Protective film high-precision cutting equipment

A technology for cutting equipment and protective film, which is applied in the field of high-precision cutting equipment for protective film, which can solve the problems of lack of fixed limit for protective film, low cutting precision, inconvenient fixing of protective film roll, etc., to ensure cutting and accuracy performance, anti-wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

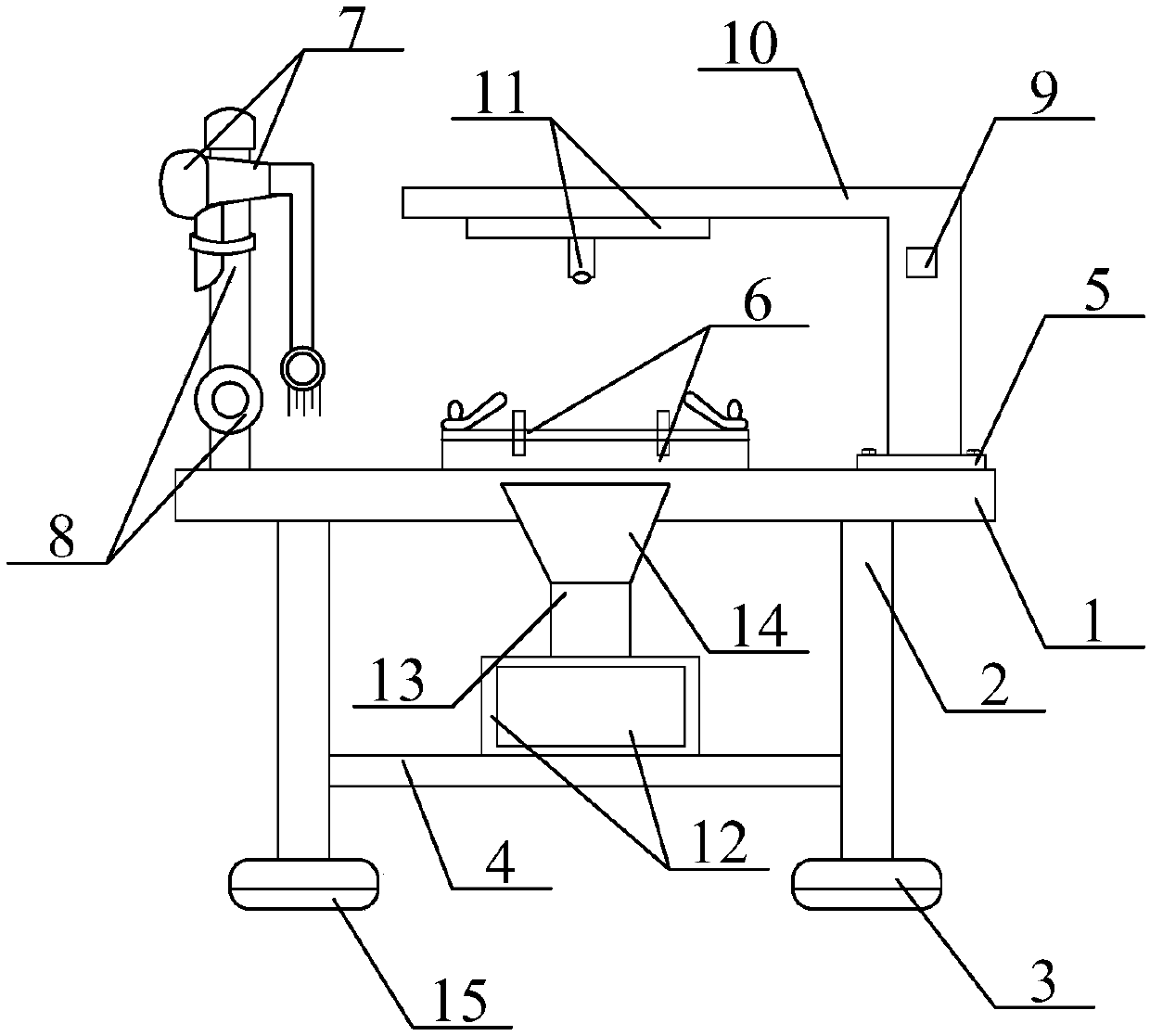

[0033] The present invention will be further described below in conjunction with accompanying drawing:

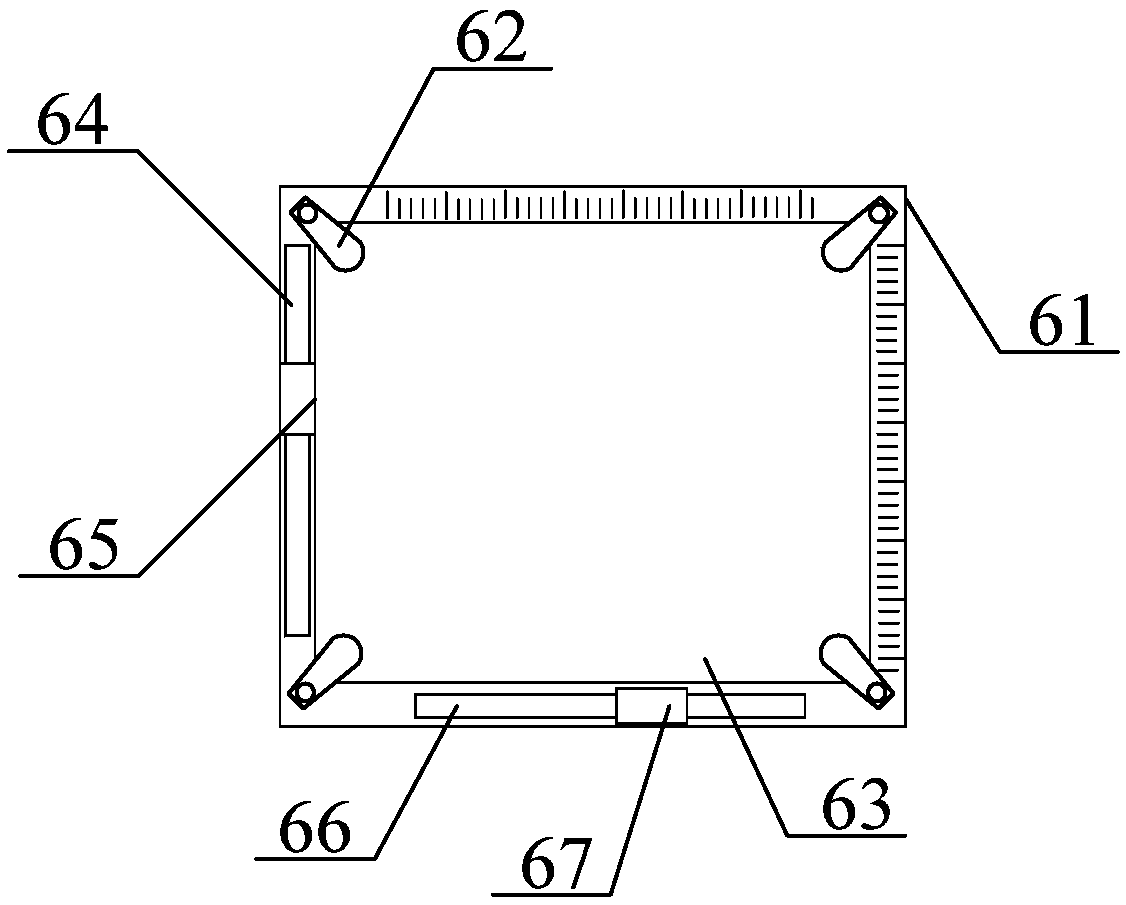

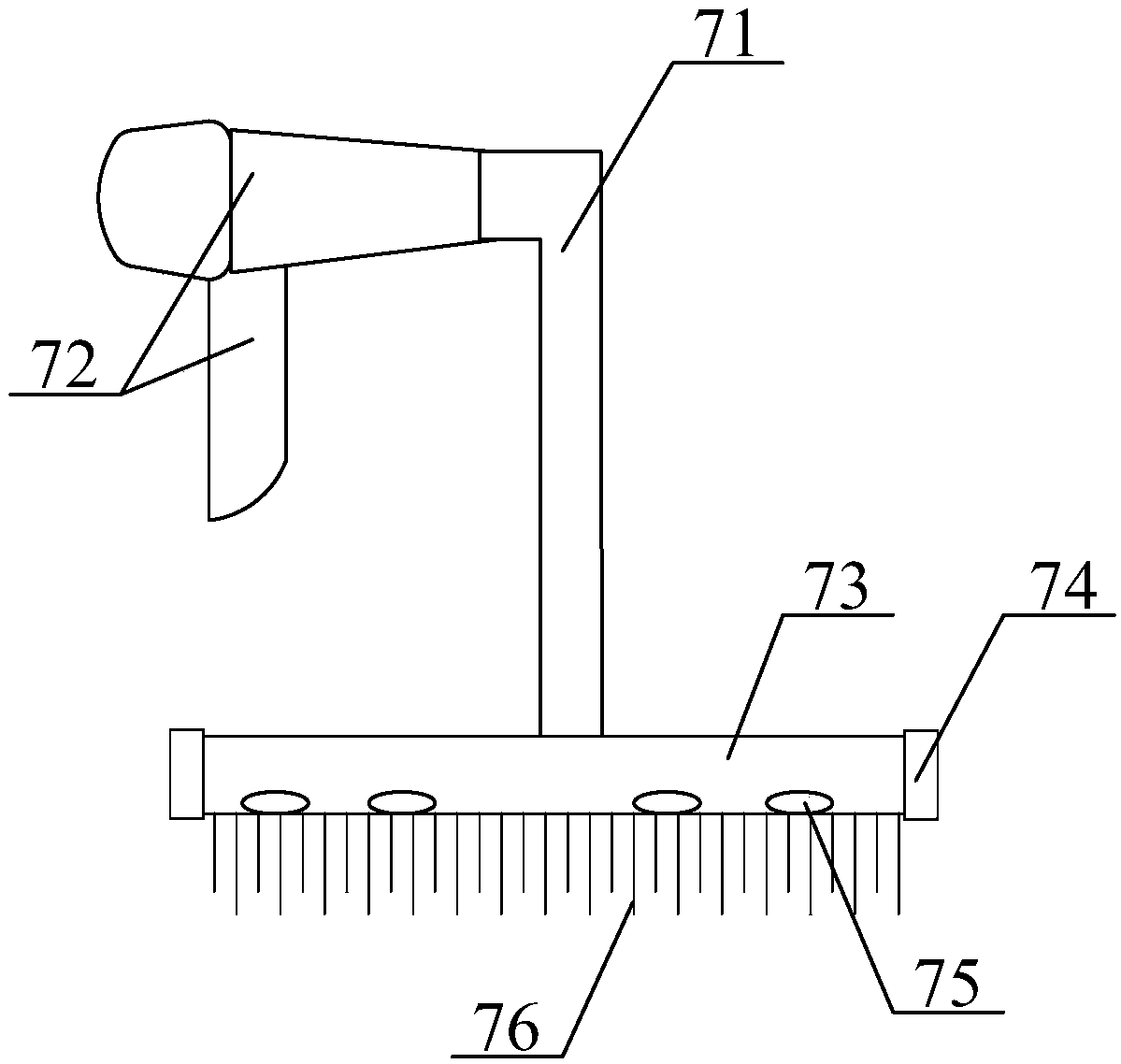

[0034] Such as figure 1 , figure 2As shown, a protective film high-precision cutting equipment according to the present invention includes a cutting table 1, a support column 2, a shaped and stable seat 3, a horizontal plate for storage 4, a connecting stainless steel plate 5, and an anti-wear protective film fixing seat structure 6 , air blowing impurity cleaning pipe structure 7, adjustable protective film reel support rod structure 8, control switch 9, L-shaped boom rod 10, high-precision laser cutter 11, scrap recycling box 12, material guide pipe 13, hopper 14 and anti-skid pad 15, the support columns 2 are respectively bolted to the four corners of the lower surface of the cutting table 1; 4. Horizontal bolts are connected to the support column 2 and the inner lower part of the support column 2; the connecting stainless steel plate 5 is bolted to the right side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com