Automatic mechanical cutting device and using method thereof

A technology of mechanical cutting and cutting table, applied in the direction of metal processing, etc., can solve the problems of mismatching, different workpiece sizes, time waste, etc., and achieve the effect of deepening the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

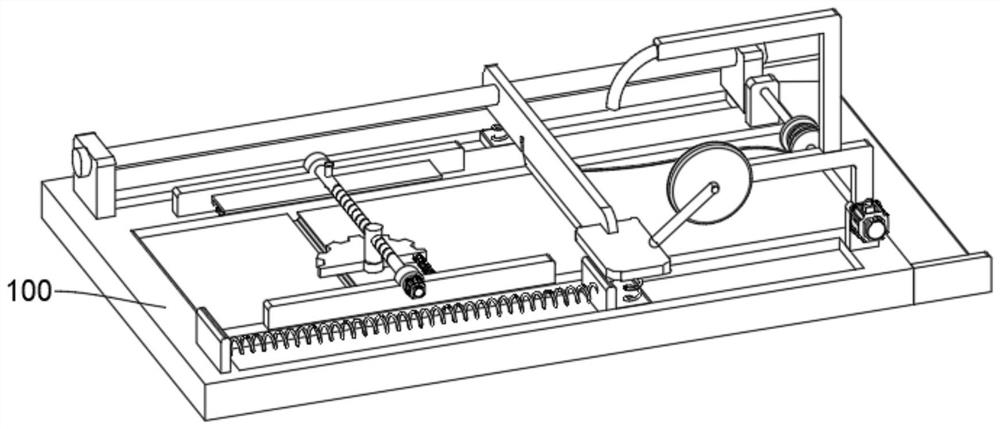

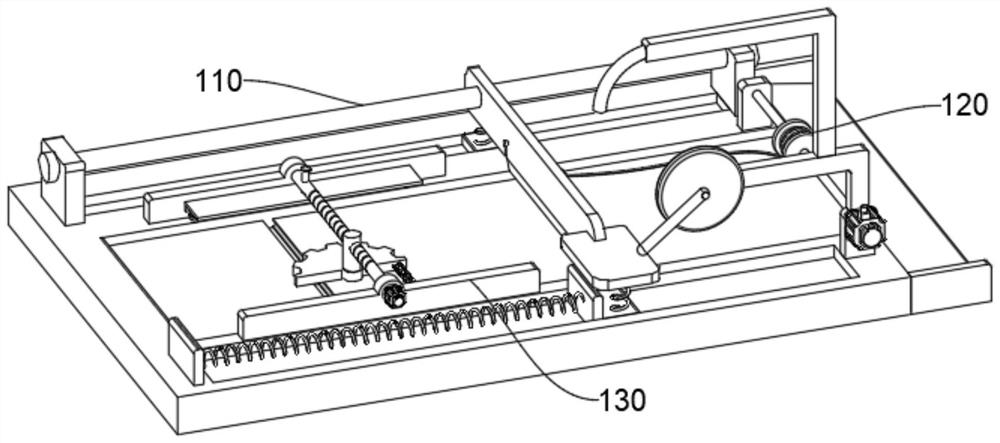

[0054] see Figure 1-Figure 8 As shown, the purpose of this embodiment is to provide an automatic mechanical cutting device, including a cutting mechanism 100, and the cutting mechanism 100 at least includes:

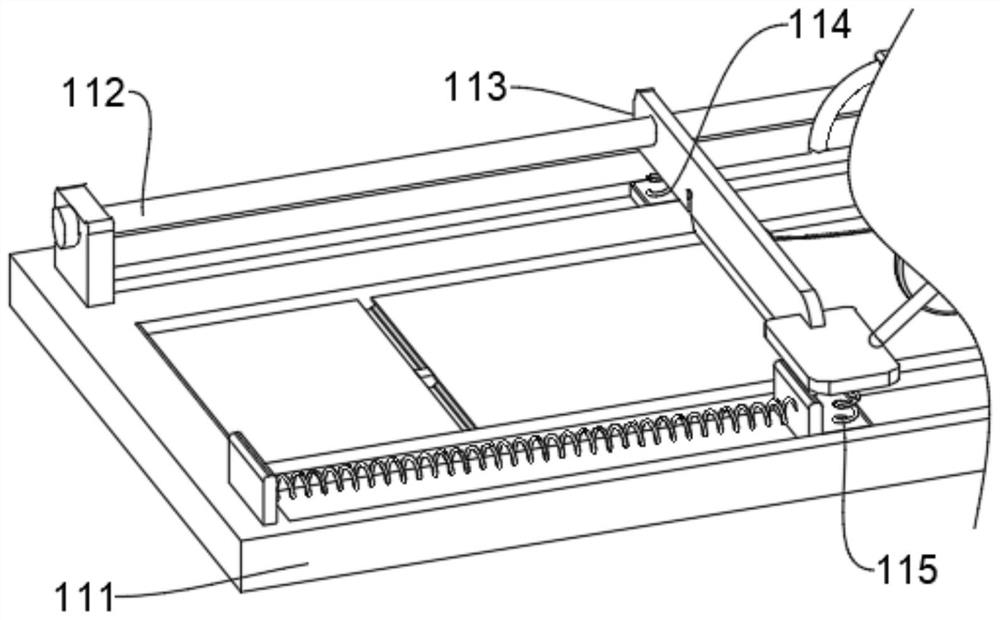

[0055] Cutting body 110, cutting body 110 comprises the rectangular cutting table 111 that opening upwards, on the surface of cutting table 111, the block plate that end portion is arranged symmetrically is equipped with fixed rod 112, and the surface of fixed rod 112 is connected with knife rest 113 in rotation, and knife rest The inside of 113 is provided with a cutting knife 1132, and one end of the knife holder 113 is equipped with a knife handle 1134, and a return plate 115 is installed below the knife handle 1134 via an upper spring 1151, and the upper spring 1151 is used to squeeze and rise the knife handle 1134. ;

[0056] The automatic transmission body 120, the automatic transmission body 120 is installed on an end of the knife rest 113, the automatic transmi...

Embodiment 2

[0062] In order to process the cut material to prevent accumulation from affecting re-cutting, the difference between this embodiment and embodiment 1 is that please refer to Figure 7 and Figure 9 Shown:

[0063] Wherein, the bottom of fixed frame 121 is provided with symmetrical mounting plate 125, and wherein one mounting plate 125 is fixedly installed with fixed frame 121, is rotatably connected by rotating rod 126 between mounting plate 125, and the surface end of rotating rod 126 is provided with surface The runner 127 that is wound with fixed rope 1271, one end of fixed rope 1271 is fixedly connected with knife rest 113 through fixed ring 1272, and one end of rotating rod 126 is connected with rotating rod motor 128 in rotation, when knife rest 113 carries out upward transmission, The fixed rope 1271 is formed to rotate and release the fixed rope 1271 through the rotation of the runner 127 and the rotating rod 126. After the cutting work is completed, the material aft...

Embodiment 3

[0066] In order to perform preliminary position adjustment and positioning on the cutting material, the difference between this embodiment and Embodiment 1 is that please refer to Figure 4 , Figure 10 and Figure 11 Shown:

[0067] Wherein, the other end of the surface of the cutting table 111 is provided with a shape finishing mechanism 130, and the shape finishing mechanism 130 includes an end plate 131 which is fixed and installed symmetrically with the surface of the cutting table 111. One end of 132 is rotatably connected with a screw motor 1321, and the rotation shaft connected by surface threads is rotatably connected with a finishing wheel 133 under the screw 132. Considering that for material workpieces, how long is the material or level after stacking at the same time? Placed multiple materials for cutting, because the materials are prone to shaking on the surface of the horizontal cutting table 111, such as plastic tubes, mechanical grinding paper or sandpaper, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com