Production technology of flame-retardant composite fabric

A production process and flame-retardant compounding technology, which is applied in the field of home decoration fabrics, can solve the problems of flame retardant environmental protection indicators not up to standard, unstable method of scraping and adhesive backing, adhesive adhesion on the back, etc., to maintain a soft feel , good hand feel, good environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A production process of flame-retardant composite cloth, comprising the following steps:

[0029] S1. Processing of flame retardant cloth:

[0030] a, acrylic fiber is modified: utilize treatment liquid to carry out dip-dyeing to acrylic fiber, the liquid ratio of dipping is 1:20, the temperature of dipping is 40 ℃, and dipping time is 40 minutes; The content of cyanohydrolase in the processing liquid and The weight ratio of the acrylic fiber is 3:50; after the dip-dyeing is completed, dry at a temperature of 40-45° C. to obtain the modified acrylic fiber;

[0031] b. Mixing modified acrylic fibers with acrylic pre-oxidized yarns to obtain mixed fibers, wherein the modified acrylic fibers account for 60% by weight, and the mixed fibers are processed into non-woven fabric flame-retardant cloth, knitted fabric flame-retardant cloth, etc. Flame-retardant cloth or woven cloth;

[0032] S2, dyeing and drying the flame-retardant cloth;

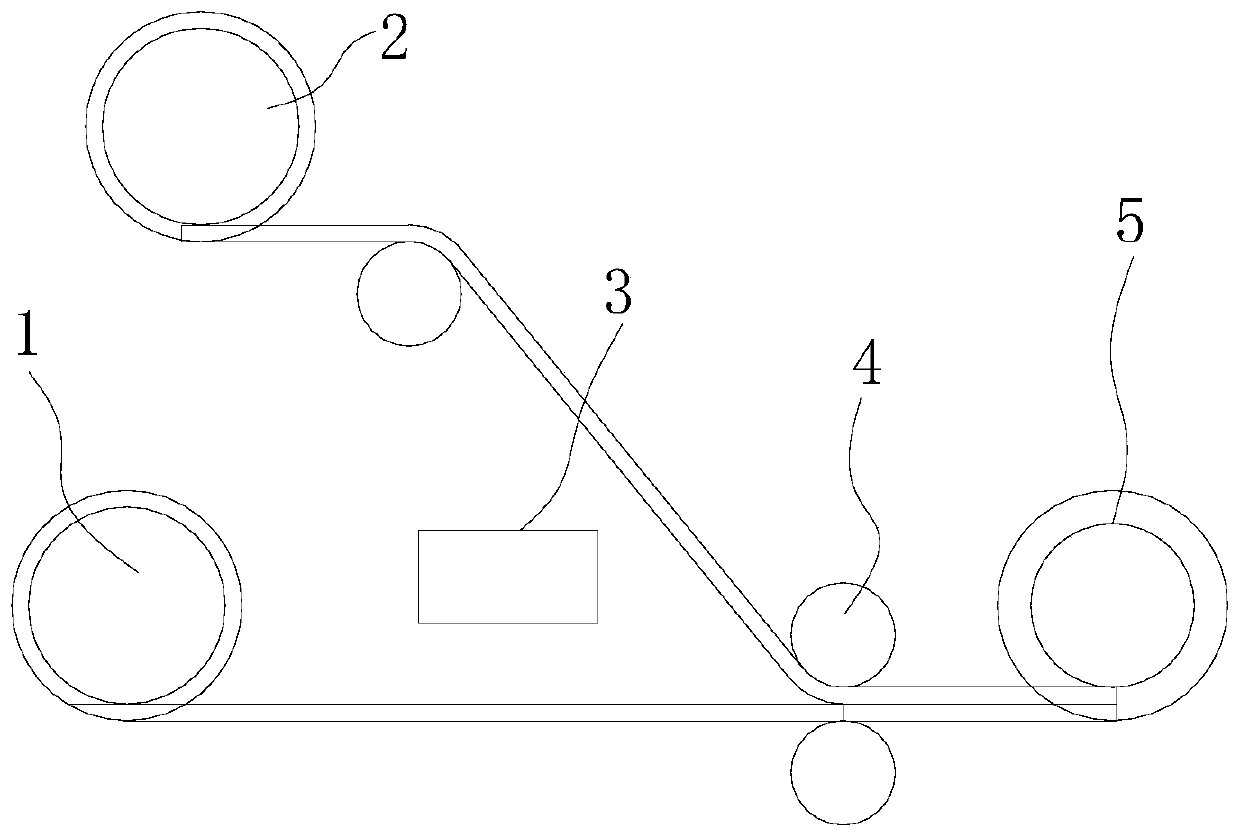

[0033] S3. Composite molding: compo...

Embodiment 2

[0035] Compared with Example 1, the difference is that the modified acrylic fiber accounts for 65% by weight in the mixed fiber.

Embodiment 3

[0037] Compared with Example 1, the difference is that the modified acrylic fiber accounts for 70% by weight in the mixed fiber.

[0038] The flame-retardant composite fabric prepared by the process of the invention not only has good flame-retardant performance, but also has excellent hand feeling. The environmental protection is better than the post-treatment method of adhesive, which solves the defects caused by the traditional drying of adhesive, and has achieved excellent market evaluation.

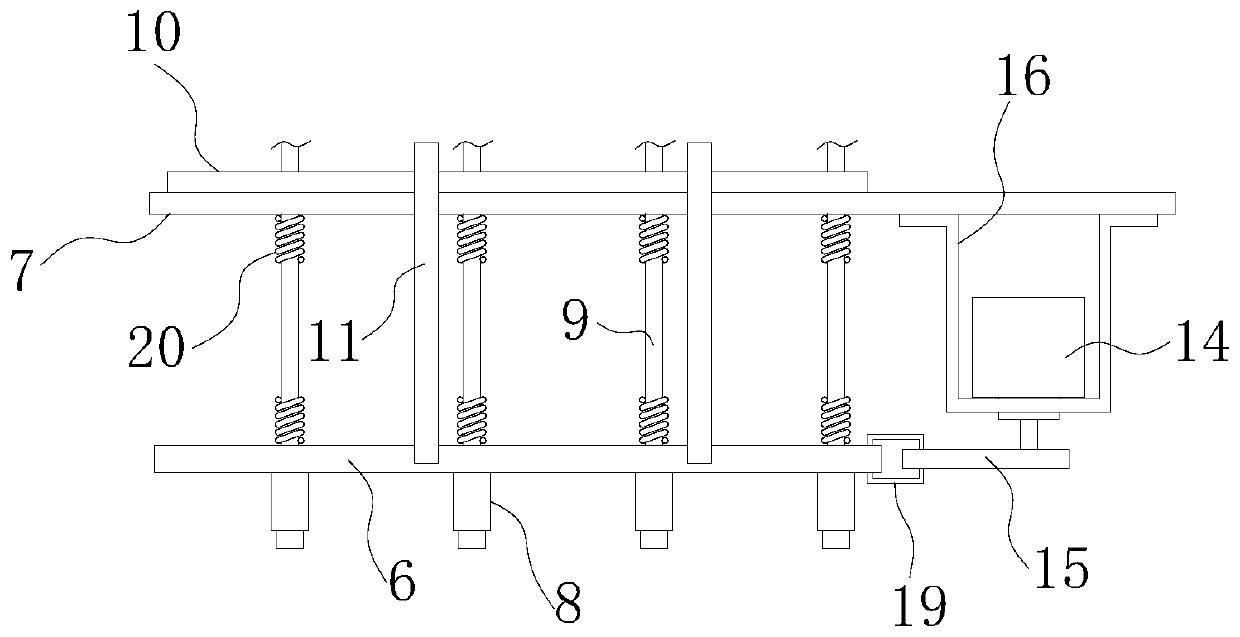

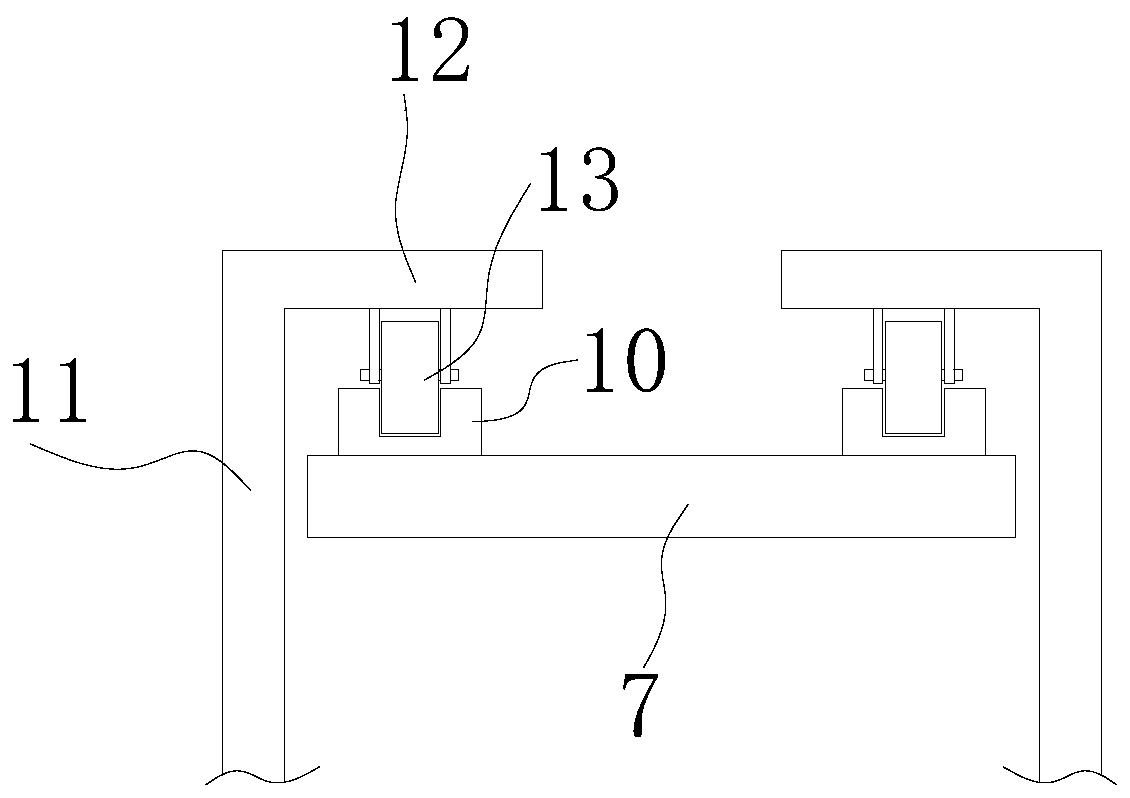

[0039] In the composite process of flame-retardant cloth and face cloth, because the flame-retardant cloth and face cloth have a certain width, the traditional glue spraying method is adopted, and the glue spraying force close to the center of the glue spraying port is large, resulting in a large amount of glue. The glue spraying force near the edge of the glue spray port is relatively small, resulting in a small amount of glue. In the end, the partial composite reliability of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com