Mechanical structure of dual-loading-mode grinding and polishing machine driven by electric push rod

A mechanical structure and electric push rod technology, applied in the direction of grinding machine tools, grinding devices, metal processing equipment, etc., can solve the problem of inability to accurately control the process parameters of the processing process, low replaceability of machine parts, and short service life of the whole machine Long and other problems, to achieve simple and convenient installation and maintenance, improve work efficiency and processing quality, and achieve perfect maintenance functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

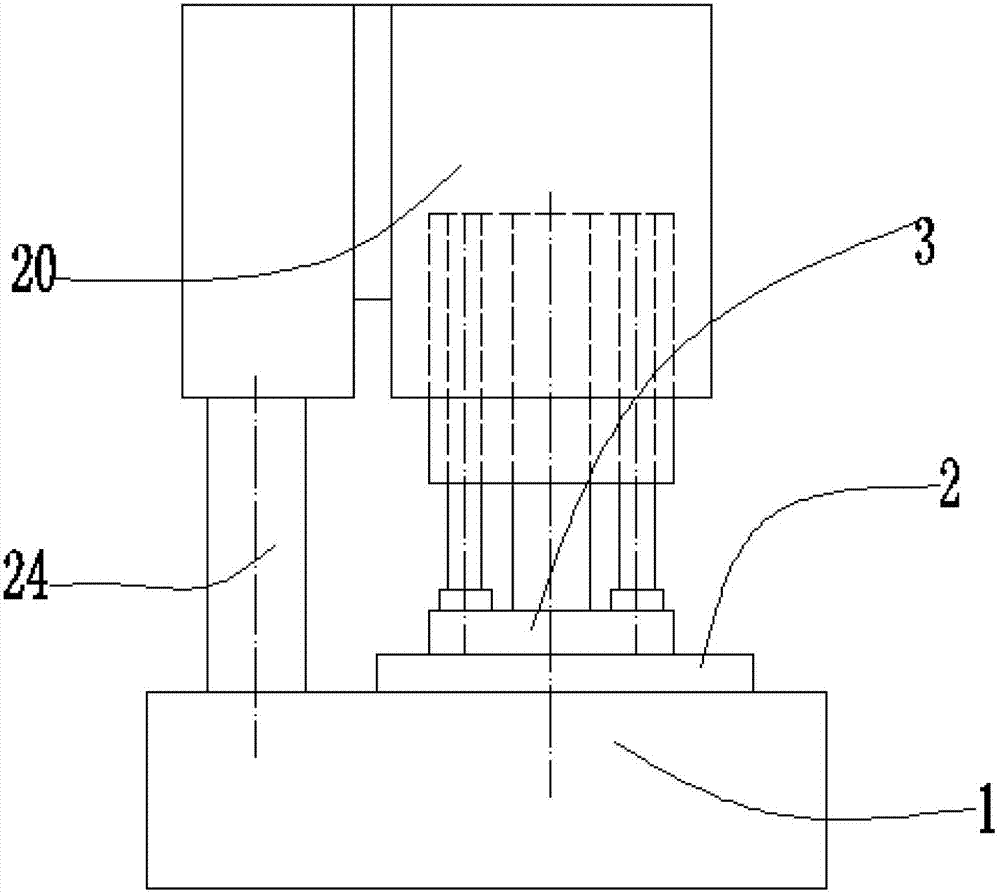

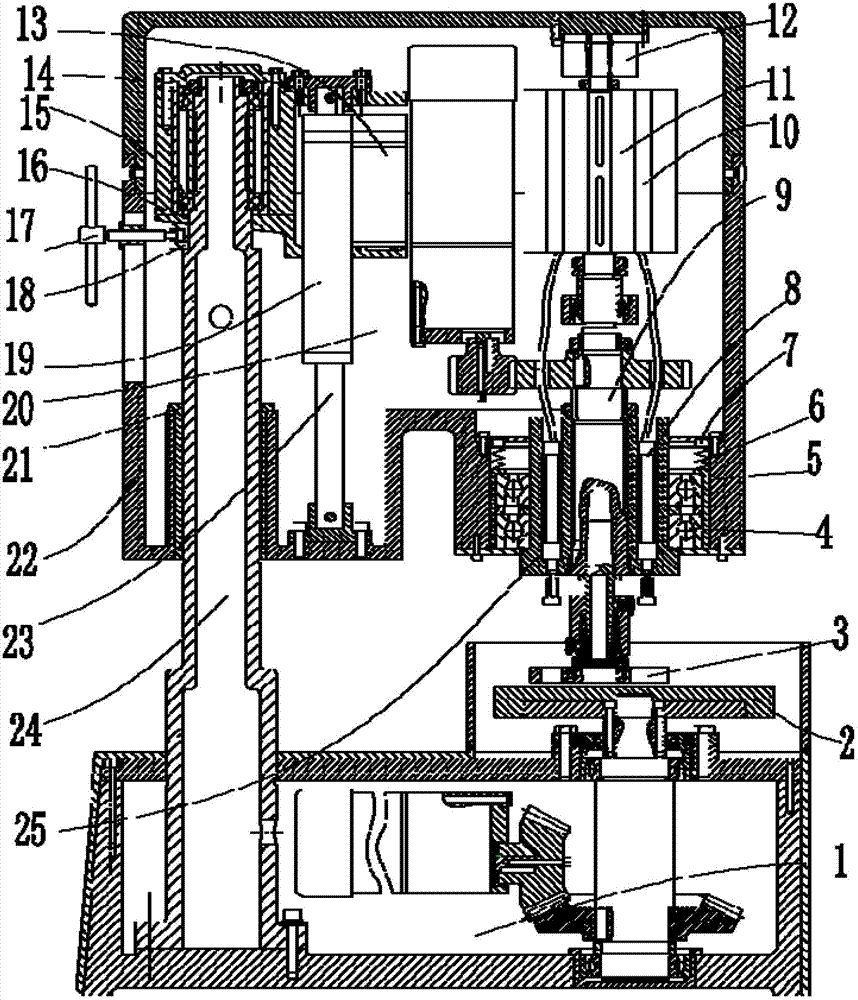

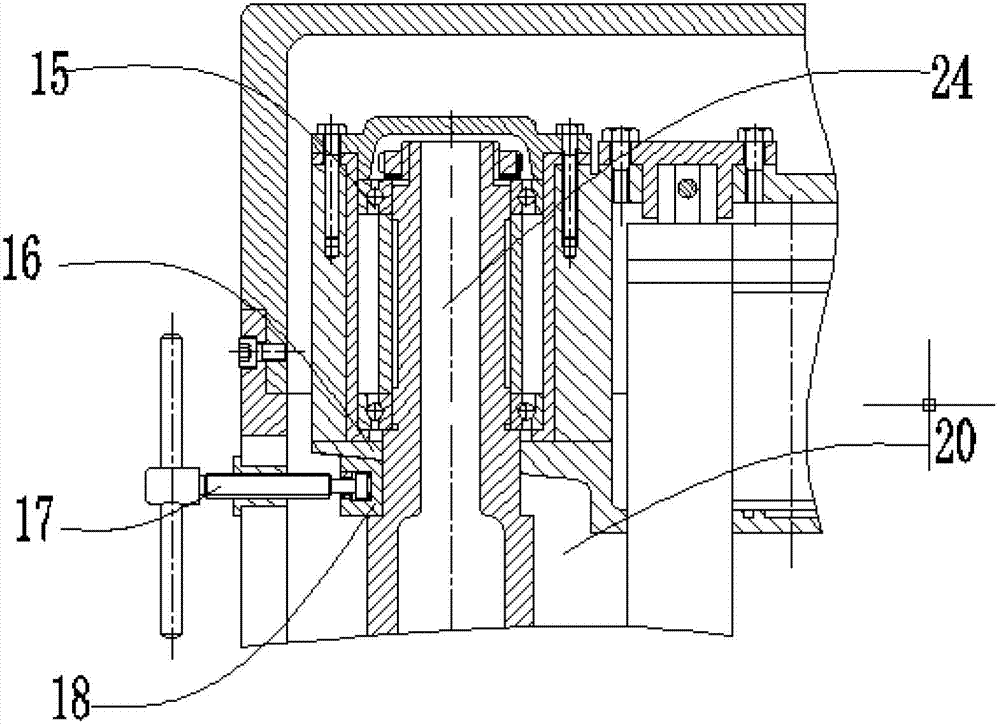

[0024] A mechanical structure of a dual-mode loading grinding and polishing machine driven by an electric push rod, including a base 1, and a grinding and polishing chassis 2 mounted on the top side of the base 1 for horizontal rotation, and a vertical column 24 fixed on the other side of the top of the base 1 , also includes the machine head 20 located above the base 1, the top of the column 24 extends into the machine head 20, and the joint of the column 24 and the lower wall 22 of the machine head is slidably fitted, and the top of the column 24 is installed with a relative rotation fit with the top of the column 24 Top cover, the upper and lower ends of the top cover respectively extend to the inside of the machine head on one side of the column 24 to form a support frame 16, between the support frames 16 are fixed with an electric push rod that is vertically arranged with the outlet downward, and the end of the electric push rod lever arm 23 The head is fixed vertically do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com