Preparation method of carbon and silicon carbide composite material

A carbon composite material and a composite material technology, which are applied in the field of carbon and silicon carbide composite material preparation, can solve the problems of low energy efficiency, high manufacturing cost, complicated process and the like, and achieve the effects of high precision, reduced preparation cost and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

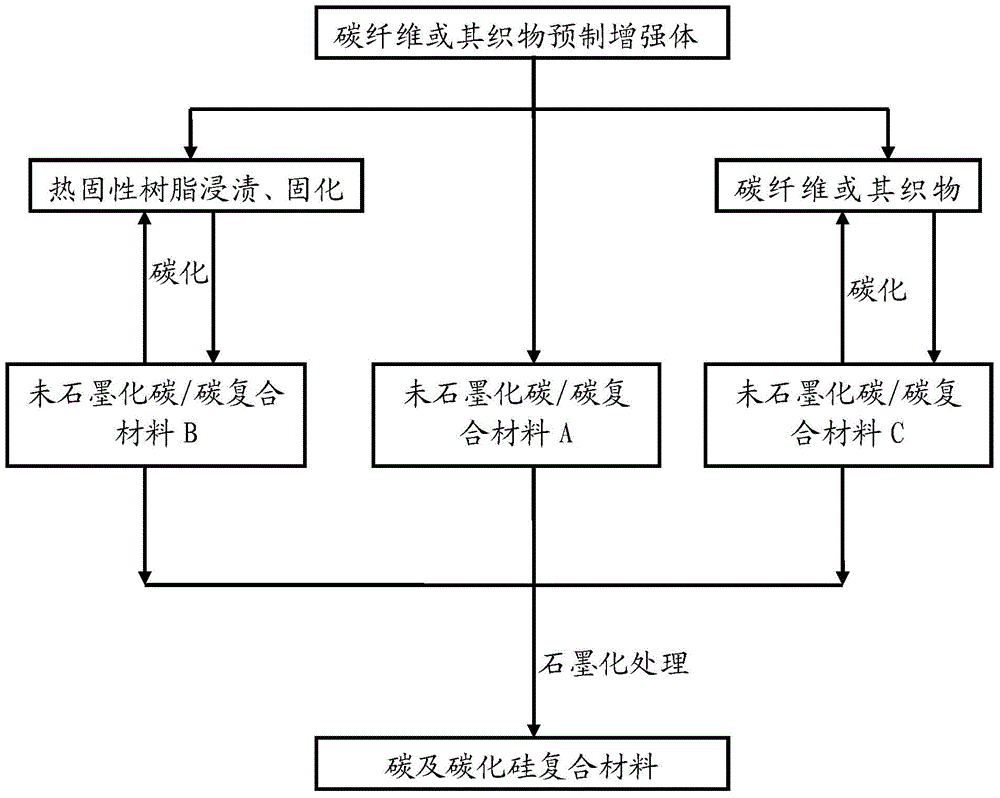

[0023] Such as figure 1 Shown, a kind of carbon and silicon carbide composite material preparation method, comprises the steps:

[0024] Carrying out chemical vapor deposition of carbon fiber or its fabric prefabricated reinforcement to obtain non-graphitized carbon / carbon composite material A;

[0025] Prefabricated reinforcement of carbon fiber or its fabric is impregnated with thermosetting resin, cured, and then cyclically carbonized to obtain non-graphitized carbon / carbon composite material B;

[0026] Carbon fiber or its fabric prefabricated reinforcement and pitch impregnated cyclic carbonization to obtain non-graphitized carbon / carbon composite material C;

[0027] Graphitizing the graphitized carbon / carbon composite material A, the non-graphitized carbon / carbon composite material B, and the non-graphitized carbon / carbon composite material C to obtain carbon and silicon carbide composite materials.

Embodiment 1

[0029] Chemical vapor deposition of carbon fiber or its fabric prefabricated reinforcement to obtain non-graphitized carbon / carbon composite material A; carbon fiber or its fabric prefabricated reinforcement is impregnated and cured with thermosetting resin, and then cyclic carbonization is carried out at a deposition temperature of 900°C to obtain an ungraphitized carbon / carbon composite material A. Graphitized carbon / carbon composite material B; carbon fiber or its fabric prefabricated reinforcement and pitch impregnated with cyclic carbonization at a deposition temperature of 900°C to obtain non-graphitized carbon / carbon composite material C; graphitized carbon / carbon composite material A, non-graphitized Carbon / carbon composite material B and non-graphitized carbon / carbon composite material C were graphitized at a deposition temperature of 2100°C to obtain carbon and silicon carbide composite materials.

Embodiment 2

[0031] Carbon fiber or its fabric prefabricated reinforcement is subjected to chemical vapor deposition to obtain non-graphitized carbon / carbon composite material A; carbon fiber or its fabric prefabricated reinforcement is impregnated with thermosetting resin, cured, and then cyclically carbonized at a deposition temperature of 1200°C to obtain a non-graphitized carbon / carbon composite material A. Graphitized carbon / carbon composite material B; carbon fiber or its fabric prefabricated reinforcement and pitch impregnated with cyclic carbonization at a deposition temperature of 1000°C to obtain non-graphitized carbon / carbon composite material C; graphitized carbon / carbon composite material A, non-graphitized Carbon / carbon composite material B and non-graphitized carbon / carbon composite material C are graphitized at a deposition temperature of 2500°C to obtain carbon and silicon carbide composite materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com