Multi-station precise solid wax block cutting method

A precision cutting and multi-station technology, applied in the field of machinery, can solve problems such as difficulty in ensuring accuracy, difficulty in ensuring the consistency of small wax blocks or thin slices, and achieve the effect of reasonable structure and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be described in further detail below in conjunction with the accompanying drawings.

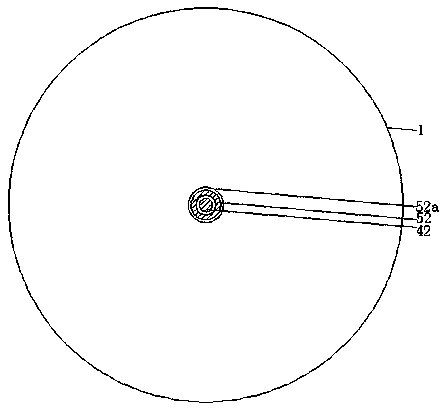

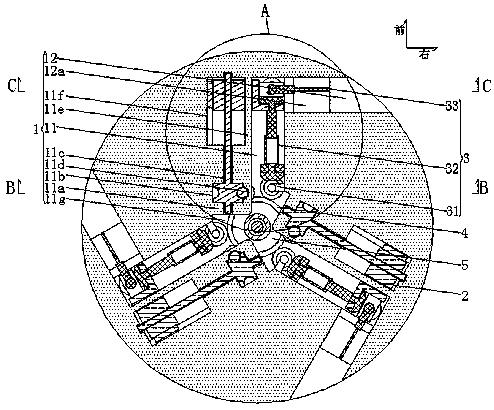

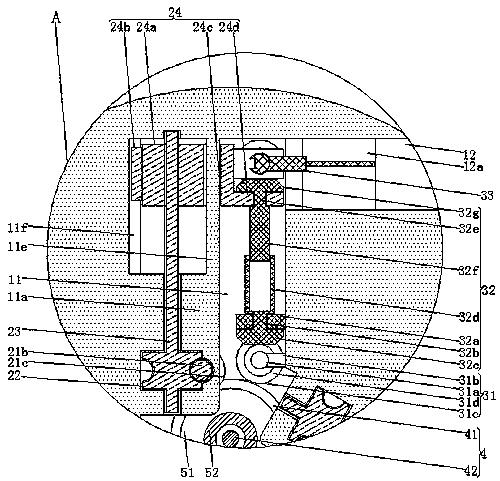

[0065] A multi-station precision cutting method for solid wax blocks, using a slicer, including a circular shell 1, a displacement device 2, a cutting device 3, and an operating device 4;

[0066] The circular housing 1 includes:

[0067] There are at least three transmission inner cavities 11. The transmission inner cavities 11 are evenly distributed inside the circular housing 1 along the radial direction and circumferential direction. The left half of the left side of the transmission inner cavity 11 is formed with a left housing 11a. , the inner cavity of the left housing 11a is provided with a worm gear chamber 11b, and the middle part of the left housing 11a is provided with a central through hole 11c communicating with the worm gear chamber 11b along the front and rear direction, and the left housing 11a The right half part is longitudinally penetrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com