A device and method for preparing cement stone microscopic samples and testing bending and tensile strength

A technology of bending and tensile strength and cement stone, which is applied in the field of equipment for preparation and bending and tensile strength testing, can solve the problems that the mechanical properties of cement stone cannot be measured, the accuracy of the experiment cannot be guaranteed, and the accuracy of the evaluation result is reduced, so as to ensure the accuracy The effect of high stability, saving test time, and high-quality preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

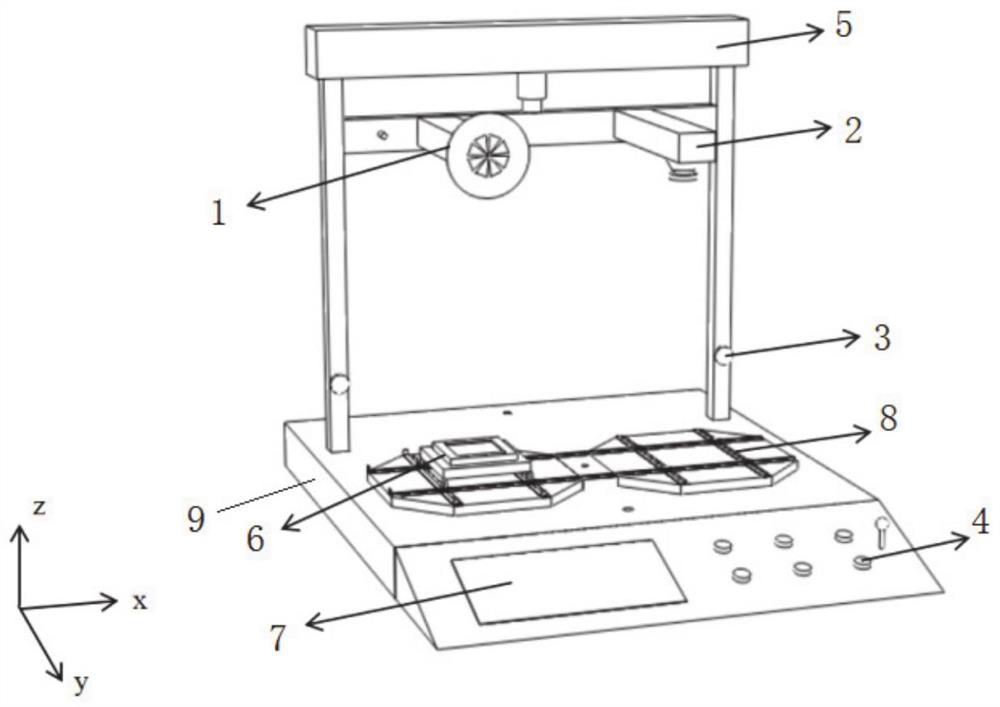

[0054] In a typical embodiment of the present invention, such as figure 1 As shown, a device for preparation of cement stone microscopic samples and bending and tensile strength testing is proposed, including a workbench 9 on which a grinding and cutting component 1, a testing component 2, a microscopic observation component 3, a manipulation component 4, Support frame 5, console 6, display 7, chute track 8; support frame 5 and chute track 8 are all fixed on the workbench, and the workbench and chute track are respectively provided with drain holes 10 for discharging waste liquid.

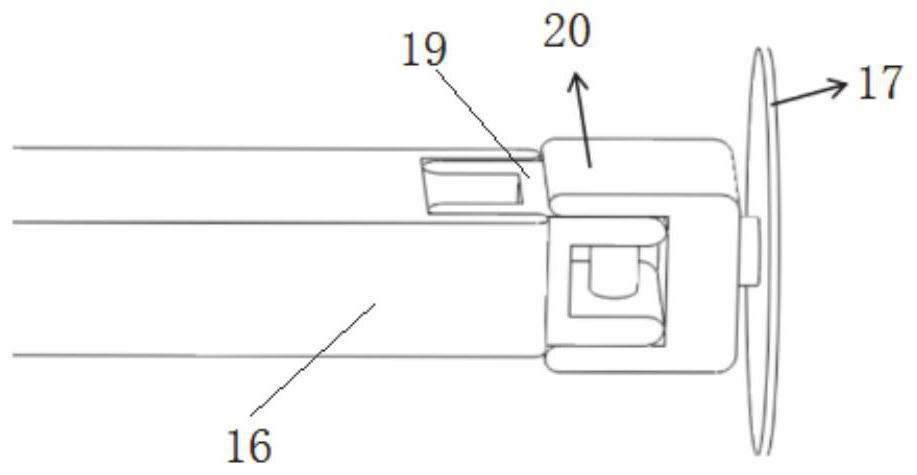

[0055] like Figure 5 As shown, the support frame 5 includes two columns 11 , two beams and a telescopic rod 13 , the two columns 11 are vertically opposite to each other, and the bottom ends of the two columns 11 are fixed on the workbench 9 . A first beam 12 is fixedly arranged at the top of the two columns 11; a second beam 37 is arranged on the top of the two columns, the second beam is locate...

Embodiment 2

[0074]In this embodiment, a method for preparing a cement stone microscopic sample and testing the bending and tensile strength is proposed, and the device for preparing a cement stone microscopic sample and testing the bending and tensile strength described in Example 1 is used.

[0075] The specific process is:

[0076] (1) After the curing period is over, remove the cement stone sample from the mold, cut it into a thin slice of cement stone sample with a thickness of 2mm with a precision cutting machine, and use isopropanol solvent to prevent hydration; use ultraviolet hardening resin (UV glue) to seal the sample Bond the sample to a glass slide (50mm×50mm×5mm in size), put the slide into the slot on the operating table, press the slide so that the slide can be firmly adsorbed on the operating table by the vacuum suction cup;

[0077] (2) Adjust the position of the console through the joystick of the table so that it is located in the middle of the left half of the chute tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com