Marine sail-shaped plate line-fire bending plate live wire path and flame parameter determination method

A water-fire bending plate and flame parameter technology, applied in neural learning methods, special data processing applications, biological neural network models, etc., can solve the problems of low efficiency, low accuracy, unstable outer plate forming quality, etc. Accurate, improve forming efficiency, improve the effect of one-time forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

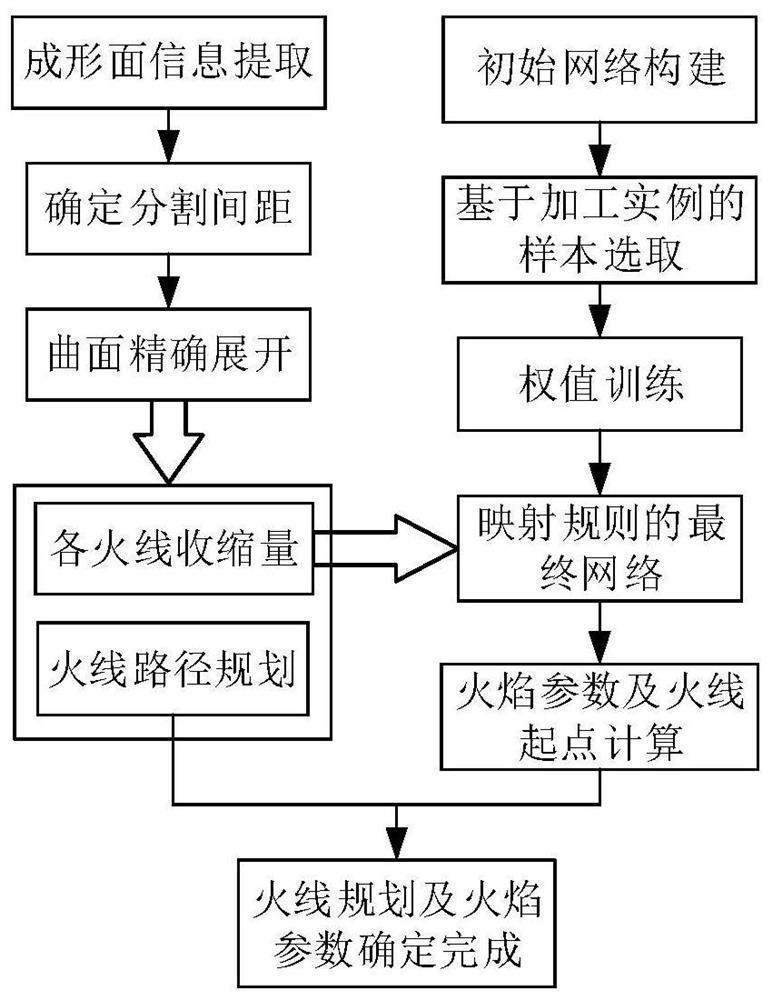

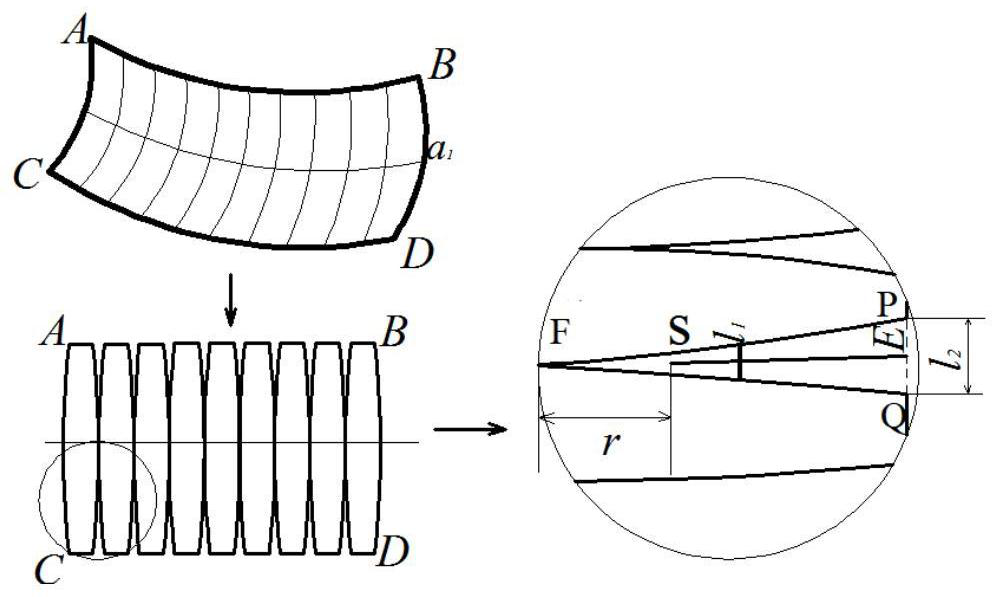

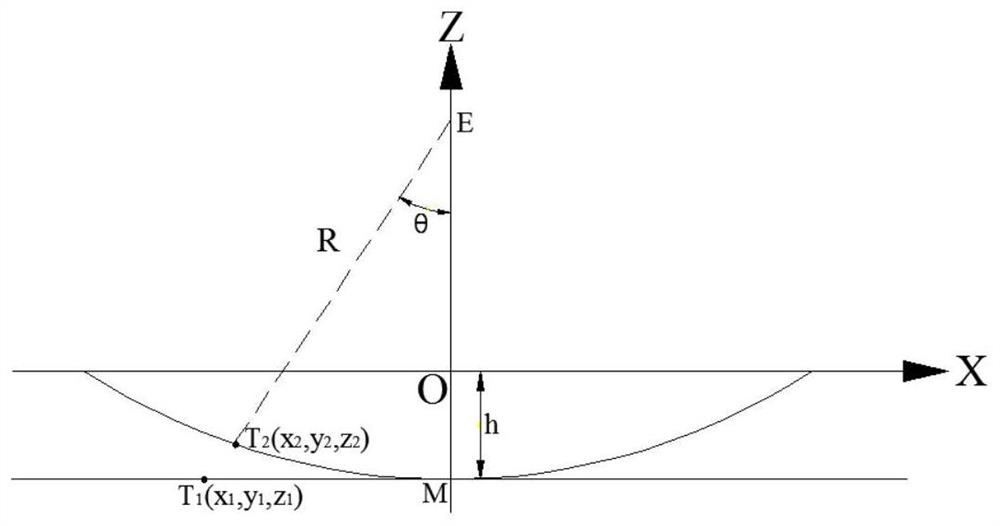

[0029] Such as figure 1 As shown, the fire path planning and flame parameter determination method of the marine sail-shaped water-fire bending plate is centered on the lateral contraction, including two functions of fire path planning and flame parameter calculation. The realization process of the fire path planning is: forming surface information extraction, Determine the segmentation distance, accurately develop the curved surface, determine the end position and the starting line of the line of fire based on the contraction unit, design the coordinate conversion mechanism of each point on the line of fire before and after roll bending, and complete the path planning of the line of fire on the curved surface after roll bending; the flame parameter determination process is: based on Water-fire bending process characteristics Determine the input and output parameters of the calculation model, initialize the neural network calculation model, select samples based on processing exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com