A precision connecting flange

A technology for connecting flanges and flanges, applied in the direction of flange connections, pipes/pipe joints/fittings, passing components, etc., can solve the problem that the precision of flanges cannot reach high-end precision instruments, etc., to improve the reaction effect and response The effect of speed and precision improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

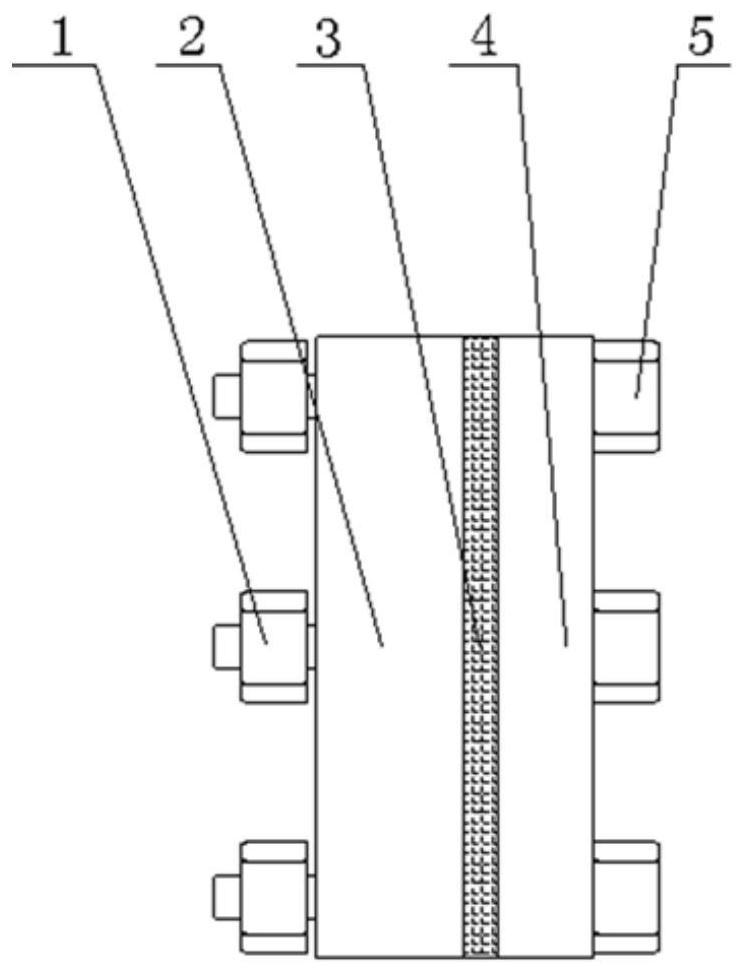

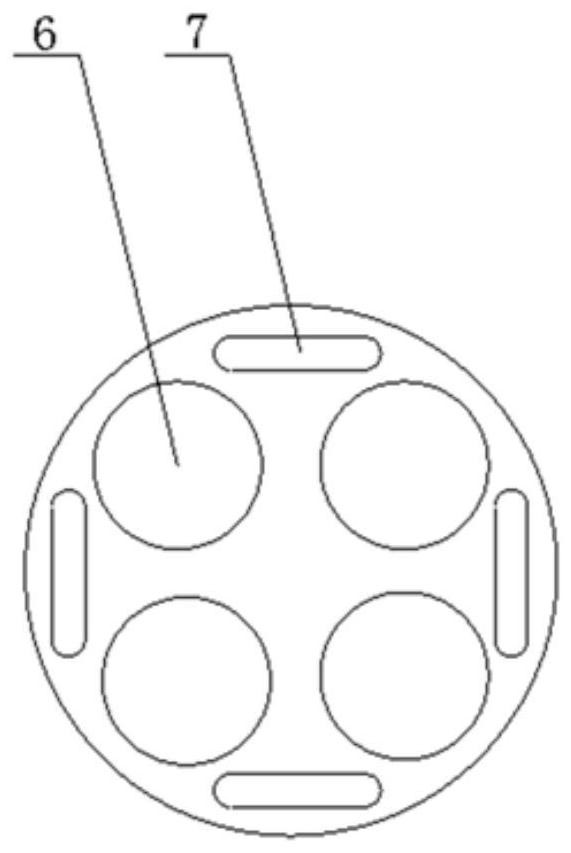

[0026] A precision connection flange includes a first flange, a second flange, a sealing gasket, fastening bolts and nuts, the sealing gasket is arranged between the first flange and the second flange, and the first Corresponding positions of the first flange and the second flange are respectively provided with pipe receiving holes, and corresponding positions of the first flange and the second flange are respectively provided with fastening through holes, and the fastening bolts pass through the first The fastening through holes of the flange and the second flange are threadedly connected with the nut, the fastening through holes are waist-shaped holes, and the fastening through holes of the first flange and the second flange are four respectively. , the four fastening through holes are symmetrically arranged in pairs, and the corresponding positions of the first flange and the second flange are respectively uniformly provided with four tube receiving holes; the first flange a...

Embodiment 2

[0032] A precision connection flange includes a first flange, a second flange, a sealing gasket, fastening bolts and nuts, the sealing gasket is arranged between the first flange and the second flange, and the first Corresponding positions of the first flange and the second flange are respectively provided with pipe receiving holes, and corresponding positions of the first flange and the second flange are respectively provided with fastening through holes, and the fastening bolts pass through the first The fastening through holes of the flange and the second flange are threadedly connected with the nut, the fastening through holes are waist-shaped holes, and the fastening through holes of the first flange and the second flange are four respectively. , the four fastening through holes are symmetrically arranged in pairs, and the corresponding positions of the first flange and the second flange are respectively uniformly provided with four tube receiving holes; the first flange a...

Embodiment 3

[0038] A precision connection flange includes a first flange, a second flange, a sealing gasket, fastening bolts and nuts, the sealing gasket is arranged between the first flange and the second flange, and the first Corresponding positions of the first flange and the second flange are respectively provided with pipe receiving holes, and corresponding positions of the first flange and the second flange are respectively provided with fastening through holes, and the fastening bolts pass through the first The fastening through holes of the flange and the second flange are threadedly connected with the nut, the fastening through holes are waist-shaped holes, and the fastening through holes of the first flange and the second flange are four respectively. , the four fastening through holes are symmetrically arranged in pairs, and the corresponding positions of the first flange and the second flange are respectively uniformly provided with four tube receiving holes; the first flange a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com