Bimodule stranding device and manufacturing technique

A technology of installation position and formwork, applied in the production process of stranded wire and its corresponding technical equipment, the production process of metal stranded wire and its corresponding technical equipment, can solve the problem that the surface quality of the extruded wire and the number of broken wires cannot be effectively guaranteed. Increase, affect production efficiency and other issues, to achieve the effect of eliminating poor stranding, improving roundness, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

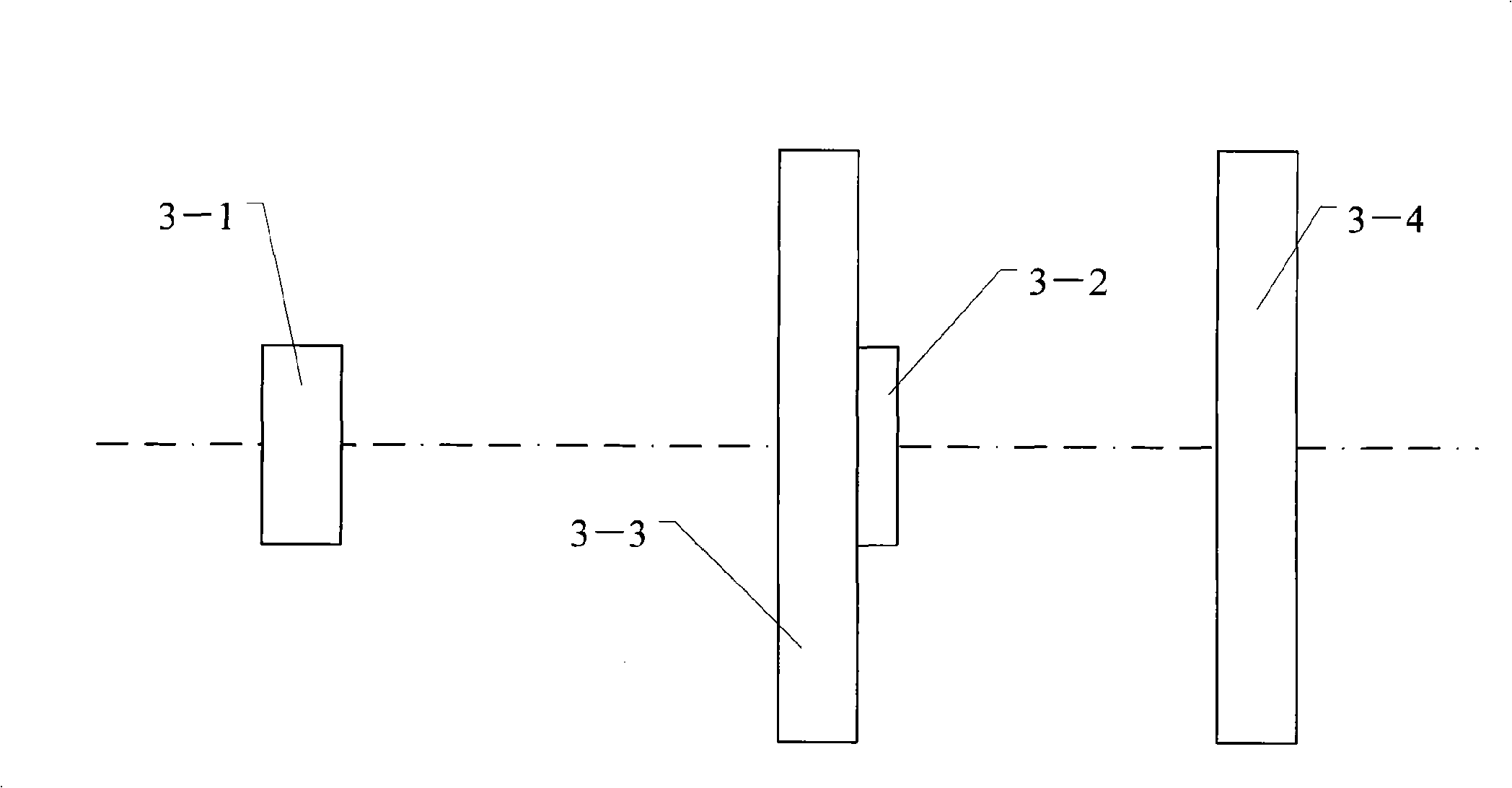

[0018] as attached figure 1 , attached figure 2 And attached image 3 Shown, a kind of dual-mode stranding device comprises a primary branching template (3-4), a secondary branching template (3-3), a primary stranding mold (3-2), a finished stranding mold ( 3-1).

[0019] In the above-mentioned dual-mode twisting device, the primary branching template (3-4) can be various known branching templates, and is installed on the branching board installation bracket of the main engine according to the known original installation process;

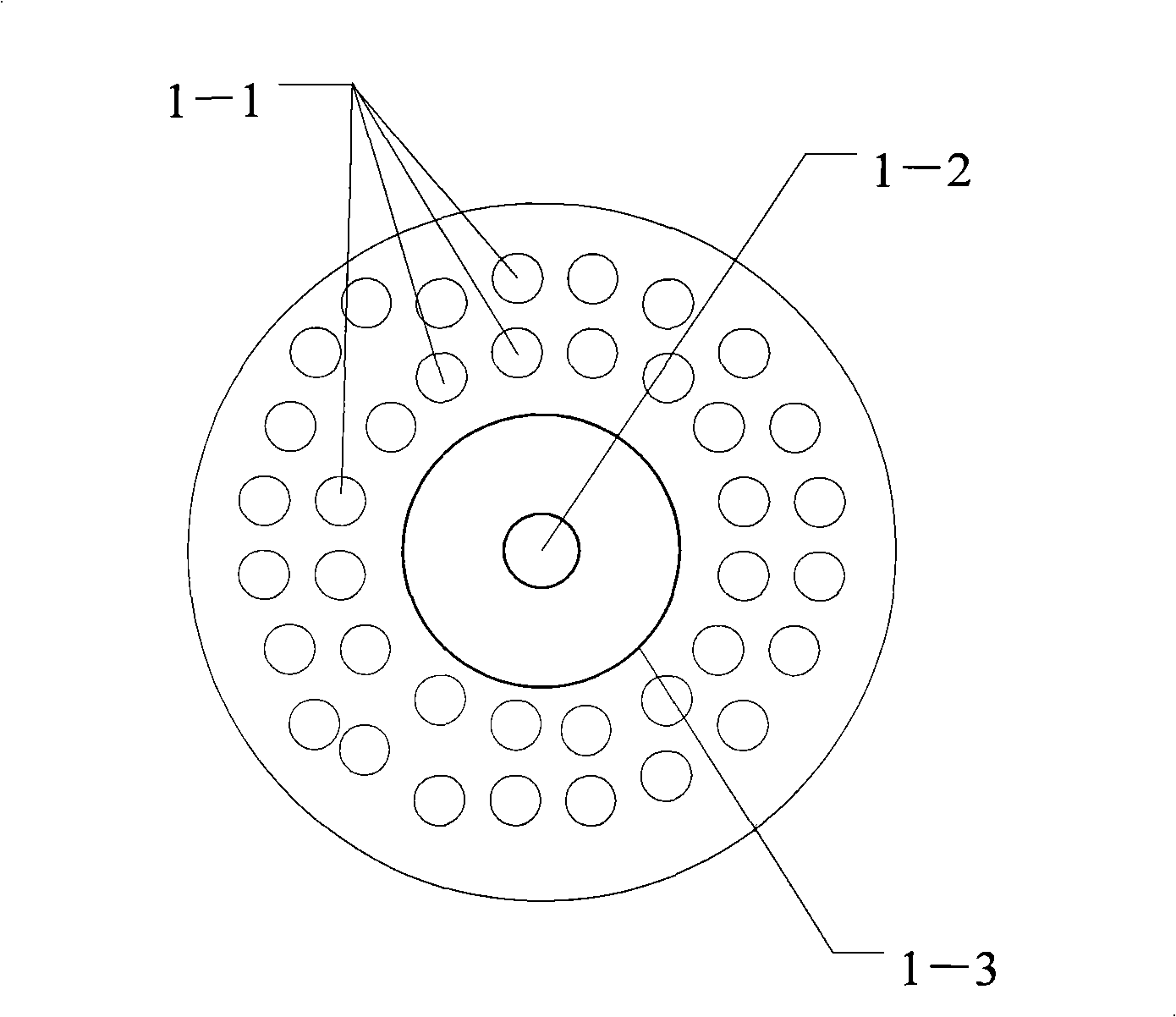

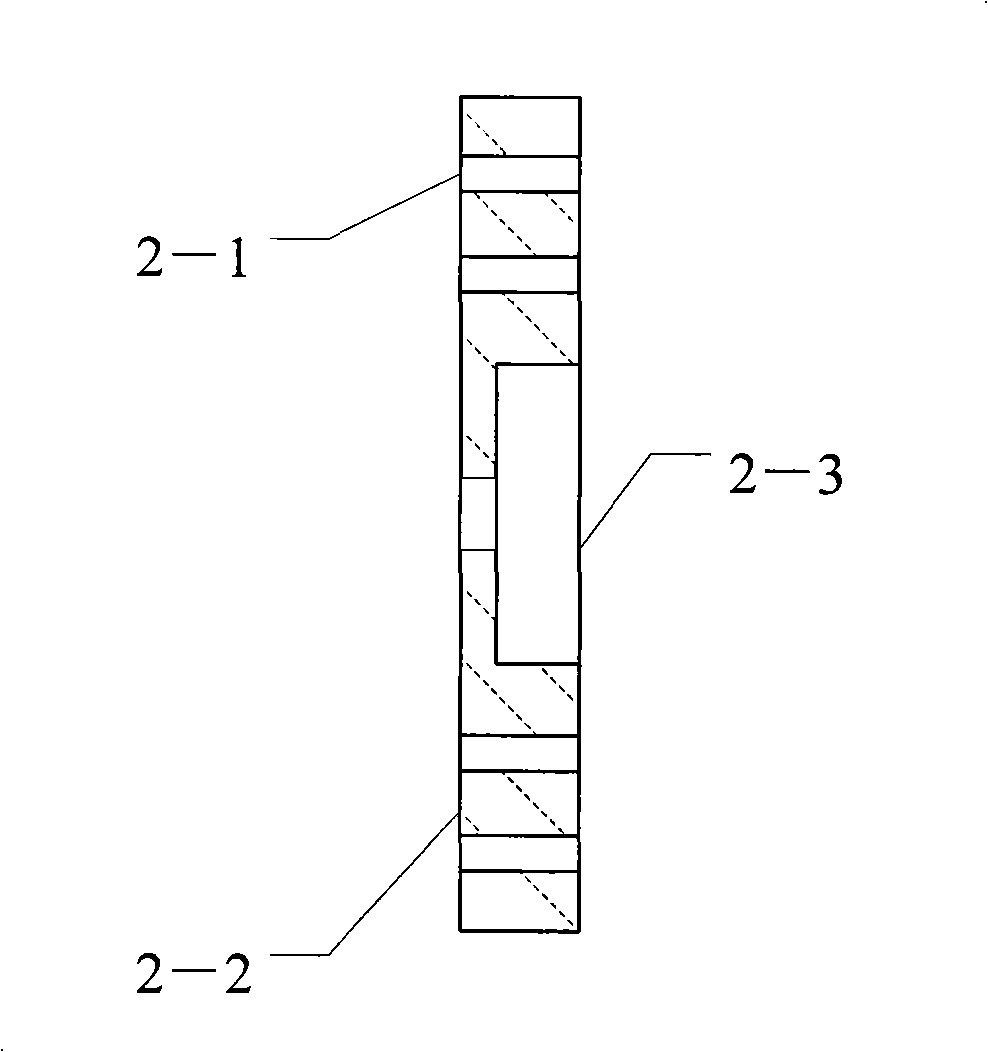

[0020] The second-level branching template (3-3) is a branching template with a circular inlay opening (1-3, 2-3) having a certain depth in the center, and the circular inlay opening (1-3, 2 The diameter of -3) matches the outer diameter of the primary stranding mold (3-2), which can ensure that the primary (3-2) is embedded in it, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com