Laser precision welding method for edge sealing of soft-package aluminum shell battery cell

A precision welding and soft wrapping technology, applied in circuits, electrical components, sealing materials, etc., can solve the problems of air bubbles at the soft wrapping opening, the sealing performance of the soft wrapping and the sealing performance deterioration, etc., to avoid the embrittlement of the aluminum layer, High welding efficiency and the effect of avoiding burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] The invention provides a laser precision welding method for sealing the edge of a battery cell with a soft-clad aluminum case, comprising the following steps:

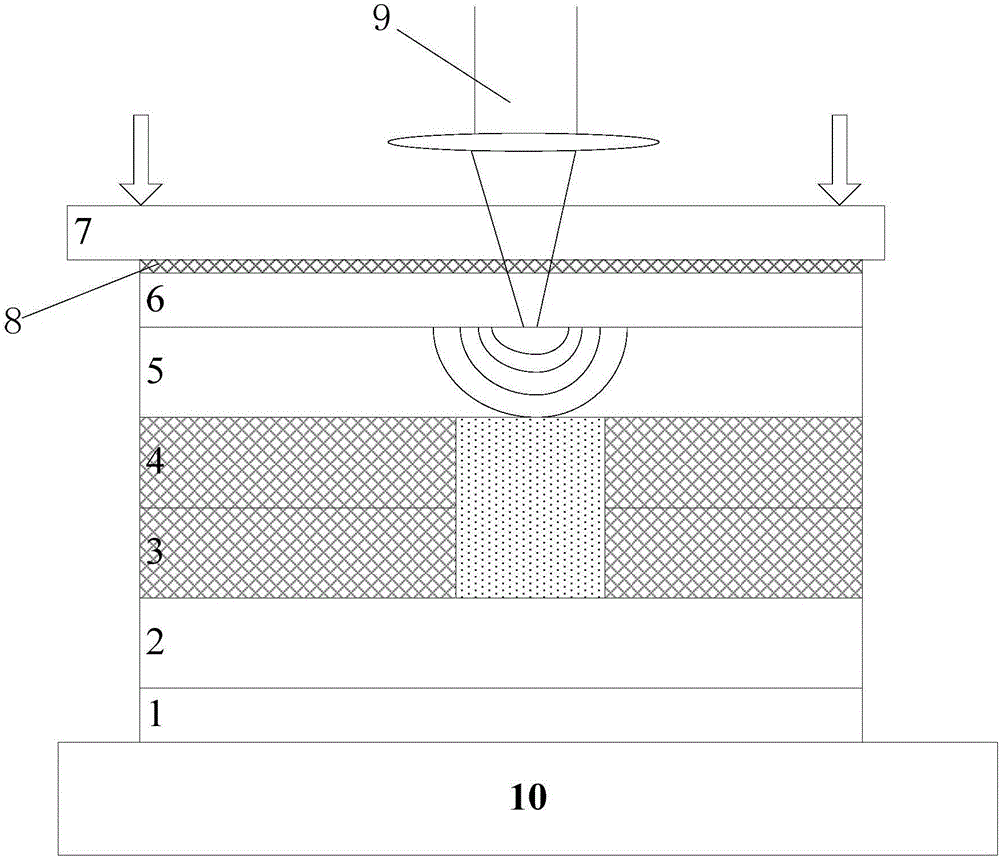

[0026] (1) if figure 1 As shown, on the workbench 10, place the two soft-wrapped aluminum-plastic composite films to be edge-sealed and welded according to the edge-sealed welding position, so that the PP inner layer is placed relatively close together, that is, the lower nylon layer 1 from bottom to top. , the lower aluminum layer 2, the lower PP layer 3, the upper PP layer 4, the upper aluminum layer 5 and the upper nylon layer 6; wherein the thickness of the lower nylon layer 1 and the upper nylon layer 6 are both 10-100 μm, the lower aluminum layer 2 and the upper The aluminum layer 5 has a thickness of 10-100 μm, and the lower PP layer 3 and the upper PP layer 4 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com