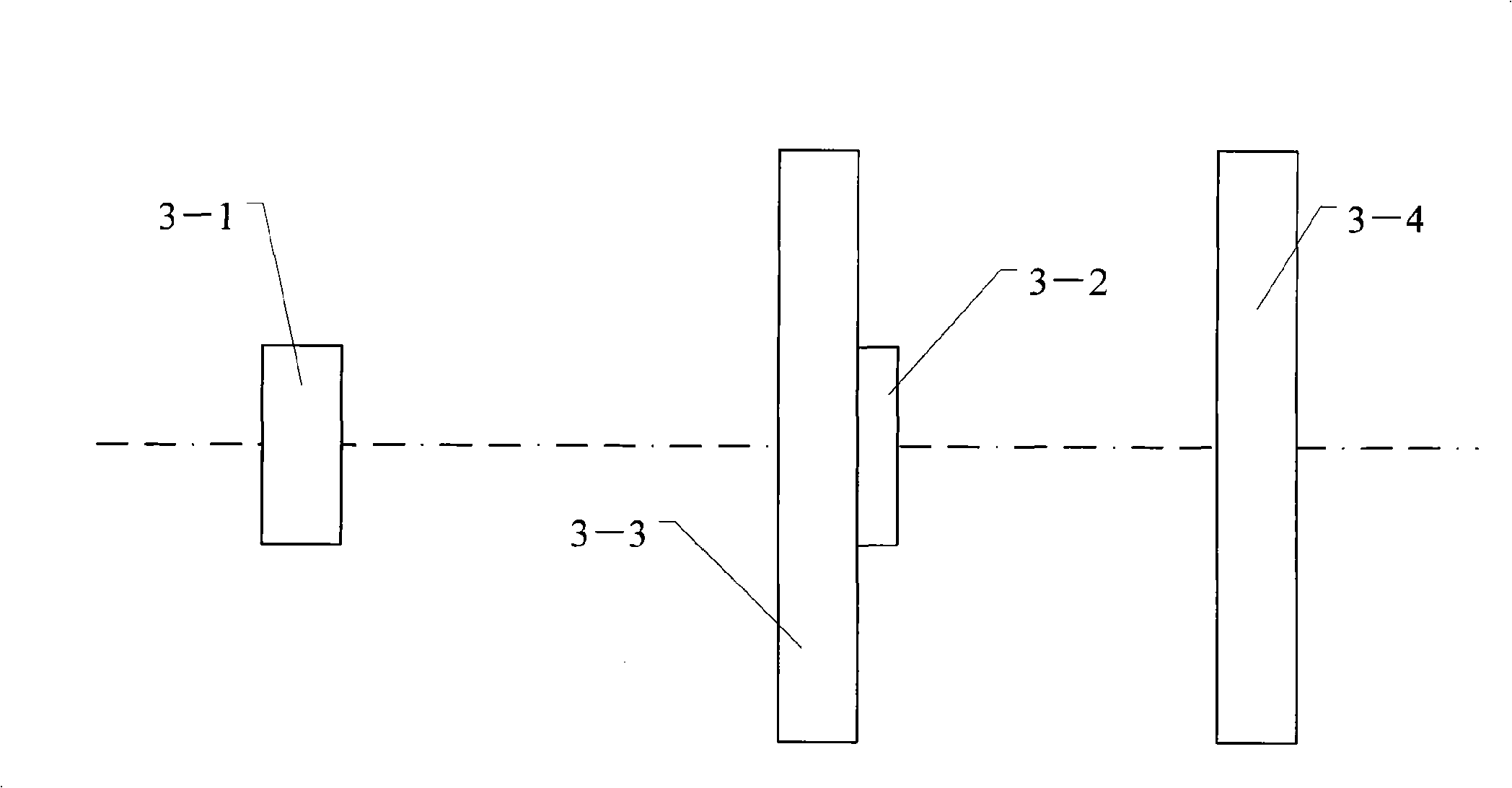

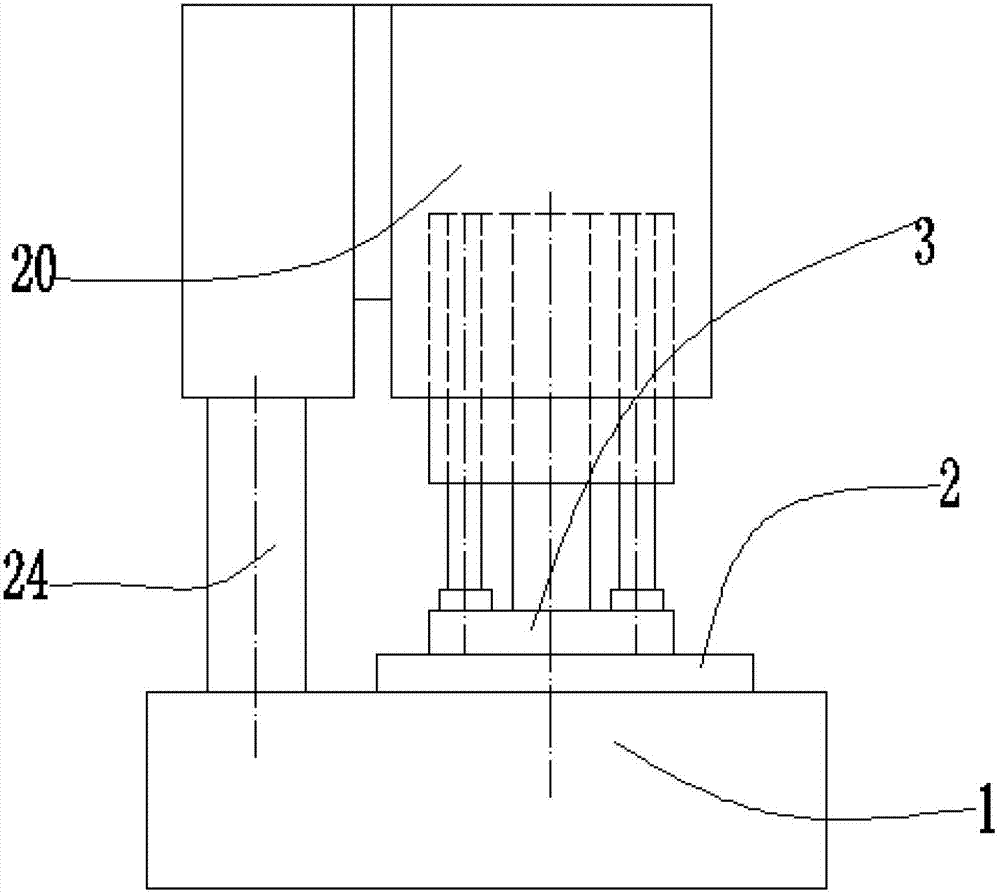

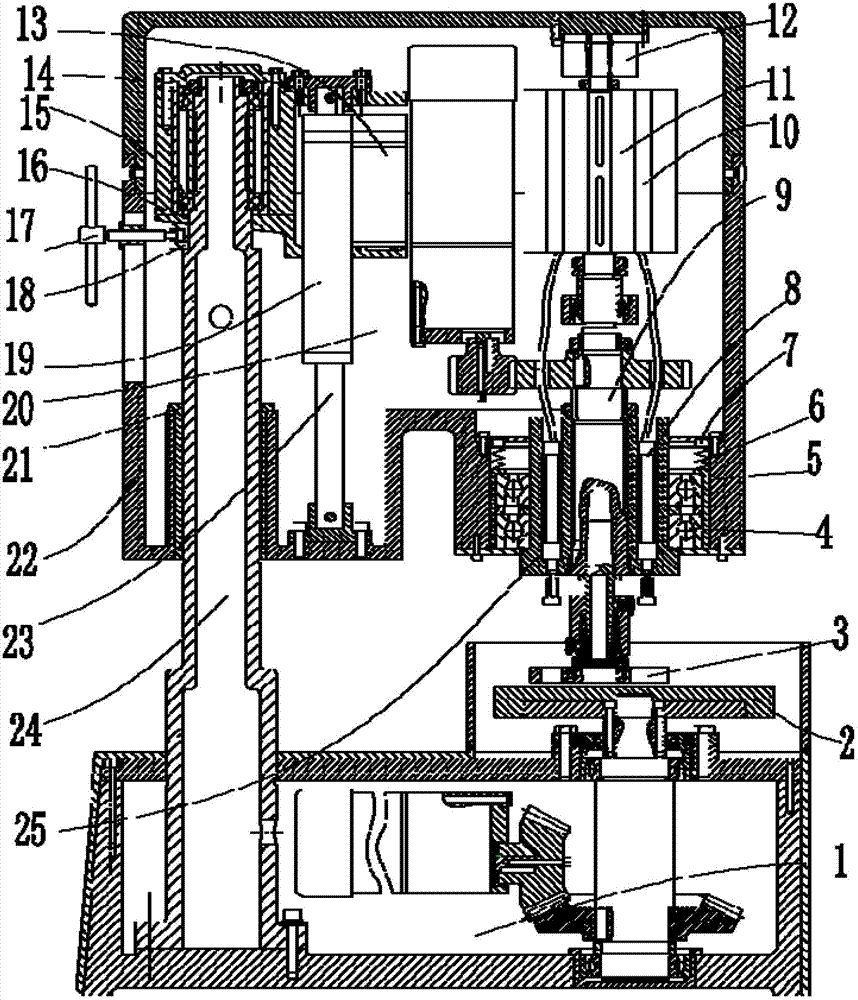

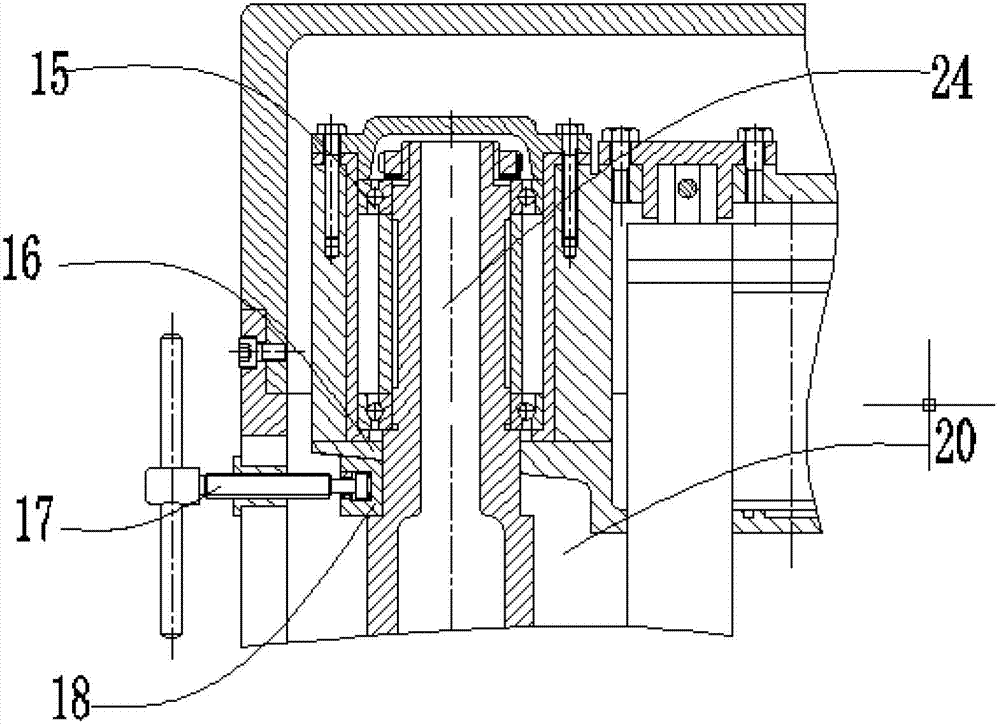

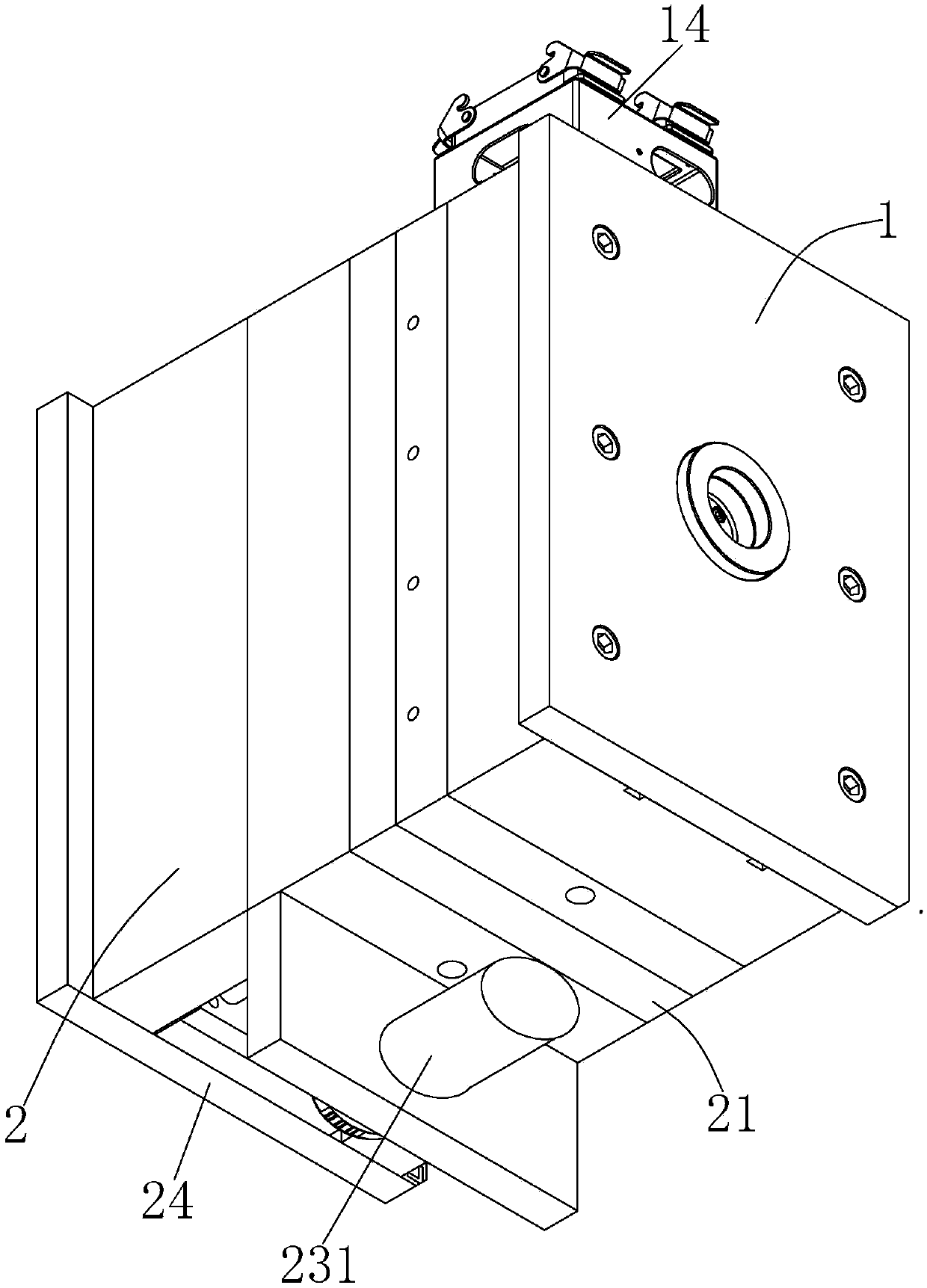

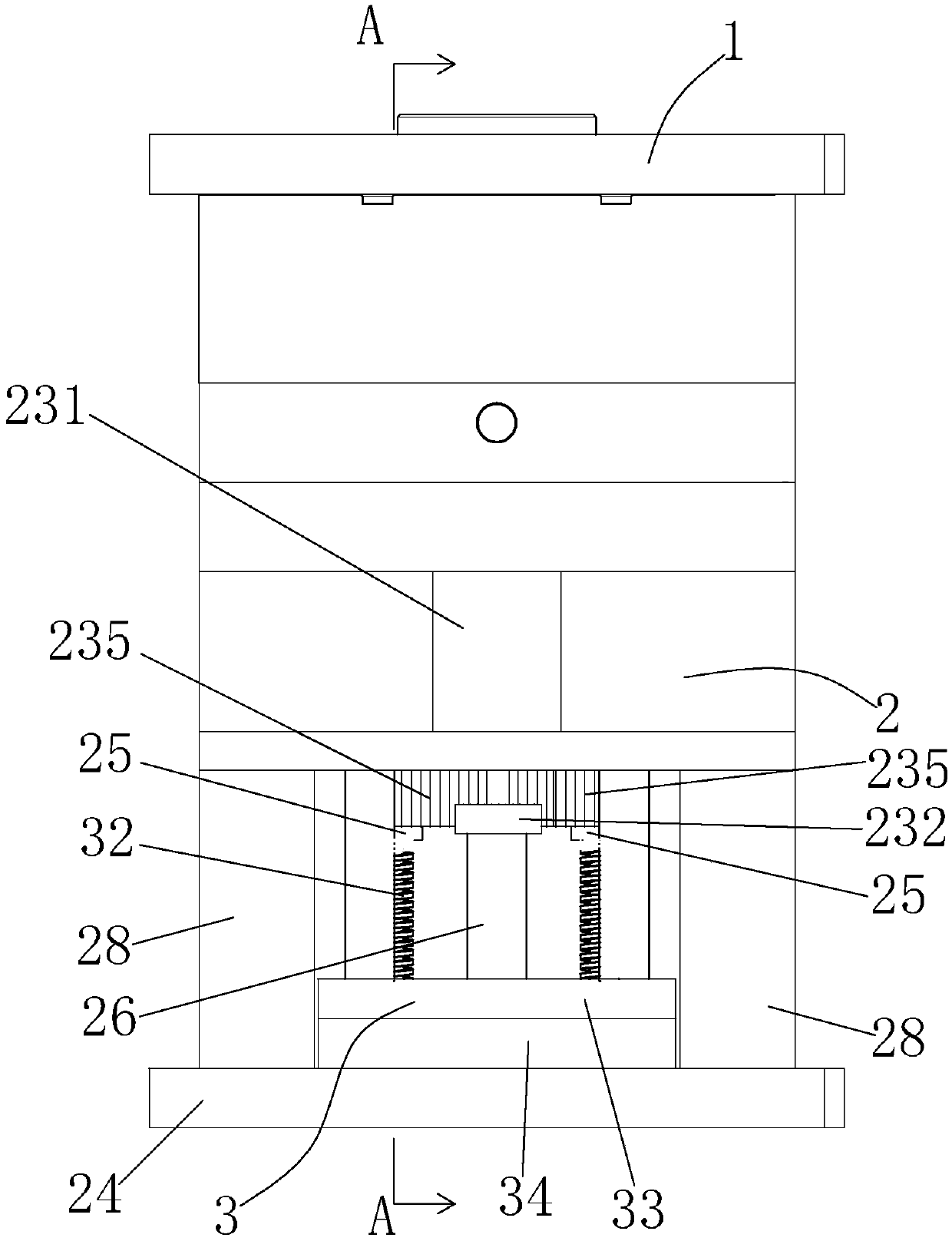

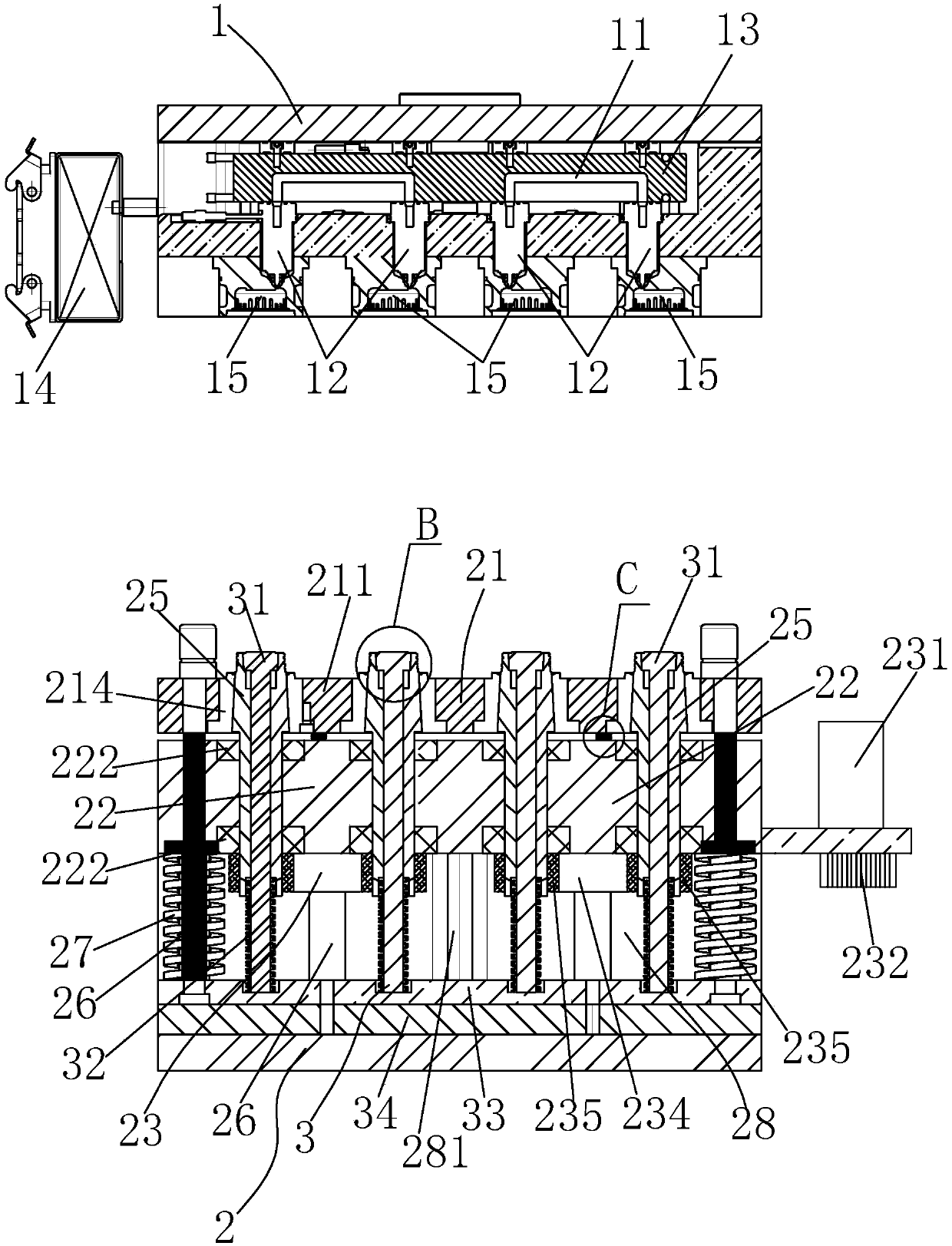

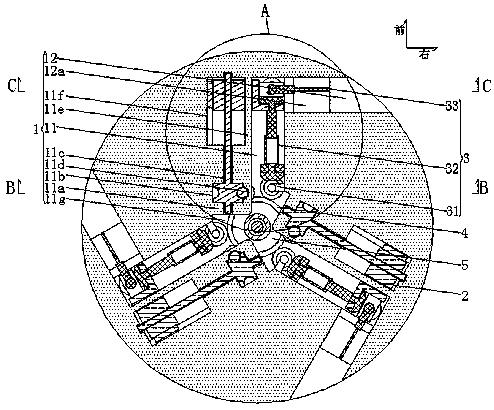

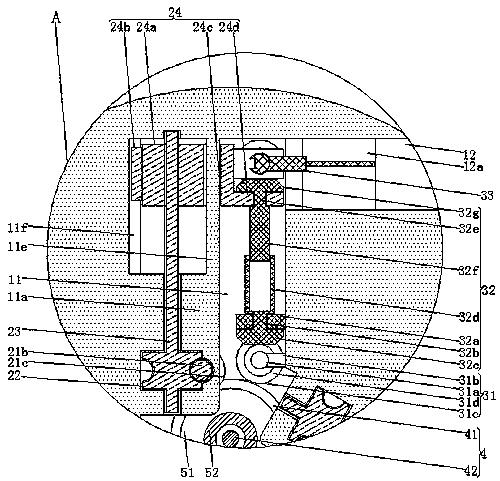

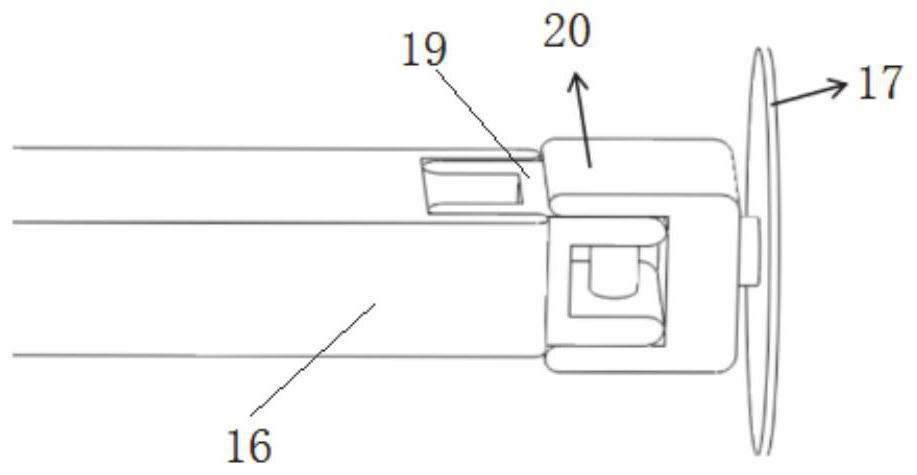

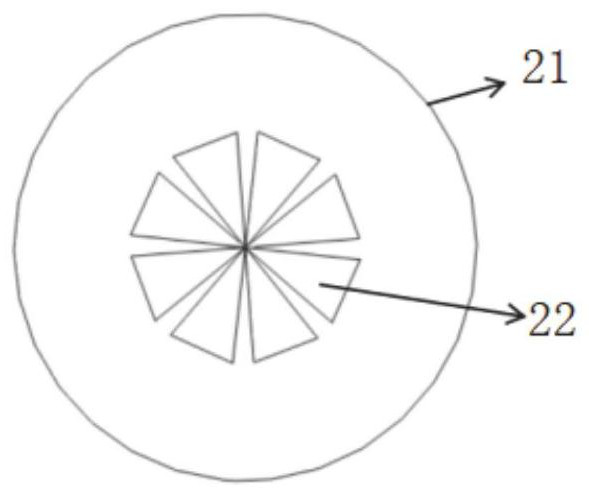

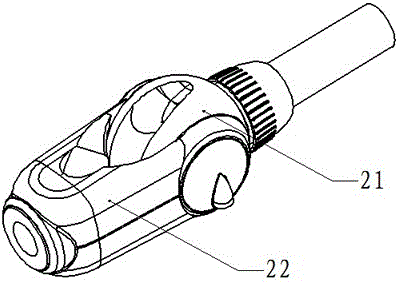

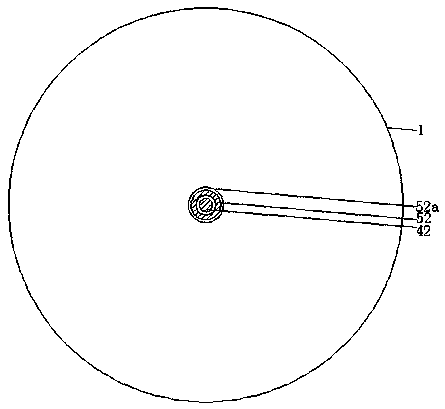

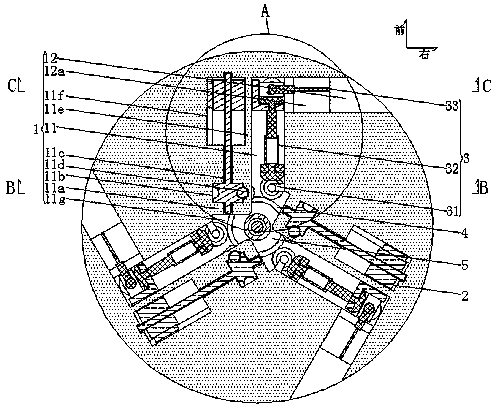

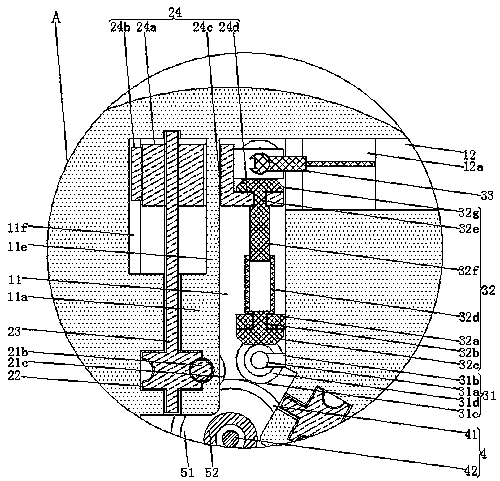

Machine tool for processing gate valve sealing surface

InactiveCN103406576ASingle processed productIncrease productivityMilling equipment detailsDriving apparatusElectric machineryMachine tool

The invention discloses a machine tool for processing a gate valve sealing surface. The machine tool comprises driving systems, milling systems and a workbench system, wherein each driving system comprises a main shaft motor and drives the corresponding milling system to mill a workpiece; each milling system comprises a machine body and a cutter; the workbench system comprises a base and a clamp; the machine tool for processing the gate valve sealing surface is eudipleural. Each driving system also comprises an X-axis motor and a Y-axis motor; the X-axis motor can drive the corresponding milling system to move leftwards and rightwards along a horizontal plane; the Y-axis motor can drive the corresponding milling system to move up and down along a vertical direction; the machine body is arranged on adjustment systems; the adjustment systems comprise vertical columns and slope plates; the slope plates are connected with the vertical columns in a split manner. According to the invention, the processing capacity of the machine tool can be improved, and the production efficiency can be improved.

Owner:WUXI FUSHENG VALVE IND

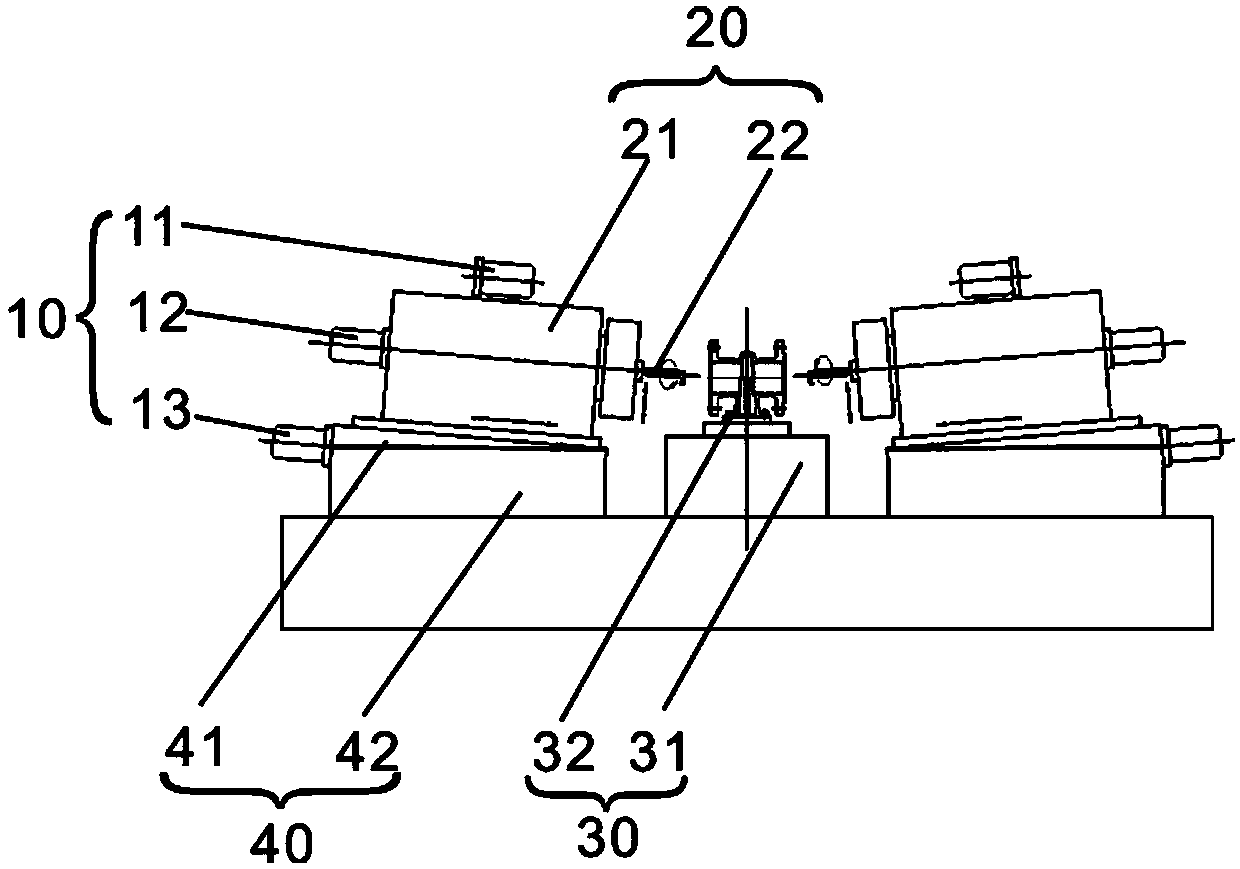

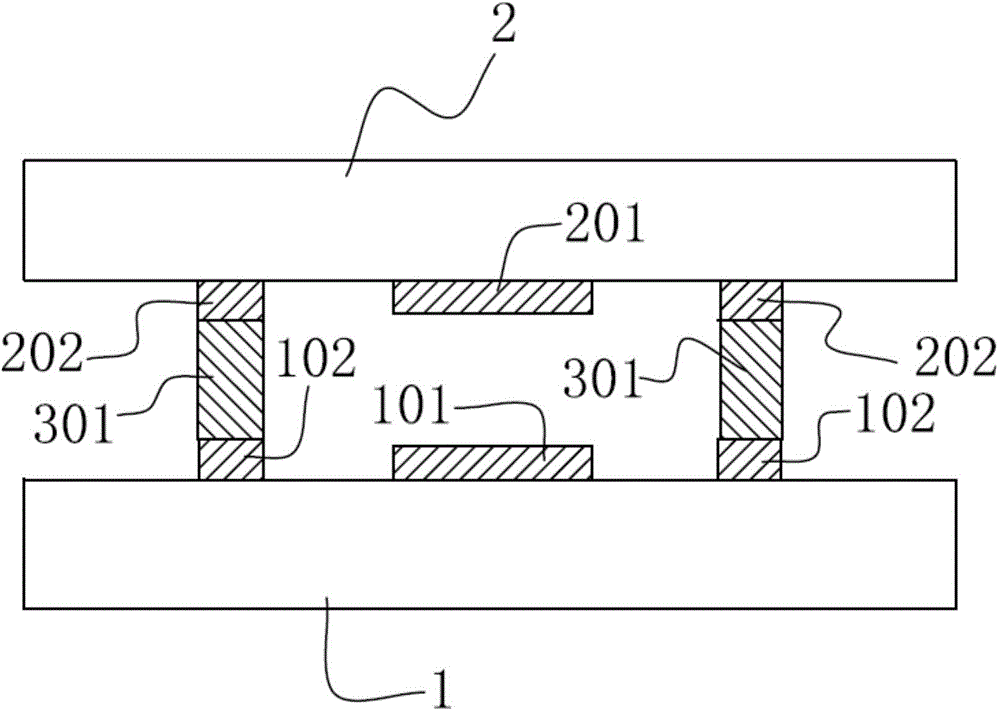

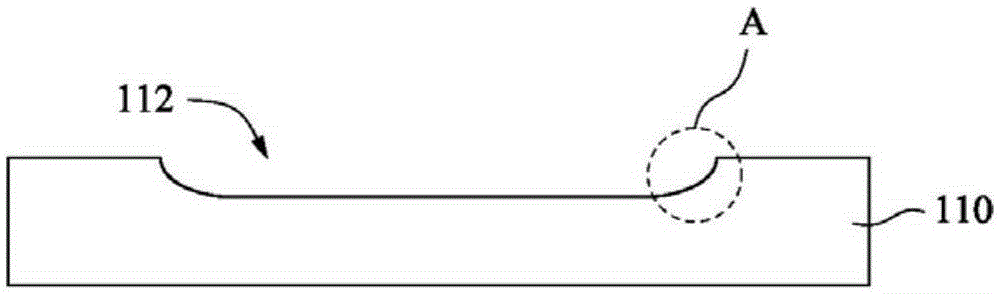

Electrical switch structure and electronic equipment

InactiveCN104538225AIncreased precisionHigh precisionContact electric connectionFlexible circuitsEngineering

The invention provides an electrical switch structure adopting no metal dome and electronic equipment with the electrical switch structure. Inherent defects of a metal dome switch are overcome. The electrical switch structure comprises a rigid printed circuit board and a flexible circuit board. The rigid printed circuit board is opposite to the flexible circuit board. The rigid printed circuit board is provided with a first contact, the flexible circuit board is provided with a second contact, the first contact and the second contact are opposite and correspond to each other in position, and the first contact and the second contact are used as the two ends of a switch of the electrical switch structure respectively. Supporting posts are arranged between the rigid circuit board and the flexible circuit board. The two ends of each supporting post are connected with the rigid printed circuit board and the flexible circuit board respectively. The supporting posts are distributed around the first contact. A gap is reserved between the first contact and the second contact. When the portion, with the second contact, of the flexible circuit board is subjected to the pressure facing the first contact and exceeding the preset value, the first contact and the second contact make contact with each other and are connected.

Owner:FUJIAN LANDI COMML EQUIP CO LTD

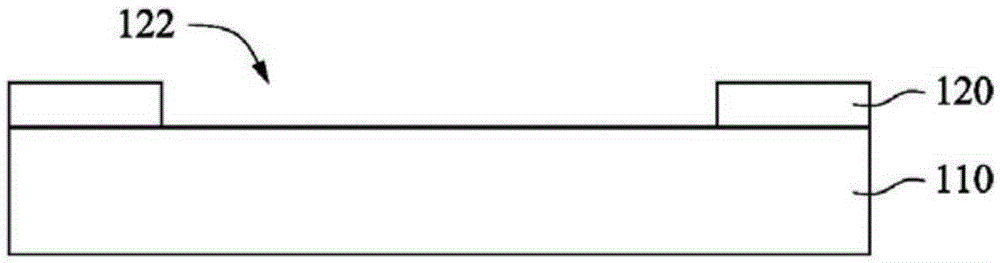

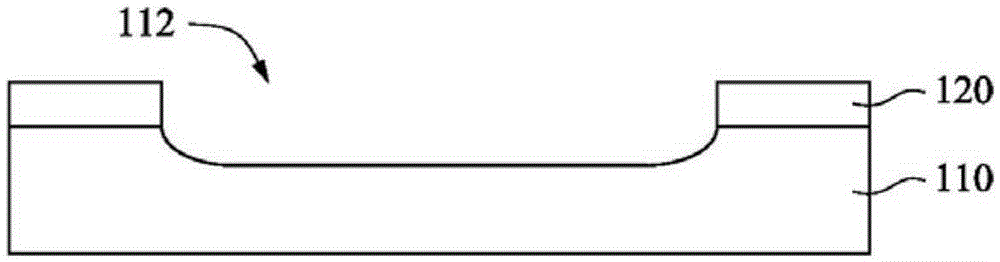

Manufacturing method for blind hole of insulating substrate for electronic apparatus

InactiveCN105261569AIncreased precisionImprove side erosionPhotomechanical apparatusSemiconductor/solid-state device manufacturingEtchingPhotoresist

The invention relates to a manufacturing method for a blind hole of an insulating substrate for an electronic apparatus. The manufacturing method comprises the following steps of forming a patterned photoresist layer on the insulating substrate, wherein an opening is formed in the patterned photoresist layer, and a part of the insulating substrate is exposed out of the opening; performing a wet etching process to move the exposed insulating substrate, wherein the blind hole is formed in the opening. The manufacturing method can dramatically reduce the side etching phenomenon of an etching liquid and reduce the residual width in the edge of the blind hole so as to further improve the precision degree of the blind hole formed by the wet etching method.

Owner:INTERFACE OPTOELECTRONICS SHENZHEN +1

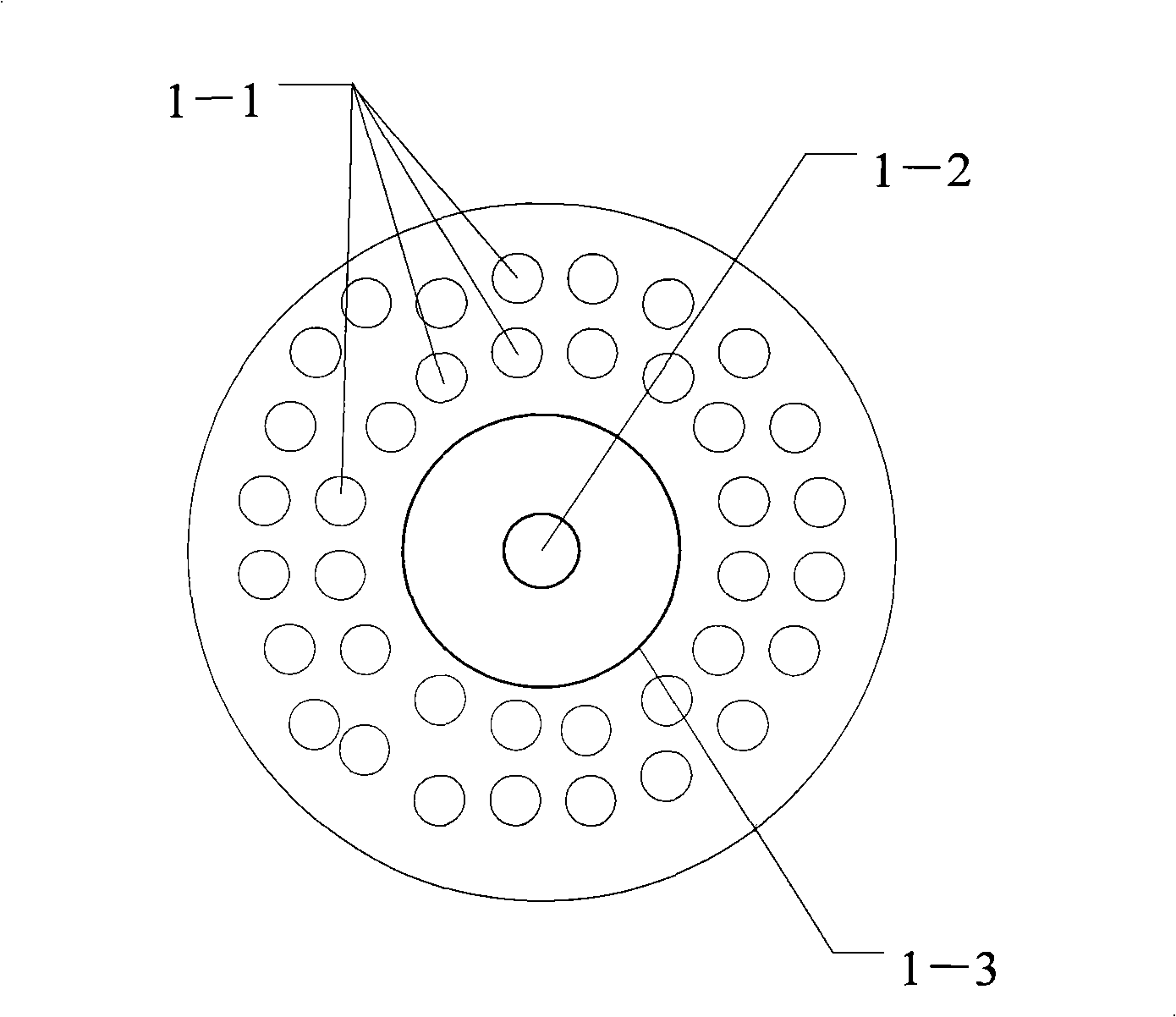

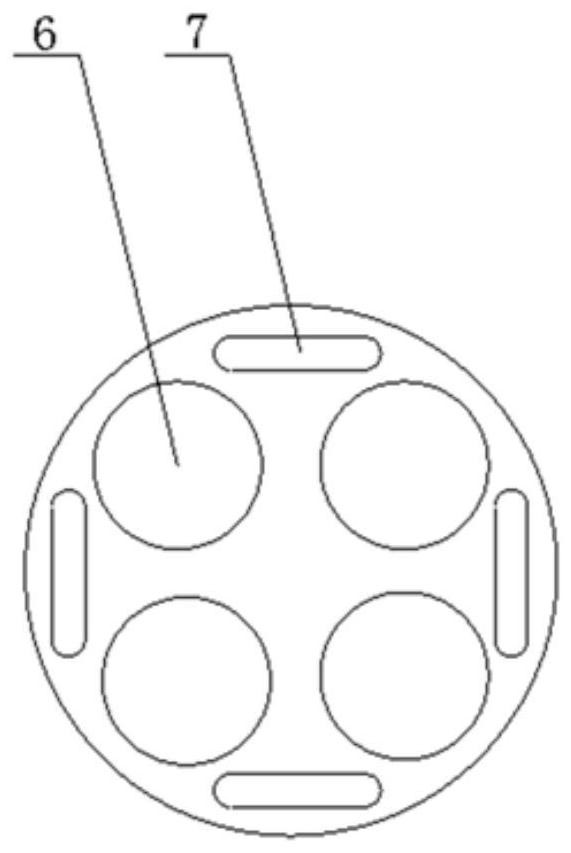

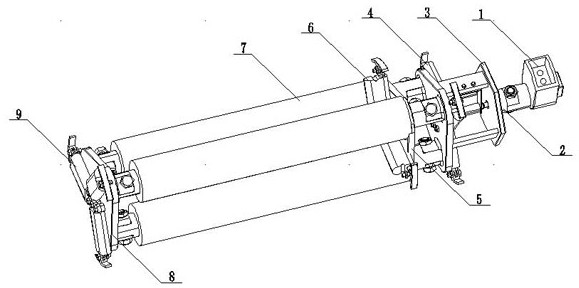

Bimodule stranding device and manufacturing technique

InactiveCN101286389AImprove roundnessIncreased precisionCable/conductor manufactureEngineeringMechanical engineering

Owner:SHENZHEN DAYANG ELECTRONICSAL

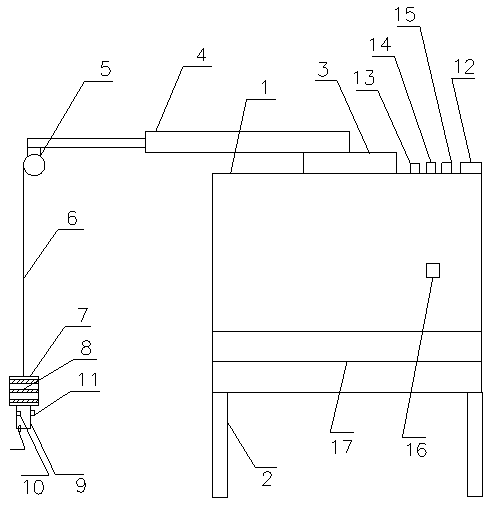

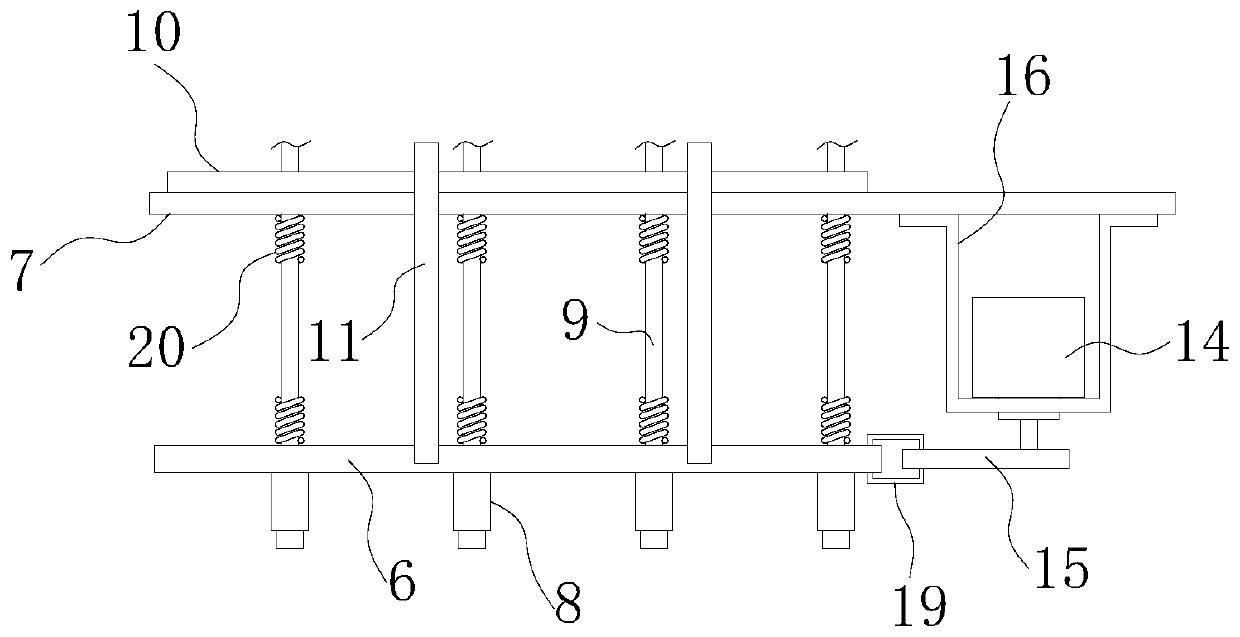

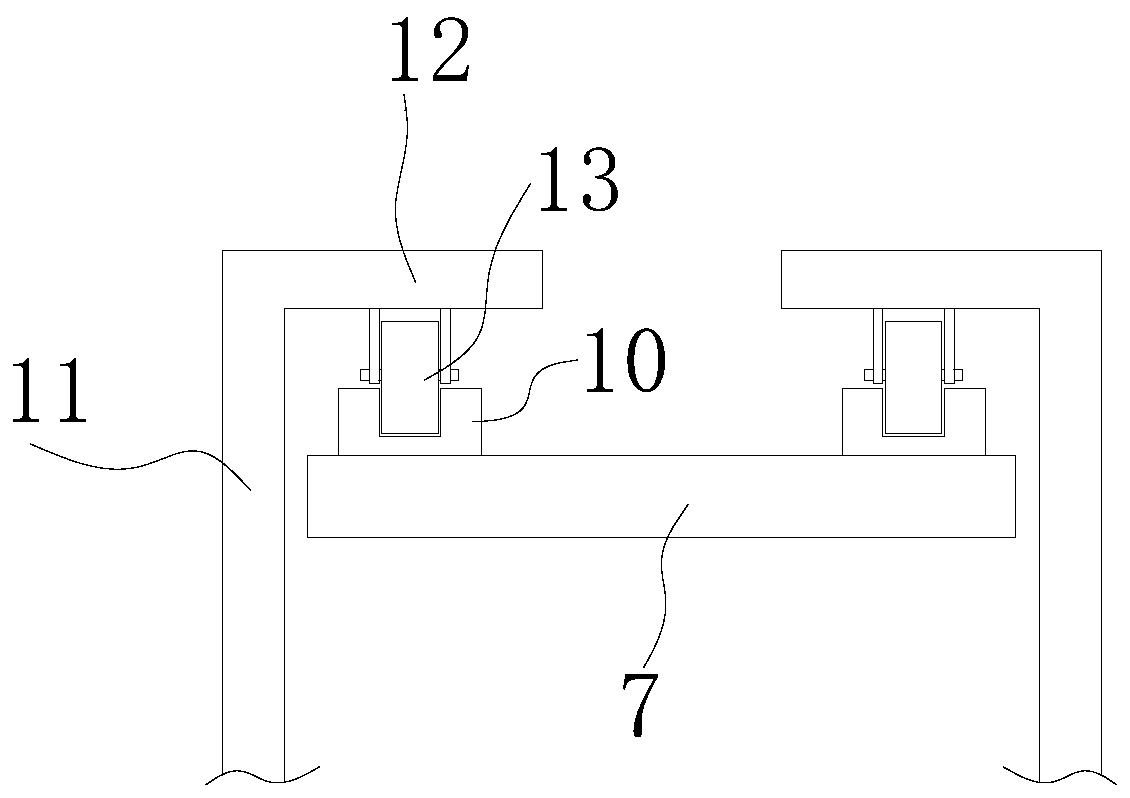

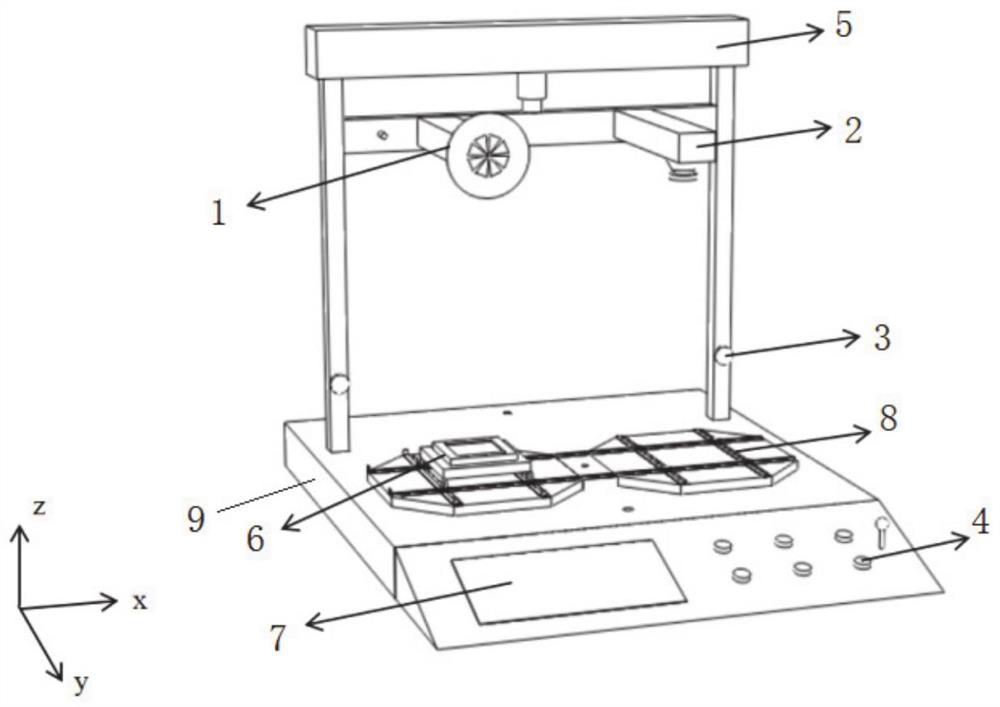

Mechanical structure of dual-loading-mode grinding and polishing machine driven by electric push rod

The invention discloses a mechanical structure of a dual-loading-mode grinding and polishing machine driven by an electric push rod. The mechanical structure of the dual-loading-mode grinding and polishing machine driven by the electric push rod is composed of a machine head, a vertical column and a base. The machine head can be controlled manually to rotate around the vertical column and can be reliably locked in a working position. The mechanical structure of the dual-loading-mode grinding and polishing machine driven by the electric push rod comprises two loading modes of a single-point force mode and a middle force mode, the middle force mode is achieved though the integrated descending and pressing of a working head to process a batch of samples with a same depth, and the single-point force mode is achieved through the pressing of an independent cylinder driven by a group of independent air pumps press to process the same batch of samples with different depths. The electric push rod is utilized as the power mechanism and the transmission mechanism for lifting the machine head as well as the force application mechanism and the force adjusting mechanism in the middle force mode; and the machine head can be driven by the electric push rod to move vertically along the vertical column and is matched with the use of a force sensor to achieve controlling the magnitude of the loading force. The mechanical structure of the dual-loading-mode grinding and polishing machine driven by the electric push rod is simple in structure, high in automation degree, processing precision and working efficiency, easy to operate and high in commutativity.

Owner:HEFEI UNIV OF TECH

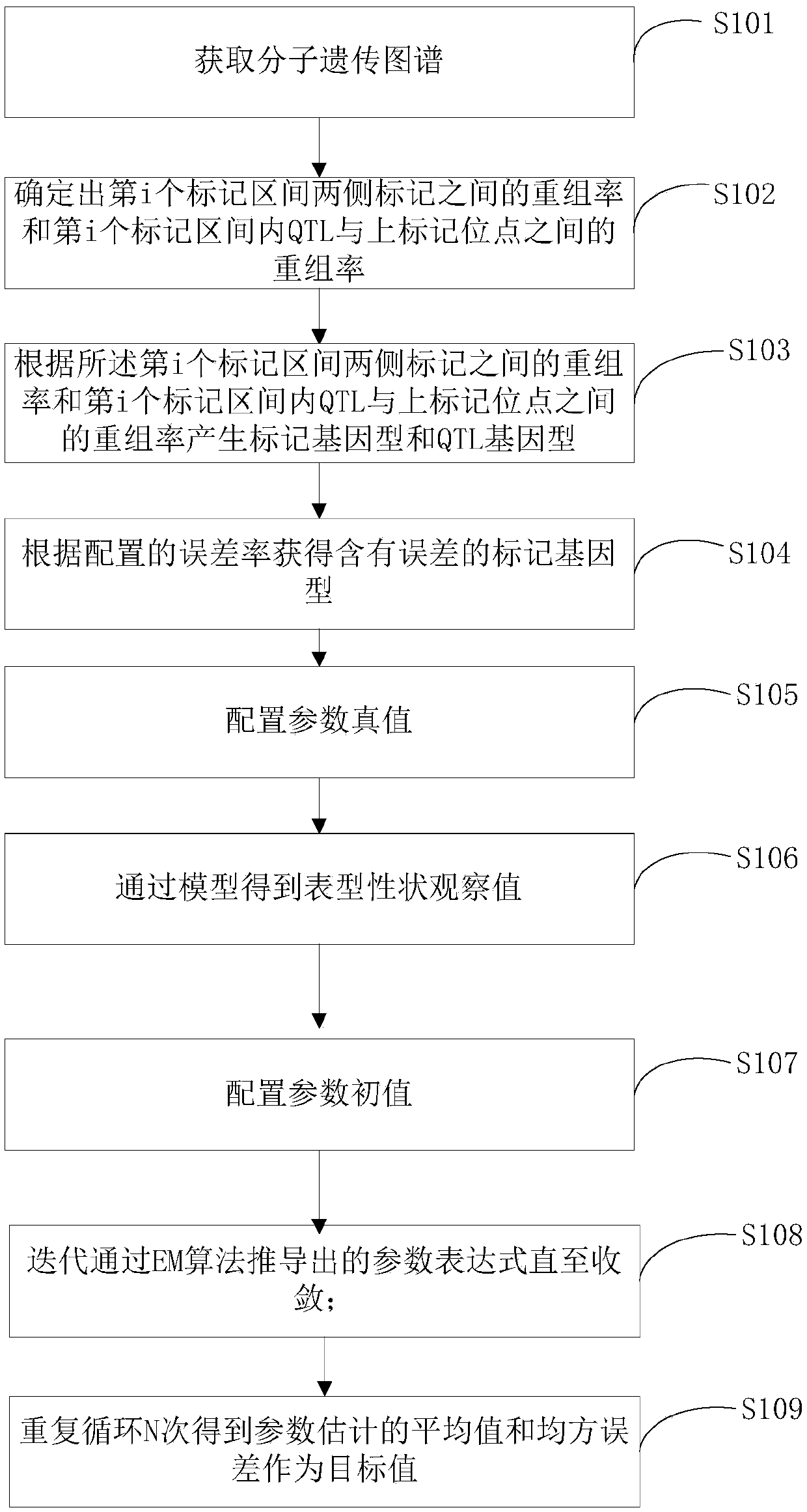

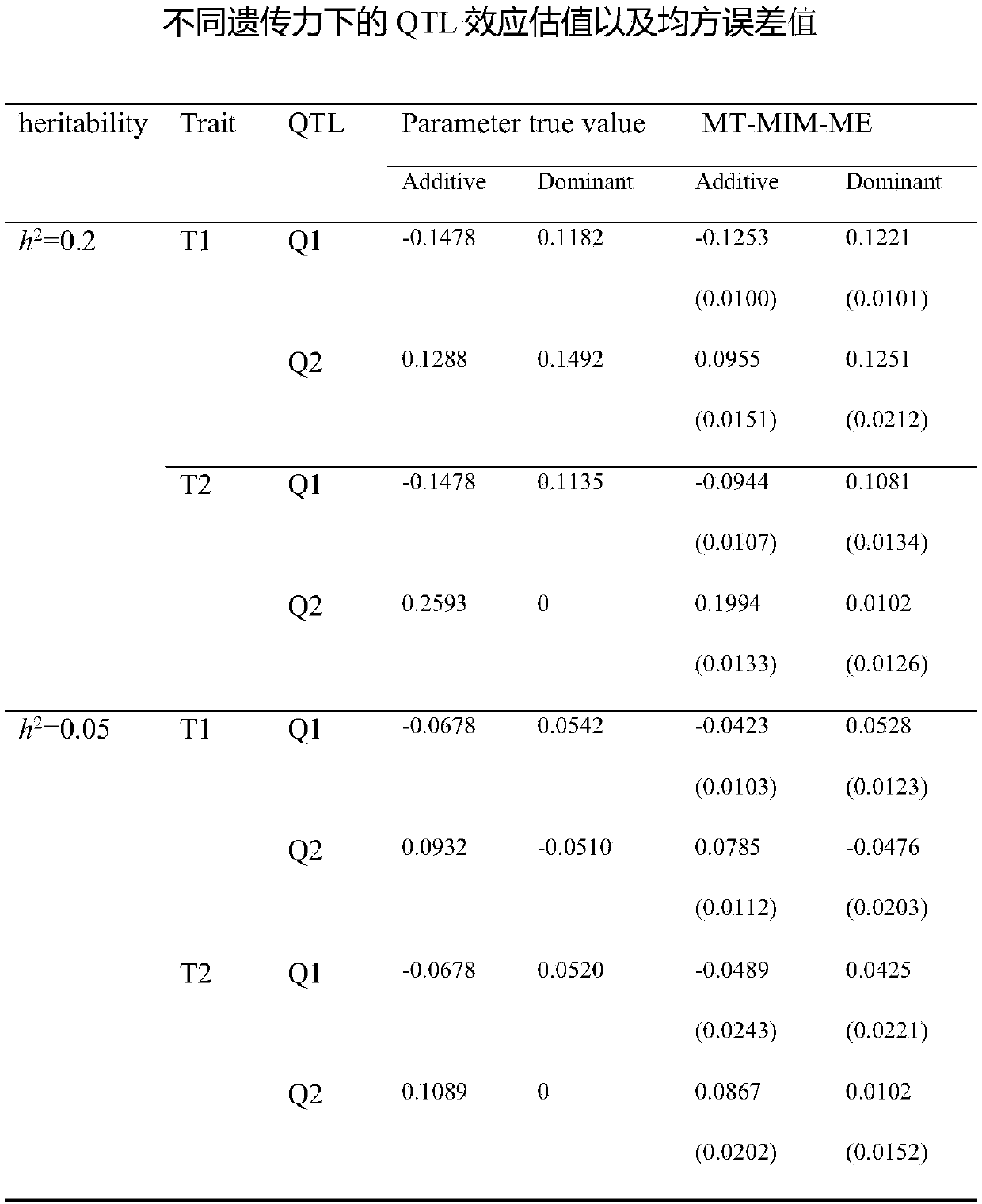

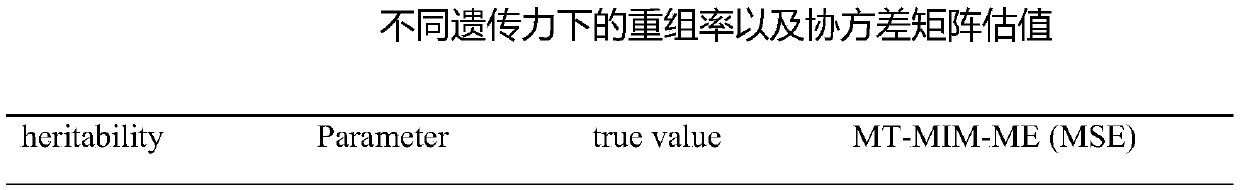

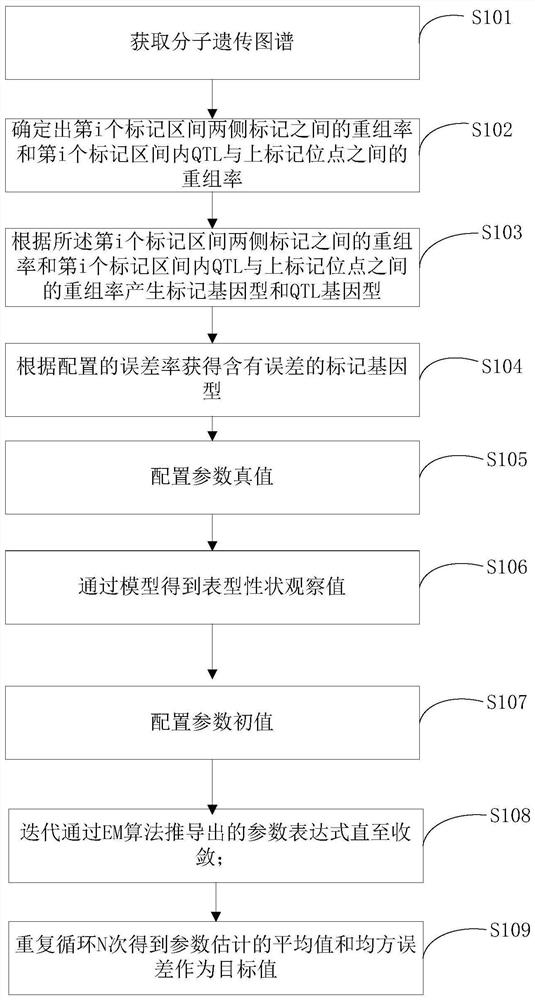

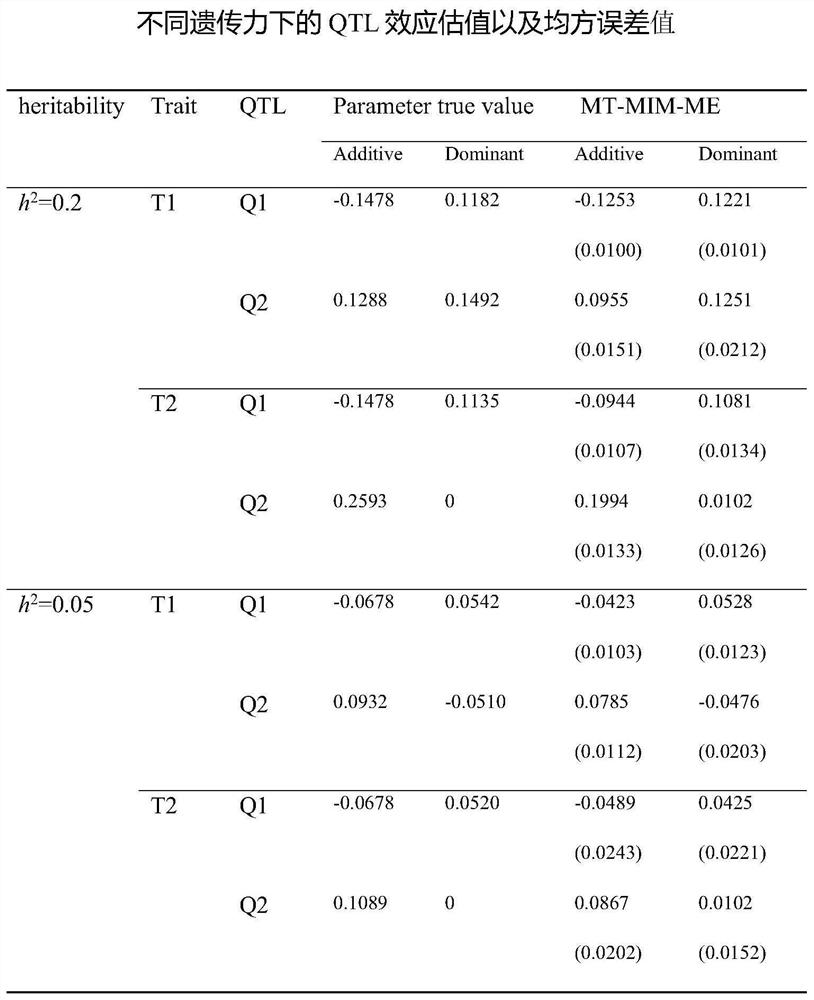

Error-containing multi-character multi-interval positioning method based on marker locus genotypes

ActiveCN108197435ASolve the problem with errorsAccurate estimateProteomicsGenomicsMean squareTruth value

The invention discloses an error-containing multi-character multi-interval positioning method based on marker locus genotypes. The method includes the steps: acquiring a molecular genetic map; determining a recombination rate gamma i between markers on two sides of an i marker interval and a recombination rate gamma il between a QTL (quantitative trait locus) and an upper marker locus within the i marker interval; generating a marker genotype and a QTL genotype according to the recombination rate gamma i between the markers on the two sides of the i marker interval and the recombination rate gamma il between the QTL (quantitative trait locus) and the upper marker locus within the i marker interval; acquiring the error-containing marker genotype according to a configured error rate; configuring parameter truth-values; acquiring phenotypic character observation values by a model; configuring initial values of parameters; iterating a parameter expression deducted by an EM(expectation maximization) algorithm until convergence; repeating the process for N times to obtain the average value of parameter estimation and mean square errors serving as target values. The method can effectively solve the problem that marker gene information contains errors, and the error rate of the marker gene information can be estimated.

Owner:SUIHUA UNIV

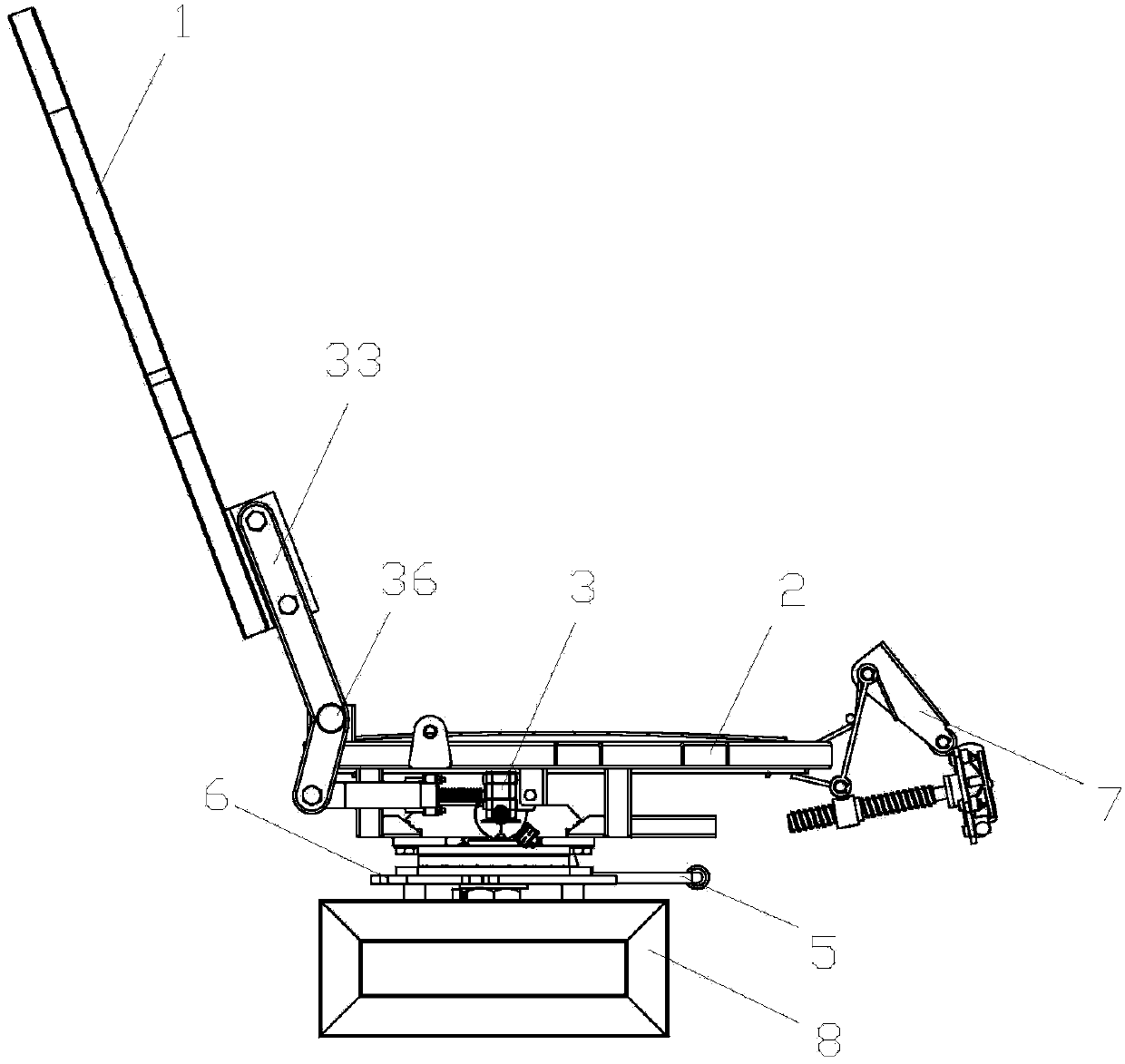

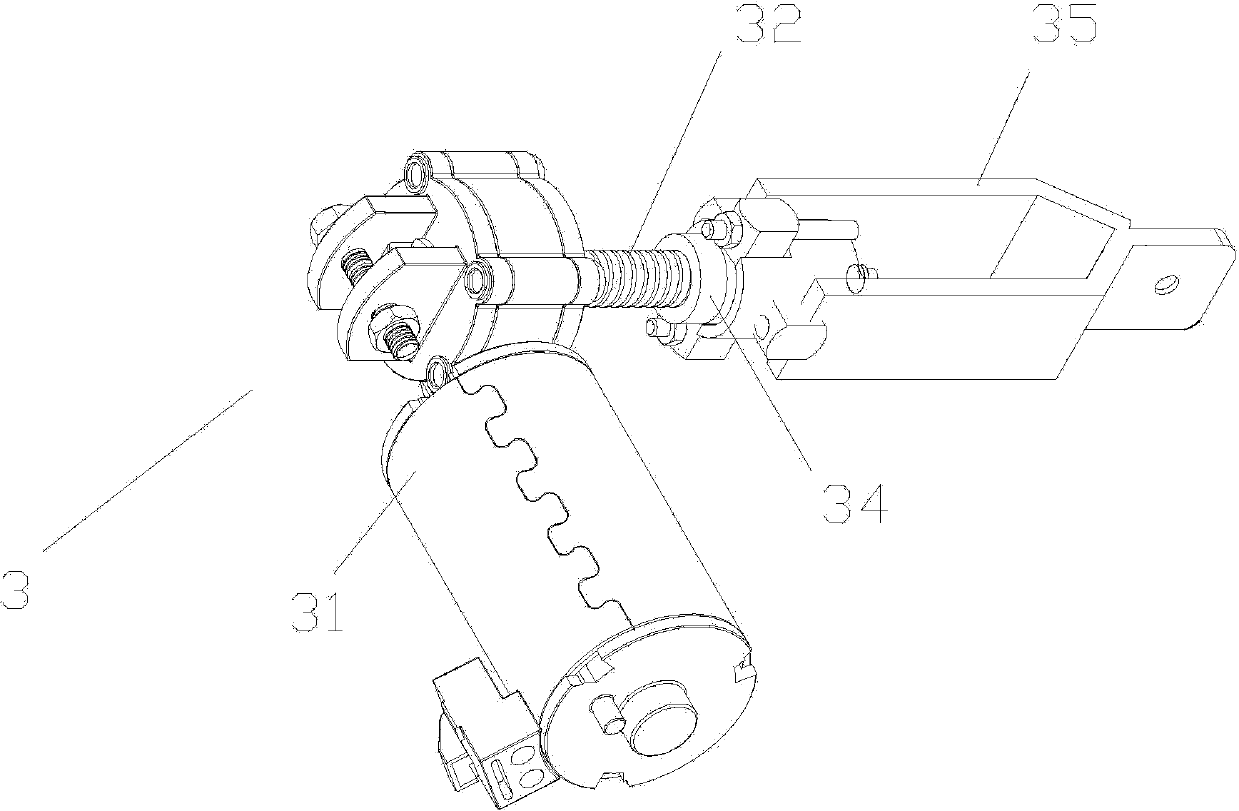

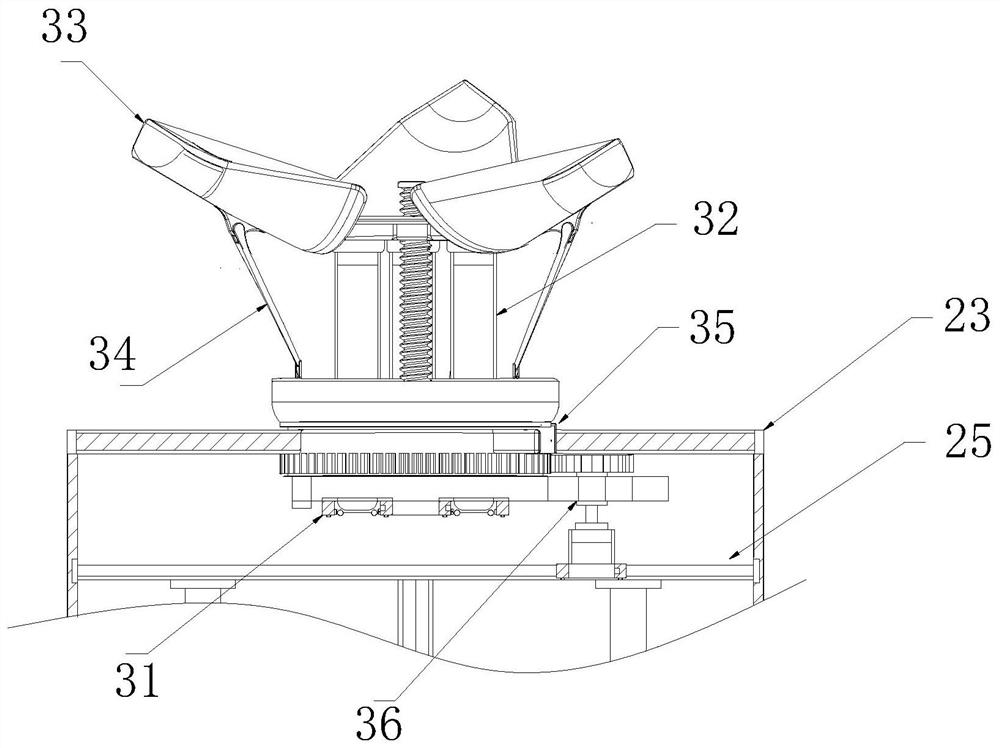

Electric adjustable seat frame and seat provided with frame

The invention discloses an electric adjustable seat frame and a seat provided with a frame, according to the technique solution, the electric adjustable seat frame comprises a backrest frame and a seat frame; the electric adjustable seat frame further comprises a backrest regulating mechanism, having a backrest regulating motor, a backrest regulating screw, a backrest regulating screw nut and an angle regulating lever; the angle regulating lever is rotatably connected with the seat frame and fixedly connected with the backrest frame at the upper end; a connecting piece fixed with the backrest regulating screw nut is actively connected with the lower end of the backrest regulating screw. The adjustable automation degree of the seat backrest and the legs is high and labour-saving due to the electric mechanism; the seat can be rotatably adjusted and the seat can be automatically locked while not rotating, the stabilization is good and the technology is improved compared with the prior art.

Owner:中欧飞机有限公司

Sewage sampler for environmental monitoring

InactiveCN108181131AAccurate detection of water depthIncreased water areaProgramme controlComputer controlEngineeringSewage

The invention relates to a sampler, specifically to a sewage sampler for environmental monitoring. The sewage sampler comprises a stable table, support legs, a rotating mechanism, an extension mechanism, an electric reel, a rope, a bearing case, a weighting block, a sampling box, an electromagnetic valve, a water depth sensor, a water depth indicator gauge, a first switch, a second switch, a thirdswitch, a singlechip and a power supply. According to the sampler, the first switch is used for controlling the extension mechanism to extend or retract; water area to be sampled can be enlarged; thesecond switch is used for controlling the electric reel to rotate; the sampling depth can be adjusted flexibly according to sampling requirements; the water depth sensor is additionally arranged on the sampling box; the underwater depth of the sampling box can be detected accurately; precise sampling according to required is facilitated; a precision degree of the sampler can be increased.

Owner:河南蓝图环保科技有限公司

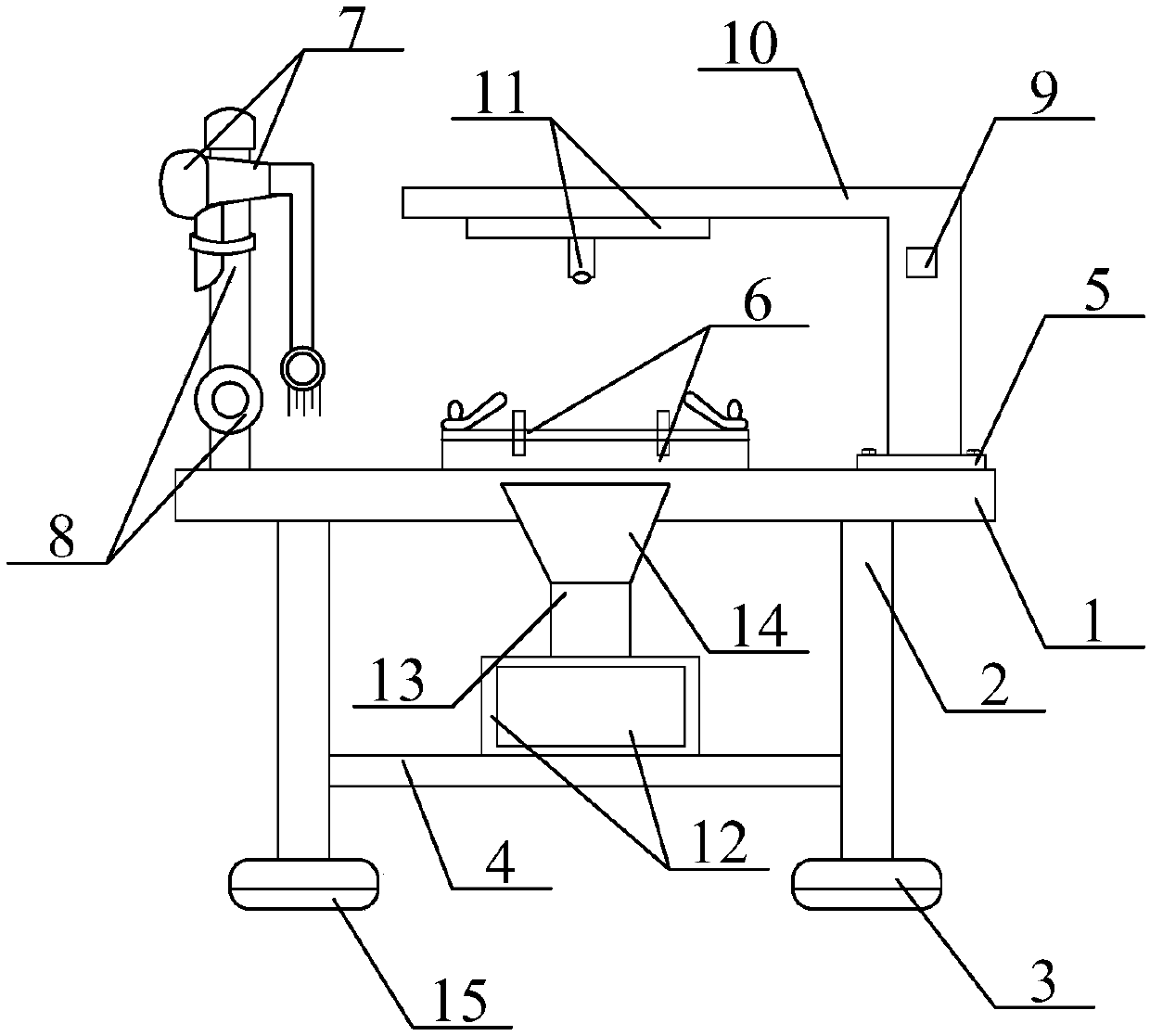

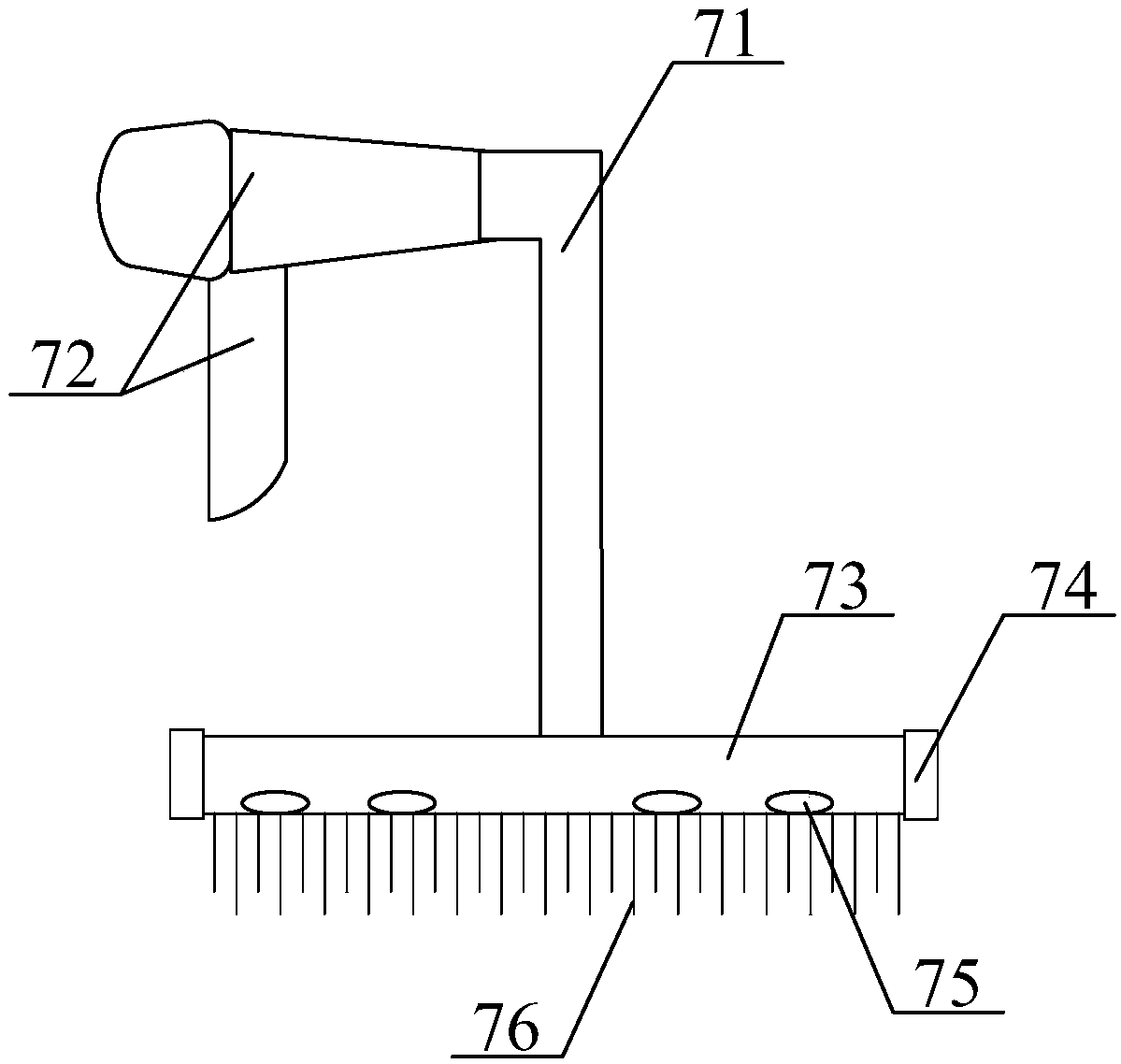

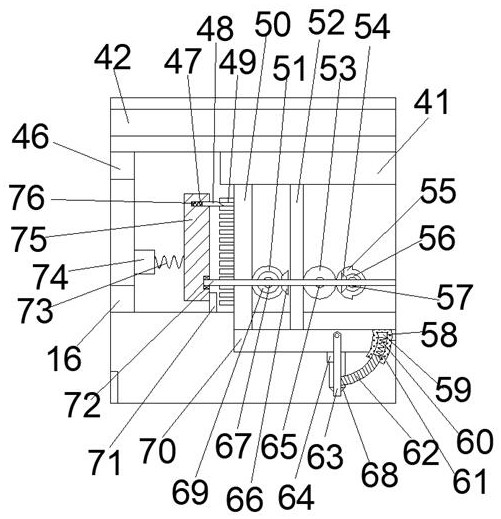

Protective film high-precision cutting equipment

InactiveCN109623165AEasy to fixGuaranteed accuracyLaser beam welding apparatusTectorial membraneBristle

The invention discloses protective film high-precision cutting equipment. The protective film high-precision cutting equipment comprises a cutting worktable, support columns, a fixed stabilizing base,an object placing transverse plate, a connecting stainless steel plate, a wear-resistance protective film fixed base structure, an air blowing and impurity removing cleaning pipe structure, an adjustable protective film drum support rod structure, a control switch, an L-shaped lifting arm rod, a high-precision laser cutting machine, a leftover recovery box, a guide pipe, a receiving hopper and anantiskid pad; the support columns are connected to four corners of the lower surface of the cutting worktable by bolts; and the fixed stabilizing base is transversely connected to the lower surfacesof the support columns by screws. Through arrangement of a fixed spring piece, the fixation of protective films to be cut is facilitated, and the cutting accuracy is guaranteed; and through arrangement of an air guide pipe, an air blower, a dust removing pipe, a limiting plug, an exhaust hole and cleaning brush bristles, the air blowing and dust removing operation is facilitated, impurities on theupper surfaces of protective films can be removed, and the effective cutting operation is guaranteed.

Owner:苏州博研精进光电有限公司

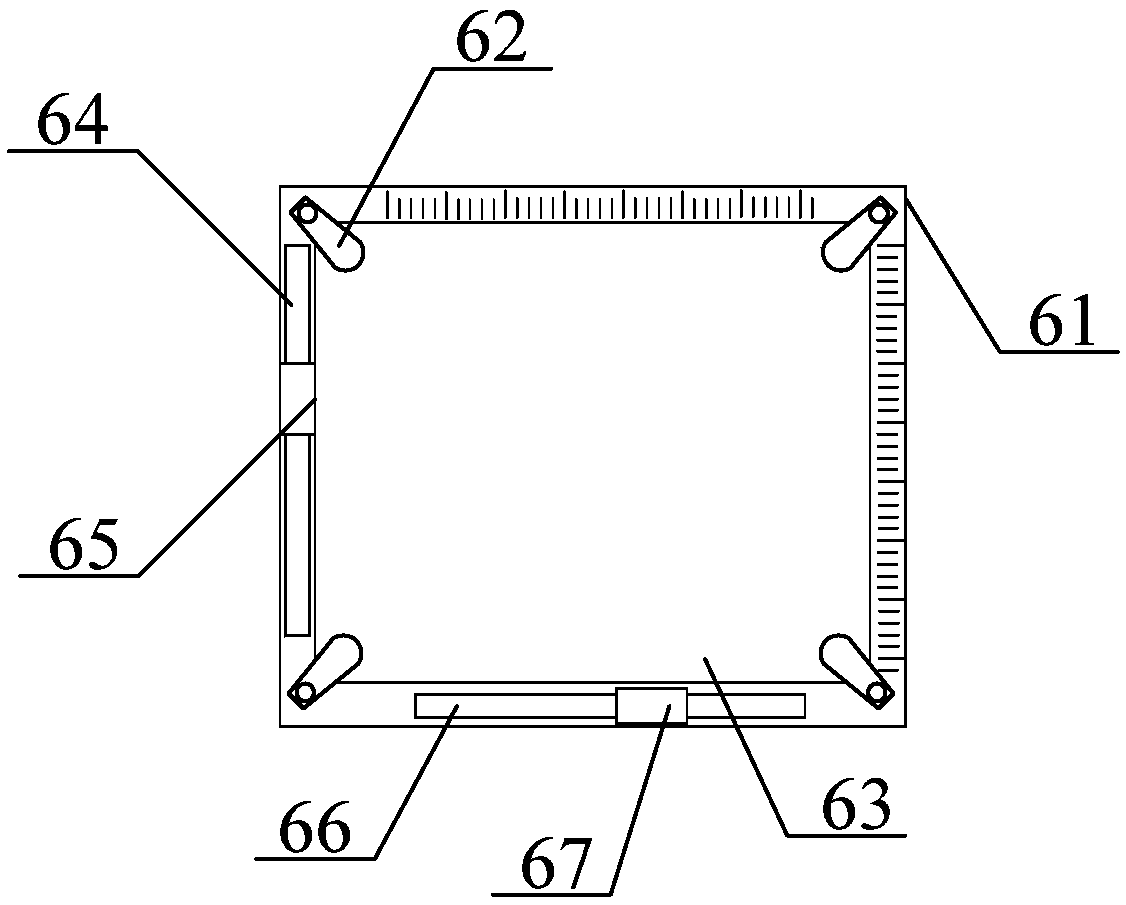

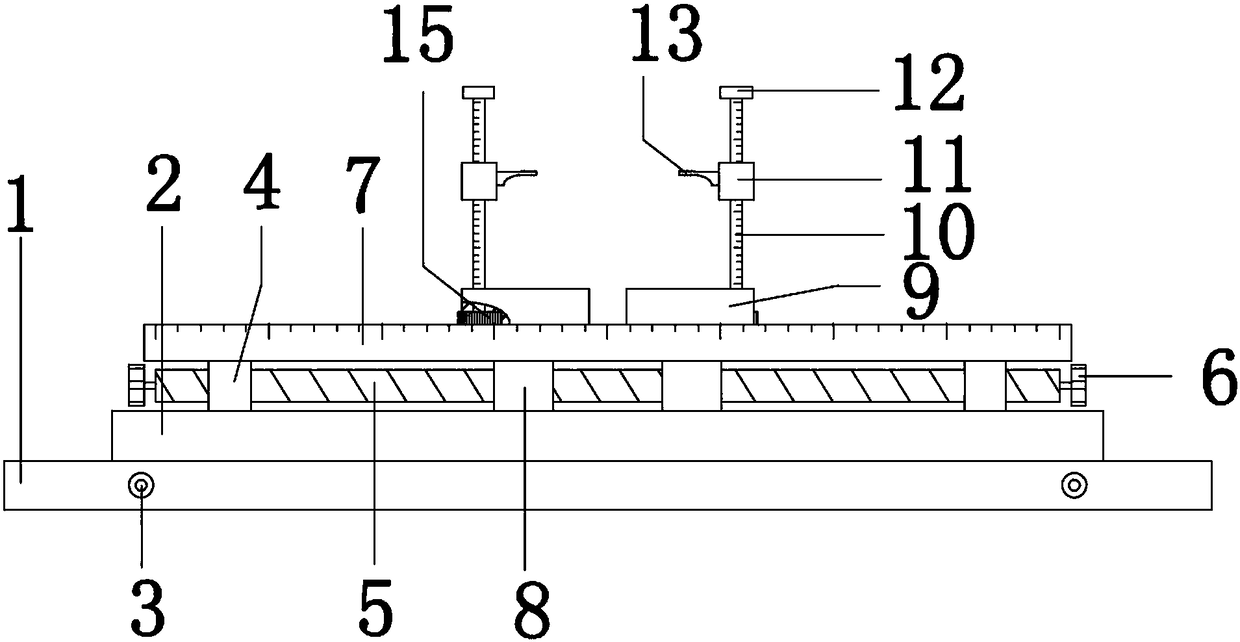

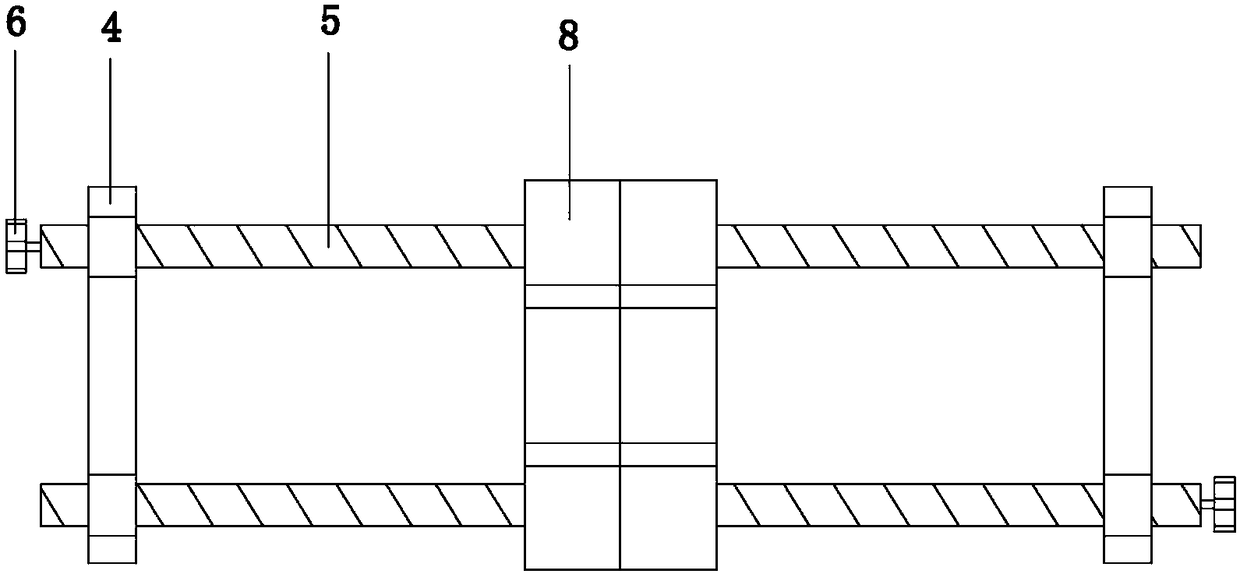

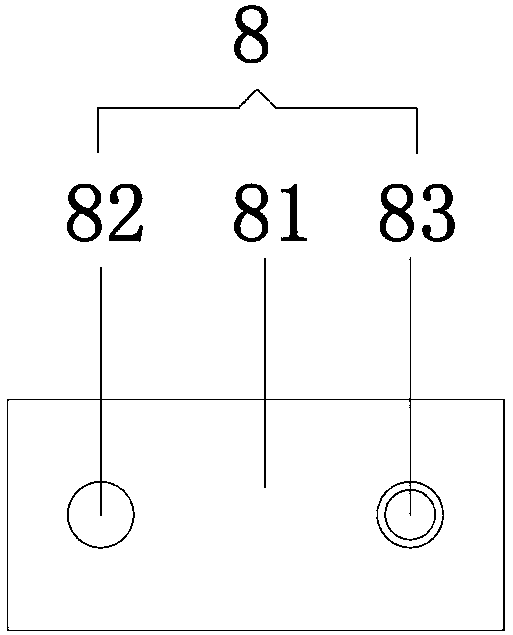

Size-adjustable high-precision machine tool clamp

InactiveCN108067903AIncreased precisionGuaranteed accuracyMeasurement/indication equipmentsPositioning apparatusSize measurementEngineering

The invention discloses a size-adjustable high-precision machine tool clamp, and belongs to the technical field of high-precision machine tool clamps. The size-adjustable high-precision machine tool clamp comprises a machine tool base, and a clamping mounting base is clamped at the top of the machine tool base. The front side and the rear side of the machine tool base are in screwed connection with two sets of fastening bolts, and the clamping mounting base is connected with the machine tool base through the fastening bolts. Fixed frames are mounted on the left side and the right side of the top of the clamping mounting base, and two sets of adjusting rods are mounted on the fixed frames. Adjusting bolts are mounted on the right side of the front adjusting rod and the left side of the rearadjusting rod, and a movable table is mounted at the tops of the fixed frames. According to the size-adjustable high-precision machine tool clamp, the clamping size is adjusted through screwed joint,and the precision degree of data is improved; size measurement before machining, data monitoring during machining and quality monitoring after machining are well assisted, and machining precision isguaranteed; and measurement can be accurate to the millimeter, machining errors during machining are obtained in time, and therefore machining is stopped, and loss increasing is avoided.

Owner:谢小坚

Device and brine solution for fast appraising salinity and alkalinity resistance of tree

InactiveCN101294943BQuick testIncreased precisionMaterial analysisDipotassium hydrogen phosphatePhosphoric acid

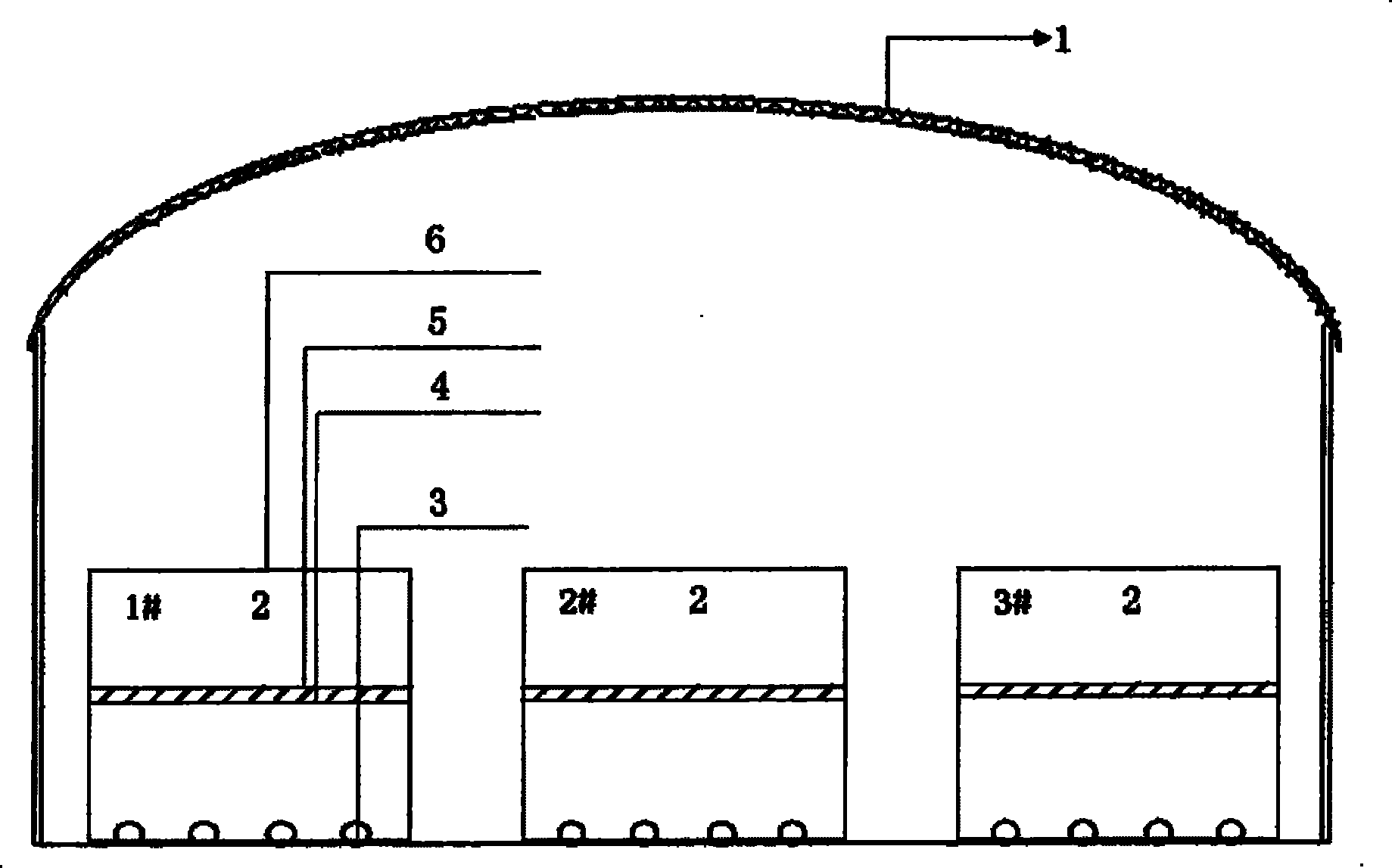

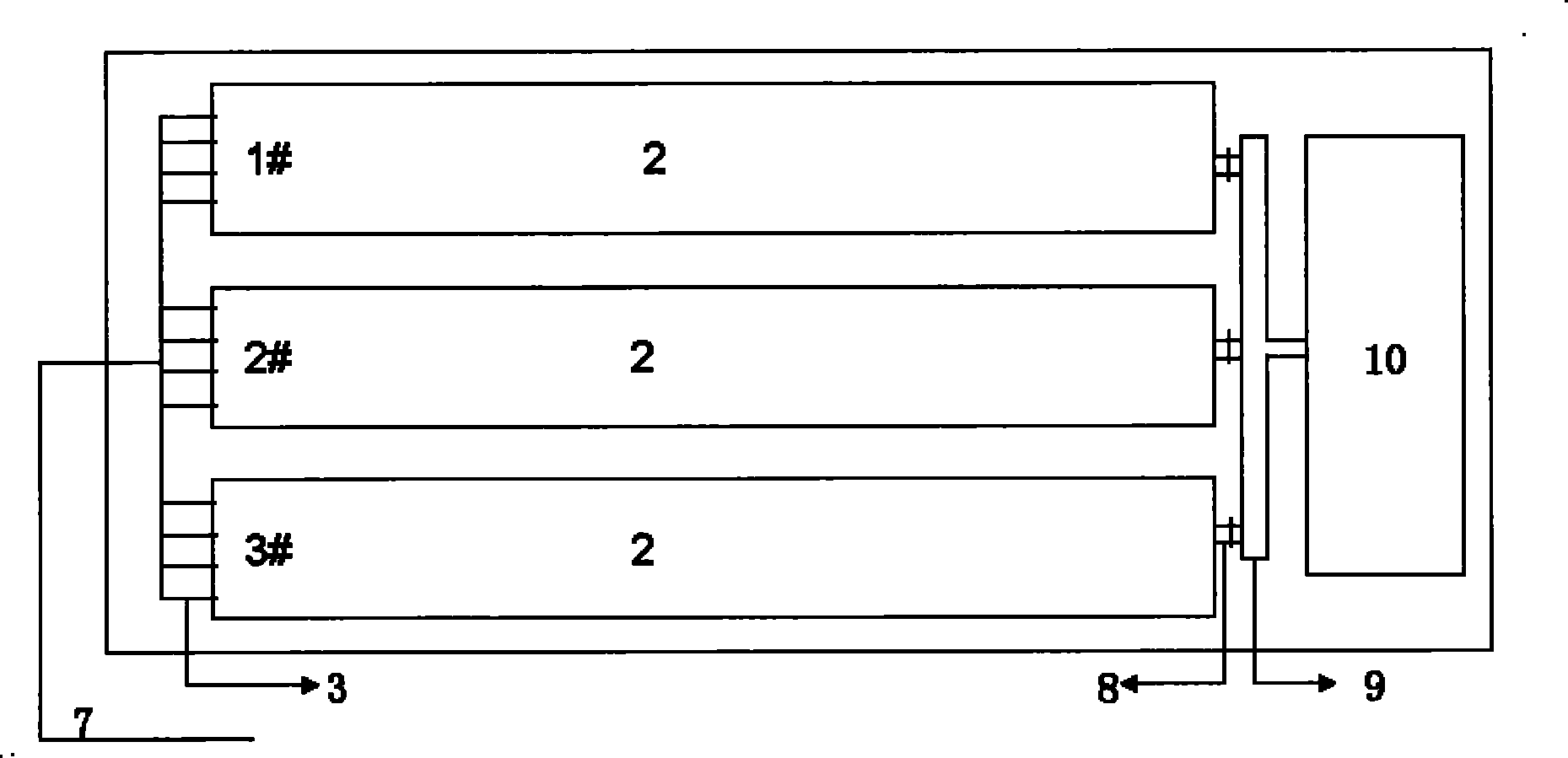

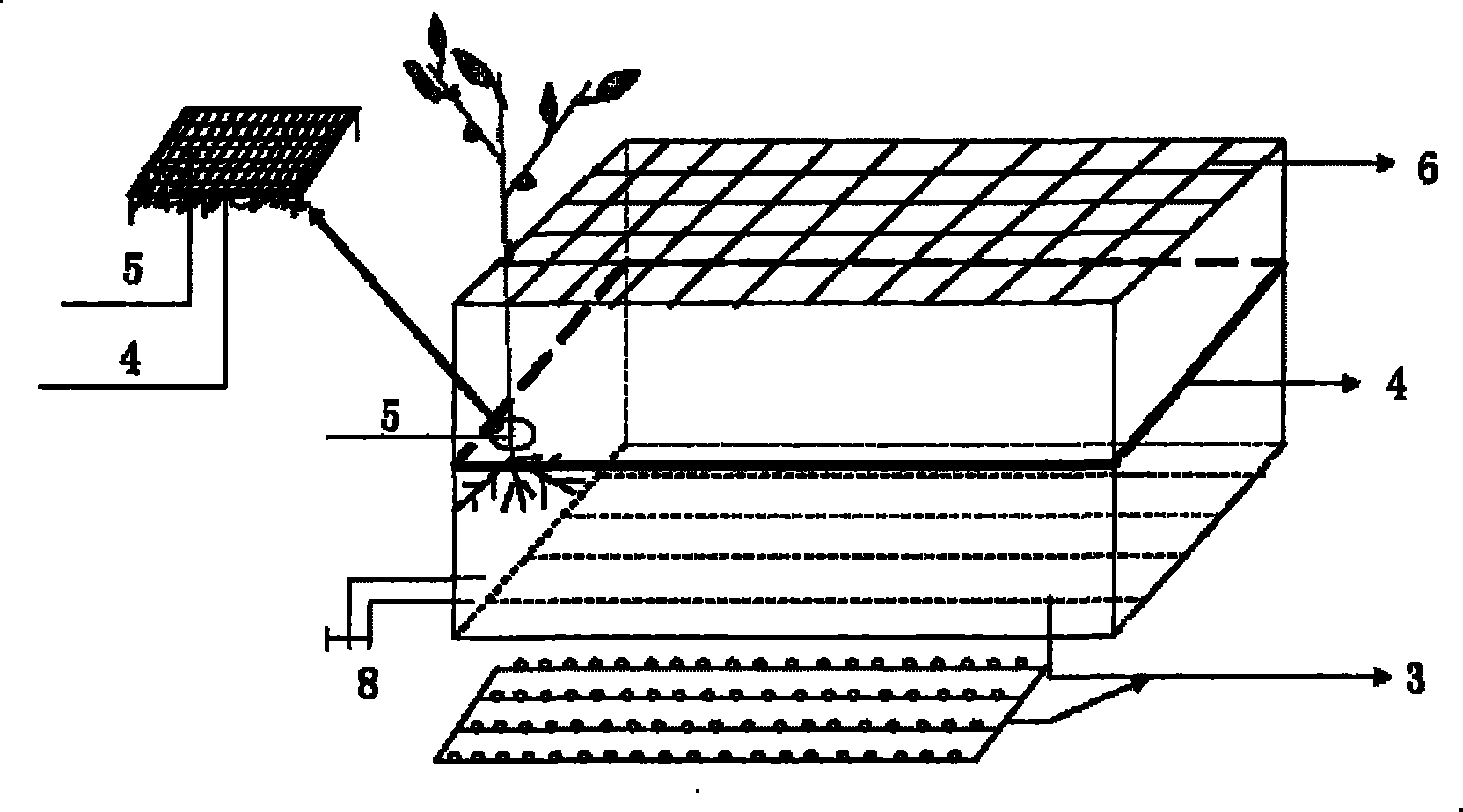

The invention relates to a device and salt solution used for fast identifying the characteristic of salinity-alkalinity tolerance of trees, belonging to the agriculture and forestry technical field; the device of the invention comprises a rain proof shed, a salt pond, an aerator pipe, a floating plate carrier, a non-woven fabric, a fixed net side, an air pump, a water outlet, a drainage ditch anda wastewater disposal basin in sequence; wherein, the salt pond holds salt solution and the weight percentage of the composition of the salt solution is: 0.007 percent to 0.031 percent of calcium nitrate, 0.007 percent to 0.030 percent of dipotassium hydrogen phosphate, 0.003 percent to 0.018 percent of magnesium sulfate, 0.00004 percent to 0.009 percent of sodium chloride and sodium hydroxide and the rest of distilled water; the device and salt solution of the invention provide good environment for the growth of plants, have simple structure, easy operation, convenient maintenance, little one-time investment, low operating cost, high level of precision of ion concentration in the salt solution, faster identifying speed, wide application range and stronger practicability and direction.

Owner:SHANGHAI JIAO TONG UNIV

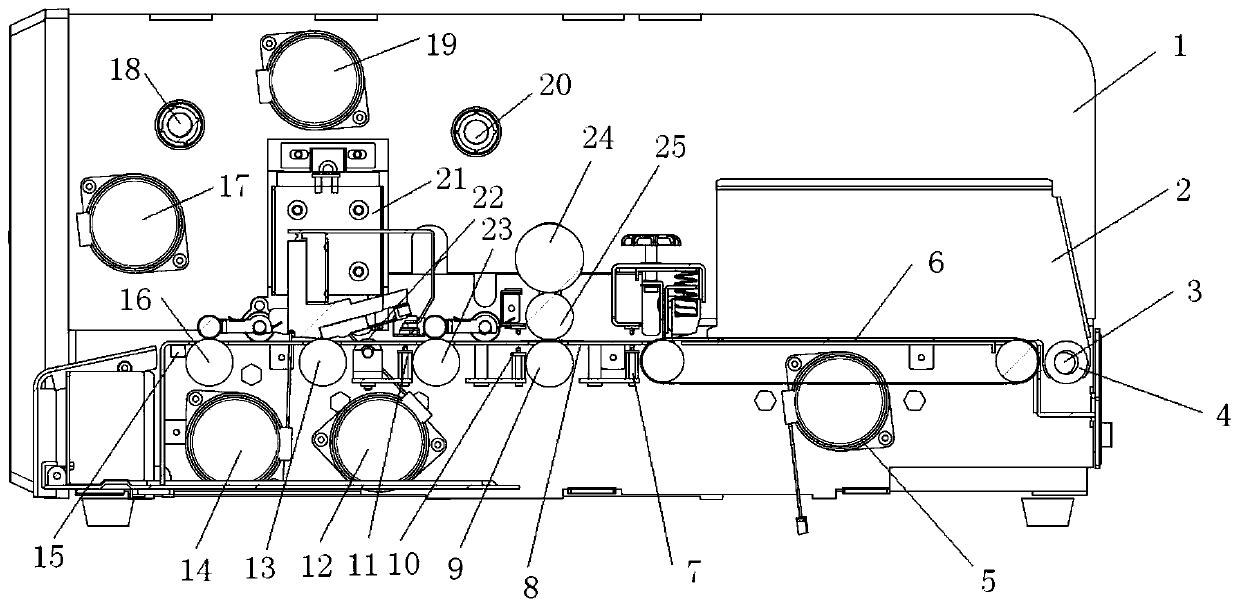

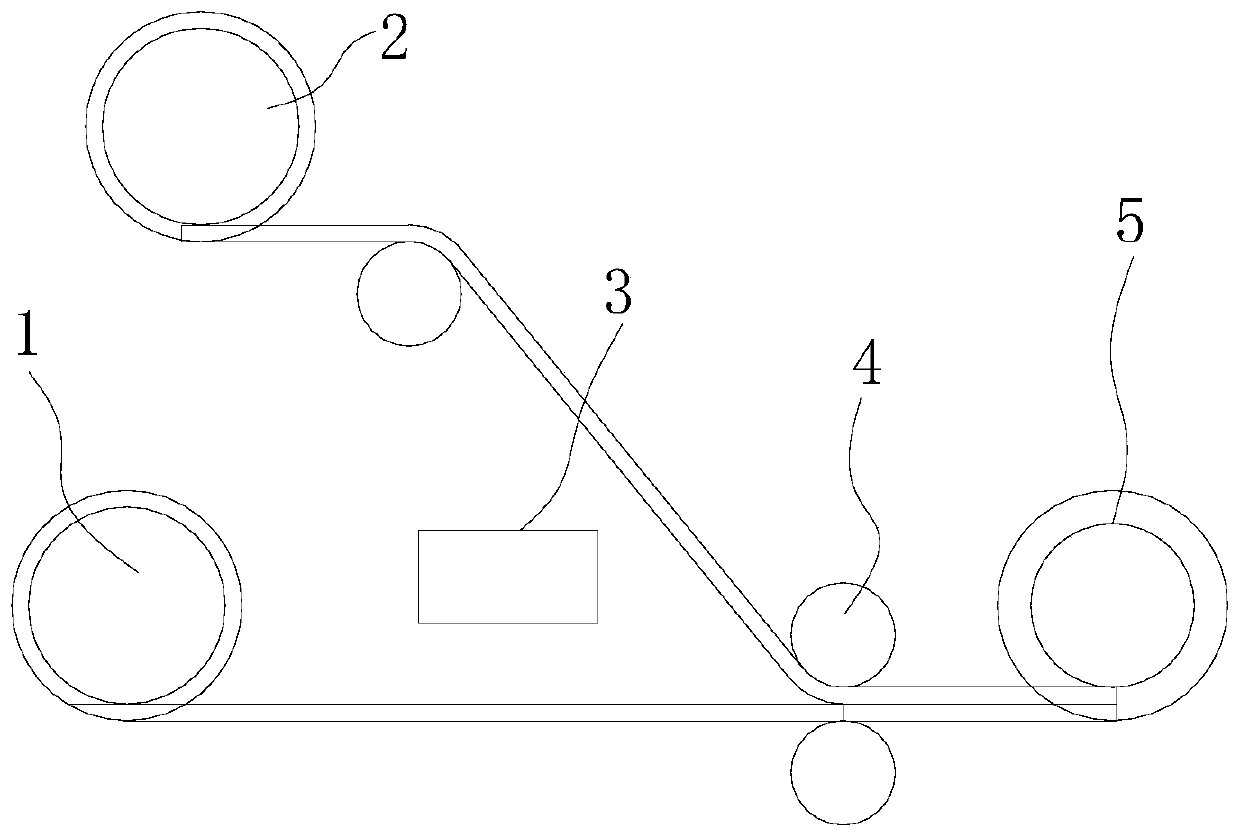

Precision printing machine

PendingCN110682700AAvoid wear and tearPrevent paper jamsOther printing apparatusComputer printingDust control

The invention relates to the field of a printing machine, in particular to a precision printing machine. The precision printing machine comprises a machine shell, an annular card absorbing belt, a paper inlet channel dust-removing roller and a printing head; the dust-removing roller is arranged in front of the annular card absorbing belt and comprises a dust-removing active rotary roller and a dust-removing passive rotary roller; a card dust-removing sensor is arranged in front of the dust-removing roller; the printing head is hinged in front of the card dust-removing sensor; a printing rollerdriven by a printing motor to rotate is arranged below the printing head; transmission gears which are mutually engaged are arranged between a motor shaft of the printing motor and a roller shaft ofthe dust-removing active rotary roller; the control end of the card dust-removing sensor is connected with a card absorbing motor through a cable; a front positioning roller, a back positioning rollerand a positioning sensor are arranged in front of and at back of the printing roller; and the control end of the positioning end is connected with the printing motor through a cable. The precision printing machine provided by the invention is simple in structure, high in printing precision and good in printing effect and can prevent the printing roller or card paper from being worn.

Owner:南京莱贝尔特软件科技有限公司

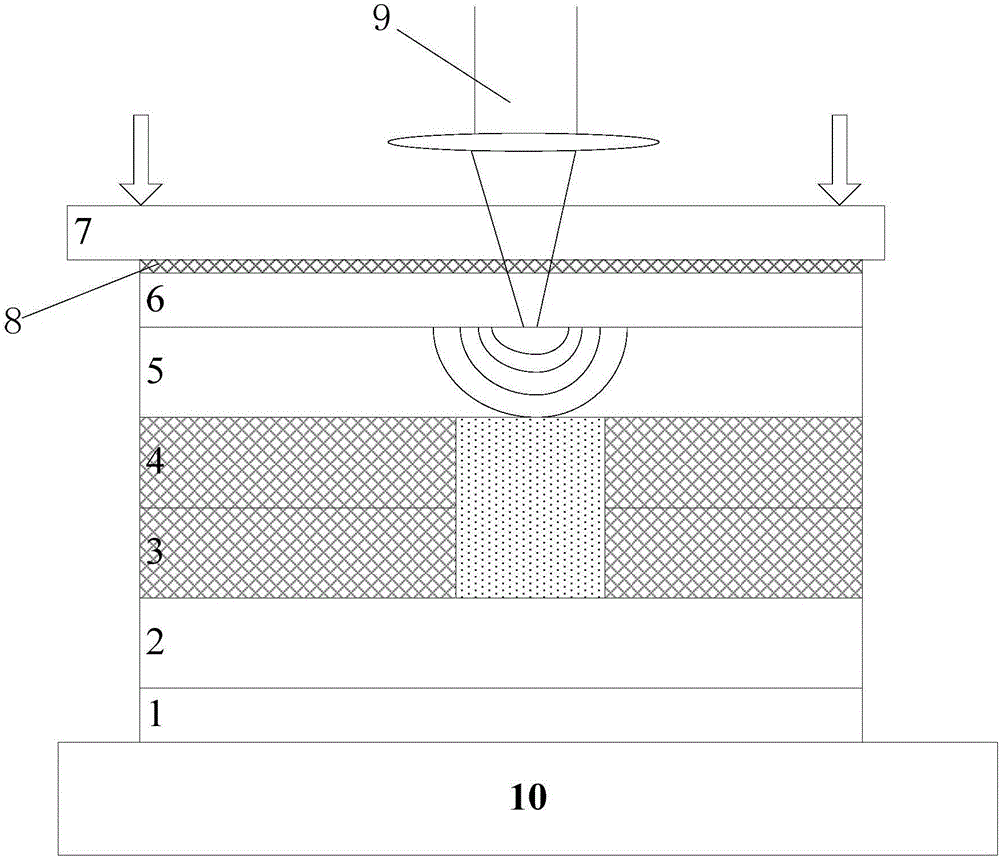

Laser precision welding method for edge sealing of soft-package aluminum shell battery cell

ActiveCN105914389AHeating fastImprove welding efficiencyAssembling battery machinesFinal product manufactureThin layerAluminium

The invention provides a laser precision welding method for edge sealing of a soft-package aluminum shell battery cell. The method comprises the steps as follows: two to-be-sealed and welded battery cell soft-package aluminum-plastic composite membranes are placed in a manner that PP inner layers are oppositely laminated according to an edge sealing and welding position; a transparent glass layer is added to an upper nylon layer; the gap between the upper nylon layer and the transparent glass layer is filled with a thin-layer cooling liquid to isolate the transparent glass layer from the upper nylon layer; pressure is exerted, so that various layers are in tight contact; a laser beam is utilized to enter from the upper part of the transparent glass layer and is focused on the surface of an upper aluminum layer, so that an upper PP layer and a lower PP layer are melted; irradiation is stopped or the laser beam is moved away; and the melted upper PP layer and lower PP layer are quickly cooled and condensed to achieve firm and tight edge sealing. By laser absorption, fast heating and heat conduction of aluminum foil middle layers, the process effect that the PP layers are melted while nylon outer layers are not melted is achieved; and laser precision welding of the PP inner layers of the upper and lower aluminum-plastic composite membranes is achieved under the added pressure-assisted action. The laser precision welding method has the advantages of small edge sealing width, good sealing quality, high production efficiency and the like.

Owner:山东承坤信息科技有限公司

Production technology of flame-retardant composite fabric

ActiveCN109703140AGood flame retardant performanceFeel goodLamination ancillary operationsSynthetic resin layered productsEnvironmental resistanceDyeing

The invention relates to the field of home furnishing fabrics, and aims to provide a production technology of a flame-retardant composite fabric. The flame-retardant composite fabric with excellent hand feeling, environmental protection and stable quality can be processed through the production technology. The production technology of the flame-retardant composite fabric comprises the following steps: S1, processing of a flame-retardant fabric: a, modifying of acrylic fibers: dip dyeing of the acrylic fibers with a treatment liquid at a dip dying liquor ratio of 1:20 at 40 DEG C for 40 min; and b, mixing of 60-70 wt% of the modified acrylic fibers with pre-oxidized acrylic fibers to obtain mixed fibers, and processing of the mixed fibers to form a nonwoven flame-retardant fabric, a knittedflame-retardant fabric or a woven flame-retardant fabric. The flame-retardant fabric makes the product have good flame retardancy and excellent hand feeling.

Owner:MORGAN INT TRADING SHANGHAI CO LTD

Automatic demolding injection mold

Owner:浙江功夫宝贝婴童用品有限公司

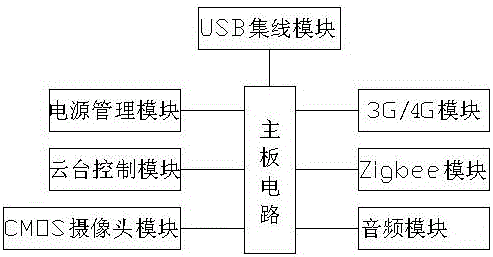

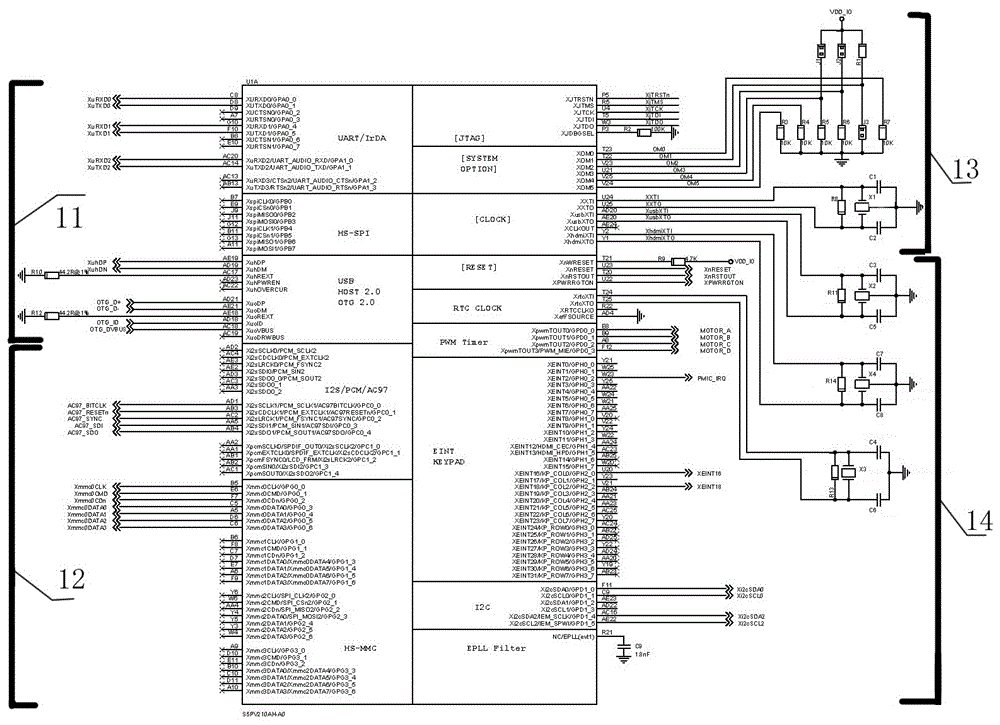

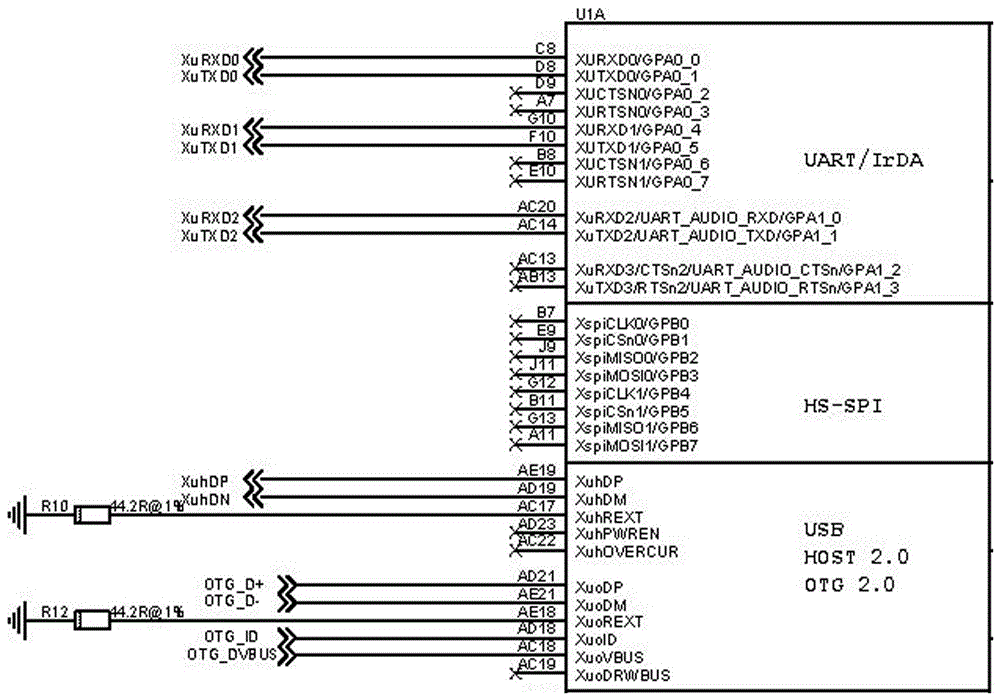

A cloud terminal control module for cloud platform

ActiveCN104238569BSmall step sizeIncreased precisionPosition/direction controlComputer moduleComputer terminal

The invention relates to a pan-tilt control module for a cloud terminal. The pan-tilt control module includes a vertical pan-tilt control circuit and a horizontal pan-tilt control circuit. The motor has a small step size of 0.5 degrees and a high degree of precision.

Owner:山东中鸿新能源科技有限公司

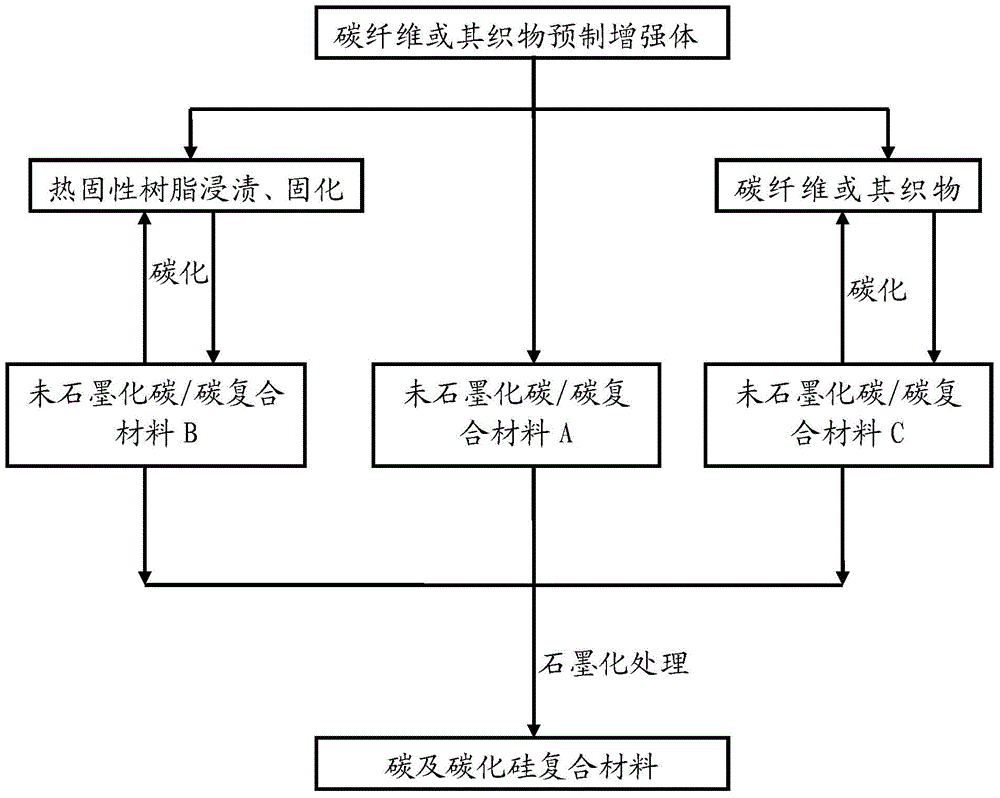

Preparation method of carbon and silicon carbide composite material

The invention relates to a preparation method of a carbon and silicon carbide composite material, wherein the preparation method comprises the following steps: carrying out chemical vapor deposition of a prefabricated reinforcement body of carbon fiber or fabrics thereof to obtain a non-graphitized carbon / carbon composite material A; impregnating the prefabricated reinforcement body of the carbon fiber or the fabrics thereof with a thermosetting resin, curing, then carrying out cyclic carbonation to obtain a non-graphitized carbon / carbon composite material B; impregnating the prefabricated reinforcement body of the carbon fiber or the fabrics thereof with asphalt, carrying out cyclic carbonization to obtain a non-graphitized carbon / carbon composite material C; carrying out graphitization treatment of the non-graphitized carbon / carbon composite material A, the non-graphitized carbon / carbon composite material B and the non-graphitized carbon / carbon composite material C to obtain the carbon and silicon carbide composite material. The preparation method is simple, is high in precision degree, makes full use of raw materials, and can fast and efficiently prepare the carbon and silicon carbide composite material.

Owner:CHONGQING XUXING CHEM

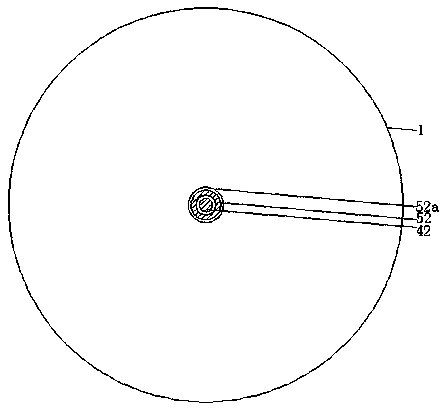

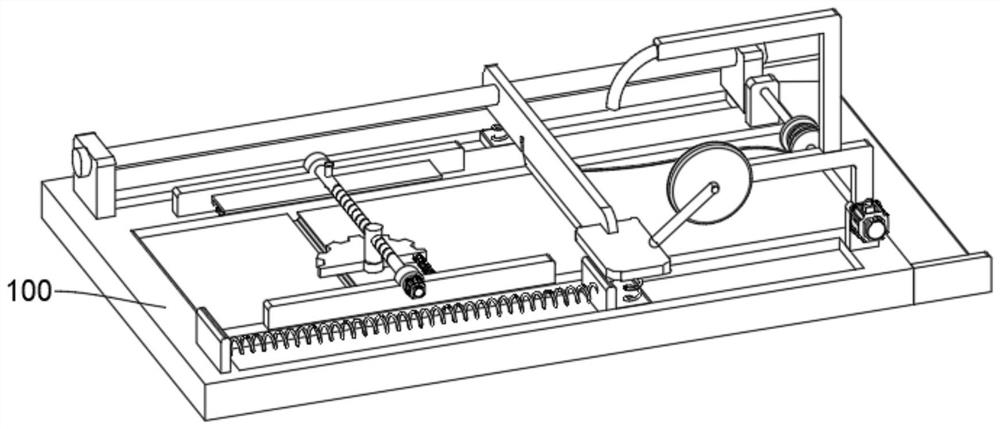

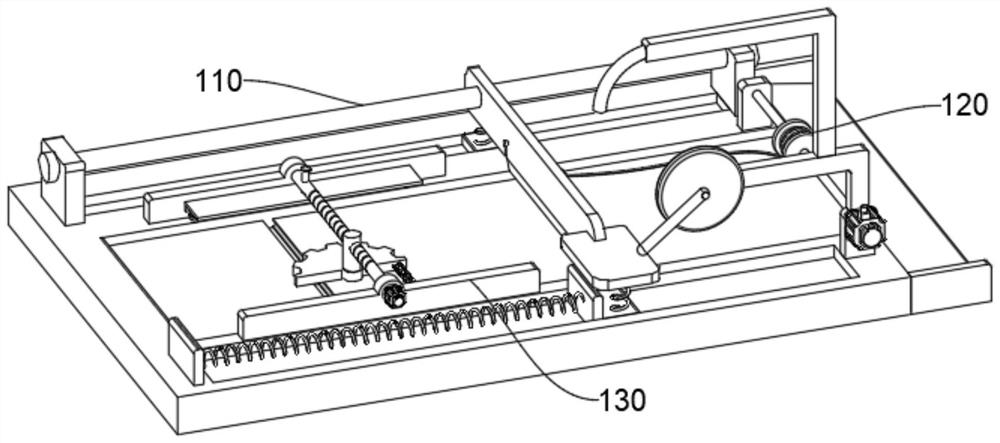

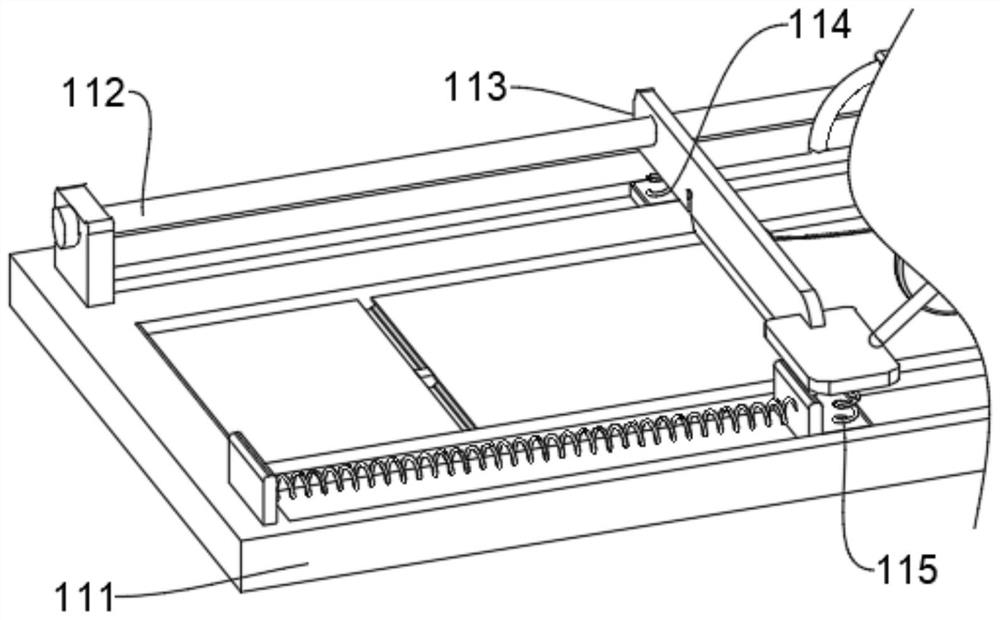

Multi-station precise solid wax block cutting method

ActiveCN109895163AReasonable structureEasy to operateWithdrawing sample devicesPreparing sample for investigationWaxAgricultural engineering

The invention relates to a multi-station precise solid wax block cutting method. A slicing machine is used, and a circular shell, a displacement device, a cutting device and an operation device are included. The solid wax block cutting method comprises the first step of solid wax block installing, the second step of pre-cutting, the third step of position adjusting and the fourth step of cutting.According to the multi-station precise solid wax block cutting method, the adopted slicing machine is reasonable in structure and simple in operation, and mounting and synchronous cutting can be conducted on multiple solid wax blocks at the same time; and the slicing machine can precisely adjust the solid wax block cutting thickness.

Owner:罗仙花

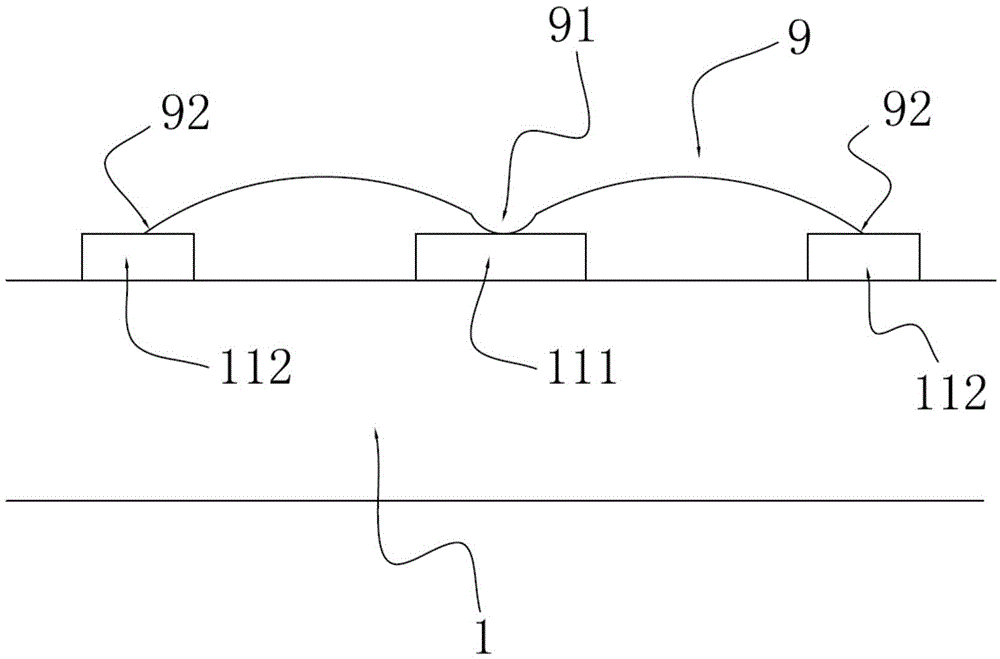

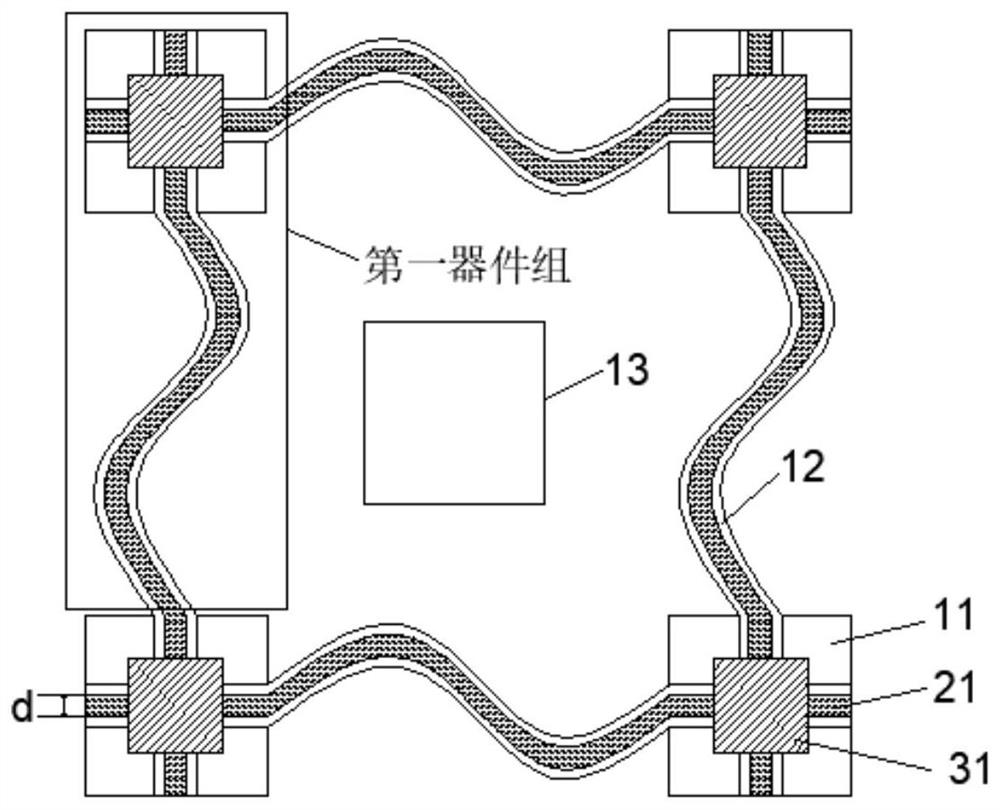

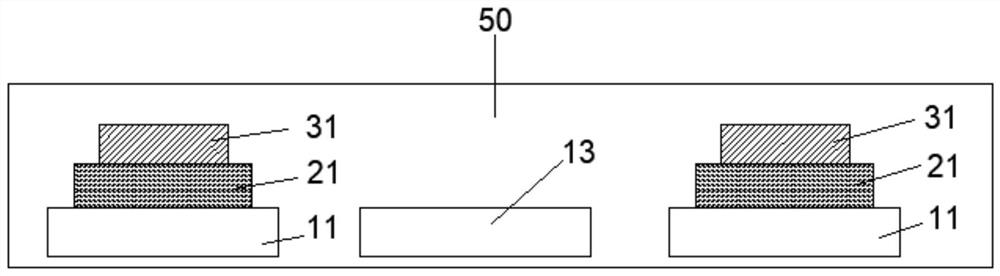

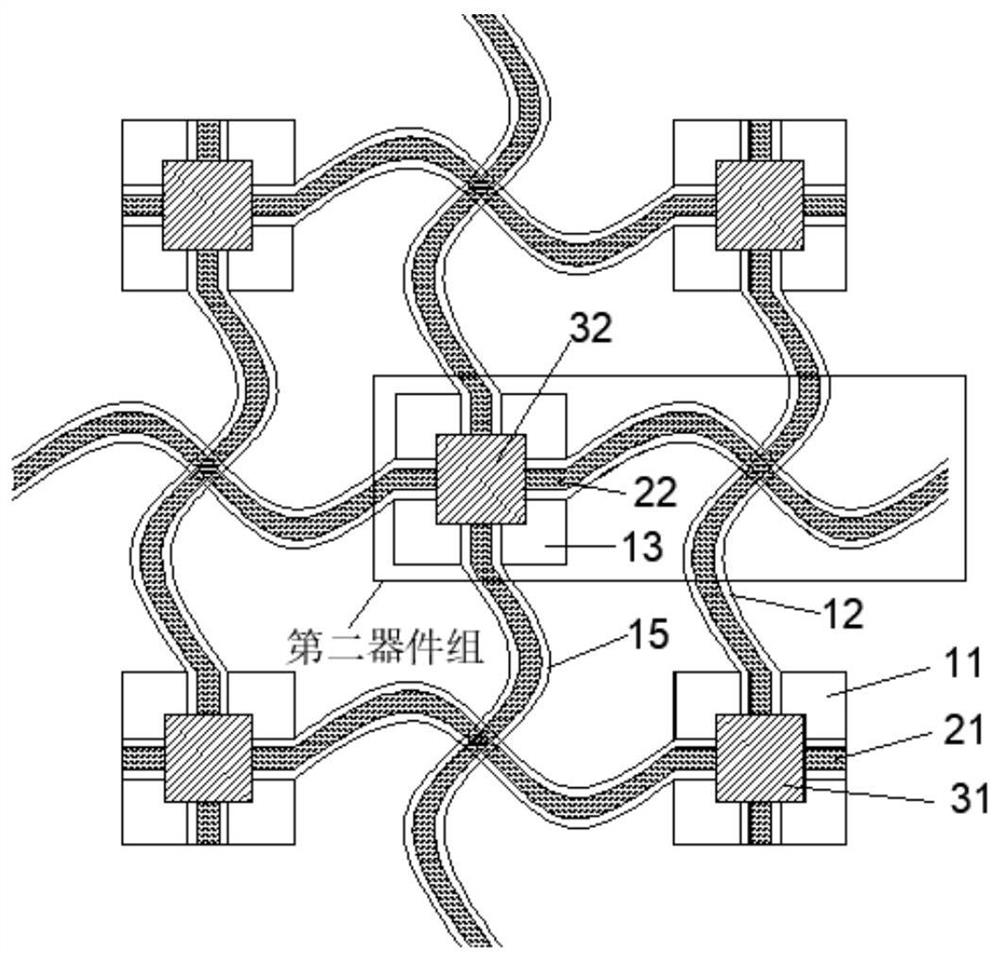

Stretchable display panel and preparation method thereof and display device

PendingCN111816675AIncreased precisionReduce processing timeFinal product manufactureSolid-state devicesPhysicsErbium lasers

The invention discloses a stretchable display panel and a preparation method thereof and a display device. The stretchable display panel comprises: a polyimide substrate which comprises a plurality offirst sub-polyimide substrates, a plurality of second sub-polyimide substrates and at least one third sub-polyimide substrate; a first wire which is positioned above the first sub-polyimide substrates and the second sub-polyimide substrates; and a first device which is located above the first sub-polyimide substrates, wherein the first wire is electrically connected with the first device, the adjacent first sub-polyimide substrates are connected through the second sub-polyimide substrates to form a closed area, and the third sub-polyimide substrate is located in the closed area, and the firstsub-polyimide substrates, the second sub-polyimide substrates, the first device and the first wire form a first device group. By means of the stretchable display panel, the laser processing time canbe shortened, the service life of a laser is prolonged, and meanwhile the precision degree of the stretchable display panel can be improved.

Owner:YUNGU GUAN TECH CO LTD

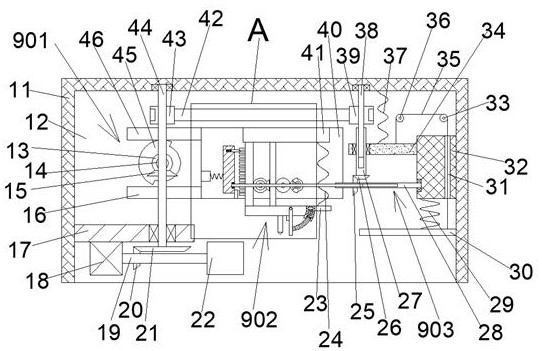

Special lathe suitable for machining and producing of multiple sizes of hot-forged materials

InactiveCN112720072AImprove efficiencyIncreased precisionAutomatic control devicesAuxillary equipmentFriction driveGear tooth

The invention discloses a special lathe suitable for machining and producing of multiple sizes of hot-forged materials. The special lathe comprises an equipment shell, a working cavity with an opening in the lower side is formed in the equipment shell, and a turning assembly is arranged in the working cavity; and the turning assembly comprises a movable supporting plate which is arranged on the inner wall of the rear side of the working cavity and can slide leftwards and rightwards, and a linkage sliding rod which is arranged at the front end of the movable supporting plate and can slide up and down. According to the special lathe, a hinge rod capable of abutting against a hot-forged workpiece when the size of the hot-forged workpiece is detected is arranged, when the hinge rod abuts against the hot-forged workpiece, the mode of enabling a horizontal connecting rod and a special tool descend through switching (friction transmission is switched to gear and rack transmission) is adopted, the feeding is uniformly and stably conducted every time, the reasonable tool feeding amount every time is guaranteed, automatic turning of workpieces is achieved, the efficiency is high, and due to the adoption of a non-manual measurement mode, the precision is greatly improved.

Owner:深圳市鸿跃新科技有限公司

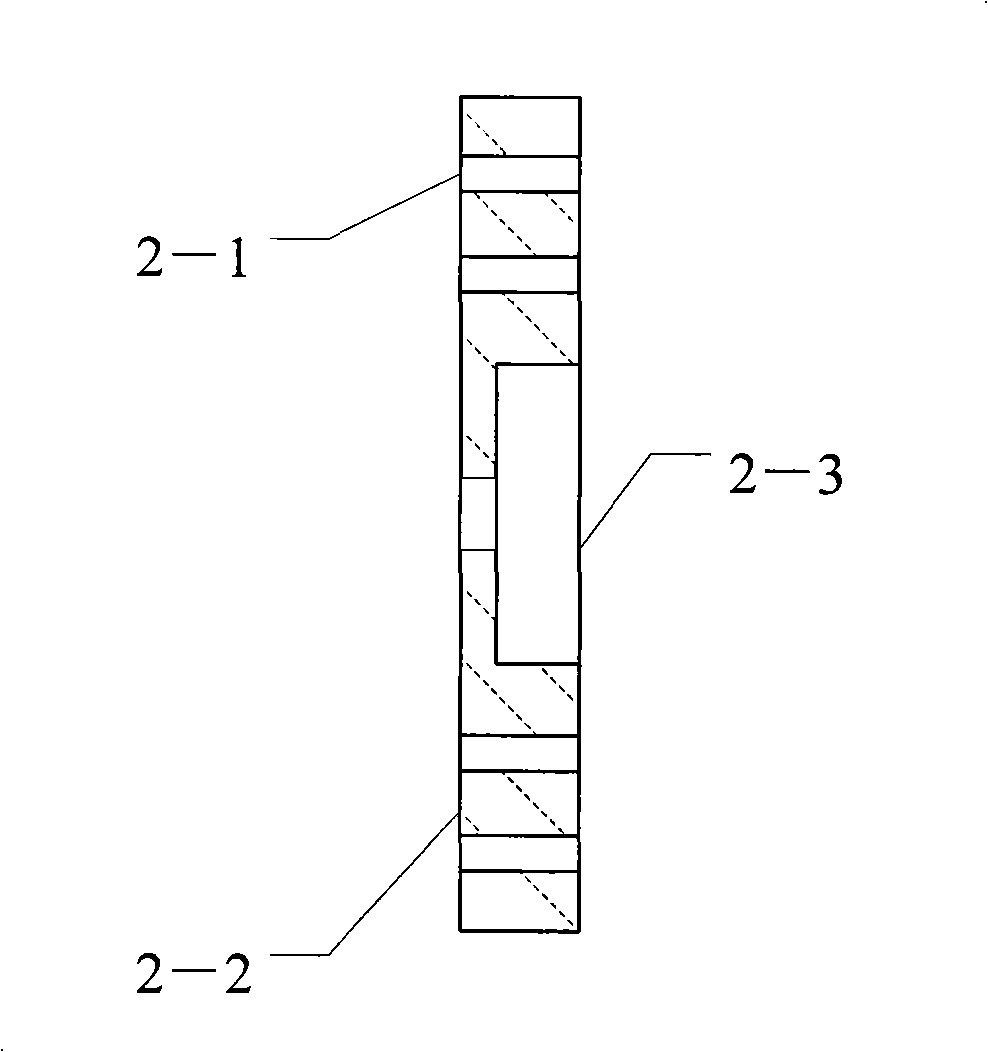

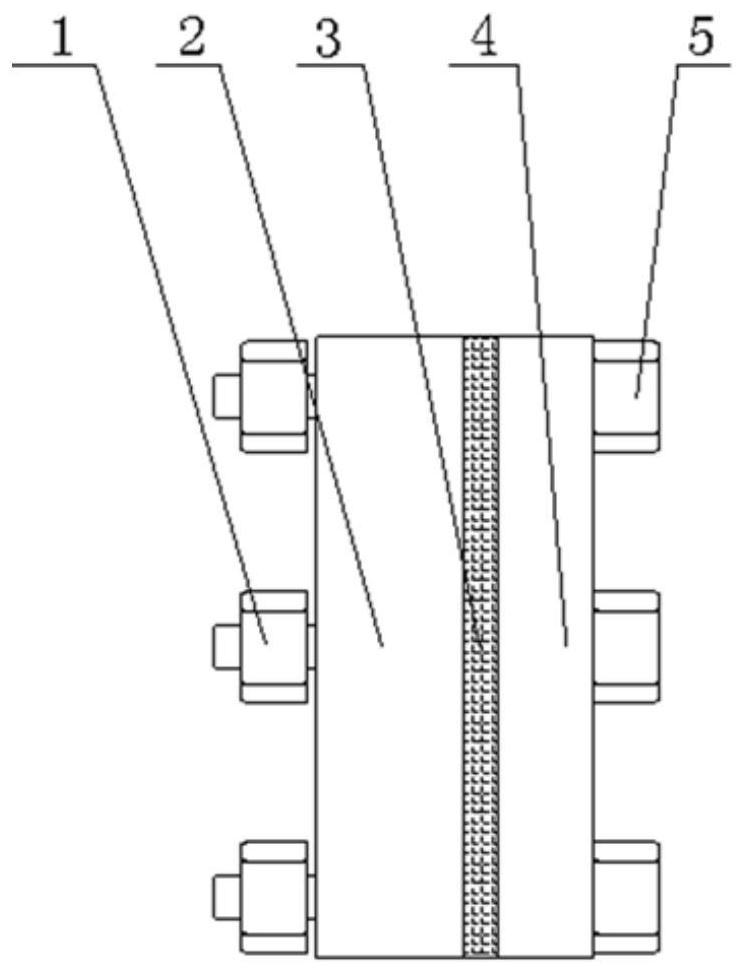

A precision connecting flange

ActiveCN109882671BIncrease roughnessIncreased precisionFlanged jointsPolishing compositions with abrasivesClassical mechanicsEngineering

The present invention relates to a precision connecting flange, comprising a first flange, a second flange, a sealing gasket, fastening bolts and nuts, the sealing gasket is arranged between the first flange and the second flange, Corresponding positions of the first flange and the second flange are respectively provided with pipe accommodation holes, and corresponding positions of the first flange and the second flange are respectively provided with fastening through holes, and the fastening bolts are in turn The fastening through holes passing through the first flange and the second flange are threadedly connected with the nuts. The precision connecting flange of the invention has the advantages of smooth surface, low crack rate, good sealing performance, etc., and can meet the requirements of high-precision equipment.

Owner:山西昊坤法兰股份有限公司

Automatic mechanical cutting device and using method thereof

InactiveCN114161498AIncreased precisionSpeed up sortingMetal working apparatusAutomatic transmissionElectric machinery

The invention relates to the technical field of cutting devices, in particular to an automatic mechanical cutting device and a using method thereof. The device comprises a cutting mechanism, the cutting mechanism at least comprises a cutting body, the cutting body comprises a cutting table, a fixing rod is installed on the surface of the cutting table through block plates symmetrically arranged at the ends, the surface of the fixing rod is rotationally connected with a tool rest, a cutting tool is arranged in the tool rest, a tool handle is installed at one end of the tool rest, and a return plate is installed below the tool handle through an upper spring; and the automatic transmission body comprises a fixing frame installed on the cutting table, one end of the fixing frame is rotationally connected with a wheel disc, one end face of the wheel disc is rotationally connected with a wheel disc motor, and a guide rod is installed at one end of the surface of the wheel disc. According to the automatic material cutting device, automatic material cutting operation can be conducted on small or fragile materials, manpower is saved, and waste of resources is reduced.

Owner:CHONGQING COLLEGE OF ELECTRONICS ENG

A multi-trait and multi-interval localization method based on genotype error at marker loci

ActiveCN108197435BPrecise positioningIncreased precisionProteomicsGenomicsGenotypeMolecular genetics

Owner:SUIHUA UNIV

A device and method for preparing cement stone microscopic samples and testing bending and tensile strength

ActiveCN112014237BGuaranteed production quantityHigh precisionPreparing sample for investigationMaterial strength using steady bending forcesProcess engineeringUltimate tensile strength

The invention discloses a device and method for preparing microscopic samples of cement stone and testing the bending and tensile strength, including a workbench, a support frame and a chute track are fixedly arranged on the workbench; a grinding and cutting assembly is fixedly arranged on the support frame for Grinding and cutting the sample to form a sample, and the support frame is also fixedly equipped with a test component to test the bending and tensile strength of the sample; the grinding and cutting component and the test component are both located above the chute track, and are used to fix the sample or the operating table of the sample It is set on the chute track and can move along the chute track.

Owner:SHANDONG UNIV +1

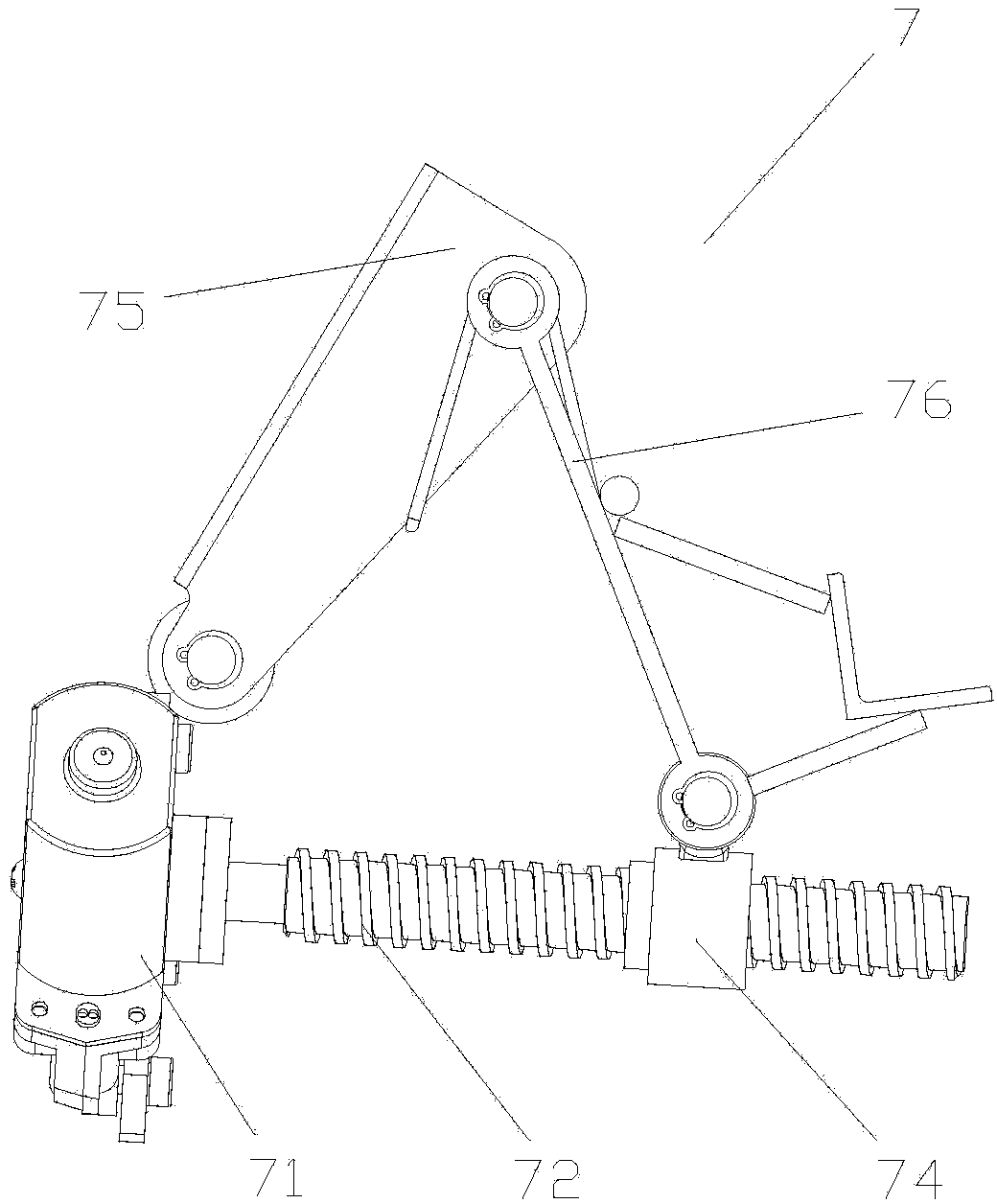

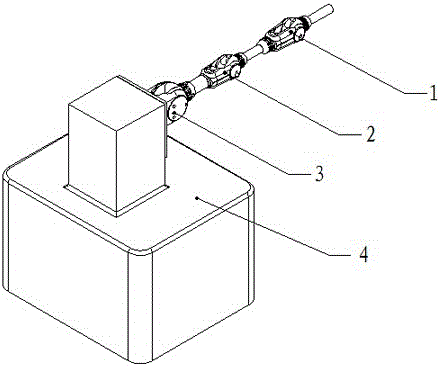

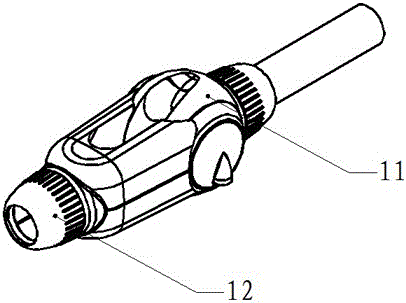

Robot arm joint controlled through wire pulling method

The invention discloses a robot arm joint controlled through a wire pulling method. The robot arm joint comprises a first joint arm, a second joint arm connected to the first joint arm, a third joint base connected to the second joint arm, and a drive control box, wherein the drive control box is connected to the third joint base and drives the first joint arm, the second joint arm and the third joint base to do the wire pulling movement through forward and reverse wire winding. According to the robot arm joint controlled through the wire pulling method, the movement control over a robot is achieved through wire pulling control, the application range of the robot is minimized to be minimal, and the working precision degree of the robot is improved.

Owner:KUSN TAMI ROBOT

A microtome for embedding paraffin block of esophageal cancer pathological tissue

ActiveCN109895164BReasonable structureEasy to operateWithdrawing sample devicesPreparing sample for investigationOncologySurgery

Owner:THE AFFILIATED HOSPITAL OF SHANDONG UNIV OF TCM

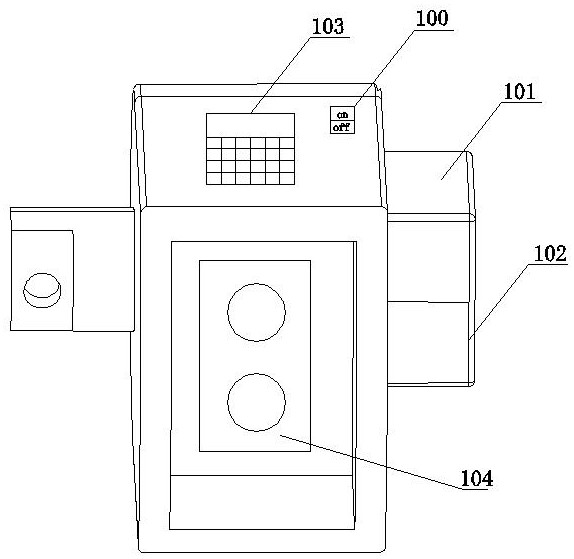

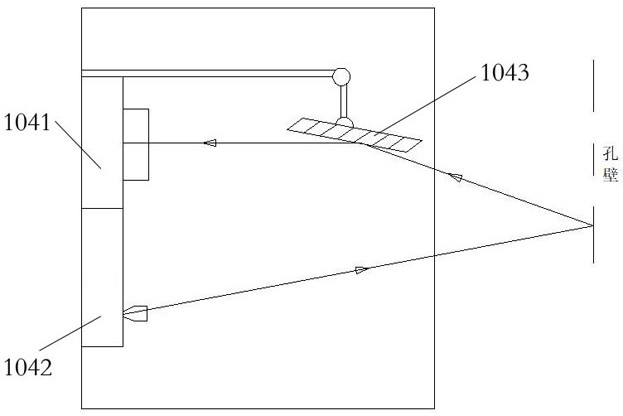

Deep hole inner wall geometric structure detection robot system based on line structure light detection method

ActiveCN112082504AImprove intelligenceImprove automationUsing optical meansVehiclesCcd cameraRobotic systems

The invention provides a deep hole inner wall geometric structure detection robot system based on a line structured light detection method, which realizes bionic wriggling, automatically and stably moves back and forth in a spiral groove deep hole workpiece, also can control the rotating speed of a rotating detection head according to different requirements in the advancing process, and utilizes the line structure light detection principle, namely, a structure light controller emits a structured light beam to the wall of the spiral groove hole, the light beam is modulated into a deformed structure light beam under the influence of the spiral groove on the surface of the inner wall, and the deformed structure light beam is collected by corresponding CCD camera after being reflected by a plane mirror, so that complete morphology data of the complex hole wall can be detected and obtained. The detection method is not influenced by factors like workpiece shape, material, electromagnetism, vibration and the like. The system provided by the invention is unique in structure, is provided for solving the problem of spiral groove deep hole workpiece inner wall geometric structure detection, is combined with an efficient linear structure light detection principle and intelligent detection equipment, and has important significance for improving the intelligent, automatic and precise degreeof spiral groove deep hole workpiece inner wall geometric structure detection.

Owner:ZHONGBEI UNIV

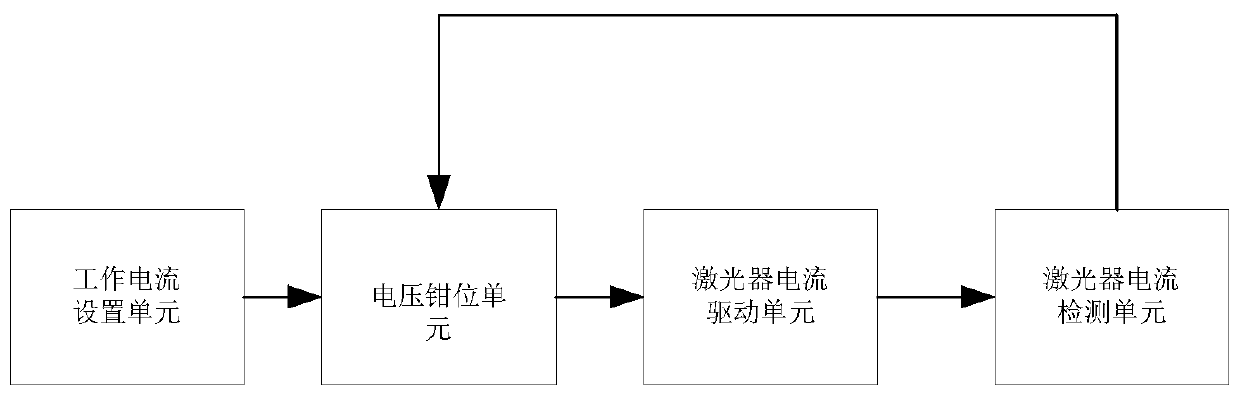

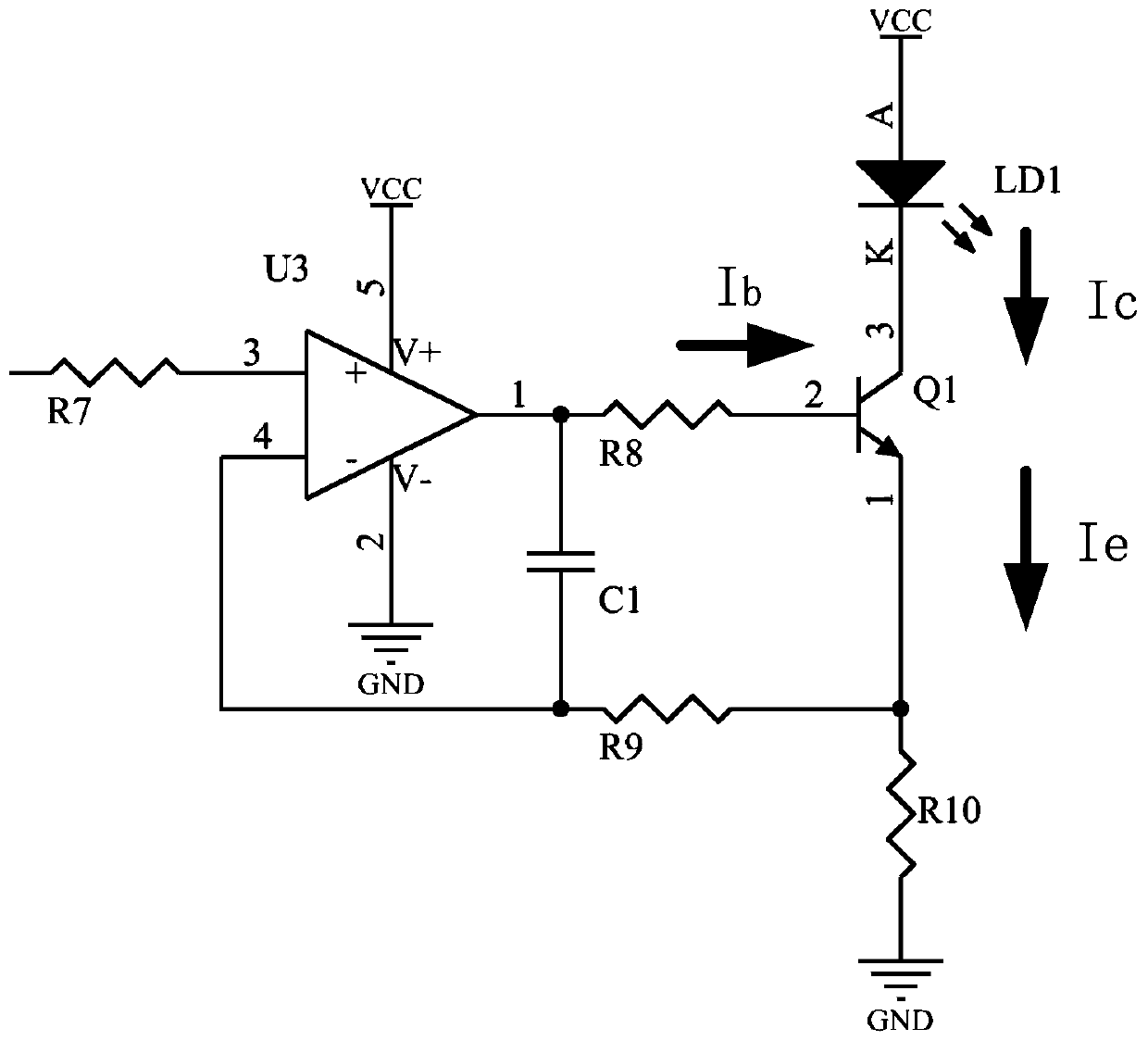

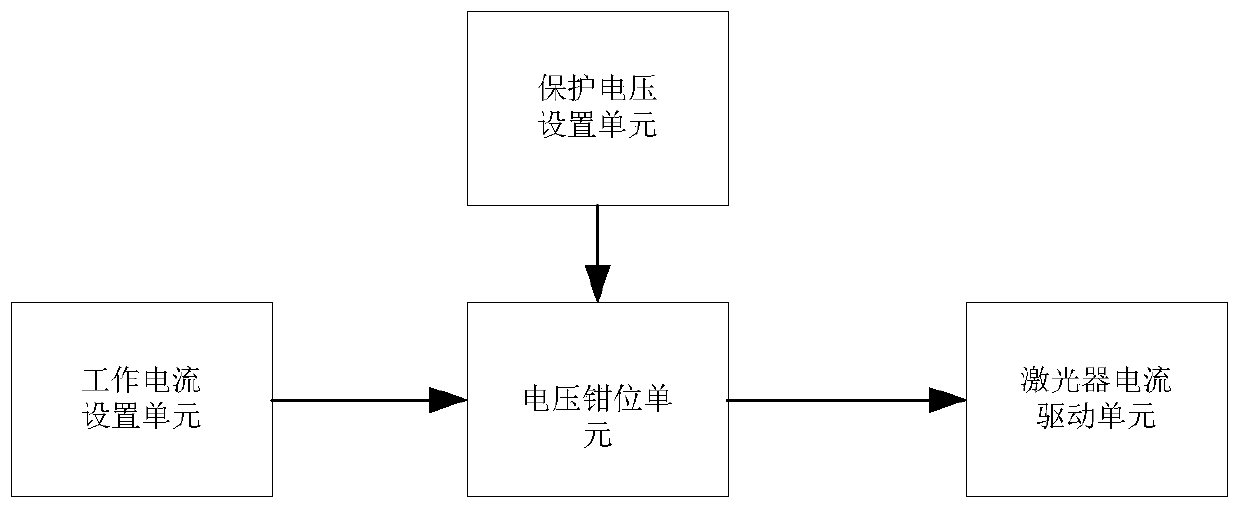

A laser current drive circuit and drive method with maximum current protection

ActiveCN109217101BIncreased precisionLaser detailsSemiconductor lasersControl engineeringHemt circuits

The invention relates to the technical field of semiconductor laser driving, and provides a laser current driving circuit with maximum current protection and a driving method. Wherein the circuit comprises a protection voltage setting unit for setting a reference protection voltage according to which the supply voltage clamping unit is used as a comparison basis; Wherein, the reference protectionvoltage value is calculated according to the maximum permissible current of the laser; The voltage clamping unit is configured to obtain a reference protection voltage of the protection voltage setting unit, and determine whether the output amount of the working current setting unit or the clamping voltage clamped by the voltage clamping unit is output to the laser current driving unit by comparing the input amount of the working current setting unit. The circuit structure of the invention is simple, because the intervention of the external main controller is not required, the precision is higher, the realization is easy, and only a few components need to be added, so that the laser can be remarkably protected, and the safety, the stability and the precision of the system are improved.

Owner:ACCELINK ELECTRONICS TECH

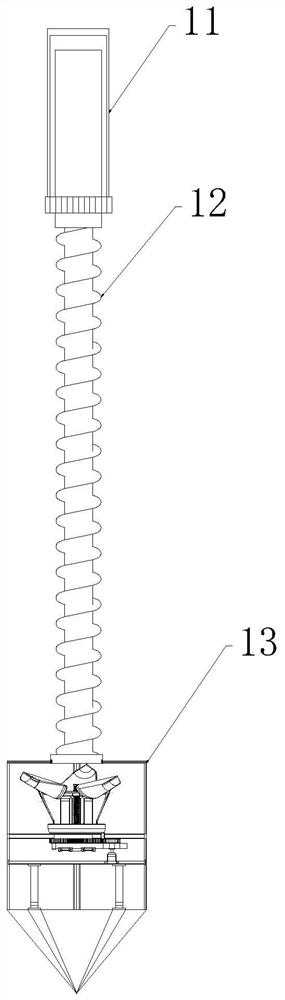

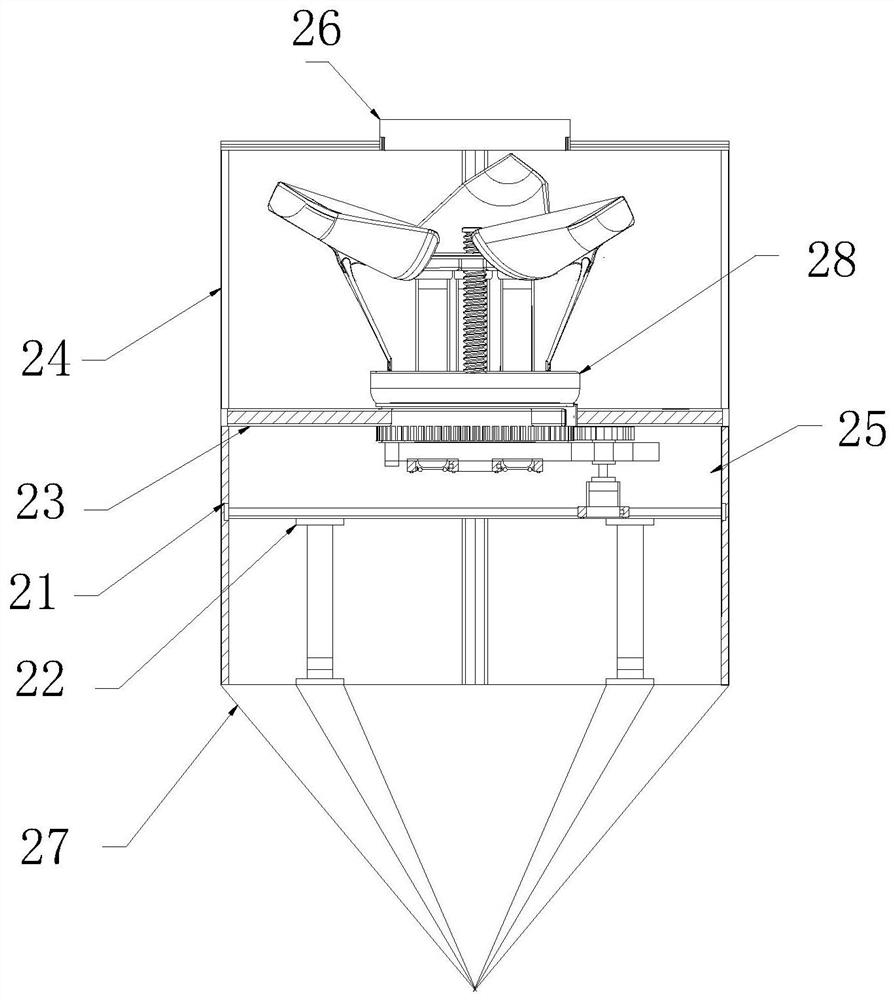

Sample sampling and storing device for coal field exploration and use method

InactiveCN114371028AGuaranteed accuracyIncreased precisionWithdrawing sample devicesStructural engineeringMachine parts

The invention relates to the technical field of coal field exploration, in particular to a coal field exploration sample sampling and storing device and a using method, and the coal field exploration sample sampling and storing device comprises a driving machine part, an extension rod part mounted on the driving machine part, and a soil drilling assembly mounted at the rod end of the extension rod part; the soil drilling assembly comprises a machine part frame connected with the soil drilling assembly, a soil drilling cone mounted at the soil drilling end of the machine part frame, and a sampling machine part embedded in the machine part frame; the sampling machine part comprises a fixed base installed in an inner cavity of the machine part frame, a loading assembly arranged on the fixed base and a plurality of sampling bottles installed on the loading assembly, the opening ends of the sampling bottles are exposed, and covering assemblies are arranged on the peripheries of the opening ends; the covering assembly is installed on the fixed base through an opening and closing transmission part, a transmission assembly is arranged in the machine part frame, and the transmission assembly is used for controlling opening and closing of the covering assembly through the opening and closing transmission part.

Owner:张建军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com