Rail temperature stress detection method and terminal equipment

A technology of temperature stress and detection method, applied in the direction of measuring force, measuring device, instrument, etc., can solve the security threats of railway system and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

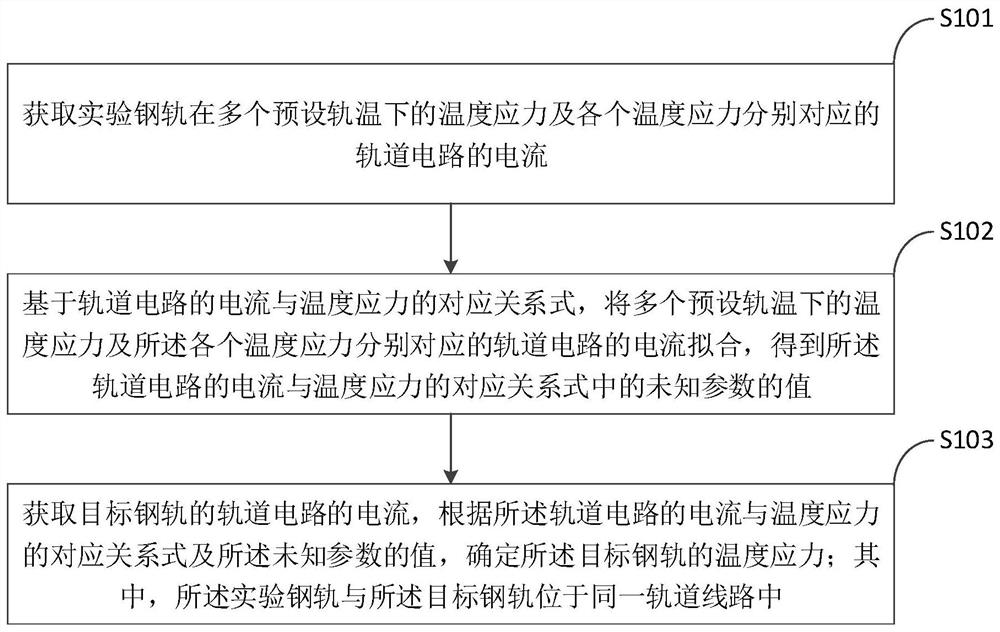

Method used

Image

Examples

Embodiment Construction

[0024] In the following description, for purposes of illustration and not for limitation, features such as specific system structures, techniques, and the like are presented.

[0025] In order to illustrate the technical solutions of the present invention, the following specific embodiments will be described.

[0030] Wherein, the experimental rail and the target rail are located in the same track line.

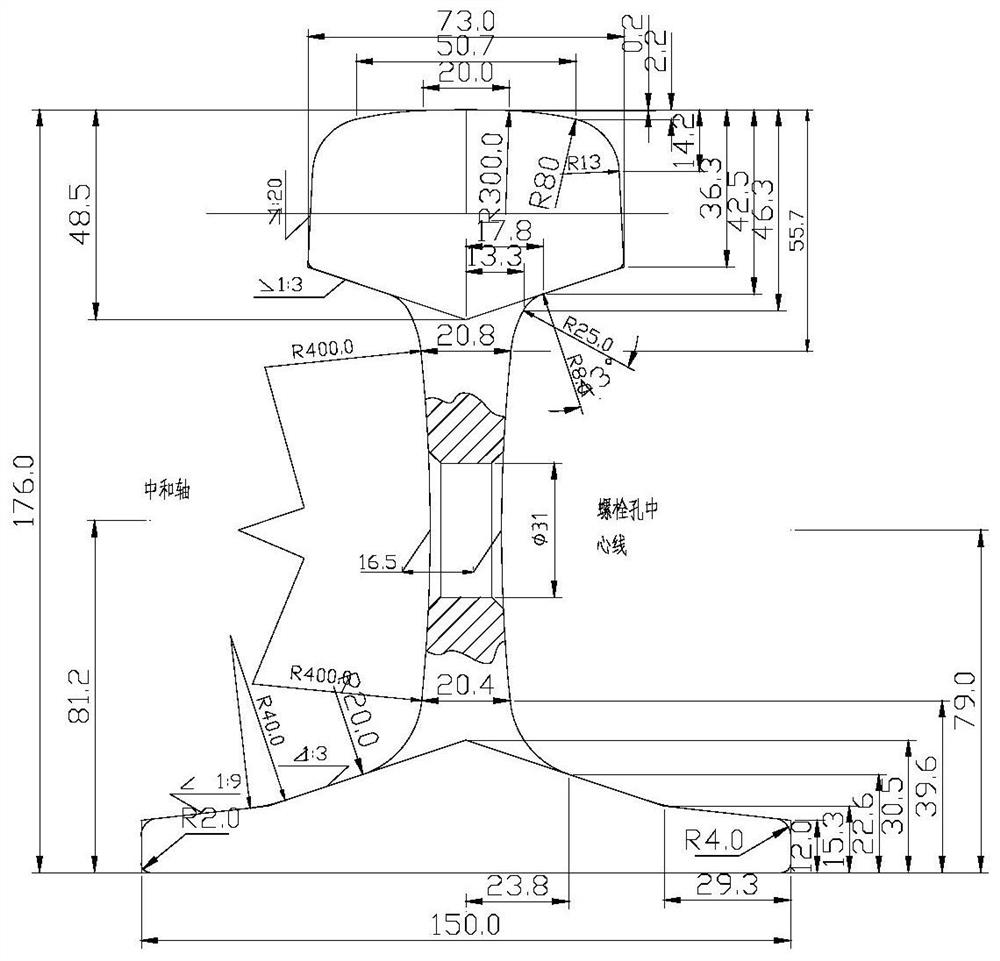

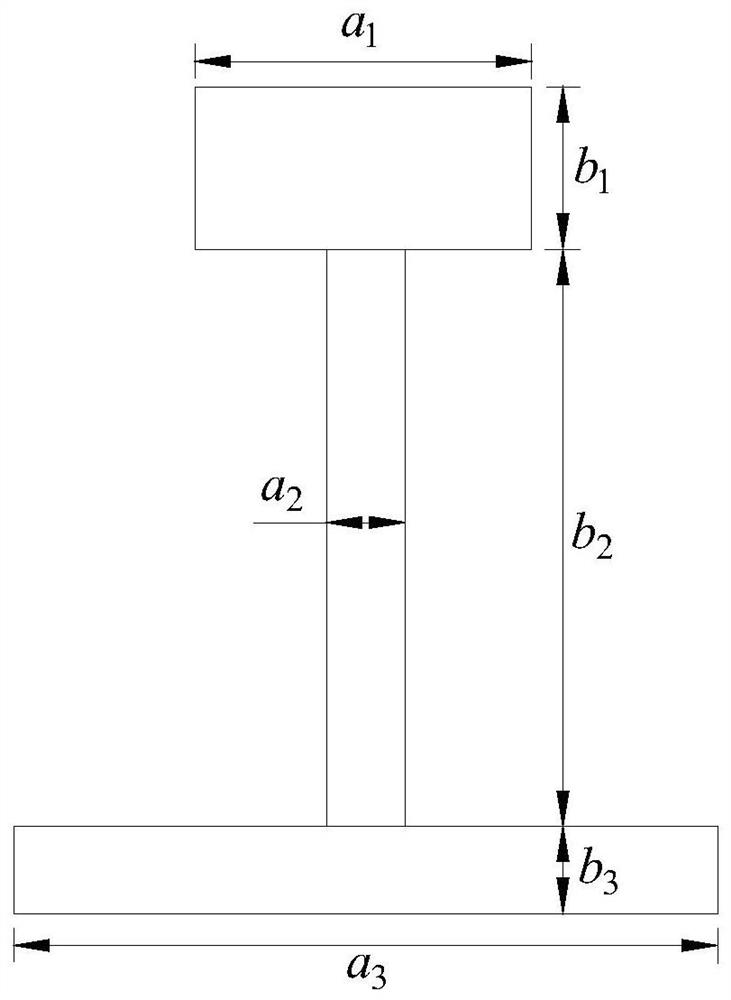

[0033] Figure 2 presents a schematic diagram of a cross-section of a 60kg / m rail. It can be seen from Figure 2 that the cross-section of the rail is relatively complex, in order to

[0036]

[0042]

[0043] Wherein, L is the length of the rail in the track circuit.

[0045]

[0048] Wherein, E is the elastic modulus of the rail.

[0050]

[0051] It can be seen from the above that there is a certain correspondence between the current of the track circuit and the temperature stress of the rail. for

[0053] In some embodiments, the corresponding relationship between the current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com